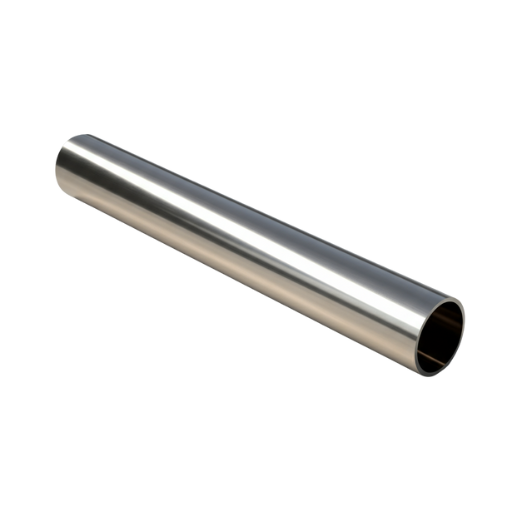

Trusted N06022 / 2.4602 Stainless Steel Seamless Tube Supplier in China

Engineered for exceptional performance, N06022 / 2.4602 stainless steel seamless tubes offer high-temperature resistance and unmatched reliability. Perfect for critical applications in furnaces and chemical plants, their seamless design ensures durability and strength in the most demanding environments.

N06022 / 2.4602 Stainless Steel Seamless Tube - Detailed Specifications

| Parameter | Specification |

|---|---|

| Material Grade | N06022 / 2.4602 |

| Standards | ASME SB-622, ASTM B622 |

| Outer Diameter | 6mm - 219mm |

| Wall Thickness | 0.5mm - 20mm |

| Length | Upto 6 meters |

| Corrosion Resistance | Excellent in oxidizing & reducing environments |

| Maximum Operating Temperature | Up to 1200°F (650°C) |

| Applications | Chemical plants, heat exchangers, furnaces |

| Finish | Polished, annealed, or custom finish |

Understanding N06022 / 2.4602 Stainless Steel Seamless Tube

What It Is:

These standards work in tandem to ensure a product that is both materially robust and corrosion-resistant.

- N06022 / 2.4602: This is the master specification for the alloy itself, dictating its unique chemical composition—including high levels of nickel, molybdenum, and chromium.

- Seamless Tube: This defines the manufacturing process, ensuring a smooth surface finish (Ra), integrity, and testing required to produce a durable, corrosion-free final product.

- A Certified Combination: We start with fully certified N06022 / 2.4602 material to create a seamless tube that meets or exceeds industry requirements.

Why It Is Your Core Focus:

Our strict adherence to these standards is our promise of delivering a strong, reliable solution for your critical applications.

- It guarantees superior performance against highly corrosive environments where standard alloys fail, especially in acidic conditions.

- It ensures a smooth, crevice-free internal surface that minimizes bio-burden and supports effective, repeatable cleaning cycles.

- This certification simplifies your validation process with fully traceable materials and comprehensive MTCs, essential for regulated industries.

N06022 / 2.4602 Stainless Steel Material Properties

| Element | Typical Percentage (%) |

|---|---|

| Nickel (Ni) | 56.0 min |

| Chromium (Cr) | 20.0 - 22.5 |

| Molybdenum (Mo) | 12.5 - 14.5 |

| Iron (Fe) | 2.0 - 6.0 |

| Cobalt (Co) | 2.5 max |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.08 max |

| Carbon (C) | 0.015 max |

| Sulfur (S) | 0.02 max |

| Phosphorus (P) | 0.02 max |

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 690 - 790 | MPa |

| Yield Strength (0.2%) | 310 min | MPa |

| Elongation | 40 min | % |

| Hardness (Brinell) | 220 max | HB |

| Density | 8.7 | g/cm³ |

| Melting Range | 1325 - 1370 | °C |

Versatile Applications of N06022 / 2.4602 Stainless Steel Seamless Tube

-

Chemical Processing: Ideal for heat exchangers and reactors.

-

Power Generation: Suited for high-temperature piping and boilers.

-

Marine Applications: Used in seawater cooling and ballast systems.

-

Aerospace Industry: Perfect for engine components and exhaust systems.

-

Pharmaceuticals: Applicable in sterilizers and processing equipment.

-

Oil & Gas Industry: Excellent for sour gas service and pipelines.

our latest news

Get a Quote for N06022 / 2.4602 Stainless Steel Seamless Tube

When facing aggressive chemicals and extreme temperatures, our N06022 / 2.4602 Stainless Steel Seamless Tube offers unmatched corrosion resistance and durability. Built for zero-compromise performance in critical environments, it ensures reliability under the harshest conditions. Contact our experts for a quote today!