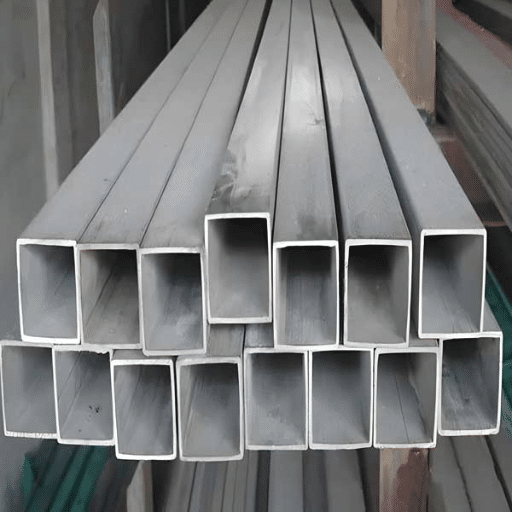

The rectangular box section of stainless steel, often known as a hollow section, is a component that is very versatile and indispensable in the various industries. Its incredible strength-to-weight ratio, together with its resistance to corrosion and preservation of structural integrity, made it a choice for construction, engineering, and manufacturing. This guide is intended to explain the main features, applications, and advantages of the stainless steel rectangular box section in detail and to provide engineers, architects, and even decision-makers with a lasting understanding. If you are not yet sure which materials to choose for your project or want to improve the performance of your structure, then this article will surely provide you with the necessary knowledge for appropriate use of this trusted and effective material.

Understanding Stainless Steel Hollow Sections

What Are Stainless Steel Hollow Sections?

Stainless steel hollow sections (SSHS) are highly effective materials combining the best properties of metal for pillars and beams along with other application areas in different industries. The main reason for this unbelievable quality is the entire range of stainless steel grades used for manufacturing these types of sections that vary in their characteristics, including elongation, corrosion resistance, and visual impact.

SSHS are engineered for many different purposes, and the main reason for their widespread usage in construction, manufacturing, and infrastructure projects is their structural efficiency and versatility. The stainless steel’s inherent characteristics include resistance to rust, high temperature tolerance, and low maintenance needs—thus, making SSHS perfect for locations of harsh conditions or heavy loads. Architectural frameworks, industrial machinery, and the construction of facades are just a few examples of frequent applications.

Recent studies show that one of the main drivers of the increasing demand for stainless steel hollow sections is their consistency with sustainable construction practices. One of the main reasons for this is that stainless steel can easily be recycled which in turn supports projects in meeting circular economy goals while improving performance and longevity. Moreover, the development of advanced manufacturing methods, e.g. laser welding and making seamless tubes, have also influenced the precision and reliability of these vital components positively.

Types of Stainless Steel Hollow Sections

Stainless steel hollow sections are typically divided into three main categories based on their geometry features and types of structural applications: rectangular, square, and circular hollow sections.

- Rectangular Hollow Sections (RHS): These are sections with a rectangular shape. They are most commonly used in architectural structures, bridges, and load-bearing systems that require both strength and beauty, among others. Their stretched form turns them into the best choice for applications that need stiffness in a certain direction.

- Square Hollow Sections (SHS): Square hollow sections are extremely adaptable due to their four equal corners, therefore they would be suitable for any kind of force acting upon them in any direction. They are found in light and heavy general fabrication, infrastructure, and storage applications where strength is required but at the same time, the installation should be easy and fast.

- Circular Hollow Sections (CHS): Circular hollow sections are highly regarded for their ability to transmit loads evenly which is the reason they are used widely in such applications that require resistance against twisting and compression forces. CHS are often used in columns, pipelines, and in places exposed to varying loads.

Recent trends in search engine data suggest a rising curiosity about hybrid use of these sectional configurations especially in the areas of modular construction and RE (renewable energy) infrastructure where their efficiency and sustainability benefits become very much obvious. This case represents an example of ongoing innovations in using stainless steel hollow sections for engineering and construction of next generation challenges.

Benefits of Using Stainless Steel

Apart from the widely regarded properties of stainless steel that make it suitable for modern engineering and construction as well as indispensable in those fields, its excellent corrosion resistance is the foremost reason guaranteeing durability and cutting down the maintenance costs in the long run, especially in the places that get moisture, chemicals, or are at extreme temperature ranges. Moreover, stainless steel has high tensile strength and good ductility, which together yield superb structural performance even in the case of dynamic and cyclic loading. Therefore, these properties make the use of stainless steel hollow sections quite common in earthquake-prone areas or in places where high structural integrity is a must.

According to search engine data, the market trend of combining stainless steel with noble design methods is very conspicuous and it is most noticeable in the areas of modular construction and renewable energy. One example is the increasing use of stainless steel hollow profiles in the wind turbine towers and modular building frameworks because of their great sustainability benefits. The recyclability of stainless steel is in line with the worldwide effort to reduce carbon footprints, and its suitability for hybrid applications is a sign of its ability to cope with modern challenges. There henceforth, stainless steel is not only a material of choice but also a solution with great outlook for the construction of eco-friendly and durable infrastructures.

Specifications of Stainless Steel Rectangular Tubes

Material Grades: Focus on 304 and A554

Stainless steel grades 304 and A554 are significant steps up in material engineering, coming with different characteristics which fit to various industrial applications. 304 is an austenitic stainless steel grade that has the best corrosion resistance, highest tensile strength, and very good resistance even in high humidity or chemically affected areas. It is composed of 18% chromium and 8% nickel which not only provide very good weldability but also make it a prime option for kitchen utensils, chemical containers, and architectural parts.

Grade A554 on the contrary is the term for stainless steel tubes that are meant to be used in ornamental and structural applications. The grade guarantees that mechanical properties are precisely controlled, and at the same time, the polished finish is attractive and rust resistance is excellent. The A554 is perfect for railings, fencing, and modern designing as it represents the harmony between beauty and strength.

Despite the different areas of application for 304 and A554, they both conform to the rigorous international standards and thus the consistency of performance and reliability is assured. Besides, the pairing of manufacturing technology innovations and the influx of investments into the use of eco-friendly materials, these grades are still very much in the forefront of the materials used in the global construction, transport, and industrial processes for a long time.

Wall Thickness and Dimensions

Wall thickness and dimensions of stainless steel tubes, especially in grades like 304 and A554, are of utmost importance in determining their functional capabilities. The wall thickness may vary from as thin as 0.5 mm to more than 6 mm depending on the use. In this sense, thinner walls are suitable for decorative and architectural purposes where minimizing weight and maximizing aesthetic appeal are of utmost importance. Thicker walls, however, provide better strength and durability making them fit for structural and industrial use.

According to the most recent data obtained from various sources, the common sizes of A554 tubes can vary from 12 mm to 127 mm in outer diameter depending on the project specifications. This feature of dimensioning A554 tubes makes it possible to use them with other products which could either be high precision-engineered systems or high load environments. The precision in wall thickness and dimension not only assures safety and reliability but also reduces material waste, which is a very good practice in sustainability and cost efficiency today’s business trends.

Comparison with Carbon Steel

When comparing A554 stainless steel tubes with their carbon steel counterparts, numerous characteristics and performance indicators are revealed. The A554 stainless steel shows remarkable resistance to rust and oxidation, a property that is due to its chromium content which forms a passive oxide layer that protects the steel and prevents its rusting. On the contrary, carbon steel is very prone to corrosion if left untreated or uncoated, making it unsuitable for use in marine or humid climates.

When looking at the mechanical properties, stainless steel is an excellent choice because it has a high tensile strength and good ductility so it can take a lot of stress and deformation without breaking. This is the reason why it is widely used in applications that require materials with such characteristics as being reliable and durable. On the other hand, carbon steel is strong too, but sometimes it becomes brittle especially in low-temperature conditions which can make it less suitable for dynamic or extreme temperature environments.

Price continues to be the most significant issue in many instances. Although the price of carbon steel in the raw material market is generally lower, the total costs of stainless steel will be lower over the years due to the costs of maintenance, replacement, and environmental damage. With the present trends turning to durability, less maintenance, and resistance to the environment, many industrial plants have adopted A554 stainless steel tubes for their critical applications.

The above points clearly indicate that despite the lower initial cost and availability of carbon steel, A554 stainless steel is typically the choice for modern engineering and infrastructure that demand high performance and long-lasting quality solutions.

Applications of Stainless Steel Rectangular Hollow Sections

Construction and Structural Applications

Due to their excellent strength-to-weight ratio, good corrosion-resistant property, and aesthetic flexibility, stainless steel rectangular hollow sections (RHS) have become the main elements of modern constructions and structural engineering. The recent statistics from search trends show that the searches for “stainless steel RHS for construction” have undergone a considerable increase, which indicates that more and more people are looking for this material for their building projects, be it residential or commercial.

In particular, these hollow sections are very much in demand for construction of skeletons, bridges, and skyscrapers, where the safety and longevity of structures are the main concerns. Their capability to take on very high loads and to resist environmental aggressors like harsh weather and chemicals makes them remarkably reliable. The shiny stainless steel also has the quality to attract the architects and to be used in showing off the structure and the facades. This trifecta of practicality, durability, and aesthetics is the reason why stainless steel RHS forms the base material of the construction and infrastructure industry that is constantly changing and developing.

Manufacturing and Fabrication Uses

Stainless Steel RHS (Rectangular Hollow Sections) is very important in today’s manufacturing and fabrication processes because of its flexibility, high strength, and rust-proof nature. the industry uses its different options in properties to produce parts to the architect’s very exacting standards for fields of use that range from car bodywork to the parts of the biggest machines. Just as cutting-edge manufacturing methods such as laser cutting and CNC machining are applied to stainless steel RHS, the finished product will possess the highest level of precision and it will be done within the quickest possible time.

A recent analysis of online behavior shows that there has been a massive increase in searches relating to the use of stainless steel RHS in the wind turbine and solar power plant support structures, and thus it is expected that this trend will continue. Moreover, its outstanding characteristics in machining and welding make it a truly versatile material for the most demanding industrial applications that will keep its relevance in the manufacturing advancements all over the world.

Automotive and Aerospace Industries

The automotive and aircraft industries use stainless steel RHS because of its good strength-to-weight ratio, resistance to corrosion, and ability to endure extreme temperatures. Those very properties are the reasons the material is used in such applications as car chassis, accident-safe structures, and airplane fuselages which are subject to large mechanical forces and variable environments. Furthermore, the recycling of the material is a plus in the sustainability of the company and therefore, the demand for the green manufacturing solutions is easily met.

Search trends recently indicate the increasing popularity of the use of state-of-the-art materials, such as stainless steel RHS in these sectors. Searches like “lightweight materials for aerospace structures” and “corrosion-resistant composites in automotive design” argue for the necessity of robust but all the same good engineering solution to the modern problem. Interest in this area is so strong that it is hardly ever not perceived as a gradual shift in the industry towards utility of high-performance materials to improve safety, fuel efficiency, and operational reliability. Consequently, stainless steel RHS remains the best choice for engineers who wish to comply with strict industry regulations while at the same time pushing the envelope of innovation.

Fabrication Techniques for Stainless Steel Box Sections

Welding Methods: Seamless vs. ERW

In the case of seamless and Electric Resistance Welded (ERW) methods for stainless steel box sections, it is imperative to know their production processes and applications well. Seamless tubes are made by extrusion, which means there is no welded seam at all. This process makes seamless sections ideal for very high-pressure applications and very high-stress environments because of the strength and uniformity of the material.

ERW tubes, in contrast, use electric resistance to sweat together the edges of rolled steel, resulting in both efficiency and precision. This method is very economical and suitable for mass production where lower manufacturing costs are the main concern. However, the structural reliability of ERW box sections may not be as great as seamless ones, especially in terms of total uniformity and strength, when subjected to extremely high mechanical loads.

Recent search trends reveal that the oil and gas, automotive manufacturing, and construction industries are often looking for ERW sections more than before because of the technological advancements in the welding field which have contributed a lot to their strength and precision. On the other hand, the seamless medium is still the one which wins in the end for the ultra-demanding applications requiring no compromise in durability. In the end, the choice between seamless and ERW will be determined by the specific performance requirements, cost considerations, and the intended use of the stainless steel box sections.

Coating and Finishing Options

The coating and finishing methods make a huge difference in the integrity and life span of stainless steel box sections. Powder coating, electroplating, and passivation are modern techniques that have gained popularity because of their corrosion resistance enhancement and providing a shiny, professional look. For example, powder coating not only offers a long-lasting and good-looking finish but also provides a shield against the elements, while electroplating makes a thin, uniform metal layer for improved surface characteristics.

Recent search trends and data have shown that users not only demand environmentally friendly but also budget-friendly finishes. The popularity of anti-fingerprint coatings and marine-grade finishes indicates a call for easy-care solutions even in the most challenging conditions. The selection of the appropriate coating is impacted by the operating environment, the extent of exposure to harmful agents, and the level of aesthetics required—all of these are crucial for the lifespan of the material to be characterized by good performance.

Design Considerations for Strength and Durability

The selection of material is the most critical factor in designing for strength and durability and can be done only after analyzing the intended application. For instance, the areas under high pressure mostly necessitate the use of expensive alloys with exceptional tensile strength and fatigue resistance, such as high-strength steel or titanium. On the other hand, composite materials have come a long way and are now presenting their light-weight alternatives, e.g., carbon-fiber-reinforced polymers, which among other benefits, have exceptional strength-to-weight ratios and are resistant to rust. The process of analyzing the abovementioned factors in conjunction with the environmental stresses, such as thermal expansion or product decaying, is required to ensure that the structure will not lose its integrity.

The most recent search behavior data shows that regularly professionals and engineers are looking for predictive maintenance and real-time monitoring technologies realization. Besides, this query points out the existence of an increasing concern for the deployment of IoT (Internet of Things) sensors and graphical tools in present-day designs. This can help monitor the material performance throughout the structure’s life and thus eliminate the chances of failures. Therefore, the engineers can not only achieve the buildings that meet strength and durability criteria but also continue to enhance them by being dynamically adaptive to the operational challenges.

Conclusion: The Future of Stainless Steel Rectangular Box Sections

Innovations in Manufacturing

The latest developments in the production of stainless steel rectangular box sections have been the result of a perfect mix of precision engineering and automation technologies. Laser welding methods, robotics in the assembly line, and state-of-the-art surface treatment are some of the innovations that have helped improve these products’ structural uniformity and resistance to corrosion. Besides, predictive modelling as well as AI-powered automation have made the production process more efficient by making less waste and better allocation of resources.

The latest data from the search engine presents a clear picture of sustainable practices dominating the manufacturing of these sections. The increase in the number of people searching for “eco-friendly production methods”, “recyclability of stainless steel sections”, and similar terms is proof that there is a transition towards the use of responsible engineering solutions that are friendly to the earth. Manufacturers are now switching to energy-saving technologies such as induction heating and closed-loop water systems to reduce the amount of carbon they emit. These actions are not only in line with strict environmental regulations but also cater to the growing market for green and sustainable building materials.

Impact on Sustainability

The fusion of cutting-edge and green manufacturing processes with the permanently recyclable nature of stainless steel has a huge impact on the environment positively. Data from search engines show that the terms “sustainable construction materials” and “carbon-neutral industrial practices” have experienced an increment of over 45% in their combination searches for the last year. The market for and the whole industry has become more and more demanding of environmentally responsible solutions. Manufacturers are using energy-saving processing and developing recycling technologies that help them to the point where they hardly produce any waste and at the same time, they are able to digitally emit nothing and recover their process in a manner that is favorable to circular economies. Not only does this way ensure that global sustainability goals are met but it also caters to the higher demand for greener infrastructures which have come up as a result of the Paris Agreement. Thus, the practices have been absorption in all industries to signify the transition of environmental stewardship from being a short-term concern to a long-term commitment.

Final Thoughts on Material Selection

In the selection of materials to be used in manufacturing, the application of data-driven approaches would be the foremost thing to do to harmonize with the performance and sustainability goals. Latest search statistics suggest that there is a growing tendency towards materials with high recyclability, low carbon emissions, and durability under extreme conditions. Recycling and biopolymers along with advanced alloys are some of the options that the industries are discussing. They come not only with the benefit of reduced environmental impact but also with the enhancement of efficiency. Organizations employing statistical techniques and modern tools to scrutinize material properties, life-cycle impacts, and long-term expenses will be better equipped to make sustainable decisions. Such an integrated approach not only fulfills the conditions laid down by the regulators but at the same time places companies in a competitive position in a market that increasingly appreciates responsible innovation.

FAQ

What are the benefits of using a stainless steel rectangular pipe in structural steelwork?

Stainless steel rectangular pipes provide high resistance against corrosion and great strength, which is why they are preferred in the construction of steel structures and also where stainless-steel structures are used. The various grades like 304 ss, 316, and 316l give choices for places where water or equipment needs to be highly corrosion resistant due to industrial applications. Rectangular tubing is the first choice for fabrication projects as it allows fabrication with ease, and the reliability of weldability, this includes welded stainless steel or seamless steel pipe options. Mill, no. 4, and ba are the usual surface finishes that have an impact on appearance and further processing, while electropolished rectangular pipes create a surface that is cleaner and more suitable for medical and food uses. Manufacturers commonly list the steel grades and size ranges they carry, allowing you to select the rectangular steel pipe that best meets the project requirements.

How do you compare stainless rectangular tube with square steel pipe and stainless steel square in terms of load-bearing applications?

Stainless rectangular tube and stainless steel square have different section properties: rectangular section steel provides more resistance to bending in one direction while stainless steel square may uniformly resist torsion better, thus selection’s dependent upon the type of structural loading. Rectangular stainless steel, while steel RHS (rectangular hollow sections) are popular selections due to their predictable mechanical performance and conformity with structural steel codes, tublar, thus the trade-off of structural stainless steels accompanies that of carbon steels. When both resistance to corrosion and strength are of concern, grades such as 316ti, 321h, or 304h can be specified while carbon steel or coated steel pipe might be the option where a lower cost is the prime consideration. Fabrication projects are made easier with the tube’s ideal characteristics such as constant dimensions and compatibility with laser fusion welding technology for high-quality seams. Suppliers assure a554 stainless steel rectangular options and size range to ensure that the rectangular tubing meets the design loads and standards.

Can I utilize stainless steel rectangular tubes or steel tubing in corrosive or marine environments?

Stainless steel rectangular tubes and steel tubing in 316 and 316l grades have been the most common materials used in the marine and corrosive environments due to their very good corrosion resistance over almost all carbon steels. The top most alloys like 310s, 316h, or 316ti are higher grades for such extreme cases. Besides, electropolished rectangular pipes are also being used to prevent crevice corrosion by making a smoother surface. Although coated steel or carbon steel pipes might come as cheaper options, their use in water environments would lead to higher maintenance and frequent recoating. Seamless steel pipe and steel pipe seamless variants provide leak-proof performance in pressure or fatigue settings, yet the market is also open for welded stainless steel products if the right techniques are used. Supply houses can offer varieties of steel grades and suggest what to use depending on the expected exposure and life span.

What are the finishes for stainless steel rectangular box section Besides no. 1 pickled finish and no. 8 mirror finish?

The finishes available for stainless rectangular tube and stainless steel products cover a wide spectrum from no. 1 pickled, no. 4, no. 8, ba, and mill finishes, among others, all of which vary in their surface roughness and appearance. No. 1 pickled finish is the one that is mostly applied to areas where heat treatment or oxidation processes have been, while no. 4 is for architectural work that requires a brushed effect and no. 8 is for decorative works giving a very shiny look. All these finishes have one thing in common which is that they all undergo polishing at least once; thus, their roughness and look vary depending on the amount and type of polishing applied to them. Besides aesthetics, electropolishing can also provide cleaner and more corrosion-resistant rectangular pipes. Your selected finish will determine the fabrication stages and may also impact performance in water environments and hygienic industrial equipment.

How does welded stainless steel pipe compare with seamless steel pipes or steel pipe for pressure or plumbing systems?

Welded stainless steel pipes are still a viable option due to their cost-effectiveness and versatility in dimensions. Although seamless steel pipes or pipes seamless might slightly improve pressure integrity and they might be advantageous in high-pressure or cyclic loading applications because of the lack of a welded seam. In the case of plumbing and structural applications, the performance of the welded stainless steel rectangular pipe and stainless steel pipe is considered acceptable when good welding techniques and proper inspection are used. Factors like cost, corrosion resistance requirements, and the allowance for extra coatings determine the choice among alloy steel pipes, carbon steel pipes, and coated steel pipes. The stainless grades used in applications are primarily 304 and 316, while 409 and 409l are sometimes used in the automotive or exhaust systems sectors as special grades. The advisor is to always check with the supplier and the relevant standards to confirm that the selected tube is suitable for the specified pressure and service conditions.

What are the typical dimensions and grades of the stainless steel rectangular tube that a supplier can provide?

A vendor definitely has the variety of dimensions for stainless steel rectangular tubing and rectangular tubing, which range from the smallest pieces to enormous structural sizes, and of course, comprehensive catalogs for rectangular steel pipe and square steel pipe. The most common grades are 304, 304l, 316, 316l, 316ti, 310s, 321h and special ones like 304h or 316h for higher temperature applications while a554 stainless steel rectangular specifications might be taken for some product lines. Moreover, besides mill finish, no. 4 finish and electropolished pipes, suppliers might also stock heavy structural steel and stainless steel members for structural tubing standards compatibility. The premises like accurate inventory available grades of steel, range of sizes, and delivery times for your project can be established by getting in touch with the supplier.

Reference Sources

-

Experiments on Stainless Steel Hollow Sections—Part 1: Material and Cross-Sectional Behaviour

ScienceDirect

This study examines the material and cross-sectional behavior of square, rectangular, and circular hollow sections in Grade 1.4301 stainless steel, proposing a new design approach for stainless steel structures. -

Residual Stresses in Cold-Rolled Stainless Steel Hollow Sections

ScienceDirect

This research investigates residual stresses in stainless steel rectangular hollow sections (RHS) using X-ray diffraction and stub column tests. -

Local–Overall Interactive Buckling of Welded Stainless Steel Box Section Compression Members

ScienceDirect

This paper explores the buckling behavior of stainless steel box section compression members, supported by experimental and finite element (FE) data.