Heat treatment is one of the main processes that determine the properties of steel and stainless steel, and thus it makes the materials available for a great diversity of industrial applications. Among all heat treatment techniques, solution annealing is the one that really makes a difference regarding the performance and life span of these materials. The following discusses the very nature of solution annealing, revealing the different ways in which this treatment refines mechanical properties, improves corrosion resistance, and guarantees structural integrity. It does not matter whether you are in the field of manufacturing, engineering, or materials science, being well-informed about the advantages and process of solution annealing is the only way to get the best out of steel and stainless steel in highly demanding situations. Keep reading to find out how this basic technique changes materials and pushes innovations in different sectors of the economy.

Understanding Solution Annealing

Solution annealing is a treatment through heat to improve the properties of metals like steel and stainless steel. The metal is heated to a high temperature, which is usually within a certain range depending on the material, and is kept at that temperature until its structure becomes uniform and stress-free. The next step is to cool it very fast, most of the time by quenching in water or air, so that the improved state is locked in. This treatment increases resistance to corrosion, recovers ductility, and strengthens the material, thereby making it fit for use in harsh conditions.

What is Solution Annealing?

Solution annealing is a heat treatment process that is usually applied to metals like stainless steel and nickel-based alloys. Its primary purpose is to improve their mechanical properties and resistance to corrosion. The process involves heating the metal up to a temperature that is generally between 1,900°F and 2,100°F (1,040°C and 1,150°C), thus, allowing the alloying elements to dissolve completely into a solid solution. As a result, any segregation or undesirable precipitates formed during the manufacturing process are completely removed. After heating, the metal is promptly cooled down, usually by water or air quenching, so that the microstructure remains in its solutionized state. This treatment not only enhances the material’s microstructure but also makes the material more ductile and tough, which in turn increases its applicability in extreme or high-stress conditions, such as chemical processing, marine environments, and industrial equipment.

Key Concepts in Heat Treatment

Annealing

Annealing is the process of heating a material to a specified temperature and then slowly cooling it down. This treatment decreases the hardness, eliminates internal strains, and makes the material easier to cut. As a case in point, the annealing of steel normally takes place at temperatures ranging from 750 to 950 degrees Celsius according to its make-up.

Quenching

Quenching refers to cooling the material very fast, usually in water, oil, or air, which will freeze its microstructure in the position of being hard. This treatment raises the material’s hardness and strength considerably. An example of this is carbon steel that is quenched from a temperature of 800°C to 900°C where high cooling rates produce martensite.

Tempering

After quenching, tempering is performed to decrease the brittleness of the materials produced through hardening. It means bringing the material to a certain temperature typically in between 150°C and 700°C and then allowing it to cool down at a carefully controlled rate in such a way as to achieve a certain mixture of hardness and toughness.

Normalizing

Normalizing is a procedure in which a substance is first brought to a higher temperature than in the case of annealing (usually around 30°C to 50°C above the Ac3 point in steel) and then allowed to cool down in the air. This method improves the grain structure, makes the material more uniform, and increases its mechanical properties.

Case Hardening

Case hardening is a surface treatment process in which only the outer layer of the material is made harder while the core remains soft and tough. There are several methods, such as carburizing, nitriding, and carbonitriding. For instance, carburizing at a temperature of 850°C to 950°C is frequently performed to allow carbon to penetrate the surface.

The above-mentioned processes are great in number but still, they are the most effective techniques to enhance the properties of material so that they can be used in different areas. Each of the processes has to be done under very precise conditions to get the maximum performance from the material.

Types of Materials Involved

There are several surface hardening methods of different materials that increase their performance characteristics. The materials that are commonly used are mentioned below:

Low-Carbon Steels

The presence of carbon in low amount makes these steels ideal for carburizing as the surface gets a good amount of carbon diffusion. AISI 1018 and AISI 1020 are the widely used grades.

Alloy Steels

Alloy steels are alloying elements that include 4140 and 4340, which attain case hardening due to hardenability and wear resistance being improved during the treatment with heat.

Stainless Steels

The hard, resistant to corrosion surfaces are obtained by nitriding or diffusion heat treatment of martensitic and precipitation hardened stainless steels.

Cast Iron

Selective surface hardening is done only on certain types of cast iron to get the advantages of resistance to wear but still having an easy to core. Examples are ductile and gray iron.

Tool Steels

The utmost performance in cutting tools is achieved through surface hardening of steel types like H13 or D2 which further improves their thermal fatigue and hardness resistance during demanding operations.

The vast array of materials illustrates the effectiveness of surface hardening processes in improving the properties of wear resistance, fatigue strength, and overall durability up to the level of industrial application.

Benefits of Solution Annealing

Solution annealing is a method that comes with a lot of benefits and more specifically, it helps in the development of microstructural properties and finally, the performance of metals. Five most crucial advantages of solution annealing are listed below:

Improved Corrosion Resistance

Solution annealing removes carbide precipitates along grain boundaries and thus, makes the material much more capable of withstanding intergranular corrosion, hence it can be used even in very harsh environmental conditions.

Enhanced Ductility

The process of solution annealing transforms the microstructure of the material into a ductile one and thus, the metal can undergo deformation without cracking or breaking even if the stress is very high.

Refined Microstructure

The method purges the unnecessary phases and applies osmosis to the alloying elements, making a uniform microstructure that is the basis of improved mechanical properties and performance.

Restoration of Workability

Solution annealing brings back the workability and machinability of metals, mainly the cold-worked ones, thus, prolonging their usage in industrial applications.

Stress Relief

Solution annealing gets rid of the residual stresses created by the previous processes like welding or forming, thus reducing the risk of distortion or failure during service.

Advantages of Solution Annealing for Steel

Improved Corrosion Resistance

Dissolving carbide precipitates and homogenizing the steel’s microstructure during the solution annealing process greatly increases its corrosion resistance. For instance, 304 and 316 stainless steel grades after the solution annealing treatment show optimum corrosion resistance.

Enhanced Mechanical Strength

The process refines the microstructure of the steel and hence, the mechanical properties of the steel are improved. Researches indicate that annealed steels usually have better ductility and toughness than untreated ones, thus they are the right candidates for hard applications.

Restored Ductility and Workability

Strain hardening is the cause of loss of ductility by cold-worked steels. Annealing brings back their ductility and machinability and contributes to their versatility in manufacturing processes. An example is that stainless steel after annealing, can be made into intricate shapes very easily.

Reduction of Residual Stresses

Welding or forming may cause residual stresses which will distort the dimensions of the steel parts or even cause early failure. Solution annealing is a method that can not only relieve these stresses but also ensure regularity of dimensions and thus, the trustworthiness of the component during usage is increased.

Improved Uniformity in Microstructure

Solution annealing leads to a uniform microstructure in the steel because it redistributes the alloying elements and gets rid of the inhomogeneities. This uniformity is essential for the medical and aerospace industries where applications are that require consistent performance.

Benefits of Solution Annealing for Stainless Steel

Enhanced Corrosion Resistance

A solution annealing process not only dissolves carbide precipitates but also brings back the chromium in the steel, thus, making it highly corrosion resistant. For instance, marine-grade stainless steel with solution annealing treatment will resist far better than untreated steel in terms of pitting and crevice corrosion.

Improved Mechanical Properties

The process caused the grain structure to refine, which then resulted in the improvement of tensile strength and elongation. For instance, stainless steel that has undergone solution annealing can reach tensile strength of over 500 MPa while keeping the excellent ductility.

Elimination of Residual Stresses

Solution annealing alleviates internal stresses that were brought about by previous manufacturing processes. Therefore, the risk of warping or cracking during the machining process or usage is reduced. Studies have revealed that the stress levels are capable of going down as much as 70% after proper annealing.

Optimized Weldability

After welding, the carbides that are formed around the weld due to the heat are dissolved by the solution annealing process thus restoring the uniformity of the material. This guarantees that the weld will be strong and that the joints will be resistant to intergranular corrosion.

Longer Service Life

The components that go through the solution annealing process suffer from reduced wear and failure, which means the operational life is prolonged. Research suggests that annealed stainless steel components can stay 30-50% longer than untreated ones, especially in the case of harsh industrial conditions.

Impact on Mechanical Properties

Solution annealing is a process that has a monumental impact on the mechanical properties of stainless steel. By applying the treatment, the material becomes more resistant to various mechanical and environmental stresses and this is of utmost importance in industrial applications. Below are five key effects on the mechanical properties benefit:

Improved Ductility

The post-solution annealed material shows a higher degree of ductility, which means it can be stretched more without breaking and this is very important for the forming and shaping processes.

Enhanced Toughness

The treatment boosts toughness, which means that the material is better able to absorb energy and resist sudden impacts, a property that is critical for structural applications.

Higher Corrosion Resistance

The solution annealing process tends to cause a significant increase in corrosion resistance of the material by helping to create a uniformly distributed structure and sweeping out the chromium carbides in the process, especially in the case of the harsh chemical environments.

Consistent Hardness

The process of solution annealing results in a hardness that is distributed evenly throughout the material, lessening the chance of weak spots and providing uniform performance in the entire structure.

Better Stress Resistance

The materials that have undergone the treatment show an increased resistance to the internal stresses, which in turn results in an area where there is less likelihood of cracking or deformation when the mechanical load or the thermal fluctuation occurs.

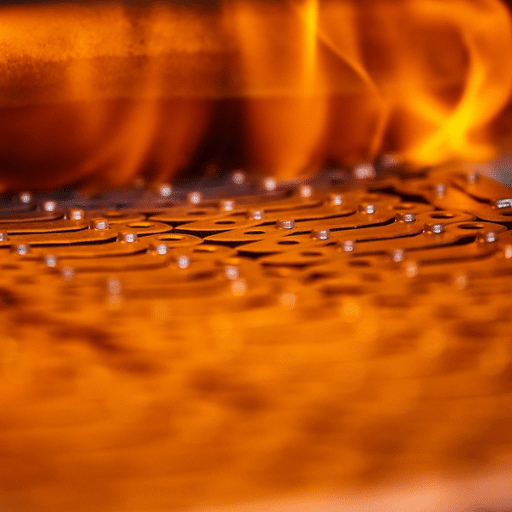

Solution Annealing Process

The solution annealing process primarily concerns stainless steel and other metal alloys, and it includes the gradual increase of temperature to around 1,850°F to 2,100°F (1,010°C to 1,150°C). The varying elements of the alloy, such as nickel and chromium, completely dissolve into the austenite phase thus avoiding any occurrence of segregations or precipitations. The metal is then cooled sharply usually in water quenching which is probably the quickest way to lock the elements in their solution state and so not let carbide formation occur which can result in corrosion.

The process consists of several steps:

Heating:

To prevent any sort of thermal stress, the material is slowly heated to the solutionizing temperature.

Oxidation and scaling are avoided by controlling the furnace atmosphere, for example, with nitrogen or argon.

Holding:

The material is held at the solutionizing temperature for a certain period based on its thickness and composition. For instance, thicker materials might need longer holding times to get the heat uniformly.

Quenching:

The hot metal is rapidly cooled in water or another suitable quenching medium. This fast cooling prevents the formation of carbide and thus maintains corrosion resistance and mechanical integrity.

Benefits Supported by Data:

Corrosion Resistance:

It has been found through studies that if stainless steel is subjected to solution annealing it becomes less prone to intergranular corrosion even in very harsh conditions such as in chemical processing plants. For example, type 316 stainless steel after solution annealing retains up to 90% of its corrosion resistance compared to untreated samples.

Improved Mechanical Properties:

As per materials engineering data, solution Annealing can enhance tensile strength and yield strength by up to 20% making steel robust under structural load.

Surface Hardness Uniformity:

Microhardness testing results show that solution-annealed materials exhibit a uniform hardness profile throughout the cross-section thus diminishing localized weakness by around 15% as compared to untreated steel.

Applications of Solution Annealing:

Solution annealing is accepted across the board and it is the basis for the production of the chemical, oil and gas, aerospace, power plants, and medical devices industries. For example:

Aerospace uses solution-annealed parts like turbine blades to ensure that they can withstand high thermal and mechanical stresses.

Pharmaceuticals need corrosion-resistant tanks and piping, which benefit from this process to keep the material pure.

By employing a step-by-step approach and utilizing modern heat treatment technologies, the solution annealing method enhances the lifespan and performance of metal pieces while being in line with strict industry standards.

Steps in the Solution Annealing Process

Heating the Material

Initially, the metal is heated uniformly to the specified temperature range, which is the first stage of the process. This temperature is usually above the alloy’s recrystallization point, thus allowing the microstructure of the material to become uniform. During this period, the precise control of temperature is very important to avoid either overheating or degradation of the material.

Holding or Soaking

The next stage of the process is holding the material at the required temperature for a specific period of time, which is predetermined. The purpose of this soaking period is to allow alloying elements to completely dissolve into the base metal and to ensure even distribution of the dissolved elements throughout the structure.

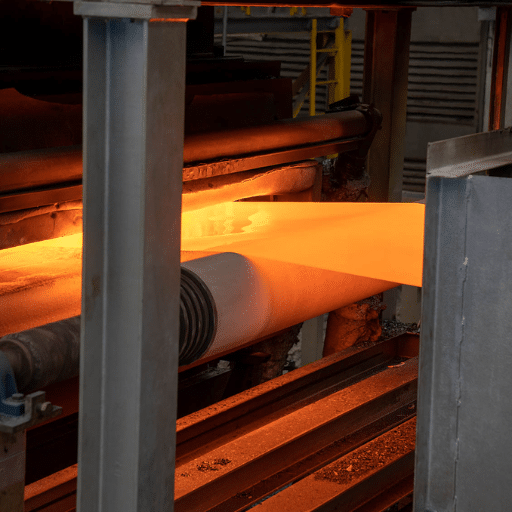

Rapid Cooling (Quenching)

The metal is then subjected to rapid cooling after soaking, which is usually done by quenching in water or air, depending on the material. This step fixes the dissolved elements in their positions, removing any stresses and resulting in a product that is uniform, corrosion-resistant, and mechanically stable.

Inspection and Testing

After treatment, the material undergoes a rigorous inspection process to ascertain that it conforms to the set quality and performance criteria. Among the non-destructive testing techniques, ultrasonic testing and X-ray diffraction are some of those frequently employed to confirm the achievement of the stated results of the annealing process.

It is by means of these steps that the solution annealing process has a tremendous impact on the durability and performance of the alloys, thus making them suitable for use in high-demanding industries such as aerospace, medical, and energy sectors..

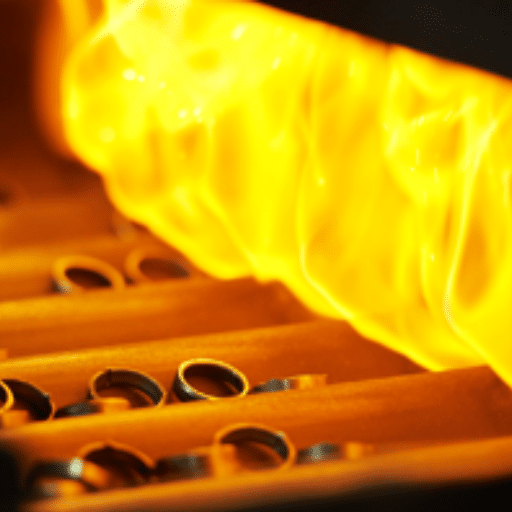

Temperature Control and Furnace Types

The temperature control becomes an extremely important factor in the solution annealing process, since the exact temperature range must be both achieved and kept for getting the desired material properties. The proper monitoring and control methods ensure that the heating and cooling cycles are consistent, and that no uneven treatment takes place which could harm the alloy’s performance. The modern furnaces come with high-tech temperature regulation systems giving the possibility of precise adjustments and the heat being perfectly distributed.

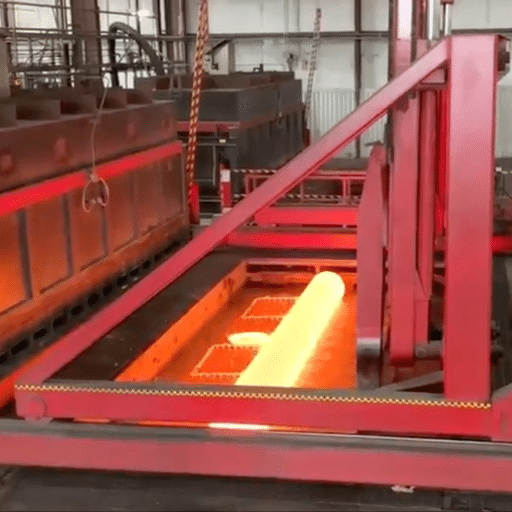

There are numerous types of furnaces that are used for solution annealing, each furnace having its own specific application and materials. Below is the list of five furnace types that are commonly used:

Box Furnace: An all-purpose furnace with a rectangular-shaped chamber, that is highly suited for small and medium-sized alloy components. It provides good heat distribution and is one of the main players in the general annealing applications.

Continuous Furnace: This furnace is to be integrated into large-scale industrial production processes; it is designed in such a way that the materials are continuously fed into the hot zone via a conveyor system guaranteeing the highest productivity and heating uniformity.

Vacuum Furnace: This type of furnace works in a vacuum that keeps oxidation and contamination off the annealing process. The vacuum is particularly beneficial for high-performance alloys used in the aerospace and medical industries.

Induction Furnace: The furnace uses electromagnetic induction to heat the materials quickly and energetically. It is meant for small batches and components that need very good temperature control.

Salt Bath Furnace: It has molten salt as the heating medium and therefore gets outstanding heat transfer and smaller temperature gradients. The type is normally selected for applications that require going through strict control of metallurgical properties.

Every furnace type has its own strengths and weaknesses when it comes to the solution annealing process, which invites manufacturers to find an approach based on material specifications and industry needs.

Cooling Methods Post-Treatment

The method of cooling after solution annealing directly impacts the final properties of the material such as strength, resistance to corrosion, and ductility. The following are the five cooling methods that are frequently employed:

Water Quenching

Quite simply, water quenching is the quickest among cooling methods and the one that is most commonly used for getting maximum hardness and at the same time the least grain growth. Stainless steels are among the materials that this method works best with but still there is a risk of internal stresses being created if not handled with care.

Air Cooling

The air cooling method is slower and is used for materials that can be tolerate with such cooling rates and do not easily get damaged in the process of cooling. This method is very much applied to alloys that cannot easily withstand fast temperature changes.

Oil Quenching

In oil quenching, one of the main advantages is the cooling rate, which is moderate – not too fast, not too slow – thus making it a suitable option for applications that require cooling to be controlled in a way that does not cause thermal stress. Alloy steels and other heat-treated parts are the ones usually treated this way.

Forced-Air Cooling

This method is using either fans or other ways of air propulsion to speed up the natural process of air cooling. It does ensure a more uniform cooling rate than natural air cooling and at the same time decreases the cooling time.

Polymer Quenching

Using water-soluble polymers in the cooling process, polymer quenching can control the rate of cooling precisely and at the same time prevent warping, which is why it is preferred in various complex applications. The cooling is done between oil and water quenching rates.

The selection of the cooling method is crucial and should be based on the specific material and the desired mechanical properties in order to ensure that the component being treated performs optimally.

Applications of Solution Heat Treatment

The process of solution heat treatment has great importance across various industries due to its property-enhancing and performance-improving nature. Below are the five major uses of solution heat treatment:

Aerospace Components

In the aerospace sector, the heat treatment of solutions is said to increase the strength and thermal resistance of aluminum and titanium alloys, which are largely used for manufacturing parts like fuselages and wings, in aircraft, and engine components, where the highest quality is demanded from the materials even in extreme conditions.

Automotive Industry

The common use of solution heat treatment in the automotive industry could be for parts like engine blocks, suspension, and cylinder heads. Optimal material properties allow for light-weight designs as a consequence of the treatment, but structural integrity and durability are maintained even in high-stress situations.

Medical Devices

Stainless steel and cobalt-chromium alloys, which are the most common in medical implants and surgical tools, are subjected to solution heat treatment to get better mechanical strength and corrosion resistance. This guarantees dependability and a long life for the devices used in the healthcare sector.

Power Generation Equipment

Solution heat treatment is one of the techniques that enhances the quality of turbine blades and other high-temperature parts that are working in power plants, as this method not only increases their fatigue resistance but also allows them to perform under very hot and pressurized conditions.

Marine Applications

The solution heat treatment of aluminum alloys, a marine-grade metal, is done to prevent the metal, from being corroded by seawater and other harsh marine environment conditions, thus increasing the durability and performance of ships, boats, and underwater systems.

Industries Utilizing Solution Heat Treatment

Solution heat treatment is a common process applied in various industrial sectors due to its positive effects on material properties and its ability to prolong the life of components. Here are five important industries where this technique is crucial:

Aerospace Industry

The components made up of aircraft such as wings, fuselage sections, and landing gear, require very high ratios of strength to weight in addition to being the resistant to fatigue. The application of solution heat treatment ensures the aluminum and titanium alloys, which are mostly used in these components, remain unbreakable and intact in terms of structure even through low-temperature extreme operations in high altitudes.

Automotive Industry

The use of solution heat treatment is not limited to high-performance cars only but also the regular vehicles in the form of parts like engine blocks, transmission systems, and suspension parts. The process increases the ability of components to withstand wear and also increases their tensile strength thus confirming that they can be relied upon in tough driving conditions.

Energy Sector

Gas turbines, nuclear power systems, and equipment for renewable energy all require materials that have undergone advanced treatment with solution heat methods. Such materials possess the ability to withstand not only high temperatures but also pressure variations and prolonged operational cycles.

Medical Equipment Manufacturing

More and more of medical devices, implants, and surgical tools are being made of metals such as titanium and stainless steel that are biocompatible and have undergone solution heat treatment. This guarantees compliance with stringent hygiene standards and provides resistance to fatigue, which is critical in terms of patient safety and the reliability of treatment.

Marine Applications

Shipbuilding and submarine manufacturing are really dependent on corrosion-resistant aluminum alloys that are treated with solution heat processes among other materials. This, in turn, leads to increased resistance to saltwater environments thereby enhancing the operational lifespan of marine vessels and offshore structures.

Industries mentioned above are constantly benefiting from the solution heat treatment’s custom-tailored mechanical and chemical properties which in turn make the materials and components of optimal performance and reliability for a long time.

Specific Alloys and Their Applications

6061 Aluminum Alloy

Applications: The material of choice for marine transportation parts, yacht structures, and shipbuilding because of its superior corrosion resistance and strength.

Key Properties: Mainly denoted by a high strength-to-weight ratio, good weldability, and seawater tolerance.

5083 Aluminum Alloy

Applications: It is the most common choice for tanker, patrol boat, and offshore structure indwelling in harsh marine environments.

Key Properties: No saltwater corrosion resistance, tensile strength, and fatigue resistance are the characteristics of this alloy.

7050 Aluminum Alloy

Applications: The alloy is used in the aerospace and marine industries for the structural components to be strong and light at the same time.

Key Properties: The alloy offers good toughness, high resistance to stress corrosion cracking, and better machining than none.

2024 Aluminum Alloy

Applications: The alloy is employed in marine gear, fittings, and transport structures where high-stress control is necessary.

Key Properties: The alloy displays high fatigue resistance that goes along with excellent machinability but requires application of strong coatings for increased corrosion protection.

7475 Aluminum Alloy

Applications: The alloy is perfect for use in aircraft parts and marine gear that are put under extreme stress and corrosive environments.

Key Properties: The alloy is characterized by high fracture toughness, lightness, and very high corrosion resistance when process done via anodizing or protective treatments.

Case Studies: Success Stories

In my experience, one memorable case involved selecting the 7475 Aluminum Alloy for a project requiring durable, lightweight materials in a highly corrosive environment. By leveraging its outstanding fracture toughness and superior corrosion resistance after protective treatments, we successfully developed robust marine equipment. This choice significantly improved the product’s performance and longevity, demonstrating the critical impact of material selection on achieving project goals.

Considerations for Implementation

When implementing the use of 7475 Aluminum Alloy in marine equipment, several factors must be carefully considered to optimize performance and sustainability. According to the latest data, environmental conditions such as salinity levels, temperature fluctuations, and prolonged moisture exposure have a direct impact on the material’s durability and effectiveness. Protective treatments, including anodization or advanced coatings, are imperative to maintain corrosion resistance, particularly in highly saline environments. Additionally, integrating predictive maintenance strategies informed by IoT sensors and real-time data analytics can greatly enhance the lifespan of the equipment. By continuously monitoring stress points and environmental changes, the alloy’s integrity can be preserved, reducing the potential for structural failures. Combining these approaches ensures the successful deployment of materials in demanding conditions while promoting long-term reliability and efficiency.

Factors Affecting Treatment Efficiency

The use of advanced materials and technologies can bring in considerable treatment process efficiency but that depends on various factors. Five such factors are:

Material Composition and Quality

The chemical make-up and structural properties of the materials have a direct influence on their performance. To illustrate, alloys with more purity are likely to be more corrosion and wear resistant thereby leading to more efficient treatment.

Temperature Variations

Temperature changes can have effects on the properties and reliability of the materials. Very high or very low temperatures can cause distortion, loss of strength or changes in chemical reactions which in turn can affect the overall process’s efficiency.

Environmental Exposure

The factors of humidity, saltiness, and UV radiations may cause the materials to deteriorate or altogether lose their effectiveness. Properly applied protective layers can lessen such impacts and allow the materials to remain functional.

Load and Stress Dynamics

Physical forces that are put on the materials, like mechanical stress and cyclical loads, can over time result in the weakening of material integrity. The use of IoT-enabled sensors for constant monitoring of the situation can be useful in locating the points of stress that are most critical and thus avoid any possible failures.

Maintenance Practices

Preventive maintenance, which is done regularly, and prompt repairs are the ways of ensuring that the operations are going on consistently and thus material fatigue or damage is not causing inefficiencies. Predictive analytics can make maintenance schedules more effective by giving data-driven insights.

Choosing the Right Furnace and Equipment

To get the most out of a furnace, it is necessary to consider its performance and if it will be energy efficient and cost-effective in the long run. The assessment of the following five aspects is essential:

Furnace Type

Determine which one among the gas, electric, oil, or dual-fuel furnace is the best for you, taking into account the availability of energy and its costs. For instance, gas furnaces are often the least expensive option, but they will limit you if there is no natural gas supply, while electric furnaces might be more eco-friendly depending on your energy source.

Energy Efficiency (AFUE Rating)

A furnace’s high Annual Fuel Utilization Efficiency (AFUE) rating is an admirable trait. Units that flaunt an AFUE of 90% or higher are regarded as energy-efficient and this helps in bringing down the energy bills and also the impact on the environment.

Dimensions and Output

Measure your premises, then determine the required heating in BTUs (British Thermal Units). Using heaters that are too large or too small can lead to wastefulness and uneven distribution of heat.

Sophisticated Properties

Take equipment such as a variable-speed blower, a programmable thermostat, and zoned heating that not only raises the level of comfort but also brings The efficiency of the operations.

Price and Guarantee

Look for and weigh the different offers in terms of their initial costs and the total of their long-term operating expenses, as well as their warranty coverage. A negligible extra expense at the beginning may end up being compensated by less money spent on the maintenance and the consumption of energy in the future.

All these aspects can alter the performance and lifetime of the heating system considerably. When you do a careful evaluation of all these factors, you are able to select the equipment that is in accordance with your needs and will deliver heating that is not only consistent but also reliable.

Challenges in the Solution Annealing Process

The solution annealing process is indispensable to the improvement of the metallurgical properties of the materials; meanwhile, it opens up a lot of problems. The five greatest challenges that are usually met are discussed below:

Temperature Control

In the case of solution annealing, absolute control over the temperature is a must in order not to damage the material by excessive heat or inadequate heating. Complete dissolution of the precipitates or, on the contrary, grain growth can be the result of these mistakes, thus producing an inferior material.

Data Example: Stainless steel is one of the materials that fall in this category; its temperature range is from 1,040°C to 1,120°C, though the exact number depends on its grade.

Uniform Heating

It is a challenging task to provide a uniformly heated material throughout its volume , especially when the measures of the component are not the same or if it has a complex shape. Heating inhomogeneously can cause thermal strains and unequal characteristics.

Quenching Difficulties

The quenching process, which is that one that freezes the solution-treated microstructure and can, therefore, distort or pump in some level of residual stresses, is the one that poses the challenge such mentioned above. In fact, the selection of the quenching medium (water, oil, or air) along with the cooling rate has to be very carefully controlled in order not to cause defects.

Oxidation and Surface Decarburization

Very high-temperature annealing is a process where oxidation or the loss of carbon from the surface can take place and which negatively influences surface properties while needing further finishing treatments such as pickling or mechanical cleaning.

Data Example: Surface oxidation layers in stainless steel can go up to 10-50µm if no proper atmospheric controls are in place.

Equipment Limitations

It is the industrial furnaces that have to match with the material requirements and production capacity. The use of the wrongly loaded or improperly heated industrial furnaces can result in large inefficiencies and inconsistent outcomes. Thus, upgrading or maintaining the appropriate equipment is usually associated with high upfront costs and a need for special technical skills.

In short, the recognition of these problems is of utmost importance for the solution annealing process optimization and, consequently, the quality and performance of the final material. Without a doubt, control, advanced technologies, and proper equipment selection should every time be the means for dealing with each of the issues.

References

- Effect of Solution Annealing Temperature on Precipitation in 2205 Duplex Stainless Steel

This research investigates the precipitation sequence in duplex stainless steel under different solution annealing temperatures.

Link to source - Designing Homogenization–Solution Heat Treatments for Single Crystal Superalloys

This study focuses on optimizing solution heat treatments for single-crystal superalloys.

Link to source - Microstructure and Mechanical Properties of Laser-Sintered 15-5PH Steel

This paper analyzes the influence of various solution annealing treatments on laser-sintered steel.

Link to source

Frequently Asked Questions (FAQ)

What is the solution annealing heat treatment process?

The solution annealing heat treatment process involves heating metal alloys, particularly austenitic stainless steels, to a specific solution annealing temperature. This allows alloying elements to dissolve into a solid solution, followed by rapid cooling to achieve the desired mechanical properties and microstructure. The goal is to enhance ductility and corrosion resistance by preventing the formation of harmful precipitates.

What are the advantages of solution annealing for stainless steel?

Solution annealing improves the corrosion resistance and ductility of austenitic stainless steels. By dissolving precipitates at high temperatures and then quenching to room temperature, the process reduces the risk of carbide formation at grain boundaries, which can lead to intergranular corrosion. Additionally, it enhances the material’s overall strength and uniformity.

How does the annealing temperature affect the microstructure of metal alloys?

The annealing temperature is crucial in determining the microstructure of metal alloys during the heat treatment process. Higher annealing temperatures typically allow for more alloying elements to dissolve, creating a single-phase solid solution. Conversely, if the temperature is too low, precipitation may occur, adversely affecting the alloy’s properties.

What types of metal alloys benefit from solution annealing?

Various types of metal alloys benefit from solution annealing, including austenitic stainless steels, nickel-based superalloys, and titanium alloys. Each of these alloys can achieve improved corrosion resistance and mechanical properties through the proper application of the solution annealing heat treatment.

What is the role of quenching in the solution heat treatment process?

Quenching plays a vital role in the solution heat treatment process by rapidly cooling the material after it has been heated to the solution annealing temperature. This rapid cooling prevents precipitates from forming and helps maintain the desired microstructure, enhancing the alloy’s strength and ductility.

How can solution annealing improve corrosion resistance?

Solution annealing improves corrosion resistance by dissolving harmful precipitates during heating, which can lead to intergranular corrosion if left in the material. By maintaining a solid solution and quenching to room temperature, the treatment helps retain the alloy’s integrity and prevents precipitation that could compromise its corrosion-resistant properties.

What is the significance of the microstructure created during solution annealing?

The microstructure created during solution annealing is significant because it determines the mechanical properties of the metal. A well-managed solution annealing process results in a uniform and stable microstructure that enhances strength, ductility, and corrosion resistance, crucial for applications in aggressive environments.

What temperature range is recommended for solution annealing?

The recommended temperature range for solution annealing typically spans from 1650°F to 1850°F, depending on the specific alloy being treated. This range allows for optimal dissolution of alloying elements into the solid solution while avoiding any precipitation that could occur if the temperature is too low.