Like other metals, stainless steel is prized for its strength and resistance to corrosion; these features allow it to be used across various industries, including construction and medical equipment. Yet few people know that many of its remarkable characteristics are often achieved through annealing, a detailed process done in advance. This form of heat treatment is crucial to advancing stainless steel’s capabilities, especially for demanding applications where the ability to resist corrosion is essential. In this article, we will delve into the intriguing process of annealing, how it changes the backbone of stainless steel, and why this transformation is important in creating materials that can endure prolonged use with minimal maintenance. Come with us as we explore the amazing applications and benefits of annealing that ensure stainless steel maintains its status as a material of ever-increasing versatility and dependability.

What is annealing, and why is it important for stainless steel?

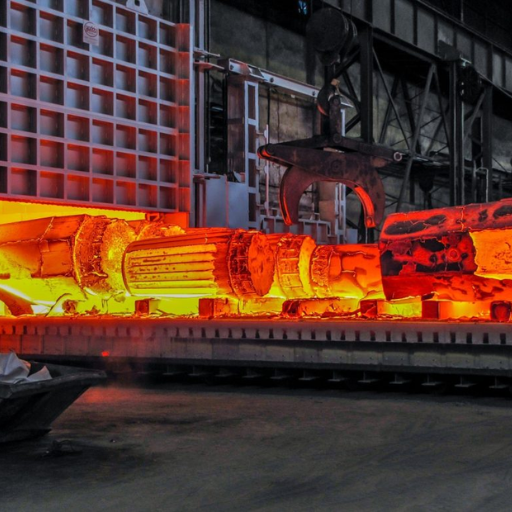

Obtaining desirable properties in stainless steel requires the use of an annealing process, which is a form of heat treatment. It includes heating the metal to a predetermined temperature, holding that temperature for a specific amount of time, then cooling it at a specific rate. The resulting effects of this process are the reduction of internal stresses, improvement of the overall grain structure, the enhancement of material strength and ductility, as well as an increase in its corrosion resistance.

Annealing is critical for stainless steel since it enables restoring the optimal mechanical properties after forming or welding. This ensures that the stainless steel maintains its structural integrity and reliability, even under harsh conditions.

Definition of annealing as a heat treatment process

Unlike other processes which are specific to an industry, annealing seems to be more versatile and is used when working with metals and glass because of its significant advantages. This process is known to improve ductility of materials, meaning that it becomes easier to be molded without fracturing during complex operations. Further, annealing aids in better machinability which decreases tool wear giving an advantage in production.

With respect to steel, relieving internal stresses caused by machining or welding results from annealing. Stress relief as a result of this process removes distortion, which leads to structural failure in critical components such as automotive parts, aerospace frames, and construction materials. Data indicates that stainless steel, which has been processed through annealing attains almost double the elongation percentage that untreated steel achieves, which improves flexibility and performance.

Steels that undergo the annealing process are much more useful when working in extreme conditions. This is because it rules out the possibility of corrosion, allowing for safe usage in chemical plants or maritime environments. Such materials, along with their refined grain structure, provide better durability and strength, aiding in meeting industry standards and performing reliably in demanding conditions.

How annealing affects the microstructure of stainless steel

Stainless steel suffers critically in numerous ways in its mechanical and physical properties due to the alteration of its microstructure in annealing. As with any thermal annealing, a specific temperature—often 1,900°F to 2,100°F (1,040°C to 1,150°C)—must be met, followed by a controlled cooling rate. Uniform grain structures and internal stresses are mitigated after this treatment. Additionally, new, strain-free grains will replace any deformed ones inflicted by manufacturing processes such as rolling or welding during the recrystallization stage.

One critical change in microstructure is the dissolution of carbide precipitates in stainless steel. The presence of chromium carbides, for instance, can lead to a process known as sensitization, where chromium near the carbides is depleted, leading to a loss in the corrosion resistance of the steel. These carbides can be dissolved during annealing to avoid sustaining chromium over portions and maintain maximum corrosion resistance throughout the stainless steel. In addition, annealing permits grain boundaries to realign and increase in area – this is referred to as grain growth or coarsening. Although controlling grain size is important to preserve desired characteristics, this increase in solid grain structure enhances ductility and toughness of the stainless steel, hence making it softer and easier to work with. As an example, some manufacturers deliberately use sophisticated annealing methods in the making of stainless steel surgical tools or aerospace parts to ensure accuracy and dependability for critical use.

It has been observed that certain austenitic stainless steels, especially grades 304 or 316, undergo an increase in elongation and a decrease in hardness after annealing. These changes are important in achieving optimum performance outcomes in a wide range of industrial activities such as construction and chemical processing. Thus, the annealing step is indispensable in customizing the microstructure of stainless steel to enhance its specific functionalities.

Benefits of annealing for stainless steel properties

Stainless steel’s annealing process improves its formability, toughness, and enhances mechanical properties. It also relieves internal stress from welding, forging, or machining. For example, annealing alters the microstructure of a material by softening it, which reduces the hardness, and is often quantified by Brinell or Rockwell hardness.

The ductility of annealed 304 and 316 grade stainless steels increases up to 40%, which allows deeper drawing and better shaping during fabrication. Also, annealing guarantees a uniform grain size, which reduces distortion under compressive stress and increases crack resistance. The enhancement of corrosion resistance is another advantage, especially for harsh industrial environments like marine settings or chemical plants. Such attributes make these types of stainless steel necessary for industries that demand versatile durability.

How does the annealing process work for different grades of stainless steel?

The annealing procedure of stainless steels differs with one’s grades but generally revolves around the steps of heating, holding, and cooling:

- Austenitic Stainless Steel (e.g., 304, 316): These grades of austenitic stainless steels are brought to a temperature of between 1,900 – 2,100°F (1,040 – 1,150°C), held on soaking, and later cooled rapidly, most times by quenching in water or air. This is done to restore ductility and improve corrosion resistance.

- Ferritic Stainless Steel (e.g., 430): The ferritic grades are heated to a less intensive range of 1,300 – 1,550°F (705 – 845°C). They are then allowed to cool slowly in the air. Quiescent cooling is better suited due to lower rates of grain growth, where higher quiescent cooling leads to greater strength and ductility.

- Martensitic Stainless Steel (e.g., 410, 420): The martensitic grades are heated to about 1,500 – 1,800°F (815 – 980°C), held at that temperature, and cooled either in air or oil, depending on the required hardness and mechanical properties.

Every grade of the material requires very specific temperature controls to guarantee performance characteristics, such as enhanced machinability, toughness, and resiliency to environmental exposure.

Annealing austenitic stainless steel (304, 316, and other 300 series stainless)

Many professionals consider annealing austenitic stainless steel an important step to refine its ductility, relieve internal stresses, and improve its corrosion-resistant capabilities. In this case, it usually involves heating the material to around 1,900-2,100 °F (1,040-1,150 °C). Temperature and time control is aid in preventing problems like grain growth that are bound to occur.

Stable holding at a given temperature of the ordered annealing value should be kept between an hour and an hour and a half, and changes as per thickness. Cooling rate especially for water quenching is critical in retaining the desired microstructure an preventing the formation of non desired carbide precipitates. For instance grade 304 loses it formability and corrosion suscessibility grade quenching surges to dot complete other grades.

Research shows that during annealing the most risk of chromium carbide precipitation is between 800- 1,600 °F (427-870 °C). Proper thermal conditioning should be employed so these grades do not lose resistance to sensitization which will lead to intergranular corrosion in more aggressive settings. This is why the actual annealing is so important when it comes to mechanical properties for medical and space technology and food processing.

Temperature ranges and annealing procedures for various stainless steel types

Stainless steel’s annealing process is clingy to the type and grade of the alloy, as the temperature range and cooling methods are precise to unlock the best possible material performance. The following are some descriptions regarding the temperature range and annealing steps for the different types of stainless steels:

- Austenitic Stainless Steels (e.g., Grade 304, 316): These most popular used steels are annealed at temperatures of 1900°F – 2100°F (1038°C – 1149°C). This will restore corrosion resistance while relaxing stress in the material, which is a result of cold working. Subsequently, rapid cooling through quenching is critical in preventing carbide precipitation as well as retaining a low-carbon structure to enhance durability.

- Ferritic Stainless Steels (e.g., Grade 430): Ferritic steels undergo lower temperatures of annealing, usually in the range of 1300°F – 1500°F (704°C – 815°C). Increases ductility and reduces brittleness without the materials moving to an austenitic phase monotropy. This type of cooling strengthens the grain structure.

- Martensitic Stainless Steels (e.g., Grade 410, 420): The martensitic types require a combination of heat treatment and annealing for achieving toughness and strength. For annealing, the temperature is usually between 1,700°F and 1,900°F (927°C–1,038°C). However, the set rate of cooling must also be slow enough to avoid hardening during the process of tempered so that suitable values of hardness and ductility are achieved.

- Duplex Stainless Steels (e.g., 2205): This type of steel incorporates characteristics of both ferritic and austenitic types. It is conducted at an increasing temperature between 1,850°F and 2,050°F (1,010°C–1,120°C) where the microstructure is ensuring a ferrite to austenite ratio. Moreover, the ferritic-austenitic ratio must be ideal for the strength and rupture class. Phase balance is stabilized when the rapid cool water or air.

- Precipitation-Hardening (PH) Stainless Steels (e.g., 17-4PH): These grades follow a two-step heat treatment approach of solution annealing at 1,900°F to 2,000°F (1,038°C–1,093°C) and aging at a lower temperature, close to 900°F to 1,150°F (482°C–621°C). This application yields a carefully calibrated strategy for achieving hardness and corrosion resistance.

Choosing the optimum annealing temperature and cooling method for each type of stainless steel ensures its unique properties are preserved or even improved. This allows the alloys to perform efficiently across various industries such as medical implants and high-stress structural systems.

Differences between solution annealing and subcritical annealing

Solution annealing and subcritical annealing differ mainly in intent and temperature ranges. Solution annealing takes place at higher temperatures—usually greater than 1,850 °F (1,010 °C)—where it meets the alloying needs of the stainless steel, enhances the corrosion resistance and ductility of the alloy by dissolving carbides and homogenizing the structure. While subcritical annealing is done to enhance internal stress relief, machinability, and perform any desired reduction of internal work without significantly changing the microstructure, it does so below the critical transformation range.

What improvements does annealing provide to stainless steel properties?

Choosing the optimum annealing temperature and cooling method for each type of stainless steel ensures its unique properties are preserved or even improved. This allows the alloys to perform efficiently across various industries such as medical implants and high-stress structural systems.

Enhanced corrosion resistance and corrosion properties

The annealing process significantly enhances the corrosion resistance of stainless steel by restoring the metal’s passive protective layer, which can be disrupted during welding, machining, or other manufacturing processes. This protective layer, primarily composed of chromium oxide, acts as a barrier against environmental factors like moisture, oxygen, and aggressive chemicals, preventing rust and oxidation.

Notably, annealed stainless steels, such as grades 316 and 304, exhibit excellent performance in highly corrosive environments, including marine settings or industrial applications involving acidic or alkaline substances. For instance, stainless steel 316 demonstrates improved resistance to chloride-ion-induced stress corrosion cracking. Studies have shown that stainless steels with a higher chromium content, typically over 10.5%, along with elements like molybdenum and nickel, see drastically reduced pitting corrosion rates.

Furthermore, annealing helps homogenize the material’s structure, reducing microstructural irregularities that might act as corrosion initiators, particularly at grain boundaries. This structural refinement ensures that the material can withstand prolonged exposure to harsh environments, making it a reliable choice for industries like chemical processing, food preparation, and construction, where superior corrosion resistance is critical.

Changes in mechanical properties: ductility, hardness, and toughness

The passive protective layer that can be harmed during welding, machining, or other processes is reformed through the protective mechanism of stainless steel’s annealing process, significantly enhancing the corrosion resistance of the steel. The layer, which is mainly made up of chromium oxide, remains intact and defends the steel from external corrosive elements such as moisture, oxygen, and aggressive chemicals.

Stainless steel grades 316 and 304 exemplify such secondary maritime or industrial corrosive environments with molten acid or alkaline, where annealed stainless steel performs exceptionally well. Cromon steel 316, for example, strongly resists stress fractures, locked by ions of chloride. Mods like molybdenum or nickel, along with stronger alloys like chromium, which make up stonishing 10.5% pitted at lightning speed in stainless steel, are known to greatly boost resistance against corrosive pitting. Studies have concluded that stainless steels with higher concentrations of chromium greatly reduce corrosion over time.

Also, the steel is now uniform after the annealing process, enhancing the technical structure of the resulting steel to possess a grain boundary free of microstructural nodules, which would otherwise trigger corrosion. This refined structure suppresses slip dislocation propulsion, allowing the material to endure extreme conditions, making this material perfect for use in construction or in food processing where reverse osmosis is required.

Effects on grain boundaries and chromium distribution

The distribution of chromium and the boundaries of grains undergo changes with annealing. This process relieves residual stresses and improves the grain structure by achieving uniform and stable boundaries. Such improvement reduces the chances of material degradation or corrosion. Moreover, the set parameters in controlled annealing provide an enhanced uniformity of chromium distribution, which increases the material’s oxidation resistance and durability under harsh conditions, particularly at elevated temperatures. These impacts are critical in changes that stress long-term structural integrity and performance.

What is the difference between annealed and unannealed stainless steel?

Annealed stainless steel has gone through a specific heating process to improve its ductility, corrosion resistance, and durability. The process improves formability and machinability while relieving internal stresses by restructuring the material’s internal framework.

In contrast, unannealed stainless steel has not gone through the heating treatment and is, therefore, untreated. Unlike the annealed version, it is harder and more brittle, which may restrict its use in corrosion-resistant flexible applications. However, in applications requiring great strength where ductility is not a necessity, unannealed stainless steel has an advantage.

Comparing mechanical properties and workability

Looking at the mechanical traits of annealed and unannealed stainless steel reveals distinct differences that affect their workability as well as practical uses. In comparison to the other type, annealed stainless steel has greater ductility, which improves its workability in terms of precise bending or shaping. Also, it is beneficial for industries such as automotive or surgical instrument manufacturing, which require intricate forming. It makes stainless steel more useful in harsh conditions or environments because it performs well there and restores corrosion resistance by renewing the protective chromium oxide layer of the steel during the annealing process.

On the other hand, unannealed stainless steel has higher tensile strength, frequently surpassing 550 MPa for some grades. This feature makes unannealed steel better suited for components that endure heavy loads or severe abuse, like parts of industrial machines and structural frameworks. Its tremendous strength is counteracted by a lack of ductility, so it is more likely to snap if excessive deformation is applied. Studies suggest that unannealed steel is more prone to environmental corrosion, especially in a saline or acidic environment.

From a practicality perspective, stainless steel in an annealed form is easier to machine, weld, and polish. Production supervisors tend to note that during machining operations, the soft and malleable nature of annealed steel contributes to lower tool wear, enhancing efficiency in production environments. In contrast, unannealed steel is more difficult to process and requires more sophisticated tools and techniques, raising construction time and increasing operational costs.

Based on this information, the difference between annealed and unannealed stainless steel is determined by the exact requirements of the project in terms of strength, flexibility, corrosion resistance, and ease of fabrication.

Corrosion resistance differences between annealed and unannealed stainless steel

The better corrosion resistance of the annealed stainless steel compared to unannealed is primarily the result of uniform microstructure obtained during the heat treatment process. Annealing relieves the internal stresses in the steel, reducing the possibility of localized forms of corrosion such as pitting or crevice corrosion under harsh environmental conditions greatly exacerbated by localized stress.

As an example, type 316 stainless steel, when annealed, still possesses exceptional resistance to chlorides and other corrosive substances, which is particularly useful in marine and industrial services. Studies have shown that unannealed stainless steel is more easily subject to intergranular corrosion, especially hot and in the presence of aggressive chemicals. The process of annealing helps eliminate carbide precipitates, otherwise capable of forming at the grain boundaries and severely diminishing the material’s corrosion resistance.

In terms of data, the improved corrosion rate of annealed stainless steel is observable in common tests, like salt spray tests or immersion tests, and generally does outperform unannealed grades by a considerable amount. Prolonged exposure to moisture, chemicals, or extreme environmental conditions shifts the balance towards stainless steel unprotected by other means and increases the reliability of the exposed structure.

Applications suitable for each type

The stainless steel in its annealed state is quite adaptable and is often selected for tough applications because of its improved mechanical properties and greater strength against corrosion. Below is a list of uses in which stainless steel in the annealed state outperforms other variants:

- Marine Equipment

Corrosion resistance plays a key role in the utilization of stainless steel in shipbuilding and annealing in the making of propellers and other components, which are exposed to seawater.

Example Data: The steel’s corrosion rate is reduced by 20 – 30% as compared to the unannealed steel.

- Chemical Processing Industry

This variant is best suited for aggressive chemicals used in storing tanks, pipelines, and heat exchangers.

Example Data: An Environment with pH up to 1 is withstood.

- Medical Instruments

Surgical tools and implants as medical instruments can be caree d for using annealed stainless steel because of its smooth surface and greater durability.

Example Data: Nearly zero material deformation observed under sterilization conditions.

- Aerospace Applications

Due to its high resistance to temperature extremes, jet engines and their structural components utilize annealed stainless steel.

Example Data: Increases in tensile strength by about 15 percent after annealing.

Unannealed Stainless Steel

Applications that require a lower performance threshold and cost effectiveness utilize unannealed stainless steel. Examples include:

- Decorative Fixtures

Unannealed grades are used in kitchen appliances, elevator panels, and other decorative interiors where they undergo minimal mechanical stress.

Example Data: Retention of surface finish under normal indoor atmospheric conditions is over five years.

- Automotive Parts

Used frequently in the automobile industry for exhaust systems and trim components of moderate durability.

Example Data: Unexceeded performance expectations up to 800°F.

- Construction Elements

Things like the roofing parts, protective barriers, and even the windows are often made from unannealed steel because this type of steel is much cheaper.

Example Data: Reinforces structure within a remarkable 90 percent efficiency.

- Household Items

Everyday products like kitchen sinks, cutlery, and cookware frequently use unannealed stainless steel for its shiny appearance and affordability.

Example Data: Most applications experience unexceeded tensile strength below 10 MPa.

How is annealed stainless steel wire manufactured, and what are its applications?

The production of annealed stainless steel wires takes place when wires are heated to a certain temperature and later cooled slowly. The aforementioned actions taken during annealing result in reduced internal stresses, increased ductility, and improvement in workability. Depending on the application requirements, the wire’s shape is drawn prior to or subsequent to the annealing process.

Applications:

- Industrial Use: Used in springs, fasteners, and even welding processes because of its flexible and corrosion-resistant properties.

- Construction: Perfect for architectural parts as well as for support components.

- Medical Devices: Found in surgical instruments and orthodontic devices due to their strength and ability to withstand repeated sterilization cycles.

- Consumer Products: Incorporated into home appliances, jewelry, and decorative objects owing to its sturdiness and aesthetically pleasing, polished surface.

The manufacturing process of annealed stainless steel wire

Producing quality, flexible, and durable annealed stainless steel wire requires following some rigid and methodical steps. Here’s an overview of the critical processes:

- Melting and Alloying: The process starts with the melting of raw materials such as iron, nickel, chromium, and other alloying components. These are put together in a furnace at temperatures greater than 2,500°F (1,370°C) to form molten stainless steel.

- Casting and Rolling: The molten steel is cast into slabs or billets, which are then rolled under high pressure rollers into wire rods. The initial diameter and structure of the wire is determined by this rolling process. The steel is both cast and rolled into billets or slabs and later into wire rods.

- Drawing the Wire: Wire rods are processed through wire-drawing machines where they are pulled through progressively smaller dies which reduce their diameter. This is called cold-working this increases the strength and hardness of the wire.

- Annealing Process: Annealing is a major step where the wire is heated to a specific range in an oven between 1,000°F and 1,000°F (540°C to 650°C). During this step, internal stresses are relieved, grain structure is refined, improving the wire’s corrosion resistance. Slow cooling is then undertaken afterthe components have been heated. This gives the wire the desired mechanical properties.

- Pickling and Cleaning: After entertaining the process of annealing, the wire is subjected to pickling which is a chemical procedure that cleans the surface of oxidation and other impurities. A smooth and clean finish is achieved, which is suitable for further processing or is ready to be utilized.

- Surface Treatment and Finishing: The wire may also have further visual enhancements for improved functionality. These enhancements include polishing, lubricant application, coating, or any other relevant treatments.

- Quality Control and Testing: The preceding steps enable the creation of the final product, which goes through several tests, including visual inspections to assess compliance with predefined standards. Mechanical tests are also performed, such as testing the tensile strength, percent elongation, and corrosion resistance, to ensure compliance with industry standards and client requirements.

Following these steps, manufacturers can achieve flexibility, strength, and surface quality in an annealed stainless steel wire. Its constructions expand to the construction, automotive, medical devices, and consumer product industries, which require great attention to detail and dependability at every step of the process.

Common applications for annealed stainless steel wire

Different industries utilize annealed stainless steel wire because it has those benefits, which are strength, malleability, and most importantly, corrosion resistance.

- Construction Industry: This wire is popular in scaffolding, binding, and other reinforcement activities. It exhibits superiority in structural scaffolding because of its strength and endurance to harsh environmental conditions.

- Automotive Sector: The production of springs, exhaust components, and safety cords relies on annealed stainless steel wire. Automotive manufacturing, however, places extreme importance on precision and dependability; the wire’s tensile strength guarantees safety and performance.

- Medical Applications: Surgical instruments, orthodontic devices, and stents hinge on the use of medical grade stainless steel wire. Meets the biocompatibility, sterilization, and other stringent processes in healthcare industries with ease because of the stringent requirements.

- Consumer Goods: Steel wire is useful in making aesthetic kitchen and household products like whisks, grills, and other decorations. The ability to shape and polish surface makes wire advantageous for everyday applications.

- Electronics Industry: The wire’s conductivity, oxidation resistance, and other electronic properties establish it as a suitable piece of electric wires, circuits, and other electronic parts.

Statistics from the materials industry demonstrate an escalating demand for stainless steel wire, with global consumption expected to grow by 5 to 7% each year in important areas. Such increases show consistency, revealing how vital this resource is in the context of change and progress.

What are the practical considerations when machining annealed stainless steel?

When it comes to machining annealed stainless steel, several practical considerations are essential to maintain quality and efficiency:

- Tool Selection: Employ appropriate industrial-grade tools that must have sufficient damage resistance to withstand stainless steel’s toughness.

- Cutting Speed and Feed Rate: Keep both cutting speeds and feed rates moderate to minimize excessive heat and damage to the tools.

- Coolant Usage: Ensure proper coolant application in sufficient amounts to maintain operational temperatures below the work hardening threshold during machining.

- Machine Stability: Be sure the machine is properly aligned and rigid enough to withstand perturbations that can interfere with accuracy and precision.

- Chip Control: Efficient chip control is directly responsible for the build-up material(maximum build-up) of construction elements and proper operation.

Achieving requirements such as tool life and the integrity of the material is possible through these considerations.

Machining characteristics of annealed stainless steel

The machinability of annealed stainless steel is influenced by quite a number of traits. Since this material is subjected to an annealing process, it is softened, thereby increasing ductility, reducing hardness, and generally making machining easier relative to other harder stainless steel grades. Nevertheless, the toughness of the alloy and its tendency to work harden makes annealed stainless steel challenging to machine.

Key characteristics include:

- Hardness and Strength: Untreated stainless steel tends to have a higher BHN compared to annealed stainless steel. The same case is with Type 304 Stainless Steel, which in its annealed state has 150-200 HB, which makes it easier to machine but requires proper tools and techniques.

- Thermal Conductivity: Other than mild steel and aluminum, stainless steel has low thermal conductivity. This means that heat produced during cutting tends to stay near the cutting area. As a result, the tools are worn out faster. To reduce the temperature and increase tool life, efficient coolant application is a necessity.

- Chip Formation: Because of a ductility feature, chips shaped during the machining process are usually long and continuous. This imposes a problem with regards to evacuation of chips which calls for additional features such as proper tool geometries like chip breakers as well as increased cutting speeds to reduce the clogging of the tools.

- Cutting Speeds and Feed Rates: The ease of machining annealed stainless steel occurs at moderate cutting speeds and feed rates. For instance, Type 316 stainless steel is considered to have a cutting speed of 80 to 120 surface feet per minute (SFM), based on the type of tooling used (high-speed steel vs. carbide).

- Surface Finish: Given the reliable consistency in structure, hydrodynamic and hydrostatic face seals can incorporate stainless steel, which has undergone annealing, machined to yield a high-quality surface finish. Further operations such as grinding or polishing significantly improve its corrosion resistance and beauty.

- Tool Wear: Although Steel is easy to machine due to its low angular rate aided by its low brittleness. the other side retains the abrasivity of the material which eventually wears out tools which experiences the abrasive effect. This is known carbide oder coated tool, resulting in improved strength and lifespan of thinner cutting edges.

Caring for these features through the right tools, coolant choice, and optimized machining strategies can achieve accurate results without damaging the material’s sensitive internal structure and surface features.

Tool selection and cutting parameters for annealed stainless

In the case of machining annealed stainless steel, achieving the desired results in terms of productivity and accuracy requires particular cutting tools as well as appropriate operating parameters. Due to the toughness of the alloy and its work hardening tendencies, heat-resistant and wear-resistant carbide inserts will be preferred. Furthermore, uncoated tools and coated carbide tools with titanium (Ti) or aluminum titanium nitride (AlTiN) coatings have lower friction and are therefore more durable in high-speed applications. To increase the service life of the tool, these coatings improve its durability.

In terms of cutting parameters, speed, feed, and depth of cut must be appropriately balanced if excessive wear and heat are to be avoided. Carbide tools can be used at a cutting speed of approximately 50-100 meters per minute (m/min), while the radial feed must be set between 0.05 and 0.3 millimeters per revolution (mm/rev), depending on the tool geometry and the surface finish required. A geometric shape is defined for the workpiece, which is then used as the reference for establishing the average depth of cut. Generalizing that for roughing, it’s 1-4mm, then for finishing, it’s less than that.

Using a proper coolant or cutting fluid can make machining operations more effective by lowering temperatures, improving chip removal, and extending tool longevity. In the case of stainless steel that is in an annealed condition, water-based emulsions or oils with better lubricating ability are frequently employed. Properly selected tool materials and coatings along with appropriate cutting parameters guarantee high precision and surface quality at low cost and high efficiency.

Post-machining heat treatment considerations

Post-machining heat treatment is an important process when it comes to the mechanical characteristics and operability of annealed stainless steels. Different techniques like annealing, or stress relieving, and hardening can be performed depending on the end goal. Stress relieving is a primary concern because it helps alleviate the residual stress from machining that can impact the dimensional stability and promote stress corrosion cracking.

For stainless steels, the range of temperatures when stress relieving is most effective lies between 300°F to 750°F (150°C to 400°C). The alloy and use will determine the applications. Corrosion resistance is enhanced by performing treatments like annealing between 1800°F to 2100°F (980°C to 1150°C), where passive oxide layer reformation is sufficient. Issues, such as warping or unplanned microstructural alteration, can be avoided with careful control of heating and cooling rates.

The need for post machining heat treatment is depicted with examples like an extensive study on stress relieving done that shows up to an 85% reduction of residual stress, prolonging the component life in high-stress applications. Advanced furnace technology ensuring accurate temperature control provides repeatable outcomes that bolster part performance and dependability.

Reference Sources

- Enhanced Mechanical Properties and Corrosion Resistance of 316L Stainless Steel1:

- Key Findings: Annealing at 700°C after surface mechanical rolling treatment (SMRT) significantly enhanced corrosion resistance due to Cr-enrichment in the surface layer. This process also improved the strength-ductility synergy.

- Methodology: The study used tensile tests and microstructural analysis to evaluate the effects of annealing on grain size, hardness, and corrosion behavior.

- Effect of Annealing on X2CrNi12 Ferritic Stainless Steel2:

- Key Findings: Annealing at 770°C provided the best anti-corrosion performance by reducing (Fe, Cr)23C6 precipitates and optimizing martensite content. Higher temperatures increased corrosion rates due to martensite-induced stress.

- Methodology: The research employed electrochemical tests, microstructural analysis, and corrosion rate measurements in chloride-rich environments.

- Annealing and Corrosion Behavior of Super-Duplex Stainless Steel3:

- Key Findings: Optimal annealing at 1070°C improved pitting corrosion resistance by minimizing secondary phases and balancing ferrite-austenite ratios.

- Methodology: Critical pitting temperature (CPT) tests and microstructural observations were used to assess corrosion resistance.

Frequently Asked Questions (FAQs)

Q: What are the different grades of annealed stainless steel, and how do they compare in terms of corrosion resistance?

A: The different grades of annealed stainless steel vary significantly in their corrosion resistance properties. Austenitic grades (300 series) like 304 and 316 offer excellent corrosion resistance after annealing, with 316 containing molybdenum for superior performance in chloride environments. Ferritic grades (400 series) such as 430 provide good corrosion resistance at a lower cost. Duplex stainless steels combine properties of both austenitic and ferritic structures, offering enhanced strength and corrosion resistance. Precipitation-hardening grades like 17-4 PH can be annealed before aging to improve workability while maintaining their potential for high strength. Each grade responds differently to annealing treatment, which optimizes the properties of the material for specific applications.

Q: How does the annealing process differ between carbon steel and stainless steel?

A: Carbon steel and stainless steel undergo distinctly different annealing processes due to their composition. For carbon steel, full annealing typically occurs at 750-900°C with slow cooling to soften the metal and reduce hardness. In contrast, stainless steel annealing often involves higher temperatures (1010-1120°C) and may require more precise atmosphere control to prevent chromium carbide precipitation, which would compromise corrosion resistance. While low alloy steel might be annealed in ambient atmospheres, stainless steel parts often require protective environments (vacuum or inert gas) to prevent oxidation and maintain surface quality. Additionally, stainless steel frequently undergoes solution annealing (rapid cooling) to ensure chromium remains in solution rather than forming carbides, which is not a concern when working with stainless steel’s carbon counterparts.

Q: What is process annealing, and how does it benefit stainless steel parts?

A: Process annealing is an intermediate heat treatment applied to stainless steel parts during manufacturing operations to restore workability between forming steps. This treatment involves heating the steel to temperatures below critical transformation (typically 550-650°C for austenitic stainless steels) and then cooling at a controlled rate. The goal of annealing in this context is to relieve internal stresses created during cold working, recrystallize the grain structure, and soften the metal without fully solution annealing it. This makes the stainless steel parts more ductile for subsequent forming operations while minimizing distortion. Process annealing helps maintain dimensional stability and prevents cracking during complex forming operations, particularly important when working with stainless grades that work harden rapidly, like 304 and 316.

Q: What happens during quench annealing of stainless steel, and why is it important?

A: Quench annealing, also known as solution annealing, involves heating stainless steel to high temperatures (1010-1150°C) and then rapidly cooling (quenching) it, typically in water or oil. This process is crucial for austenitic and duplex stainless steels because it dissolves chromium carbides into the solid solution, preventing chromium depletion at grain boundaries. The rapid quench prevents these carbides from reforming as the material cools to room temperature, thereby maximizing corrosion resistance after annealing. Without proper quench annealing, many stainless alloys would be susceptible to sensitization, a condition where chromium is tied up in carbides rather than forming the protective oxide layer essential for corrosion resistance. This heat treatment also homogenizes the microstructure, improving both mechanical properties and corrosion performance of the steel.

Q: How does low-temperature annealing affect the properties of stainless steel?

A: Low temperature annealing of stainless steel, typically performed between 150-450°C, produces effects quite different from conventional annealing. Rather than completely recrystallizing the microstructure, this treatment primarily relieves residual stresses while minimizing dimensional changes. For cold-worked stainless steel, low temperature annealing can slightly reduce strength while improving ductility, which is beneficial for parts requiring good formability but also reasonable strength. However, prolonged exposure at these lower temperatures can lead to 475°C embrittlement in ferritic stainless steels or stress relaxation in austenitic grades. Unlike full annealing, low temperature treatments don’t typically restore full corrosion resistance if the material was previously sensitized, as they don’t dissolve chromium carbides. This process is often used when the need to anneal is primarily for stress relief rather than comprehensive property restoration.

Q: What is bright annealing, and when is it preferred for stainless steel alloys?

A: Bright annealing is a specialized heat treatment process performed in hydrogen, vacuum, or inert gas atmospheres that prevents surface oxidation of stainless steel, resulting in a bright, scale-free finish. This process is preferred when working with stainless steel components that require excellent surface appearance without additional finishing operations. The temperatures used are typically the same as conventional annealing (1010-1120°C), but the controlled atmosphere preserves the bright surface while still achieving the desired microstructural changes. Bright annealing is particularly valuable for thin materials like foils and strips where mechanical descaling could damage the product, and for precision components where dimensional tolerances are critical. This process is commonly applied to austenitic stainless alloys in architectural applications, food processing equipment, and medical devices, where both corrosion resistance and aesthetic appearance are essential.

Q: What are the primary applications of annealed stainless steel in various industries?

A: Applications of annealed stainless steel span numerous industries due to its optimized combination of formability and corrosion resistance. In food and beverage processing, annealed 304 and 316 stainless steel parts form equipment surfaces that resist bacterial growth and withstand cleaning chemicals. The medical industry relies on annealed stainless for surgical instruments and implants, benefiting from both corrosion resistance and biocompatibility. Chemical processing facilities employ annealed duplex and super-austenitic grades for their exceptional resistance to aggressive media. Architectural applications utilize bright annealed finishes for aesthetic appeal combined with weather resistance. The automotive sector incorporates annealed stainless steel for exhaust components that withstand high temperatures and corrosive environments. Marine applications benefit from properly annealed 316L and super-duplex stainless tsteel o combat saltwater exposure. In each case, the annealing treatment ensures optimal corrosion performance while providing the necessary mechanical properties for the specific service conditions.

Q: How do different types of stainless steel respond to annealing treatments?

A: Different types of stainless steel exhibit varying responses to annealing treatments based on their microstructural characteristics. Austenitic stainless steels (304, 316) become fully soft and ductile after annealing at 1050-1100°C and water quenching, showing excellent corrosion resistance and non-magnetic properties. Ferritic stainless steels (430, 441) require lower annealing temperatures (760-830°C) and develop moderate ductility while maintaining their magnetic properties. Martensitic grades (410, 420) transform during cooling from annealing temperatures and typically require additional tempering to achieve the desired hardness-toughness balance. Duplex stainless steels need precise temperature control during annealing to maintain the proper balance between ferrite and austenite phases, which is critical for their corrosion performance. Precipitation-hardening stainless steels undergo solution annealing at high temperatures, followed by aging at lower temperatures to develop their strength. Each type’s response to annealing must be carefully controlled to optimize both corrosion resistance and mechanical properties for specific applications.

Q: What testing methods can verify the effectiveness of annealing on stainless steel’s corrosion resistance?

A: Several testing methods can verify corrosion resistance after annealing stainless steel. Electrochemical testing, including potentiodynamic polarization and electrochemical impedance spectroscopy, quantitatively measures corrosion resistance by evaluating passive film stability. Salt spray testing (ASTM B117) provides visual evidence of corrosion resistance in chloride environments through extended exposure. Intergranular corrosion testing, particularly ASTM A262 practices, identifies sensitization by exposing samples to aggressive environments that attack chromium-depleted regions. Critical pitting temperature tests determine the threshold temperature at which pitting corrosion initiates. Ferric chloride immersion tests (ASTM G48) specifically evaluate pitting and crevice corrosion resistance. Huey tests assess resistance to highly oxidizing acids. Additionally, metallographic examination can reveal microstructural features that influence corrosion behavior, such as grain boundary precipitates or delta ferrite content. These complementary approaches ensure that the annealing treatment has effectively optimized the stainless steel’s corrosion performance for its intended application.

Q: What are the common challenges when heat treating different grades of annealed stainless steel?

A: Heat treating different grades of annealed stainless steel presents several challenges that vary by alloy composition. For austenitic grades, preventing sensitization (chromium carbide precipitation) requires precise temperature control and rapid quenching, which can cause distortion in complex parts. Ferritic stainless steels are prone to grain growth during annealing, potentially reducing toughness and ductility if temperatures are too high or dwell times are too long. Martensitic stainless steels may develop retained austenite or excessive hardness without proper cooling rates and subsequent tempering. Duplex stainless steels require exact temperature control to maintain the proper ferrite-austenite ratio; deviation can compromise either mechanical properties or corrosion resistance. Precipitation-hardening grades need carefully controlled solution treatment and aging cycles. Additional challenges include preventing surface oxidation that could impair corrosion resistance, managing distortion of thin sections during quenching, and ensuring temperature uniformity throughout large or complex stainless steel parts. Specialized equipment and expertise are often required to overcome these challenges and achieve optimal properties.