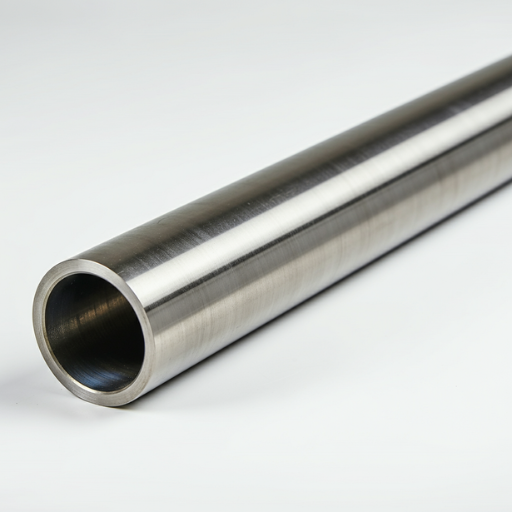

Trusted Supplier in China for N06690 / 2.4642 Stainless Steel Seamless Tubes

Engineered to excel in harsh industrial environments, N06690 / 2.4642 Stainless Steel Seamless Tubes deliver exceptional resistance to aggressive chemicals and extreme temperatures. With a robust seamless design, they ensure superior strength, durability, and reliability. Ideal for critical applications in chemical processing, power generation, and heat exchange systems, these tubes provide unmatched performance where it matters most.

N06690 / 2.4642 Stainless Steel Seamless Tube - Detailed Specifications

| Specification Parameter | Details |

|---|---|

| Material Name | N06690 / 2.4642 |

| Standard Specifications | ASTM B163, ASTM B167 |

| Outer Diameter | 6 - 219 mm |

| Wall Thickness | 0.5 - 20 mm |

| Corrosion Resistance | Superior resistance to oxidation, crevice, and pitting corrosion |

| Operating Temperature | Up to 950°C |

| Applications | Chemical processing, heat exchangers, power plants |

| Mechanical Properties | Tensile Strength > 760 MPa, Yield Strength > 300 MPa |

| Finish | Polished or custom surface treatments |

| Certification | ISO9001, PED, SGS |

Understanding N06690 / 2.4642 Stainless Steel Seamless Tube

What It Is:

These standards work in tandem to guarantee a product that is both materially superior and hygienically sound.

- N06690 / 2.4642: This is the master specification for the high-performance alloy, dictating its unique chemical composition—including high levels of nickel, chromium, and other elements.

- ASTM A270: This is the definitive standard for sanitary tubing, governing the manufacturing process, surface finish (Ra), cleanliness, and testing required to produce a hygienic, contamination-free final product.

- A Certified Combination: We start with fully certified N06690 / 2.4642 material to create a sanitary tube that meets or exceeds all ASTM A270 requirements.

Why It Is Your Core Focus:

Our strict adherence to both standards is our promise of delivering a robust, reliable, and pure solution for your critical systems.

- It guarantees superior performance against moderately to highly corrosive media where standard alloys would be inadequate, especially in the presence of acidic conditions.

- It ensures an ultra-smooth, crevice-free internal surface that minimizes bio-burden and allows for effective, repeatable Clean-in-Place (CIP) cycles.

- This dual certification simplifies your validation process with fully traceable materials and comprehensive MTCs, essential for regulated industries.

N06690 / 2.4642 Stainless Steel Material Properties

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0 - 23.0 |

| Molybdenum (Mo) | 8.0 - 10.0 |

| Iron (Fe) | 5.0 max |

| Niobium (Nb) + Tantalum (Ta) | 3.15 - 4.15 |

| Cobalt (Co) | 1.0 max |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Carbon (C) | 0.10 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

| Property | Value | Unit |

|---|---|---|

| Tensile Strength (min) | 827 | MPa |

| Yield Strength (min) | 414 | MPa |

| Elongation (min) | 30 | % |

| Hardness (max) | 35 | HRC |

| Density | 8.44 | g/cm³ |

| Melting Range | 1290 - 1350 | °C |

Versatile Applications of N06690 / 2.4642 Stainless Steel Seamless Tube

-

Chemical Processing: Used in heat exchangers, reactors, and piping systems.

-

Power Generation: Ideal for steam turbines and high-temperature piping.

-

Oil & Gas: Perfect for offshore platforms and refining processes.

-

Aerospace: Utilized in jet engines and high-temperature components.

-

Marine Industry: Resists corrosion in seawater cooling systems.

-

Pharmaceuticals: Applied in sterile and high-purity equipment.

our latest news

Get a Quote for N06690 / 2.4642 Stainless Steel Seamless Tube

When facing aggressive chemicals and extreme heat, our N06690 / 2.4642 Stainless Steel Seamless Tube delivers unparalleled corrosion resistance and durability. Designed for demanding industrial applications, it ensures long-lasting performance and reliability. Contact our experts for a custom quote today!