Key Insight: Solution annealing is a critical heat treatment process that enhances stainless steel’s corrosion resistance, mechanical properties, and overall performance by dissolving carbides and creating a homogeneous microstructure through controlled heating and rapid cooling.

Introduction to Solution Annealing

Solution annealing represents one of the most important heat treatment processes in metallurgy, specifically designed to optimize the performance characteristics of stainless steel and other high-alloy materials. This sophisticated thermal treatment involves heating materials to elevated temperatures, typically ranging from 1,010°C to 1,120°C (1,850°F to 2,050°F), followed by rapid cooling to achieve superior mechanical properties and corrosion resistance.

What is Solution Annealing?

Solution annealing is a heat treatment process applied to stainless steels, nickel-based alloys, and superalloys to achieve specific material properties. The process involves three critical stages: heating the material to dissolution temperature, maintaining that temperature for complete homogenization, and rapid cooling to preserve the desired microstructure.

Primary Objectives:

- Dissolve carbides and secondary phases

- Homogenize alloying element distribution

- Eliminate segregation

- Optimize mechanical properties

- Enhance corrosion resistance

Understanding Stainless Steel Types

Different stainless steel grades require specific solution annealing approaches based on their metallurgical composition and intended applications.

Austenitic Stainless Steel

Composition: Chromium-nickel base with possible molybdenum additions

Characteristics: Non-magnetic, excellent ductility, superior corrosion resistance

Common Grades: 304, 316, 321, 347

Ferritic Stainless Steel

Composition: High chromium, minimal nickel content

Characteristics: Magnetic properties, cost-effective, good corrosion resistance

Applications: Automotive, kitchenware, architectural

Martensitic Stainless Steel

Composition: Higher carbon content with moderate chromium

Characteristics: High strength, wear resistance

Applications: Cutting tools, turbine components, medical instruments

Duplex Stainless Steel

Composition: Balanced austenite-ferrite structure

Characteristics: Enhanced strength, superior corrosion resistance

Applications: Marine, oil & gas, chemical processing

Precipitation Hardening

Composition: Specialized alloying elements

Characteristics: Exceptional strength through heat treatment

Applications: Aerospace, precision components

Austenitic Stainless Steel Focus

Austenitic stainless steels represent approximately 70% of global stainless steel production, making them the most significant category for solution annealing applications.

Key Characteristics of Austenitic Alloys

| Property | Characteristic | Benefit |

|---|---|---|

| Corrosion Resistance | Excellent in various environments | Extended service life in harsh conditions |

| Ductility | Superior formability | Complex fabrication possibilities |

| Magnetic Properties | Non-magnetic in annealed condition | Suitable for magnetic-sensitive applications |

| Weldability | Excellent welding characteristics | Simplified manufacturing processes |

| Temperature Resistance | Maintains properties at elevated temperatures | High-temperature service applications |

Industrial Applications of Austenitic Stainless Steel

Food & Beverage

Processing equipment, storage vessels, cutlery

Healthcare

Surgical instruments, implants, hospital equipment

Construction

Architectural elements, structural components

Chemical Processing

Reactors, piping systems, storage tanks

Aerospace

Engine components, exhaust systems, structural parts

The Solution Annealing Process

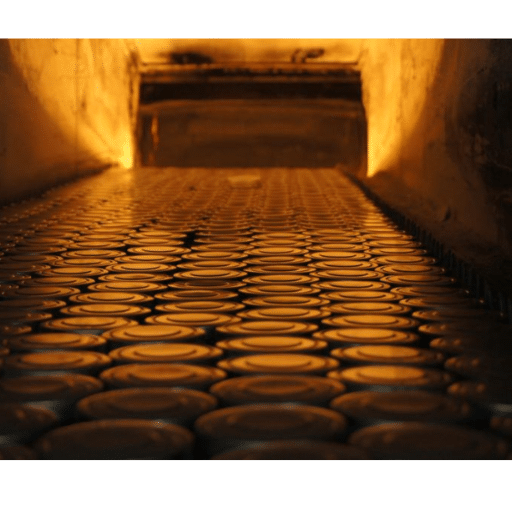

The solution annealing process follows a precisely controlled sequence of thermal operations designed to optimize material properties.

Heating Phase

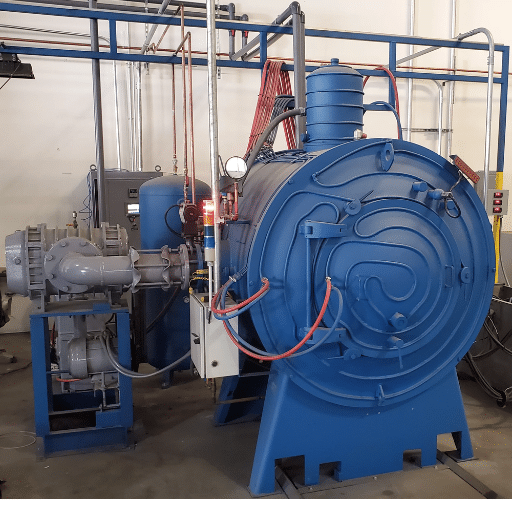

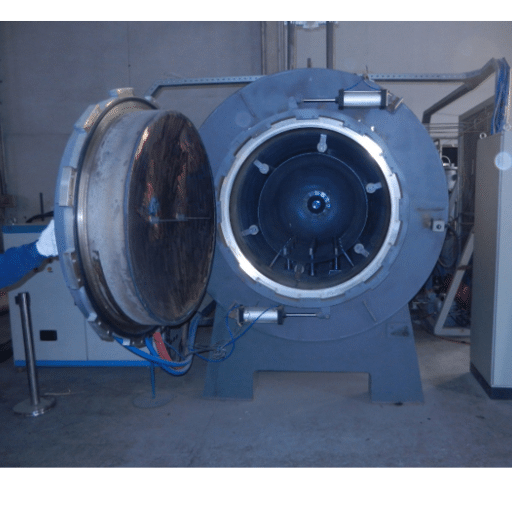

Material is uniformly heated to the target temperature range (1,850°F to 2,200°F) depending on alloy composition. Modern heating systems ensure precise temperature control and uniform heat distribution to prevent thermal gradients that could cause distortion.

Soaking/Holding Phase

The material is maintained at solution temperature for a calculated period to ensure complete dissolution of secondary phases and homogenization of alloying elements. Soaking time varies based on section thickness and alloy composition.

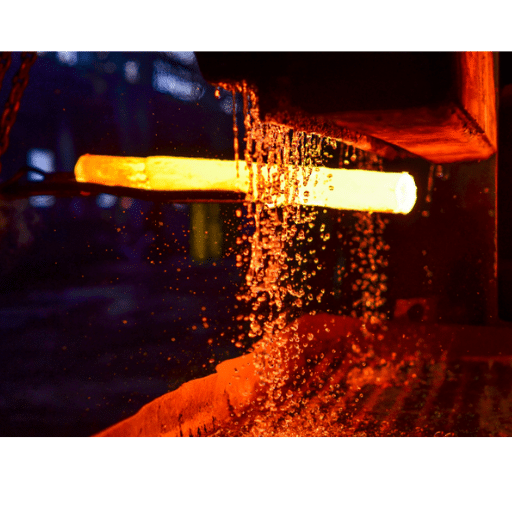

Rapid Cooling (Quenching)

Quick cooling using water, air, or inert gas preserves the high-temperature microstructure and prevents unwanted precipitation. Cooling rate selection depends on material thickness and desired properties.

Determining Optimal Annealing Temperature

Temperature selection is critical for successful solution annealing and typically ranges from 1040°F (560°C) to 2100°F (1150°C) depending on the specific stainless steel grade.

| Steel Grade | Temperature Range | Key Considerations |

|---|---|---|

| 304 Stainless Steel | 1900°F – 2100°F (1040°C – 1150°C) | Complete carbide dissolution |

| 316 Stainless Steel | 1900°F – 2100°F (1040°C – 1150°C) | Molybdenum homogenization |

| 321 Stainless Steel | 1850°F – 2050°F (1010°C – 1120°C) | Titanium carbide stability |

| 347 Stainless Steel | 1850°F – 2050°F (1010°C – 1120°C) | Niobium carbide considerations |

Advanced Quenching Techniques

Modern quenching methods have evolved to provide better control over cooling rates and minimize thermal stresses:

- Water Quenching: Fastest cooling rate, suitable for thick sections

- Air Cooling: Moderate cooling rate, reduces thermal shock

- Gas Quenching: Controlled atmosphere, prevents oxidation

- Polymer Quenching: Adjustable cooling rates, reduced distortion

- Interrupted Quenching: Staged cooling for complex geometries

Advantages of Solution Annealing

Primary Benefits

- Homogeneous Microstructure: Eliminates segregation and ensures uniform grain distribution

- Enhanced Corrosion Resistance: Dissolves harmful carbide precipitates

- Improved Mechanical Properties: Increases tensile strength up to 40% in some alloys

- Stress Relief: Reduces residual stresses by up to 70%

- Optimized Ductility: Enhances formability and workability

- Preparation for Further Treatment: Enables effective aging and precipitation hardening

Mechanical Property Improvements

| Property | Before Annealing | After Annealing | Improvement |

|---|---|---|---|

| Tensile Strength | Variable | Optimized | Up to 40% increase |

| Yield Strength | Inconsistent | Uniform | Enhanced predictability |

| Elongation | Limited | Maximized | Improved ductility |

| Residual Stress | High | Minimized | 70% reduction |

| Fatigue Life | Standard | Extended | Significant improvement |

Heat Treatment Services and Quality Control

Selecting a Heat Treatment Provider

Choosing the right heat treatment service provider is crucial for achieving optimal results. Key evaluation criteria include:

Essential Provider Qualifications

- ISO Certification: Quality management system compliance

- Advanced Equipment: Modern furnaces with precise temperature control

- Technical Expertise: Experienced metallurgists and process engineers

- Industry Experience: Track record in aerospace, automotive, and critical applications

- Real-time Monitoring: Advanced process control and documentation systems

- Environmental Compliance: Sustainable and eco-friendly practices

Quality Control Measures

Modern heat treatment facilities employ sophisticated quality control methods to ensure consistent results:

| Quality Control Method | Purpose | Benefits |

|---|---|---|

| Thermocouple Monitoring | Precise temperature measurement | Eliminates temperature variations |

| Microstructure Analysis | Verify metallurgical changes | Confirms proper treatment |

| Hardness Testing | Mechanical property verification | Ensures specification compliance |

| Real-time Data Analytics | Process optimization | Predictive maintenance capabilities |

| Automated Controls | Consistent processing parameters | Reduced human error |

Advanced Technology and Future Trends

Smart Heat Treatment Systems

The integration of Industry 4.0 technologies is revolutionizing solution annealing processes:

- IoT Sensors: Real-time monitoring of temperature, atmosphere, and mechanical properties

- Machine Learning: Predictive algorithms for optimizing process parameters

- Digital Twins: Virtual modeling of heat treatment processes

- Automated Quality Control: AI-driven defect detection and process adjustment

- Energy Optimization: Reduced power consumption and environmental impact

Emerging Applications

Solution annealing is finding new applications in cutting-edge technologies:

Additive Manufacturing

Post-processing of 3D-printed stainless steel components

Renewable Energy

Wind turbine components and solar panel hardware

Electric Vehicles

Battery housings and charging infrastructure

Hydrogen Technology

Fuel cell components and storage systems

References

-

Influence of Thermo-Mechanical and Solution Annealing Treatments

A study from the Harvard ADS database evaluating the effects of solution annealing on the properties of Ti-added austenitic stainless steel.

Visit the site -

High-Temperature Characteristics of Stainless Steel

A detailed document from Stanford University discussing annealing conditions and their impact on various types of stainless steel.

Visit the site -

Metallurgical Evaluation of Cast Duplex Stainless Steel

A report from the University of North Texas Digital Library analyzing solution annealed conditions of duplex stainless steel.

Visit the site

Frequently Asked Questions (FAQ)

What does solution annealing of stainless steel exactly mean?

Simply put solution annealing of stainless steel refers to to increasing the corrosion resistance and improving the mechanical properties of the material using the heat treatment procedure which defines heating the material to a particular temperature about which usually is around 900˚C and cooling it rapidly. The presence of these carbides and some of these precipitates during this process interferes with the homogenization of the microstructure.

What can be the advantages of doing solution annealing in case of austenitic stainless steel?

Conducting a solution annealing operation to an austenitic stainless steel structure helps to increase the stiffness and strength by making the microstructure more even and decreasing its content in these phases. It gives assurance that the material will not suddenly dissent when put under stress especially aseismic applicational applications.

Why is solution annealing essential and viable?

Solution annealing is beneficial as it improves resistance to corrosion and mechanical properties as well as stress relief occurs in this process. Because of this process, stainless steel shifts towards its complete solution position and this makes it easier to use in the more harsh conditions as in the industries where there is a requirement of greater mechanical properties as well as corrosion resistant properties.

In terms of solution annealing why is the holding time important?

The holding time at solution temperature is important during solution anneling as it dictates how well alloy additiond such nickel and chromium can dissolve into austenite. The holding time also guarantees that the temperature of the material entirely reaches the solution temperature which is of importance to achieve better properties.

In low temperature regions how best do welds of stainless steel hold?

The solution annealing process involving less heat may result in some of the carbides and other phases not dissolving completely. This may in turn destabilize the structural efficiency of the welds made of stainless steel. These weldments become weak and therefore more sensitive to corrosive environments and mechanical properties are also limited.

Why is air-cooling done after solution annealing?

Stainless steel is usually air-cooled after solution annealing in order to bring down its temperature very quickly. The aim of this high rate cooling is to maintain the austenite phase in one phase region and to avoid formation of any chromium or other elements that could weaken the material.

What does solution annealing do as far as super duplex stainless steel is concerned?

Stainless steels, especially those more resistive to diffusion, are beneficial from solution annealing as this will make the microstructure even and prevent deformation on annealing layers containing austenite, versus ferrite.

In stainless steel structures how does the precipitation only of chromium take place during solution treatment?

Yes, solution heat treatment of stainless steel especially 4XX grades would help significantly reduce chromium precipitation. Appropriate heating regime allows the increase in temperature when the lattice is able to retain chromium meaning it does not cause any desirable precipitates-deficient in structure thus resulting in loss of properties of resistance to corrosion or strength.

How is a solution treated and heat affected zone zone in Stainless steels?

Zones that have been subjected to this process have a more even structure and this is what is meant by the zone where solution treated stainless steel. On the other hand when it comes to, the heat affected zone (haz), this is the part of the material next to the weld which has experienced metallurgical changes, due to the heat involved in welding. This is most likely something that is undesired if left without mitigation measures.