The knowledge of thermal properties of steel and its alloys is essential for industries such as construction and aerospace. The way materials react to heat, either by way of conductivity, expansion, or resistance to temperature changes, can be a factor in their usefulness and lifespan in different applications. The article takes the reader on an interesting journey into the world of steel by revealing the role of its thermal conductivity and coefficient of expansion in different scenarios. The article is useful to anybody who may be designing heat-resistant machinery or engaging in structural integrity investigations, as it contains essential information for steel’s performance in high-temperature settings. Be alert for the unveiling of the underlying science associated with these properties and their significance to contemporary engineering.

Introduction to Thermal Properties

The thermal properties of steel, like its thermal conductivity and expansion coefficient, are determining factors in the material’s reaction to temperature fluctuations. The thermal conductivity of steel is the main factor for its heat transfer rate; thus, if the thermal conductivity is low, the transfer of heat will be negligible. The thermal expansion coefficient indicates the degree of steel’s expansion or contraction each time the temperature changes, which can lead to the material’s loss of structural integrity. It is and always has been necessary to comprehend these characteristics in very hot or fluctuating temperature applications as it has become so done through engineering and design safety, efficiency, and durability.

What are Thermal Properties?

Thermal properties are characteristic features of a substance that determine its reaction to heat or variation in temperature. Among these properties are the thermal conductivity, which assesses the capability of a substance to transfer heat; the specific heat capacity which portrays the heat energy necessary to increase the temperature of a substance; and the coefficient of thermal expansion which demonstrates the degree to which a substance changes in size due to temperature variations. It is vital to comprehend thermal properties for steel as well as for other engineering materials while designing systems that are exposed to high heat or rapid temperature shifts; thus, the materials will not only retain their structural integrity but also perform reliably under the changing thermal conditions.

Importance of Thermal Properties in Metals

During their lifetime, metals get exposed to different temperatures and thermal properties become one of the main factors that decide whether a metal performs well or not and if it’s reliable. These properties dictate the behavior of metals in heat and at the same time make sure that they can be used in the respective engineering and industrial applications without any problem. The following is the summary of the most important thermal properties of metals and their implications:

Thermal Conductivity

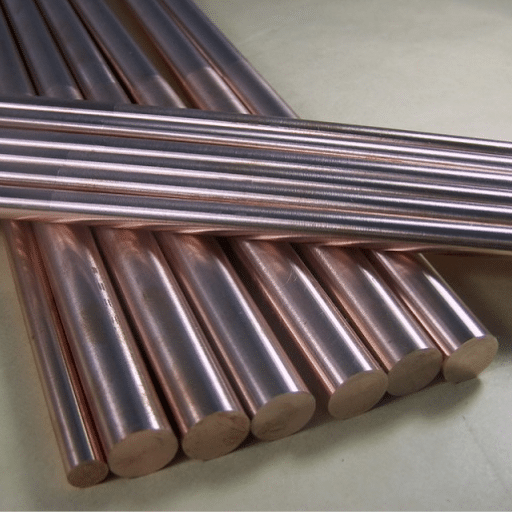

Thermal conductivity is the measurement of the heat conduction ability of a certain metal. The metals that have the highest thermal conductivity, for instance, copper and aluminum, are used in heat exchangers and electronic parts frequently as they can remove the heat very efficiently.

Specific Heat Capacity

One of the aspects measured in this property is the energy that must be provided to increase the temperature of one kilogram of metal by one degree Celsius. The energy input-output in aluminum, for example, is very high and thus the material is used in applications where good thermal energy storage and slow heat release are required.

Thermal Expansion Coefficient

Thermal expansion coefficient indicates the extent of a metal’s expansion or contraction with temperature changes. This property is important in situations such as water-supplying systems or bridges where temperature changes could cause the structure to become unstable if not taken into account.

Melting Point

The melting point is the temperature that marks the transition of a metal from solid to liquid. Rising melting point metals, such as tungsten, are being used in very hot and hard to work with places like space or industrial furnaces just because of their physical properties.

Thermal Shock Resistance

This property indicates the capacity of a metal to survive sudden temperature changes without breaking or losing its shape. Its significance is enormous in engine parts or materials subjected to thermal cycling.

If the thermal features of the metals are understood and properly used, it can be trusted that the metals would act best and also be safe in a wide range of applications.

Overview of Steel and Its Alloys

Steel and its alloys are the most adaptable and extensively utilized materials across the globe. The main components of these metals are iron and carbon, together with some other metals in minor amounts to improve their specific properties e.g. strength, corrosion resistance, and machinability. The use of these alloys is crucial in the construction, automotive, aerospace, and manufacturing industries because of their flexibility and good performance. The types of steel and their alloys mentioned below make up the five most common varieties with detailed information regarding their composition, properties, and applications:

Carbon Steel

Mainly iron and carbon with small quantities of other elements.

Very strong and hard but somewhat low in corrosion resistance.

Load-bearing parts, car skins, and oil and gas pipelines.

Stainless Steel

More than 10.5% of chromium and often nickel and molybdenum.

Corrosion resistance to a high degree, long-lasting, and attractive.

Household appliances, surgical instruments, and equipment in chemical processing.

Alloy Steel

Main constituents are alloying elements like manganese, chromium, vanadium, or molybdenum, in large quantities.

Strength, toughness, and resistance to wear are increased.

Production of gears, shafts, and tools for high-stress areas.

Tool Steel

Contains a lot of carbon plus tungsten, chromium, and vanadium.

Very hard, can withstand high temperatures, and has a long life.

Production of cutting tools, drilling machines, and molds.

High-Speed Steel (HSS)

Mixed with tungsten, molybdenum, cobalt, or chromium.

Keeps hardness and strength even at high temperatures, which is why it is very suitable for use in high-speed operations.

Fabrication of drill bits, saw blades, and other cutting tools.

The materials are little by little shaped and picked for their specific uses based on their distinctive properties, and so their low cycle and high performance in various conditions are guaranteed.

Thermal Conductivities of Steel

One of the most crucial properties of steel that determines its efficiency in heat transfer related applications is thermal conductivity. In other words, it is the capability of a given material to transfer heat and is quantified in watts per meter-kelvin (W/m·K). Depending on the steel grade, the thermal conductivity may vary and even reach different values within a single type according to steel’s composition and microstructure thus some steels might even show opposite thermal behaviors. The following are the five different kinds of steel and their thermal conductivity:

| Steel Type | Thermal Conductivity (W/m·K) | Characteristics |

|---|---|---|

| Carbon Steel | ~54 | Good mix of strength and weight, usually applied in construction and to the general public. |

| Stainless Steel (304) | ~16.2 | Less conductive than carbon steel, used in kitchens and chemical processing, excellent rust resistance. |

| Tool Steel | ~24 | Tough and resistant to wear, ideal for cutting and machining tools. |

| High-Speed Steel (HSS) | ~20-25 | Preserves hardness and strength at high temperatures, perfect for fast cutting tools. |

| Low-Alloy Steel | ~30-40 | Good combination of strength, toughness, and heat conduction, widely used in pipes and load-carrying structures. |

The knowledge of thermal conductivities of different steel types helps to make sure selection and usage of them are in line with specific thermal performance criteria already set for industrial and engineering applications.

Defining Thermal Conductivity

Thermal conductivity is the property of a material to transferring heat. This property is the major factor in engineering and material science, as it determines the rate of heat transfer through a material in a particular system. The thermal conductivity coefficient is the measure of this property, expressed in watts per meter-kelvin (W/m·K) most of the time. The greater the number, the greater the heat-conducting capacity of the material.

Thermal Conductivity of Common Materials

| Material | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|

| Copper | ~385-400 | Wiring, heat exchangers, electronic components |

| Aluminum | ~205-250 | Heat sinks, aerospace sectors |

| Stainless Steel (Type 304) | ~16-20 | Applications requiring minimal thermal transfer |

| Diamond | ~2000 | High-performance heat-dissipation, electronic and laser systems |

| Concrete | ~0.8-1.8 | Construction, thermal insulation |

The understanding of thermal conductivity is such that it helps the users in selecting the proper materials according to the needs for different applications in industries as well as daily life.

Comparative Analysis of Thermal Conductivities in Metals

The thermal conductivities of different metals are very significant for the right material selection in the industries where the heat transfer or dissipation is part of the process. Over the following lines is a complete comparison of the thermal conductivities of five metals that are commonly used:

| Metal | Thermal Conductivity (W/m·K) | Key Applications |

|---|---|---|

| Copper | ~400 | Electronics, heat exchangers, cooling systems |

| Aluminum | ~205 | Aerospace parts, automobile heat sinks, kitchen utensils |

| Gold | ~318 | Luxury electronics, aerospace technology |

| Iron | ~80 | Radiators, metal structures requiring moderate thermal management |

| Stainless Steel | ~15-25 | Cooking, building insulation, industrial machines |

This comparison reveals the various thermal conductive properties of metals clearly, thus helping the experts to choose the right materials according to their thermal and structural requirements.

Thermal Conductivity of Stainless Steel

Stainless steel has a moderate thermal conductivity that is recognized as being around the same level as that of other metals. This characteristic renders them applicable in a range of specialized situations where heat-resistance or controlled heat transfer is essential. A comprehensive chart of thermal conductivity properties for the standard grades of stainless steel is given below:

| Stainless Steel Grade | Thermal Conductivity (W/m·K) | Primary Applications |

|---|---|---|

| Austenitic Stainless Steel (304, 316) | ~16-21 | Kitchenware, chemical processing equipment, clinical environments |

| Ferritic Stainless Steel (430) | ~23-25 | Automotive exhaust systems, heat exchangers, residential appliances |

| Martensitic Stainless Steel (410, 420) | ~24-26 | Cutlery, surgical instruments, structural components |

| Duplex Stainless Steel (2205) | ~19-22 | Marine, oil & gas, pressure vessel applications |

| Precipitation-Hardening (17-4 PH) | ~18-20 | Aerospace, mechanical components, high-performance areas |

Grasping the thermal characteristics of the different grades of stainless steel given above leads to the right material selection for heat-sensitive or high-performance areas.

Thermal Properties of Steel at Elevated Temperatures

Steel reveals drastic modifications in its thermal characteristics when subjected to high temperatures. Definitely, these properties are essential for hot applications, and their complete understanding would guarantee safety, performance, and longevity. The following are the five major thermal properties of steel at elevated temperatures and their elaborations:

- Thermal Expansion: It is the case that steel when heated up expands and its dimensional change may affect the whole component.

Value Range: ~10–15 x 10^-6 /°C, depending on the steel grade. - Thermal Conductivity: It is a property of steel where the conduction of heat varies with the change of temperature. In most cases, the reduction of thermal conductivity occurs at a somewhat higher temperature.

Value Range: ~25–40 W/m·K at room temperature but it drops at higher temperatures. - Specific Heat Capacity: It tells the amount of heat that is necessary for raising the temperature of steel by one degree Celsius.

Value Range: ~0.46–0.50 kJ/kg·K, although it can change with temperature. - Melting Point: This is the temperature at which steel changes from solid to liquid state, it is very important for production and heat treatment.

Value Range: Usually 1370–1510°C depending on the composition of the alloy. - Creep Resistance: Creep means that there is slow permanent deformation of the material due to the application of stress over a long time at elevated temperatures. This property gives steel the ability to retain its original dimensions even if exposed to high temperatures for a long time.

Value Range: Significant around 400°C and above, depending on temperature and stress combination.

With the knowledge of these properties, it will not be difficult to choose and design steel parts for high-temperature applications, such as in power plants, furnaces, and jet engines.

Behavior of Steel Under Heat

When steel is subjected to high temperatures, its characteristics and behavior are greatly altered by the degree of heat and its duration of the heating. Here are the five main behaviors of steel under heat along with the respective details:

Thermal Expansion

Description: When the steel is heated, it expands because of the higher energy of its atomic structure and this might be the reason for dimensional changes and possibly problems in the case of structural purposes.

Value Range: The thermal expansion coefficient is around 11-13 x 10⁻⁶ /°C for most steels.

Reduction in Yield Strength

Description: The yield point of steel diminishes with an increase in temperature, hence the steel becomes less and less able to bear the loads applied to it without undergoing deformation. This having been said, it is a matter of structural safety in the case of high-temperature environments.

Value Range: There are cases of yield strength reductions starting at 200°C, above which more and more such losses occur as the temperature continues to rise.

Creep Resistance

Description: Creep happens when steel is slowly deformed over time under high-stress and at high temperatures. Creep resistance is what allows steel to retain its shape under thermal conditions that are prolonged.

Value Range: Marked only when combination of stress and temperatures are over 400-500°C.

Thermal Conductivity Changes

Description: Steel’s capacity to transfer heat varies at high temperatures with lower thermal conductivity possibly resulting in non-uniform heating and the creation of localized thermal stresses.

Value Range: The thermal conductivity of steel decreases typically with the increase in temperature, being 45 W/m·K at the room temperature and around 25-30 W/m·K at elevated temperatures.

Phase Transformation

Description: Steel experiences various changes, one being the formation of austenite at high temperatures which the crystal structure gets altered. The resulting transformations impact thermal and mechanical properties.

Key Temperatures: The formation of austenite generally occurs in the temperature range from 727°C to 912°C varying with the steel composition.

Knowledge of these steel behaviors is vital for the designers of steel components to ensure that they can endure thermal stressing while performing and maintaining safety of their characteristics.

Effects of Elevated Temperatures on Steel Properties

The steel’s mechanical and structural properties are greatly affected by the elevated temperatures. The changes are very important to take into account in such fields as construction, manufacturing, and the like. The following are the five main impacts of the high temperatures on the steel properties:

- Reduction in Strength: When the temperature exceeds 400°C, the yield strength and ultimate tensile strength of steel get reduced quite significantly. The progressive decline in strength of some grades of steel becomes very noticeable when the temperature reaches 600°C.

- Loss of Elasticity: The elasticity that the modulus of elasticity quenches at the high temperature level just determines the quality of steel stiffness being less and the matter of deformation under stress more.

- Thermal Expansion: Steel is subjected to thermal expansion which leads to the increase in volume and linear dimensions when heated up. It can cause the distortion and misalignment of structural applications that are the most common problems caused by thermal expansion.

- Microstructural Changes: The continued presence of high temperatures can result in phase changes such as the change of ferrite to austenite and the changes that will directly impact the steel’s ductility and toughness.

- Decreased Hardness: Softening of steel at the elevated temperatures means reduced resistance to wear and abrasion on the surface during mechanical loading.

Awareness of these effects is not only important but also necessary for guaranteeing the safe and effective utilization of steel under high-temperature conditions. Some harmful effects can be reduced through the use of proper design strategies, material selection, and heat treatments.

Applications Requiring High-Temperature Steel

High-temperature steel is a must-have material for many industries and applications where the components are subject to high temperatures and rough conditions. The following five applications where high-temperature steel is necessary are provided alongside their respective details and data:

Power Plants (Boilers and Turbines)

The high-temperature alloy is a major component in the manufacture of boilers, turbines, and heat exchangers in thermal power stations.

- Operating Range: 500°F to 1300°F (260°C to 700°C)

- Materials Used: Chromium-molybdenum alloys are most frequently used because of their high strength and resistance to oxidation.

Aerospace Components

High-temperature steel is an indispensable material for manufacturing jet engines, exhaust systems, and other components in the aerospace sector, which must withstand high-temperature and stress conditions during service.

- Temperature Limit: Up to 1800°F (980°C)

- Materials Used: Nickel-based superalloys and heat-treated martensitic steels for durability.

Petrochemical and Refinery Equipment

Petrochemical plants high-temperature steel is being used in the construction of reactors, pressure vessels, and pipelines for processing chemicals under high pressure and temperatures.

- Operating Environment: Up to 800°F (427°C)

- Requirements: Alloys with the highest creep and corrosion resistance.

Automotive Industry (Exhaust Systems)

High-temperature steel is a key element in exhaust manifolds, catalytic converters, and turbochargers manufacturing in vehicles.

- Temperature Range: Up to 1200°F (649°C) at full load

- Materials Used: Austenitic stainless steel grades for heat and oxidation resistance.

Industrial Furnaces and Heat Treating Equipment

High-temperature steel is the raw material for furnace linings, kiln rollers, and heat treatment trays in manufacturing industries.

- Temperature Exposure: Continuously above 2000°F (1093°C)

- Materials Used: Refractory stainless steels and alloys containing chromium, aluminum, and silicon.

The ability of engineers and material scientists to select the best high-temperature steel grades to ensure both performance and durability under extreme conditions is directly related to their understanding of the unique requirements of these applications.

Thermal Expansion in Metals and Alloys

Thermal expansion is an essential characteristic that specifies the extent of the volume or length change of a material when it is subjected to temperature changes. This property is of major concern in the mechanical and manufacturing fields, where the metals and alloys are frequently exposed to varying temperatures. The understanding of thermal expansion is critical in the process of materials selection, which ultimately reduces or controls the possibility of thermal induced structural stress, deformation, or even failure.

Main Factors Affecting Thermal Expansion

- Material Composition: The atomic structure of metals and alloys is the reason for their different atomic and thus thermal expansion rates.

- Temperature Range: The thermal expansion coefficients may vary according to the temperature range in which the material operates.

- Phase Changes: Materials that change their state (e.g., during melting) can also alter their thermal expansion properties significantly.

- Environment: The thermal expansion of a material can be influenced by the external atmosphere if it includes oxygen or other reacting gases.

- Thermal Cycling: Exposure to high temperatures and then cooling down repeatedly can eventually cause the materials to become fatigued or their expansion properties to change over time.

Thermal Expansion Coefficients of Common Metals and Alloys

The following table provides the coefficients of thermal expansion (CTE) for different metals and alloys, approximately giving values in microns per meter per degree Celsius (µm/m·°C):

| Metal/Alloy | CTE (µm/m·°C) | Key Characteristics |

|---|---|---|

| Aluminum (Pure) | ~23 | Very much appreciated for its high thermal expansion rate and low density. |

| Copper | ~16.5 | Copper has very good electrical conductivity and a low rate of thermal expansion. |

| Stainless Steel (304) | ~17.2 | One of the most widely used stainless steels because of its good corrosion resistance, control over thermal expansion, and versatility. |

| Brass | ~19 | It possesses excellent machinability and thermal expansion characteristics that are suitable for industrial uses. |

| Titanium | ~8.6 | Titanium has a very low thermal expansion coefficient and a very high strength-to-weight ratio. |

Through the examination and comparison of these rates, it becomes possible for the engineers to have a foresight of the metals and alloys’ thermal response under specific conditions, thus making it possible to create dependable as well as efficient systems.

Understanding Thermal Expansion

Thermal expansion signifies a material characteristic that can quantify the amount of increase in size of a material with the rise in temperature. This property differs greatly from one material to another and is essential to know for engineering, manufacturing, and building sectors to keep systems working efficiently and without faults.

Thermal Expansion Data of Common Materials

| Material | CTE (µm/m·°C) | Applications |

|---|---|---|

| Aluminum | ~23 | Light and heat expanding, major component where flexibility with temperature change is important. |

| Steel | ~11-13 | Weaker thermal characteristics but high strength, popular in construction and heavy machinery. |

| Copper | ~16.5 | Best conductivity with reasonable expansion, first choice for electrical applications and heat exchangers. |

| Titanium | ~8.6 | Slow expansion and high strength-to-weight ratio, ideal for space and highly accurate engineering. |

| Glass (Borosilicate) | ~3.3 | Very low thermal expansion, excellent for laboratory applications requiring high temperature stability. |

Engineers through the above data on thermal expansion will always be able to make the right choice of materials according to the particular demands that the systems they work on would pose.

Factors Influencing Thermal Expansion in Steel

The thermal expansion of steel is dependent on a number of influential factors, and each of them has a significant role in revealing the material’s behavior when subjected to different temperatures. With a good grasp on these factors, one can ensure the steel’s performance in particular situations. The five major factors are as follows:

- Alloy Composition: The thermal expansion coefficient of the steel can differ widely with respect to the alloying elements. To illustrate, the expansion gets diminished with increased carbon or chromium content.

- Temperature Interval: The extent of the expansion exhibits a different proportion with temperature. The thermal expansion of steel varies depending on the temperature range, and thus the peak rates are noted in case of higher temperatures.

- Microstructure: Steel’s microstructure can be the determining factor giving rise to different expansion characteristics; for instance, ferritic or austenitic structures.

- Heat Treatment: Processes like annealing or quenching constitute heat treatment processes that modify the steel’s internal properties, and this, in turn, directly influences its thermal expansion behavior.

- Residual Stress: The manufacturing processes, such as welding and rolling, might impose internal stresses within the steel that can subsequently lead to an uneven expansion of the material during heating.

Considering these factors, the predicting and optimizing of steel’s performance in thermal-critical applications become easier for engineers and designers.

Thermal Expansion in Steel vs. Other Metals

Thermal expansion rate is a significant factor that varies between steel and other metals due to their distinct material properties. Analogous to thermal expansion, temperature change is also considered when deciding on the metal for the use in a product, and that is why the following table presents the characteristics of steel and five other metals usually employed in the industry concerning their coefficients of thermal expansion and thermal changes:

| Metal | CTE (x 10⁻⁶ /°C) | Characteristics & Applications |

|---|---|---|

| Steel | ~11-13 | Moderate expansion rate, perfect for structural applications requiring dimensional stability over large temperature ranges. |

| Aluminum | ~23-24 | Almost double the size of steel in heat tolerance. Major factor in aluminum-combination designs. |

| Copper | ~16-17 | Higher than steel but lower than aluminum. Good thermal conductivity couples with moderate expansion in heat exchange applications. |

| Brass | ~18-19 | Copper-zinc alloy that expands more than copper and steel but less than aluminum. Employed where appearance is essential with moderate expansion tolerance. |

| Titanium | ~8-9 | Lower CTE than steel. Preferred in aerospace due to unbeatable combination of strength, lightness, and minimum shrinkage/expansion. |

Through a proper selection of metal, designers and engineers can ensure that the performance and the life of the metal in different thermal environments are guaranteed when they analyze these variations.

Applications of Steel Thermal Properties

The thermal properties of steel are very important for the metal’s use in various industries and applications. Five applications of steel, where its thermal characteristics are critical, are pointed out below:

Construction and Structural Engineering

The very good thermal conductivity and very well-defined thermal expansion of steel make it an excellent material for bridges, buildings, and other infrastructures.

Data Example: The common grades of steel (such as ASTM A36) have a CTE of about 11-13 x 10⁻⁶ /°C, which guarantees very little thermal distortion in the structural components.

Automotive Industry

Steel is in great demand for engine parts, exhaust systems, and body panels because of its ability to tolerate the high-temperature changes.

Data Example: High-strength steel alloys are very stable and also resist deformation at temperatures over 500°C.

Energy and Power Plants

Steel’s ability to conduct heat and its resistance to thermal fatigue make it the best material for piping, boilers, and heat exchangers in power plants.

Data Example: Carbon steel pipes have stable performance under temperatures ranging from -50°C to over 400°C in power generation environments.

Kitchenware and Appliances

Stainless steel’s low CTE and high heat resistance are essential for cookware and household appliances as they provide durability and even heat distribution.

Data Example: 304 stainless steel has a CTE of around 16 x 10⁻⁶ /°C, which ensures great thermal stability for pots, pans, and oven parts.

Aerospace Sector

Aerospace-grade steel alloys are utilized in the manufacture of turbine blades and structural parts, where thermal stability is necessary at extreme temperatures.

Data Example: Maraging steel is to be used for applications where the operating temperature can go as high as 600°C and still possess high strength and stability.

The thermal properties of steel give the metal a basic material that can fulfill a wide range of thermal and mechanical conditions.

Industrial Applications of Steel

The qualities of steel like its versatility and strength have led it to become a necessary material across diverse industries. The five main industrial uses of steel are listed below, with their explanations and data examples provided in detail:

| Industry | Applications | Key Data |

|---|---|---|

| Construction Industry | Buildings, bridges, roads – structural steel for wear and tear resistance | Can tolerate up to 250 MPa of stress; used in skyscrapers and long-span bridges |

| Automotive Industry | Vehicle frames, engines, safety components | Modern car contains about 950 lbs of steel; advanced high-strength steel accounts for over 60% of body structure |

| Energy Sector | Pipelines, wind turbines, nuclear reactor parts | Offshore wind turbine towers withstand wind speeds up to 150 mph in marine environments |

| Shipbuilding Industry | Hulls, bulkheads, decks – structural stability | Marine-grade steel tolerates stress levels as high as 355 MPa without corrosion in saltwater |

| Oil and Gas Industry | Drilling strings, pipelines, offshore platforms | Heat-treated steel drill pipes endure pressures over 15,000 psi in difficult oil fields |

All of these applications point to the superior capabilities of steel in industries where strength, durability, and versatility are the main requirements.

Construction and Engineering Considerations

Choosing the right metal for construction and engineering works involves a lot of important factors. The mentioned factors are the main reasons for the quality of structures and systems in terms of safety, durability, and efficiency. These five aspects are the main ones with details to back them up:

Load-Bearing Capacity

The remarkable strength-to-weight ratio is one of the most important features of steel that makes it suitable for supporting heavy loads without adding much bulk, thus making it perfect for industries like skyscrapers, bridges, and large-scale infrastructure.

Data Example: Depending on its grade, structural steel can manage tensions and compressions of up to 50,000 psi.

Corrosion Resistance

The life of steel in harsh environments is guaranteed by the combination of protective coatings and alloying elements like chromium in stainless steel, which contributes a lot to the steel’s corrosion resistance.

Data Example: In marine environments, stainless steel can endure around 50 years without any significant corrosion.

Seismic Performance

In addition to its ductility, steel is flexible and can easily withstand seismic activity by absorbing energy and resisting cracking or collapse during earthquakes.

Data Example: Steel-reinforced structures have an earthquake damage reduction rate of 40% over non-steel structures.

Thermal Stability

The property of steel to maintain its characteristics even at high temperatures is very important for its usage in fire-resistant buildings. Sometimes fireproofing materials are used to further improve its performance.

Data Example: Steel with fireproof coatings can last up to 2000°F for such long periods without failing structurally.

Ease of Fabrication and Assembly

The bending of steel also enables it to be shaped in any way, making prefabrication and the use of modular construction very efficient in terms of design.

Data Example: The use of prefabricated steel components in a construction project can save up to 30% in time and labor costs, thus minimizing both the duration of the project and its overall cost.

If these factors are taken into account, the professionals in the construction and engineering sectors will be able to make steel the main material in winning and economic resilient designs.

Innovative Uses of Steel in High-Temperature Environments

Based on what I have experienced, the qualities of steel that are the most important and its resistance to heat make it the most important metal in high-temperature areas. The most advanced alloys like stainless steel and heat-resistant non-ferrous metals, keep their properties even when they are subjected to very high temperatures. These materials are also found in applications like power generation, industrial cooling, and automotive exhaust system,s where safety and efficiency are a must. Using the latest technologies, I have seen how steel can be made to adapt to the challenging conditions of these applications.

References

Published by OSTI – This paper discusses the thermodynamic and thermal conductivity properties of stainless steels.

Published in ScienceDirect – This study examines the thermal properties of S280 GD+Z steel at various temperatures.

Published by AIVC – This document provides insights into the thermal properties of building materials, including steel.

Frequently Asked Questions (FAQ)