Stainless steel has long been praised for its strength, adaptability, and resistance to rust, making it one of the most widely used materials in different sectors. The steel’s thermal conductivity plays a vital role in its superb performance. Engineers, designers, and manufacturers must thoroughly understand the thermal conductivities of stainless steel before deciding on materials for different applications. This comprehensive article explores the basics of stainless steel, its thermal conductivity range compared with other materials, and its importance in construction, automotive, and energy sectors. Whether you are a designer wanting to optimize your designs or simply curious about the science behind stainless steel’s properties, you will gain valuable insights and practical knowledge to enhance your understanding.

Understanding Thermal Conductivity

Thermal conductivity is a characteristic of a substance that indicates the extent of its heat transfer ability. When considering metals, stainless steel has lower thermal conductivity compared to more conductive metals such as aluminum or copper. Hence, it heats up more slowly and distributes heat less evenly, which is favorable in processes requiring controlled or localized heating. The presence of chromium and nickel, the main alloying elements, is responsible for stainless steel’s low thermal conductivity. These elements impart strength and corrosion resistance but simultaneously inhibit heat conduction. This thermal property of stainless steel has made it a popular choice in the manufacture of cookware, insulation in construction, and industrial equipment where heat containment is essential.

Definition of Thermal Conductivity

Thermal conductivity is a characteristic that denotes the heat conduction capacity of a substance. It reflects the speed of heat movement through the material and is usually expressed in units of watts per meter per kelvin (W/m·K).

Conductivity Categories

🔥 High-Conductivity Materials

Materials such as copper and aluminum are very good at heat transfer, which is why they are used in heat exchangers and cooling systems for electronics.

Examples: Copper (~400 W/m·K), Aluminum (~237 W/m·K)

❄️ Low-Conductivity Materials

Materials like stainless steel or ceramics are poor heat transferers, hence their use for insulation, making it harder for heat to move through.

Examples: Stainless Steel (~16 W/m·K), Ceramics (< 10 W/m·K)

💡 Critical Importance: This property is crucial in the fields of engineering, material science, and industrial design because it helps maintain the right systems and ensure safety.

Importance in Materials Science

Thermal conductivity is a vital property in materials science, as it indicates the conductance of heat and the temperature levels that materials can withstand. Understanding this property helps industries select materials that will perform best according to specific demands.

5 Essential Considerations for Material Selection

Cooling Substances

Electronic devices naturally produce heat. Heat sinks and cooling fans made of high thermal conductivity metals like aluminum and copper are main factors to dissipate heat efficiently, ensuring devices work at maximum performance.

Insulation Materials

Ceramics and fibers are common dielectrics with low thermal conductivity, giving high resistance to heat flow and being widely used in insulating applications to reduce heat losses and increase energy efficiency in buildings, cars, and appliances.

Thermal Coating

Thermal barrier coatings find their use in advanced aerospace and automotive industries through application of low thermal conductivity materials like zirconia. Components are protected from high temperatures while maintaining their strength.

Heat Transfer

Heat is the medium connecting various energy exchangers. Higher heat conductivity means less energy transfer loss, experienced in overall system performance. Materials with good heat transfer are used in solar energy systems and geothermal applications.

Casting and Welding

Industries involving metal processing, like casting and welding, are highly dependent on metals with specific thermal properties as they directly influence cooling rates and quality of finished products.

🎯 Key Insight: Knowing the thermal conductivity of a material precisely allows for development of various innovative solutions. This important property still plays a major role in areas of technology and sustainability.

Comparison with Other Metals

Stainless steel has significantly lower thermal conductivity compared to metals like copper and aluminum, making it less efficient for heat transfer but ideal for applications requiring heat resistance.

Comparative Properties Table

| Key Point | Stainless Steel | Copper | Aluminum |

|---|---|---|---|

| Thermal Conductivity | ~15 W/m·K | ~400 W/m·K | ~205 W/m·K |

| Heat Transfer | Low | High | High |

| Applications | Heat resistance | Electrical, Heat sinks | Lightweight, Heat exchangers |

| Cost | Moderate | High | Moderate |

| Durability | High | Moderate | Moderate |

| Corrosion Resistance | Excellent | Poor | Moderate |

Stainless Steel: Composition and Types

Stainless steel is a versatile alloy that mainly consists of iron, chromium, and other elements like nickel, carbon, and molybdenum to improve its qualities. One of the main components is chromium (at least 10.5%), which not only makes stainless steel highly resistant to corrosion but also enables the formation of a passive protective oxide layer on the surface. Through different compositions, a whole range of stainless steel types designed for particular applications and environments is formed.

5 Most Commonly Used Types of Stainless Steel

1. Austenitic Stainless Steel

Composition: High amount of chromium (16-26%) and nickel (up to 35%) combined with low carbon.

Key Features:

- Superior resistance to corrosion

- Not magnetic

- Great forming and welding properties

Applications: Utensils, tanks for chemicals, and equipment for food processing.

2. Ferritic Stainless Steel

Composition: High chromium content and low carbon with little or no nickel.

Key Features:

- Fair resistance to corrosion and oxidation

- Magnetic

- Better weldability for higher grades

Applications: Car parts, machine parts, and building.

3. Martensitic Stainless Steel

Composition: Between 12-18% chromium, some carbon, and low nickel.

Key Features:

- High strength and hardness

- Less resistant to corrosion compared to austenitic and ferritic grades

- Magnetic

Applications: Knives, surgical instruments, and turbine blades.

4. Duplex Stainless Steel

Composition: Equal parts of austenite and ferrite with high chromium and low nickel.

Key Features:

- Very good tensile strength

- Improved corrosion resistance, especially to stress-corrosion cracking

- Moderate weldability

Applications: Offshore structures, chemical processing, and desalination plants.

5. Precipitation-Hardening Stainless Steel

Composition: Chromium, nickel, and addition of other metals like aluminum, copper, and titanium.

Key Features:

- Extraordinary strength after heat treatment

- Good corrosion resistance

- High-performance material

Applications: Aerospace industry parts, shafts, and tooling for high-strength applications.

🔧 Versatility: The distinct characteristics of each type of steel enable various industrial and commercial applications. As a result, stainless steel finds its way into a wide variety of fields due to its exceptional adaptability.

Focus on 304 Stainless Steel

304 stainless steel is a fundamental and remarkable grade of stainless steel that is the best choice in terms of corrosion resistance, strength, and versatility. It is an austenitic stainless steel type with high content of chromium (around 18%) and nickel (close to 8%), which not only provide remarkable ductility but also make it resistant to oxidation and impart other mechanical properties.

Key Properties of 304 Stainless Steel

🛡️ Corrosion Resistance

Pivotal resistance to corrosion makes 304 stainless steel especially suitable for areas and applications subject to environmental impacts, such as chemical exposures and atmospheric moisture.

💪 Strength and Durability

- Yield Strength (Rp0.2): ~205 MPa

- Tensile Strength (Rm): ~515 MPa

- Elongation at Break (A50): ~40%

🔥 Temperature Resistance

Does not lose capability to bear stress and doesn’t suffer scaling even at temperatures of 870°C (1598°F) for intermittent use and 925°C (1697°F) for continuous use.

🔧 Workability

Not only weldable but also easy to form and present in a wide variety of shapes, catering to industrial as well as decorative applications.

🧲 Non-Magnetic Nature

304 is typically non-magnetic when annealed but might demonstrate some magnetic characteristics after being cold worked.

Applications of 304 Stainless Steel

- 🍴 Food Industry: Widely applied in food processing machines, kitchen appliances, and cookware because of its safe, non-reactive, and easy-to-clean properties.

- 🏗️ Construction: Highly valued for both aesthetic and weathering-resistant properties in architectural cladding, handrails, and structural elements.

- ⚕️ Medical Equipment: Due to non-reactive nature, accepted in surgical instruments and parts of medical devices.

- 🚗 Automotive and Transportation: Covers exhaust systems, trim designs, and high-stress fittings.

- ⚗️ Chemical Sector: First choice for mild chemical storage tanks, piping, and heat exchangers due to ability to withstand corrosive solutions.

📊 Comparison Note: Despite its versatility, 304 stainless steel is constantly compared to 316 stainless steel, which incorporates molybdenum to provide stronger corrosion protection, particularly against chlorides. The good news about 304 stainless steel is its combination of properties, affordability, and availability, making it the most popular material in many sectors.

Characteristics of UNS S30400

UNS S30400, or 304 stainless steel, is known for its remarkable properties combined in a single material. Good resistance to corrosion is one of the major features of this steel, especially in atmospheres where mainly oxidizing and reducing agents are present. Due to this property, stainless steel 304 is widely used in kitchens, pharmaceuticals, and construction.

Key Characteristics

Chromium Content

Nickel Content

High Durability

Rust Resistant

The approximately 18% chromium and 8% nickel content of UNS S30400 allows it to be very durable and rust resistant. It also has good mechanical properties, including high tensile strength and medium ductility, making it easy to machine and weld. Its non-magnetic character in the annealed state and low maintenance needs are among the factors that have made it popular in industry and commerce.

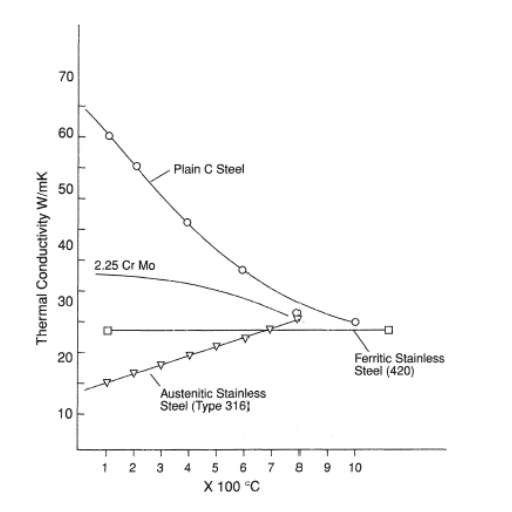

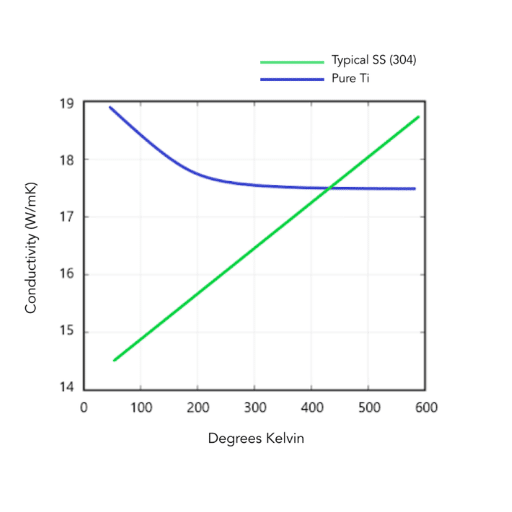

Thermal Conductivity of Stainless Steel

Unlike aluminum and copper, stainless steel has the property of being a relatively poor heat conductor. This property makes stainless steel suitable for applications that require insulation or allow little heat transfer. However, the steel’s ability to conduct heat changes with different grades and compositions of the material.

Key Thermal Conductivity Data (at Room Temperature)

| Stainless Steel Type | Examples | Thermal Conductivity (W/m·K) | Characteristics |

|---|---|---|---|

| Austenitic | 304, 316 | 16-21 | Excellent corrosion resistance with versatility |

| Ferritic | 430 | 23-28 | Used in domestic appliances and automotive applications |

| Martensitic | 410, 420 | 24-28 | Hardness and wear resistance for cutlery and tooling |

| Duplex | 2205 | 19-26 | Strong combination of strength and corrosion resistance |

| Precipitation-Hardening | 17-4 PH | 22-25 | High strength for aerospace and advanced structural applications |

🎯 Critical Knowledge: Understanding the thermal conductivity of each stainless steel grade is of utmost importance to select materials wisely for applications like heat exchange, insulation, or maintaining structural integrity during temperature changes.

Measurement Techniques

Precise and reliable measurement methods are necessary for accurate determination of the thermal conductivity of stainless steels. Below are the five most commonly used measuring methods.

5 Primary Measurement Methods

Steady-State Method

A constant temperature gradient maintained during this technique yields heat transfer measurement across a material. Among the most accurate methods, yet requires a very stable system and long period until steady-state condition is reached.

Transient Hot Wire Method

A thin wire placed in or on the sample serves as both heat source and temperature sensor. By evaluating temperature increase during a certain time interval, thermal conductivity is calculated. Provides rapid and precise results, suitable for liquid and gas measurements.

Laser Flash Analysis (LFA)

A laser pulse is directed towards one side of a sample, and subsequent temperature increase on the opposite side is recorded. This non-invasive technique is quite common in characterization of solids, particularly in research and development contexts.

Guarded Hot Plate Method

Involves placing a flat sample between a hot plate and cold plate, where the hot plate is insulated around edges, and measurement of heat flow through sample to determine thermal conductivity. Very useful for characterization of homogeneous materials.

Heat Flow Meter Method

Sensors in this technique measure flow of heat and temperature differences across a material. Easy to use and very effective for large, flat samples, often applied in insulation and construction material testing.

⚙️ Selection Criteria: All methods have pros and cons particular to features that make them suitable for specific material types or applications. The technique selected is based on material characteristics, sample form, and desired accuracy level.

Factors Affecting Thermal Conductivity

A variety of factors affect thermal conductivity, and each one is important for deciding the heat conduction of a material. Below are five such factors explained in detail:

5 Key Influencing Factors

🔬 Material Composition

Thermal conductivity of a material is directly related to its atomic and molecular structure. Metals have very high thermal conductivity due to unrestricted movement of electrons among atoms. However, non-metallic materials like wood and plastics have very low conductivity.

🌡️ Temperature

Thermal conductivity of most materials varies with temperature. For metals, conductivity usually drops when temperature rises due to increased lattice vibrations that hinder electron movement. However, some insulating materials become good conductors at higher temperatures.

⚖️ Density

Generally, the denser a material, the more thermal energy it can conduct, since its atoms are so compact that heat transfer is pretty fast. Still, this is not true for all materials and specific material structure plays a crucial role.

💧 Moisture Content

Thermal conductivity can be dramatically altered by moisture. Wet materials are better conductors than dry ones as water has higher thermal conductivity than air, which is the case with dry materials.

🔷 Grain Structure and Orientation

Within a material, especially in crystalline or anisotropic substances, orientation and structure of grains can influence heat flow. A material with grains aligned in a certain direction might transfer heat more efficiently along that axis as opposed to other axes.

✅ Essential Understanding: Knowledge of these factors is required to refine thermal properties of materials for uses in insulation, building, electronics, and other industries.

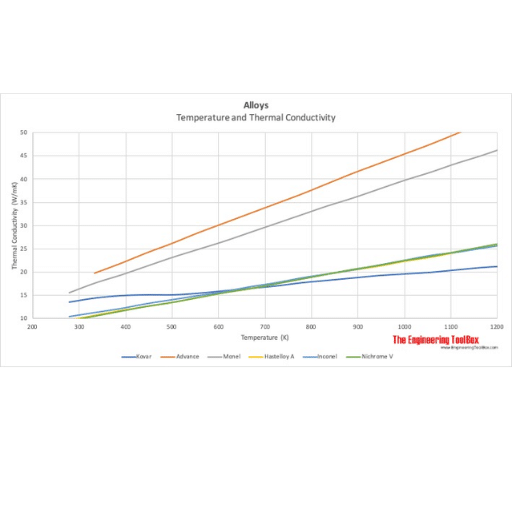

Comparative Analysis with Other Metals and Alloys

The differences in composition, structure, and application suitability of metals and alloys become quite evident when measuring their thermal conductivities. Here is a thorough comparison of five metals and alloys often listed together based on their thermal properties:

Detailed Thermal Conductivity Comparison

🥇 Copper

Thermal Conductivity: ~400 W/(m·K)

Details: Copper has the best thermal conductivity; hence, it is the most common material for heat sinks, radiators, and electrical wiring. It beats other metals in heat transfer by a large margin.

🥈 Aluminum

Thermal Conductivity: ~237 W/(m·K)

Details: Aluminum, though not as good a conductor as copper, is still the most economical and practical option for heat exchangers and refrigeration systems because of its low cost, light weight, and efficient thermal conductivity.

⚙️ Steel (Carbon Steel)

Thermal Conductivity: ~50 W/(m·K)

Details: Steel’s heat conductivity property when compared with non-ferrous metals is poor. But high strength and durability ensure steel’s continued usage in structural applications where thermal performance is of secondary importance.

🔶 Brass

Thermal Conductivity: ~109 W/(m·K)

Details: Brass, the mixture of copper and zinc, is not as conductive as metals mentioned above, but its moderate conductivity makes it ideal for both decorative and heat transfer applications to a certain extent. Resistance to corrosion further contributes to its versatility.

⚗️ Titanium

Thermal Conductivity: ~21 W/(m·K)

Details: Titanium is a great example of a material with low thermal conductivity compared to other metals but that is still very beneficial in places with high strength, weightless, and anti-corrosive needs such as aerospace and medical industry.

🎯 Selection Principle: Materials selection should not only consider thermal conductivity property but also cost, weight, and environmental resistance among others depending on particular requirements of the industry.

Comparison Chart of Thermal Conductivities

Below is a detailed comparison of the thermal conductivities of various metals and alloys, measured in W/(m·K) at room temperature:

| Material | Thermal Conductivity (W/m·K) | Notes |

|---|---|---|

| Copper | 400 | Excellent thermal conductor, widely used in electrical wiring and heat sinks |

| Aluminum | 237 | Lightweight and highly conductive, commonly used in electronics and automotive applications |

| Silver | 429 | The best thermal conductor among metals, often used in specialized applications |

| Stainless Steel | 16 | Lower conductivity compared to pure metals; valued for its corrosion resistance |

| Brass | 109 | A good balance between conductivity and strength, used in fittings and decorative applications |

📊 Analysis: This chart reflects the diversity in material properties and helps in selecting the right material for specific applications based on their thermal performance.

Applications of Stainless Steel Based on Thermal Properties

The superb combination of stainless steel’s thermal properties, such as average thermal conductivity and thermal expansion resistance, is the primary reason for its range of applications. Here are five important applications utilizing these thermal properties:

Cookware and Kitchen Equipment

Stainless steel is the first choice for cookware and kitchen appliances as it can bear high temperatures without changing shape, has moderate thermal conductivity for uniformly heated cooking, and is easy to clean. Saucepans, frying pans, and other kitchen utensils are made of stainless steel to last long and remain thermally efficient.

Heat Exchangers

Stainless steel is a hot material for production of heat exchangers in industries such as power and chemical processing. Its property to hold up to thermal expansion and corrosion gives the facility to perform regularly under very high and low temperature shifts.

Automotive Exhaust Systems

The reason for employing stainless steel in manufacturing automotive exhaust systems including mufflers and converters is its resistance against very high-temperature oxidation and ability to handle hot gas for longer periods.

Construction of Cryogenic Equipment

Stainless steel’s thermal stability at very low temperature is a perfect case for cryogenic tanks and piping systems employed in storing and transporting liquefied gases like oxygen and nitrogen.

Furnaces and Heating Elements

Stainless steel is the go-to material for furnace, industrial oven, and high-temperature heating element construction due to its ability to withstand thermal shocks and high temperatures. Its strength assures a long lifespan even in harsh thermal conditions.

✅ Industry Impact: Using stainless steel specifically according to its thermal properties, industries can realize efficiency, trustworthiness, and cost-saving in their applications.

Use in Heat Exchangers

Stainless steel has gained wide acceptance in manufacturing heat exchangers, making use of its thermal conductivity as a good attribute, resistance to corrosion, and durability. For this reason, it is a favored material in various industries where efficient heat transfer is a critical factor.

5 Major Types of Heat Exchangers

1. Shell and Tube Heat Exchangers

Stainless steel is the material of choice for both tubes and shells because it will not corrode even under aggressive fluids. Its high ratio of strength to weight also makes it very durable, guaranteeing efficient heat transfer in petrochemical and power generation sectors.

2. Plate Heat Exchangers

Thick, corrugated stainless steel plates increase surface area for heat exchange while able to withstand high pressures and exposure to corrosive substances, making them suitable for food processing, chemical, and marine applications.

3. Air Cooled Heat Exchangers

Stainless steel fins and coils are able to endure very harsh environmental conditions and prevent oxidizing atmospheres from affecting them. They are quite good at working in HVAC and oil refineries where air-cooled solutions are needed.

4. Double Pipe Heat Exchangers

Thermal and erosion resistant, stainless steel is the material of choice for both inner and outer pipes. This comes in handy in chemical and HVAC industries for both heating and cooling applications.

5. Compact Microchannel Heat Exchangers

By making use of stainless steel, design of microchannels can be realized efficiently with very high heat transfer rates at very small footprints. Often found in automotive, aerospace, and refrigeration systems.

🏭 Industrial Value: Use of stainless steel in these applications helps heat exchangers achieve superior performance, reduces maintenance needs, and increases device lifespan, making heat exchangers a vital part of modern industrial processes.

Applications in the Food and Beverage Industry

The use of stainless steel in the food and beverage industry is not only a matter of convenience but also an absolute necessity. Its characteristics of being durable, hygienic, and resistant to corrosion make it the most suitable material for the industry, guaranteeing quality and health compliance simultaneously.

5 Major Uses in Food & Beverage Sector

Storage Tanks and Silos

Primary material for construction of storage tanks and silos for liquids like milk, juice, and beer. High resistance to corrosion ensures storage environment is free of contamination and lasts for a long time.

Processing Equipment

Mixers, blenders, and conveyors are examples of food processing machines that use stainless steel because of its non-reactive surface which avoids unwanted chemical interactions during food preparation.

Piping Systems

Stainless steel piping is very important in moving ingredients and drinks while simultaneously taking care of sanitation and preventing corrosion even at conditions of high pressure or high temperature.

Kitchen Tools and Utensils

Commonly used tools and utensils such as knives, pots, and pans are often made out of stainless steel due to its toughness, easy-to-clean property, and capability of maintaining safety in food preparation areas.

Packaging Machinery

Packaging systems for products including bottled water, canned goods, and vacuum-sealed items depend on stainless steel parts to ensure durability and precision in high-speed industrial operations.

🍽️ Industry Standard: These applications exemplify stainless steel’s role as a catalyst in the food and beverage industry regarding efficiency, cleanliness, and productivity. The material has been indirectly involved in continuous innovations and improvements of food safety throughout the entire production process to the point of consumption.

Role in Electrical Conductivity

Among the most significant materials for applications needing electrical conductivity is stainless steel, and the main reasons are its durability, corrosion resistance, and ability to hold structure under different environments. Although it has a lower conduction rate than materials such as copper, stainless steel is still a great choice for industries where strength and environmental toughness are as necessary as conductivity.

Key Electrical Applications

-

⚡ Electrical Enclosures

Electrical enclosures made of stainless steel protect delicate devices from harm done by moisture, dust, and corrosive agents, ensuring they work for a long time in both interior and exterior places.

-

🔌 Busbars and Connectors

Used in busbars and connectors at electrical systems where conductivity level is not too high and advantages of amazing structural strength are a plus.

-

🌍 Grounding Applications

The metal’s ability to withstand environmental degradation is the reason for its use in grounding systems, providing reliable grounding even in hard conditions.

-

🔥 Heating Elements

Chosen for heating elements because of moderate electrical conductivity together with very good thermal properties, hence an efficient heating solution.

-

📡 Electromagnetic Shielding

Does a good job at protecting electronic devices from electromagnetic interference, thereby ensuring device performance and integrity.

🔧 Versatile Performance: All these applications together demonstrate the extensibility of stainless steel in electrical conductivity, where performance is just good enough while durability and resistance to harsh environmental conditions are all there.

Thermal Properties of Metals and Alloys

The characteristics of metals and alloys regarding heating and cooling are very important for their use in different industries as they heat and cool materials in different ways. Therefore, they are the most important properties to help engineers and designers to choose the right materials for heat resistance or conducting tasks. There are five key thermal properties of metals and alloys, which are thermal conductivity, and specific heat capacity, and their significance is discussed below:

Conductivity of Heat

Thermal conductivity is a property of a material that determines its capacity to pass on heat. Copper (401 W/m·K) and aluminum (237 W/m·K) are the most perfect conductors and thus they can be used in the making of heat exchangers or electronic cooling systems. On the other hand, brass, an alloy, generally has lower thermal conductivity than pure metals but at the same time offers improved strength and resistance against corrosion.

Specific Heat Capacity

The specific heat capacity is the heat energy needed to raise the temperature of a material by one degree Celsius. Taking aluminum as an example, it has a specific heat capacity of nearly 0.897 J/g·°C, which is why it is used in applications that require efficient heat absorption, like cookware and automotive parts.

Thermal Expansion

The thermal expansion property indicates how much the material will expand on heating. For instance, steel expands at a rate of about 12 x 10^-6/°C and this property becomes significant when the application is related to the design of parts like bridges and aircraft that are subjected to varying temperatures.

Melting Point

Melting point is the key thermal property that characterizes the transformation of solid to liquid at a certain temperature. Tungsten, a pure metal, has an unbelievable melting point of 3422°C which is why it is extensively applied in the high-temperature environments of aerospace engineering and electrical systems.

Resistance to Thermal Shock

Thermal shock resistance is a criterion that denotes how tolerant the material is to abrupt changes in temperature without being cracked or deformed. Alloys like stainless steel are among the materials which have such a property and thus they are often utilized in extreme temperature fluctuations in power generation and chemical processing industries for their excellent thermal shock resistance.

From these thermal properties, one can easily understand the significance of along with the drawbacks of materials in heat application and the willingness of metals and alloys to be used in making efficient, sturdy, and high-performance systems.

Comparison Chart of Thermal Conductivities

Below is a detailed comparison of the thermal conductivities of various metals and alloys, measured in W/(m·K) at room temperature:

|

Material |

Thermal Conductivity (W/m·K) |

Notes |

|---|---|---|

|

Copper |

400 |

Excellent thermal conductor, widely used in electrical wiring and heat sinks. |

|

Aluminum |

237 |

Lightweight and highly conductive, commonly used in electronics and automotive applications. |

|

Silver |

429 |

The best thermal conductor among metals, often used in specialized applications. |

|

Stainless Steel |

16 |

Lower conductivity compared to pure metals; valued for its corrosion resistance. |

|

Brass |

109 |

A good balance between conductivity and strength, used in fittings and decorative applications. |

This chart reflects the diversity in material properties and helps in selecting the right material for specific applications based on their thermal performance.

Insights into Carbon and Carbon Steel

Carbon and its alloy, carbon steel, are key elements in many industries because of their ruggedness, longevity, and versatility. Basically, carbon steel is a mixture of iron and carbon with the carbon amount being the differentiator between its various grades, and hence the properties and applications.

Below are five important facts concerning carbon and carbon steel:

Carbon Content

Generally, the carbon content in carbon steel lies between 0.05% and 2.0%. Low-carbon steels (mild steels) have a maximum of 0.3% carbon, medium-carbon steels have 0.3% to 0.6%, and high-carbon steels contain 0.6% to 1.25% carbon. Each category has certain features ranging from better ductility to higher strength and hardness, etc.

Strength and Hardness

The more the carbon the more the strength and hardness. However, this also reduces ductility. Thus, carbon steel finds its application in tools, blades, and structures where the factor of durability is very important.

Machinability

Cutting and joining low-carbon steels is not difficult while high-carbon ones may need the skills of a specialist because they are difficult to work and also have brittle and hard conditions after being treated thermally.

Thermal Conductivity

Carbon steel possesses moderate thermal conductivity thus it is made very useful in applications where heat resistance and consistent performance are necessary, like in kitchenware and industrial equipment.

Applications in Industry

The use of carbon steel in construction (beams, reinforcing bars), infrastructure (bridges, pipelines), and manufacturing (automotive parts, machinery) is extensive due to its cost-effectiveness and versatility.

These facts draw a picture of why carbon and carbon steel are still critical in modern engineering and industrial applications.

Identifying Poor Thermal Conductors

In the event of identifying poor thermal conductivity, I mainly consider materials which oppose heat transfer. Among such materials, wood, rubber, plastic, and air can be cited as the very first examples. The existence of their molecular structure inhibits the conduction of heat efficiently, thereby making it possible to use them as insulators and in applications where heat is to be minimized through loss.

References

- Electrical Resistivity and Thermal Conductivity of Nine Selected AISI Stainless Steels

This study examines the thermal and electrical properties of nine AISI stainless steel grades.

Link to source - Thermal Conductivity of Selected Stainless Steels

This work is part of a broader effort to analyze the thermal and electrical properties of metals and alloys.

Link to source - The Thermal Conductivity of AISI 304L Stainless Steel

A critical analysis of the thermal conductivity of AISI 304L stainless steel across a wide temperature range.

Link to source

Frequently Asked Questions (FAQ)

What is the thermal conductivity of stainless steel?

The thermal conductivity of stainless steel typically ranges between 15 to 30 W/m·K, depending on the specific alloy and its composition. This value indicates that stainless steel has lower thermal conductivity compared to metals like copper and aluminum, which are known for their high thermal conductivities.

How does the thermal conductivity of metals vary?

The thermal conductivity of metals varies significantly based on their atomic structure and bonding. For instance, metals like copper and aluminum exhibit high thermal conductivities, making them excellent conductors of heat, while stainless steel and carbon steel have lower thermal conductivities. This variation is crucial in engineering applications where efficient heat transfer is required.

What are the thermal properties of aluminum?

Aluminum has a high thermal conductivity of about 205 W/m·K, making it an excellent choice for applications requiring efficient heat transfer, such as heat sinks and food processing equipment. Its lightweight nature and good thermal expansion properties further enhance its use in various engineering applications.

How does thermal conductivity affect food processing equipment?

In food processing equipment, the thermal conductivity of materials plays a vital role in ensuring efficient heat transfer during cooking or refrigeration. Materials with high thermal conductivity, like aluminum, allow for even heating, while those with lower thermal conductivity, like stainless steel, may be used to provide insulation and minimize heat loss.

What is the relationship between thermal conductivity and temperature?

The thermal conductivity of materials can change with temperature. Generally, metals exhibit increased conductivity at higher temperatures, while non-metals, like certain polymers, may show decreased conductivity with rising temperature. Understanding this relationship is crucial for applications in environments with fluctuating temperatures, such as cryogenic processes.

What are the applications of thermal conductors?

Thermal conductors, such as copper, aluminum, and certain alloys of stainless steel, are widely used in various applications, including electronics for heat sinks, building materials for insulation, and cooking utensils like pots and pans. Their ability to conduct heat efficiently makes them essential in both residential and industrial settings.

How does the density of a material influence its thermal conductivity?

The density of a material can influence its thermal conductivity, with denser materials often having more closely packed atoms, which can enhance heat conduction. However, this is not a strict rule, as other factors, such as the material’s crystal structure and bonding, also play significant roles in determining its thermal conductivity.

What is the significance of thermal conductivity in engineering?

In engineering, thermal conductivity is a critical property that affects the design and efficiency of systems involving heat transfer. Understanding the thermal conductivities of materials helps engineers select appropriate materials for specific applications, ensuring optimal performance in systems such as refrigeration, heat exchangers, and thermal insulation.

What is the role of thermal insulation in reducing heat loss?

Thermal insulation materials, which typically have low thermal conductivity, are used to reduce heat loss in buildings and equipment. By preventing the transfer of heat, insulation helps maintain desired temperatures, improving energy efficiency and reducing heating or cooling costs. Common insulation materials include fiberglass, foam, and certain types of plastics.