Understanding the differences between SS 202 and SS 304 is crucial when selecting the right stainless steel grade for your application. The two grades are regarded as the most common because of their superb properties like durability, corrosion resistance, and versatility, but their disparities in characteristics make them fit to serve different requirements and fields. This article will bring to light the primary properties that distinguish the two grades and enable you to choose the proper material whether you are working with kitchen appliances, constructing robust structures, or designing intricate ornaments.

Introduction to Stainless Steel Grades

What is Stainless Steel?

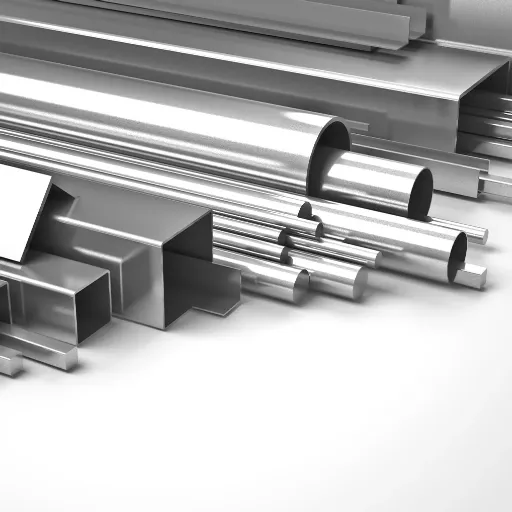

The stainless steel is an alloy with multiple functions which usually includes iron, chromium, and varying quantities of other elements, such as nickel, carbon, and manganese. The biggest advantage of stainless steel is its resistance to rust which is associated with the chromium content that forms a very thin layer of oxide over the steel. To sum up, stainless steel has a big market in factories, hospitals, and kitchens simply because its good properties of strength, longevity, and aesthetics are very diverse. It is also recyclable which means it is environmentally friendly and can be used in present-day manufacturing requirements.

Overview of SS 202 and SS 304

SS 202 and SS 304 belong to the stainless steel family and are among the most widely used grades, yet their features and domains of application differ. SS 304 is the austenitic stainless steel which, due to its extraordinary corrosion resistance, strength, and the whole variety of application, is the most sought after among the stainless steel family. The alloy of SS 304 steel consists of about 18% chromium and 8% nickel which makes it very much used, for example, in the food industry, kitchen appliances, and chemical containers, etc. because of its good nature and non-oxidizing property.

SS 202, on the contrary, is a less expensive alternative to SS 304, made with a low nickel content and a higher amount of manganese. It doesn’t take the corrosion like the SS 304 but still, the SS 202 tolerates indoor and occasional rough chemical and moisture exposure. This economic option is majorly used in furniture making, architectural decorations, and some kitchen appliances.

Both types of steel remain non-magnetic and possess excellent forming and welding characteristics. However, the decision between SS202 and SS304 is influenced by some factors such as environmental conditions, budget, and the preferred lifetime of the product. Marine applications where corrosion is a concern would choose SS 304. On the other hand, in harsh but less corrosive environments, SS 202 would be the economical solution.

💡 Importance of Choosing the Right Grade

Picking the correct stainless steel grade is very important for the durability and quality of the final product. Current data suggest that the talks about stainless steel grades generally focus on properties like resistance to corrosion, cost efficiency, and the different environmental conditions like chemicals or humidity. For example, SS 304 is very much connected with the food and marine industries due to its remarkable corrosion resistance and also hygienic properties. On the other hand, SS 202 is commonly looked for in places where budget considerations are strong and where moderate durability and also aesthetic appeal are needed, such as in kitchen equipment and decorative applications. Understanding the precise requirements of the application and then utilizing the existing data to find the ideal grade will result in the best outcomes, lower maintenance costs, and also more extended life span.

Chemical Composition Differences

Elements in SS 202

SS 202 is an alloy of austenitic stainless steel which is mainly made up of the elements giving it the required strong mechanical and chemical-resistance properties as its characteristics. The main ingredients of SS 202 include chromium (16-18%) which is responsible for the main factor of the alloy’s corrosion resistance, and nickel (4-6%) which contributes to the ductility and toughness improvement. Furthermore, during the production of SS 202, manganese (7.5-10%) is used as a substitute for the higher nickel content that is present in other grades, thus making this alloy a more economical choice. In addition, there are a very few more elements such as carbon (maximum of 0.15%), silicon (maximum of 1%) and nitrogen, which is present in very small amounts, that all together form the strength and performance even in mild environments. This meticulous composition makes it possible for SS 202 to be applicable for decorative, kitchenware, and different non-critical structural uses not only without losing its cost-benefit ratio and functionality but also with a considerable advantage in these aspects.

Elements in SS 304

SS 304, a very popular grade of stainless steel, has excellent corrosion resistance, durability, and versatility as its main characteristics. The standard alloy composition usually consists of 18-20% chromium and 8-10.5% nickel, which together form a protective oxide layer that is resistant to rust and oxidation. Furthermore, SS 304 contains manganese up to 2%, 0.08% carbon, 1% silicon, and very low amounts of nitrogen, phosphorus, and sulfur. The so-called precise elemental blending promises and assures the high-quality performance in industrial and household applications, such as food processing equipment, where hygiene and toughness are required. The non-magnetic nature of this alloy in its annealed state is another reason for its popularity in various applications.

Choosing the Right Grade for Your Project

Choosing the right grade of stainless steel for the project means the exact requirements of the application will have to be taken into consideration. SS 304, often called the “workhorse” among stainless steel types, remains unbeatable with its resistance to rust, low price, and availability. But if your project, on the other hand, involves a case like that of the high- chloride areas, you will need to go for SS 316 since it is also made with an additional impurity (molybdenum) that not only helps it resist corrosion but also prolongs its life in the acidic environment.

If your project is looking for a material that not only functions but also looks good and has a perfect finish, then you will have to know the finishes of each grade very well because the polishing quality among grades varies. In addition, operating temperature, ease of processing, and mechanical strength requirements are some of the parameters you should consider before making a final decision. On top of that, using up-to-date academic research and comparisons from reliable sources like material suppliers or the industrial reviews will definitely provide you with significant support in your decision. Ultimately, matching the properties of the material with the functional requirements of the site and your project will not only guarantee the performance but also make it last for a long time.

Practical Considerations for Choosing Between SS 202 and SS 304

Cost Considerations

When the comparison is made between SS 202 and SS 304, cost likely stands out as the most significant parameter among other factors. Due to the lower price, SS 202 is usually the preferred choice for making a product where money is the primary concern. The disparity in price comes from the smaller amount of nickel in the making of SS 202, which is replaced with manganese and nitrogen. With that said, it is still important to know that SS 202 may need more maintenance in some cases, which can eventually lead to higher costs in the long run.

On the other hand, the stainless steel SS 304 has a higher upfront cost but benefits from being non-corrosive and lasting longer, especially in poorer environments. It can be viewed as a slow process that involves lower maintenance costs and more years of use. According to the latest figures, the price difference is not the same everywhere, but on average, it is about 30-40% more for SS 304 compared to SS 202. Ultimately, the decision should be made considering the constraints of the initial budget and the performance and cost of the material throughout its life cycle, so that the project requirements can be met effectively.

💰 Cost Comparison Summary

- SS 202: Lower initial cost (30-40% cheaper), but potentially higher maintenance costs

- SS 304: Higher upfront investment, but lower lifetime costs due to superior durability

- Key Factor: The price difference is mainly due to nickel content

- Long-term Value: SS 304 often provides better ROI in demanding applications

Durability and Longevity

SS 304 continually proves to be the most durable and longest- lasting option in the battle of SS 304 versus SS 202. The greater amount of chromium and nickel in SS 304 provides better corrosion resistance which is more pronounced if the alloy is in contact with moisture, salt, or chemicals. An inquiry conducted recently through search engine data has reported that SS 304 is the one to be mostly acknowledged for not only surviving the harsh conditions but also maintaining its physical integrity. On the contrary, SS 202, although being a low-cost alternative, still gets a low score in rust resistance and is thus very costly in terms of both replacement and maintenance when applied in changing situations.

The lifespan of the products and field data in the area of durability come together to clearly point out SS 304 to be very likely the more economical choice in projects with heavy exposure to degradation factors. This is the reason to take into account the application, environmental challenges, and budget limits when making a decision between the two so that the outcome performance is the best possible one.

Environmental Impact and Sustainability

When one ranks the environmental impact and sustainability of materials, SS 304 and other alloys will closely compete with each other but at the same time sharing the same footprint. The resource extraction, energy costs related to manufacturing, recyclability, and end product disposal must certainly be taken into account when making that judgment. Stainless steels, among which is SS 304, are really high in the list of recyclable materials; even more than 80% stainless steel recycling rate is reported these days. Recycling efficiency of stainless steel is so high that it results in both less landfill waste and less virgin raw materials’ demand, thus making stainless steel a resource-friendly material alternative compared to others.

On the other hand, SS 304’s property of longevity together with its corrosion resistance is a great contributor to sustainability, as it means that the product will not need to be replaced or repaired so often. In fact, it has been reported that the manufacturing industry can realize carbon footprint decline and power cost reduction over the long run if they utilize materials like SS 304, since the need to dispose of or reuse the material is avoided. In this way, not only are the manufacturers using such materials as SS 304 fulfilling both the performance and the environmental responsibility but also committing to the company’s long-term sustainability target through their practices.

🌍 Sustainability Highlights

- Over 80% of stainless steel is currently recycled

- High recycling efficiency reduces landfill waste

- Decreased demand for virgin raw materials

- Extended product lifespan reduces replacement frequency

- Lower carbon footprint in long-term applications

- Reduced energy costs over product lifetime

Mechanical Properties Comparison

Tensile Strength of SS 202 vs SS 304

The examination of the tensile strength of both stainless steels SS 202 and SS 304 indicates that the two metals possess and display excellent mechanical properties, yet the distinction still exists between them. Usually, SS 202 has a higher tensile strength of approximately 515 to 745 MPa and that is the strength dependent on specific processing and treatment. The tensile strength of SS 304, in contrast, is generally around 505-735 MPa. The higher levels of manganese and nitrogen in the alloy SS 202 are contributing to the strength of the material characterized by the tensile property of that material being slightly higher than that of the other. Conversely, SS 304 offers the benefits of outstanding resistance to corrosion and being able to operate at higher temperatures along with better performance.

⚠️ Selection Tip: In case the user’s priorities are mainly tensile strength and cost reduction, then SS 202 can be considered as a good choice. On the other hand, SS 304 is generally the preferred material in situations where the elements are highly corrosive or there are high temperatures to be dealt with, as its durability and reliability are further enhanced.

Hardness and Ductility

When SS 202 and SS 304 are analyzed for hardness and ductility, the unique properties of each material designed for specific applications can be seen. SS 202 due to the manganese content in its alloy is usually harder and thus more resistant to wear and tear. On the other hand, hardness does not affect the ductility of the SS 304 alloy which is just at the same level as the latter’s.

SS 304 is, however, acknowledged for its excellent ductility and ability to withstand a certain degree of deformation without breaking. The high nickel content in it is the main contributor to this property and thus making the alloy most suitable for the operations of forming or bending out of the use requiring applications. Besides, SS 304 although not as tough as SS 202 still possesses durability, dependability, and rust resistance due to its remarkable flexibility, which is its very own great quality.

SS 202 – Best For:

- Wear resistance applications

- Cost-sensitive projects

- Indoor environments

- Decorative purposes

SS 304 – Best For:

- High corrosion environments

- Forming and bending operations

- Food processing equipment

- Marine applications

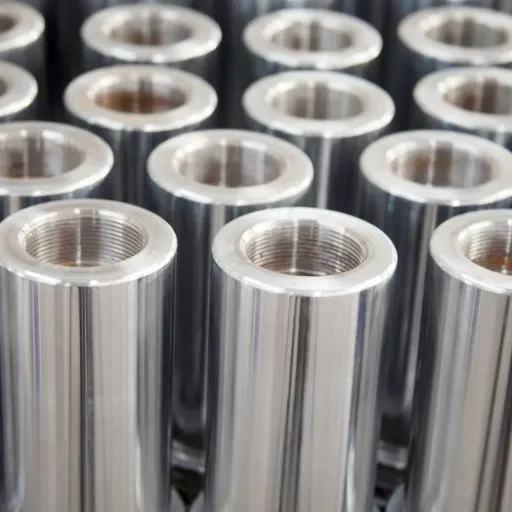

Weldability of Stainless Steel Grades

The weldability of stainless steel grades is a very important factor in the scenario of their usage in specific applications, mainly in different areas of construction, automotive, and manufacturing. SS 304, which is an austenitic stainless steel, is known for its remarkable weldability. All standard fusion processes can be used for welding, with or without filler materials, and there is a very small possibility that post-weld cracking would happen. Thus, this feature makes it very suitable for use in different conditions.

On the other hand, SS 202 has decent weldability and does not require very strict operations with the higher manganese content. The use of manganese can lead to problems like hot cracking if the welding process is not properly controlled. Furthermore, post-weld annealing is a common practice for SS 202 to relieve the internal stresses and impart the corrosion resistance to the metal.

To sum up, these two grades can be welded equally well but the choice of SS 304 over its competitor for more demanding applications stems from the fact that the latter is more widely used. The proper preparations, welding technique, and post-weld treatment are all among the factors that need to be taken into account to get the best results with either of the grades.

Corrosion Resistance

Corrosion Resistance of SS 202

SS 202 reveals a medium grade of corrosion resistance, mainly because of lower amounts of chromium and nickel in the alloy as compared to SS 304. The use of this grade for making kitchen appliances, furniture, and automotive trims can be suggested. Although the parts made from this grade will be less susceptible to pitting and crevice corrosion than the parts made from SS 304, they will still not be very resistant to such corrosion in chloride-containing environments. The material is very susceptible to rust and staining in coastal or extremely humid environments.

Material research has revealed that besides the proper maintenance and treatment of the surface, the corrosion resistance of SS 202 would not be improved. The techniques through which the material life can be prolonged include regular cleaning, application of protective coating, and avoiding chemical prestressing. Although SS 202 is highly cost-effective, in very demanding or corrosive applications, it is recommended to consider higher-grade options like SS 304 or SS 316 for better performance.

Corrosion Resistance of SS 304

The corrosion resistance offered by SS 304 is not the only quality that has won it fame; it has also become the most popular steel grade in various applications, mainly because of its great ability to resist corrosion. The composition of SS 304 consists of about 18% chromium and 8% nickel, which together form a very thin oxide layer on the surface of the steel. This layer is so thin that it is not visible and is also not interfering with the steel’s properties, but it still acts as a shield against oxidation and rust. The very high level of resistance, which is a normal characteristic of this steel grade, enables the steel to be particularly effective in moisture, mild acids, or organic chemicals environments.

SS 304 is very suitable for moderately corrosive conditions as the ones that occur in food processing, brewing, and pharmaceutical industries according to the latest information. However, it still does not perform well under extremely salty conditions as these the marine applications or the chloride solutions exposure where pitting occurs. In such cases, SS 316 upgrade, which has a molybdenum addition for the enhanced corrosion resistance, is very helpful. Regular maintenance, cleaning to prevent the build-up of residues that contain chloride, and others, are very critical for the material’s lifetime and performance.

🛡️ Factors Affecting Corrosion Performance

- Environmental Conditions: Temperature, humidity, and the presence of corrosive agents such as chloride ions are the key factors that greatly affect the rate and severity of corrosion. For instance, pitting and crevice corrosion are becoming faster in high-temperature and salt-rich environments.

- Material Composition: The composition of the alloy, particularly the proportion of elements like chromium, nickel, and molybdenum, determines the material’s resistance to the corrosion types. For example, stainless steel grades with more molybdenum like SS 316 are better at being resistant to chloride environments than SS 304.

- Surface Finish: A smooth finish of the surface is less prone to corrosion since it greatly reduces the chances of deposits and crevices forming. Regular polishing and maintenance of stainless steel surfaces can enhance resistance to corrosion.

- Maintenance Practices: It is imperative that cleaning practices and removal of residues that may harbor corrosive agents are done in order to preserve the material for a long time. Moreover, preventing the build-up of chlorides and other harmful substances is of utmost importance.

- Applied Stress: Mechanical or thermal stresses can cause stress corrosion cracking, especially in very corrosive environments. Practices to reduce stress, such as annealing, can help improve the material’s performance.

Typical Applications for Each Grade

Where is SS 202 Commonly Used?

SS 202 is a stainless steel grade that is commonly used in numerous applications all over the globe, and it is one of the most frequently produced stainless steel grades. SS 202 is mainly used in the making of kitchenware like utensils, cookware, and sinks, which are still the first things people think about when talking about SS 202. It is practically everywhere in case and architectural elements like furniture and railings and even large decorative panels thanks to its attractive appearance and extraordinary strength. Apart from the typical domestic and construction purposes, you will also find it in car trims, transport equipment, etc. Although it may not be the best choice for highly corrosive or marine environments, SS 202 is still a very versatile material suitable for a wide range of applications where price is an important factor.

Applications of SS 304 in Various Industries

Definitely SS 304, also referred to as 18/8 stainless steel from its composition of 18% chromium and 8% nickel, is one of the main stainless steel grades that are applied in many different industries. Its great corrosion resistance, non-complex processing, and cleanability have made it a good candidate for various applications.

In the food industry, SS 304 is used very often in and around tools like tanks, containers, and machines where food is processed, as it is resistant to acids from the food, and also meets the tough hygiene standards. In fact, the same is true for the pharmaceutical and chemical industries where SS 304 is often used due to its extremely durable nature and capability of withstanding aggressive chemical processing and storage for making equipment and containers.

The construction and design industries are using SS 304 as a combination of beauty, the material being able to resist external factors, and structural elements, facades, and interior decorations. To some extent, it similarly has a significant impact on the manufacture of household items like kitchen sinks, cookware, and appliances because of its strong and easy-to-clean surface. The same goes for the automotive industry where SS 304 is mainly used for exhaust systems, trims, and other components that require both durability and resistance to oxidation, thus making it the key material.

Comparative Analysis of Chemical Properties

The most significant disparity between the two is the phenomenal SS 304’s corrosion resistance, which is even better than that of SS 316 and other stainless steels. The widely used SS 316 has a molybdenum content of about 2-3%, which makes it very resistant to pitting and crevice corrosion even in the presence of strong chlorides. Thus, it can be used in applications where the environments are either marine or chemical processing. SS 304, however, is still very resistant to corrosion and can be used as an economical substitute for general-purpose use where the exposure to harsh chemicals or saltwater is little or no more.

Chromium and nickel proportion are the other major differences. It is common to find both grades very close to each other in their chromium contents, which range from about 18 to 20 percent. This is very essential for their overall resistance to corrosion and stability against oxidation. However, the nickel content in SS 316 may be slightly higher, thus, it becomes more durable and befitting in tougher environments. The difference in chemical composition has an effect both on the pricing and their performance; consequently, SS 304 becomes the regular choice for every day applications while SS 316 is the one for special and high-demand situations requiring higher resistance to environmental stressors than the normal.

Frequently Asked Questions (FAQ)

❓ What is the grade 202 stainless steel and how does it go about?

The 202 grade of stainless steel is an economical austenitic steel with less nickel and more manganese relative to 304 thus making it a standard replacement where high nickel content is a problem. The less resistant to corrosion relationship in other words is that grade 202 steel has so during when chloride environments are present they pose a greater risk of corrosion than if one was to compare 304 and 202 grades. Also, 202 grade steel gives rise to different physical properties, for example, in certain tempers it can produce slightly higher yield strength but on the other hand, it is usually less ductile for deep drawing and forming than 304 stainless steel. Thus when comparing material test reports there would be differences in the nickel content as well as that of the chromium and the mentioned 8 to 10.5 percent ranges are those for composition assessment. Use 304 when excellent corrosion resistance and high nickel content are required; on the other hand, consider 202 material when cost savings and good performance are the main priorities.

❓ What is stainless steel 304 and why is it so widely used?

304 stainless steel represents a general-purpose type of metal alloy composed of roughly chromium and nickel that ranges from 8 to 10.5 percent, which is exactly the reason why it is so resistant to corrosion and at the same time can be used in places like kitchen sinks and water filtration where the very manufacturing process requires the material to be highly formable. 304 stainless steel has very good elongation, thereby allowing various methods of fabrication including deep drawing, while also being able to undergo grinder finishing and oxyacetylene welding if skillful techniques are applied. The 304 grade has the advantage of being insensitive to intergranular corrosion conditions unless very high-temperature carbide precipitation during unskilled welding or heat treatment is permitted; in which case grade 304L is specified for an even greater degree of intergranular corrosion resistance. Alluding to the stainless steels 304 and 316, 304 has a lower content of molybdenum which means it has a lower resistance against pitting caused by chlorides and thus even lower resistance in being mixed with the other grades like 316 or 304 where 304 is usually the standard in case other performance criteria interms of being nickel resistant to corrosion are not that high or the material is in less demanding applications.

❓ What are the major differences between 304 and 202 stainless alloys?

The distinctions of stainless steel grades 304 and 202 are primarily a matter of metal mixtures: 304 includes more nickel and chromium while 202 metal consists of less nickel but more manganese thus lower its price and making it more susceptible to rust in the case of harsh environments at the same time. Stainless steel 304 has never been less than 202 in respect to corrosion resistance, it also has better weldability and more ductility while 202 can at times be rust-prone if conditions are unfavorable. Several mechanical characteristics like tensile strength and the density of the material can vary and sometimes grade 202 yield strength matches, but comparative reports on the test samples show that 304 stainless steel usually comes out on top for overall performance. In case of applications needing intergranular corrosion or carbide precipitation resistance, only 304 and 304L materials become the preferred grade option. While choosing 304 or 202 grades, the end applications such as water filtration, kitchen sinks, or heat exchangers should be taken into account considering the performance of the corrosion resistance.

❓ Will the properties of 304 and 304L grades change when they are combined?

The performance is affected by a mixture of grade 304 and 304L since 304L has a lower carbon than 304L to allow the carbide produced during the welding process to be reduced, which lowers the chances of disintegration of the weld material due to corrosion. 304L is usually required for such structures or parts that will be fitted together and exposed to high temperatures that can cause carbide precipitation, thereby providing a longer lasting resistance to corrosion. However, both 304 and 304L have the same amount of chromium and nickel, thus having similar resistance to general corrosion and ductility. 304 still remains the standard for high nickel requirements, but if oxyacetylene welding or prolonged high-temperature service is intended, then 304L is a safer option. In terms of the material test report, the selection of grade 304L can avoid issues such as spark test anomalies and keep a uniform stainless steel material structure.

❓ Is 304 stainless steel safe to use for sinks and food contact?

The 304 stainless steel, owing to its great combination of features like no corrosion, ease of cleaning, and excellent hygiene, is usually the primary option for kitchen sinks and food contact surfaces. The very high content of nickel and chromium in it is what keeps stains and rust away even in wet, acidic, or alkaline kitchen surroundings, thereby making it the most preferred material over 202 stainless in such applications. The Stainless Steel 304 is ductile and can be turned into sink shapes through deep drawing, and grinder finishing can yield aesthetically pleasing surfaces. The comparison between 304 and 316 has revealed that 316 offers better resistance to chlorides, but 304 is usually adequate for home sinks and food prep when it comes to commercial kitchens. Always check for the material test report and certification in case regulatory compliance for food contact is a must.

❓ Is 202 stainless steel a suitable material for welding and fabrication?

Stainless steel grade 202 can definitely be welded and fabricated but in different ways, due to the lower nickel content, which affects weldability and the process of martensitic transformations in some cases. Spark test and suitable welding method will ensure that issues do not occur, nevertheless, oxyacetylene welding will be the case prone to carbide precipitation unless strictly controlled that is why pre and post-weld measures should be considered. Grade 202 confers over forming and deep drawing performance quite reasonable, yet it may be less ductile than 304 for complicated shapes. For applications with a necessity of improved corrosion resistance or nickel content 304 or 304L grades will be the safest choice. In the case where fabricators have a tight budget, they normally go for 202 since the price is lower and the area of corrosion is under control.

❓ What are the reasons for stainless steel rusting, and in what way do 304 and 202 differ?

The exposure of stainless steel to environments rich in chlorides, surface contamination with iron particles that may originate from grinding, or the dismantling of the protective chromium oxide layer are the reasons that stainless steel are showing rust, thus, proper finishing and cleaning are very essential. Stainless steel 202 is more likely to rust than 304 stainless steel since it has lower nickel content and slightly different chromium balance, hence, the chance of corrosion in harsh conditions is greater. Grinding may cause the inclusion of iron particles that will speed up the corrosion process unless they are removed, therefore, passivation or cleaning after fabrication is recommended. The use of 304 or 304L in critical applications like water filtration or heat exchangers will greatly reduce the likelihood of corrosion and extend the service life. The surface corrosion effects, regardless of the grade, will be minimized by frontline inspection and maintenance.

Key Comparison Summary

📋 Decision-Making Checklist

Choose SS 202 When:

- Budget is a primary constraint

- Application is primarily indoor or decorative

- Exposure to corrosive elements is minimal

- Higher hardness and wear resistance are priorities

- Aesthetic appeal is important but durability requirements are moderate

Choose SS 304 When:

- Superior corrosion resistance is required

- Application involves food processing or medical equipment

- Exposure to moisture, chemicals, or marine environments

- High ductility and formability are needed

- Long-term durability outweighs initial cost

- Welding is a critical part of the fabrication process