Understanding Heat Exchangers

Heat exchangers are sophisticated mechanical devices designed to transfer heat from one fluid to another without allowing the fluids to come into direct contact. These systems play a crucial role in heating, cooling, and energy recovery applications where precise temperature regulation is paramount.

What Makes Heat Exchangers Essential?

- Energy Efficiency: Maximize thermal energy utilization and reduce consumption

- Cost Reduction: Lower operational expenses through optimized heat transfer

- Environmental Benefits: Reduce carbon footprint and support sustainable practices

- Process Control: Maintain precise temperature regulation for critical applications

- System Longevity: Enhance overall system lifespan and reliability

How Heat Exchangers Work

Heat exchangers operate on fundamental principles of conduction and convection. They typically consist of specialized components including plates, tubes, and coils that facilitate optimal fluid flow patterns. The fluids involved can exist in liquid or gaseous states and move along different thermal gradients to enable efficient heat transfer.

Types of Heat Exchangers

Shell and Tube Heat Exchangers

Widely used in industrial applications, power plants, oil refineries, and chemical processing. Features an array of tubes enclosed within a shell for efficient heat transfer between two fluids.

- High-pressure applications

- Large temperature differentials

- Robust construction

Plate Heat Exchangers

Compact design featuring multiple thin corrugated plates. Ideal for food processing, HVAC systems, and chemical applications with excellent thermal efficiency.

- Space-efficient design

- Easy maintenance

- Superior heat transfer

Air-Cooled Heat Exchangers

Utilize air as the cooling medium, perfect for water-scarce areas. Commonly used in power generation, oil and gas industries, and HVAC systems.

- No water requirement

- Lower operating costs

- Environmental advantages

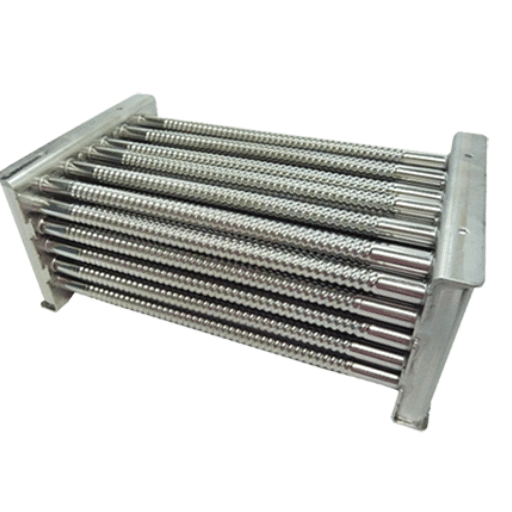

Finned Tube Heat Exchangers

Enhanced surface area through attached fins increases heat transfer efficiency. Ideal for applications requiring significant heat dissipation.

- Increased surface area

- Enhanced heat transfer

- Compact design

Plate and Frame Heat Exchangers

Modular design with stacked frames enabling easy cleaning and maintenance. Perfect for biotechnology, food processing, and beverage industries.

- Modular construction

- Easy disassembly

- Hygienic design

Regenerative Heat Exchangers

Enable heat transfer and temporary storage through heat storage medium. Commonly used in gas turbines and air preheating applications.

- Energy recovery

- High efficiency

- Reduced fuel consumption

Applications of Heat Exchangers

HVAC Systems

Heart of air conditioning, heating, and ventilation systems, facilitating energy-efficient climate control in residential, commercial, and industrial buildings.

Power Generation

Critical components in power plants for steam condensation, cooling systems, and energy optimization to maximize efficiency in thermal power generation.

Food & Beverage Processing

Essential for pasteurization, sterilization, and cooling processes, ensuring food safety while maintaining product quality and nutritional value.

Chemical Processing

Vital for temperature control in chemical reactions, cooling, condensation, and distillation processes, ensuring efficient and safe operations.

Oil & Gas Industry

Crucial for crude oil refining, natural gas liquefaction, and cooling systems, enabling smooth operation and safety in energy production.

Marine Applications

Important for engine cooling, desalination, and refrigeration management in marine environments where space and reliability are critical.

Benefits of Stainless Steel in Heat Exchangers

Why Stainless Steel Leads the Industry

Stainless steel has emerged as the preferred material for heat exchanger construction across diverse industries due to its exceptional combination of properties that enhance performance, longevity, and cost-effectiveness.

Key Advantages of Stainless Steel

| Property | Benefit | Application Impact |

|---|---|---|

| Corrosion Resistance | Superior protection against rust and chemical attack | Extended equipment life, reduced maintenance |

| Thermal Conductivity | Excellent heat transfer efficiency | Enhanced system performance, energy savings |

| Mechanical Strength | High strength-to-weight ratio | Durable construction, easy handling |

| Hygienic Properties | Non-porous, smooth surface | Easy cleaning, sanitation compliance |

| Temperature Resistance | Maintains properties at extreme temperatures | Reliable operation in harsh conditions |

| Environmental Sustainability | 100% recyclable material | Reduced environmental impact, cost savings |

Advanced Stainless Steel Alloys

316LGrade for marine applications

904LSuper austenitic grade

2205Duplex stainless steel

99%+Recyclability rate

Stainless Steel vs. Copper: Comprehensive Comparison

| Comparison Factor | Stainless Steel | Copper | Winner |

|---|---|---|---|

| Corrosion Resistance | Excellent in all environments | Vulnerable to saltwater and chemicals | Stainless Steel |

| Initial Cost | Moderate investment | Higher initial cost | Stainless Steel |

| Maintenance Requirements | Low maintenance needs | Regular maintenance required | Stainless Steel |

| Temperature Resistance | Excellent high-temperature performance | Limited by thermal expansion | Stainless Steel |

| Environmental Impact | 100% recyclable | Recyclable but energy-intensive | Stainless Steel |

| Thermal Conductivity | Good thermal performance | Superior thermal conductivity | Copper |

Design and Functionality of Tube Heat Exchangers

Advanced Engineering Solutions

Modern tube heat exchangers integrate cutting-edge materials and computational fluid dynamics (CFD) to optimize design efficiency and performance. These innovations ensure maximum heat transfer while minimizing energy losses.

Key Components of Tube Heat Exchangers

| Component | Function | Design Features |

|---|---|---|

| Tubes | Primary fluid passage element | Single or multiple pass configurations |

| Shell | Outer casing containing tube bundle | Accommodates secondary fluid flow |

| Tube Sheets | Secure tubes and prevent leakage | Located at exchanger ends |

| Baffles | Direct fluid flow and create turbulence | Enhance heat transfer efficiency |

| Nozzles | Fluid inlet and outlet ports | Optimized for flow distribution |

| Head Configuration | Accommodate thermal expansion | Fixed or floating head designs |

How Tube Heat Exchangers Work

Tube heat exchangers operate on the fundamental principle of heat transfer between two fluids without mixing. The system consists of a shell containing numerous tubes arranged to allow one fluid to flow through the tubes while the other fluid flows around the tubes within the shell.

Enhanced Geometries

Modern designs incorporate optimized tube geometries and advanced materials to improve heat transfer efficiency and reduce energy losses.

CFD Optimization

Computational Fluid Dynamics tools simulate fluid behavior to analyze and optimize heat exchanger design for maximum performance.

Material Innovation

Advanced stainless steel alloys and composite coatings provide enhanced protection against corrosion and thermal stresses.

Plate Heat Exchangers: Advanced Technology

Why Plate Heat Exchangers Excel

Plate heat exchangers represent the most modern and efficient approach to heat transfer across various industries. Their compact design and superior thermal efficiency make them the preferred choice for space-constrained applications.

Working Mechanism of Plate Heat Exchangers

Plate heat exchangers utilize thin metal plates arranged to form parallel channels, allowing fluids to flow on opposite sides of each plate. This design maximizes surface area contact for optimal thermal energy exchange while maintaining complete fluid separation.

Advantages of Plate Heat Exchangers

30%Better thermal efficiency vs conventional

50%Smaller footprint than shell-and-tube

20%Lower lifecycle costs

90%Faster maintenance cycles

| Advantage | Description | Industry Benefit |

|---|---|---|

| Thermal Efficiency | Superior heat transfer through large surface areas | 30% improvement over conventional exchangers |

| Compact Structure | Space-efficient design for tight installations | 50% smaller than equivalent shell-and-tube systems |

| Flexibility | Customizable to meet specific thermal requirements | Adaptable to varying demand conditions |

| Maintainability | Easy disassembly for cleaning and service | Reduced downtime and operational costs |

| Economic Value | Lower energy and maintenance costs | 20% reduction in lifecycle expenses |

Choosing the Right Stainless Steel Heat Exchanger

Comprehensive Selection Guide

Selecting the optimal stainless steel heat exchanger requires careful consideration of multiple factors to ensure maximum performance, efficiency, and cost-effectiveness for your specific application.

Critical Selection Factors

- Application Requirements: Define specific use case (power generation, marine, food processing, industrial)

- Material Compatibility: Select appropriate stainless steel grade (304, 316, 316L) based on environment

- Design Configuration: Choose between plate, shell-and-tube, or specialized designs

- Maintenance Accessibility: Ensure design facilitates cleaning and service requirements

- Operating Conditions: Consider temperature ranges, pressure limits, and thermal loads

- Energy Efficiency: Prioritize heat recovery and minimal energy consumption features

- Compliance Standards: Verify adherence to industry codes (ASME, ISO) for safety and reliability

- Lifecycle Value: Evaluate total cost of ownership including energy, maintenance, and replacement costs

Factors to Consider When Selecting

| Factor Category | Key Considerations | Impact on Performance |

|---|---|---|

| Thermal Performance | Heat transfer coefficient, temperature range, efficiency | Direct impact on energy costs and system effectiveness |

| Material Compatibility | Fluid chemistry, corrosion resistance, temperature limits | Determines equipment longevity and reliability |

| Flow Configuration | Counterflow vs parallel flow arrangements | Affects heat transfer efficiency and pressure drop |

| Maintenance Access | Cleaning procedures, component accessibility | Influences operational downtime and costs |

| Space Requirements | Installation footprint, height restrictions | Determines feasibility and installation costs |

| Economic Factors | Capital cost, operating expenses, lifecycle value | Affects return on investment and profitability |

Understanding BTU Requirements

BTU Calculation for Optimal Heating

British Thermal Units (BTU) represent the fundamental measurement for heating capacity. Accurate BTU calculation ensures optimal energy efficiency, comfort, and cost-effectiveness in heating applications.

BTU Calculation Factors

- Space Area: Square footage of area to be heated

- Insulation Quality: R-value and thermal barriers

- Ceiling Height: Volume considerations for heat distribution

- Climate Zone: Local weather conditions and temperature ranges

- Heat Loss Factors: Windows, doors, and thermal bridges

- Occupancy Patterns: Heat generation from people and equipment

General BTU Guidelines

- Moderate Climates: 20 BTU per square foot

- Cold Climates: 30-40 BTU per square foot

- Well-Insulated Spaces: 15-20 BTU per square foot

- Poor Insulation: 40-50 BTU per square foot

Modern BTU Calculation Tools

Today’s advanced online calculators and smart systems allow precise BTU calculations by considering multiple variables including local climate data, building materials, and usage patterns. These tools help ensure optimal system sizing while avoiding energy waste.

Expert Guidance and Best Practices

Professional Recommendations

Industry experts emphasize the importance of proper system sizing, installation quality, and ongoing maintenance for optimal heat exchanger performance. Modern smart technologies enable precise control and monitoring for maximum efficiency.

Energy Efficiency Ratings

| Rating System | Application | Efficiency Indicator | Best Practice |

|---|---|---|---|

| SEER Rating | Air conditioning systems | Seasonal Energy Efficiency Ratio | Higher SEER = lower operating costs |

| AFUE Rating | Heating systems | Annual Fuel Utilization Efficiency | Look for 90%+ efficiency ratings |

| COP Rating | Heat pumps | Coefficient of Performance | Higher COP indicates better efficiency |

| EER Rating | Cooling equipment | Energy Efficiency Ratio | Standard efficiency measurement |

Smart Technology Integration

Smart Thermostats

Advanced temperature control with learning algorithms and remote monitoring capabilities for optimal comfort and energy savings.

IoT Monitoring Systems

Real-time performance tracking, predictive maintenance alerts, and automated optimization for maximum system efficiency.

Energy Management Systems

Comprehensive energy monitoring and control systems that optimize heat exchanger operation based on demand patterns.

References

-

SSCF® Stainless Steel Heat Exchangers – Florida A&M University and Florida State University

A detailed document on the applications and benefits of SSCF heat exchangers in chemical, pharmaceutical, and refining processes.

Visit the site -

Evolving Designs of Advanced Heat Exchangers – Pennsylvania State University

A project exploring advanced heat exchanger designs, including stainless steel components and additive manufacturing techniques.

Visit the site -

Printed-Circuit Heat Exchanger (PCHE) – Massachusetts Institute of Technology (MIT)

A study on PCHEs made of stainless steel, focusing on their temperature limits and cost efficiency.

Visit the site

Frequently Asked Questions (FAQ)

What are the benefits of using a stainless steel heat exchanger?

Stainless steel heat exchangers have several advantages: Best corrosion resistance, efficiency, and durability. Suitable for all sorts of applications, from domestic water heating to industrial processes, they ensure the best heat transfer with a long service life.

How is a stainless steel heat exchanger working?

Working of a stainless steel heat exchanger means heat is exchanged between two fluids without coming into contact. Hot water passes through the exchanger, losing heat to a second fluid, the heat of which is then used for heating, like heating a pool or water chillers.

What is the extreme temperature that a stainless steel heat exchanger can endure?

The maximum temperature a stainless steel heat exchanger can handle depends on its design and materials of construction. Usually, designs in stainless steel 304 can withstand great temperatures, suitable for applications dealing with hot water and heat transfer of extremely high efficiency.

Are stainless steel heat exchangers suitable for solar heating applications?

Yes, stainless steel heat exchangers are highly suitable for solar heating applications. Since they have outstanding resistance to corrosion and durability, they are suitable for outdoor applications where they efficiently transfer heat from solar collectors to water tanks.

What are the things that I would consider in selecting stainless steel heat exchanger?

Efficiency ratings, specific application (e.g., domestic water heating or pool heat), flow rates, and type of fluids involved must be considered in the selection of stainless steel heat exchangers. Also, consider the manufacturers that can customize solutions to your specific need.

How can I ensure efficient heat transfer in my stainless steel heat exchanger?

Choose a stainless steel heat exchanger in such a way that heat transfer shall be efficient in actual use: that means the designers shall have optimized flow rates and turbulence in their choice. Maintain the exchanger, clean it, and check for blockages or leaks, all of which will keep it highly efficient and performing.

Are there any roles for pumps in stainless steel heat exchangers?

The pumps are responsible for circulating fluids through stainless steel heat exchangers. Correctly selecting pumps that ensure fluid flows at appropriate rates will optimize heat exchange efficiency and overall system performance.

Can stainless steel heat exchangers be welded?

Yes, stainless steel exchangers can be welded, something often required in installation and repair. The welding must be performed using high-grade techniques so as not to compromise the integrity of the heat exchanger and to give superior performance in heat transfer applications.