With regard to metalworking, tempering is one of the processes that is pivotal for metals to undergo certain changes. Among these processes, annealing is one that certainly increases a metal’s resistance or strength, ductility or workability, and performance. But what happens to a metal that has already been annealed? What are the influences of the processes done on the internal structure and mechanical properties of such metal? This guide will attempt to explain in greater detail the phenomena that accompany the process of metal tempering, with a major focus on annealing, explaining the objectives, advantages, and rationale behind the whole procedure. If you are a veteran in the field of metallurgy, or even a novice, this article aims to equip all readers with fundamental knowledge that can be applied in practical work, especially regarding the use of annealing.

What is the Annealing Process and How Does it Work?

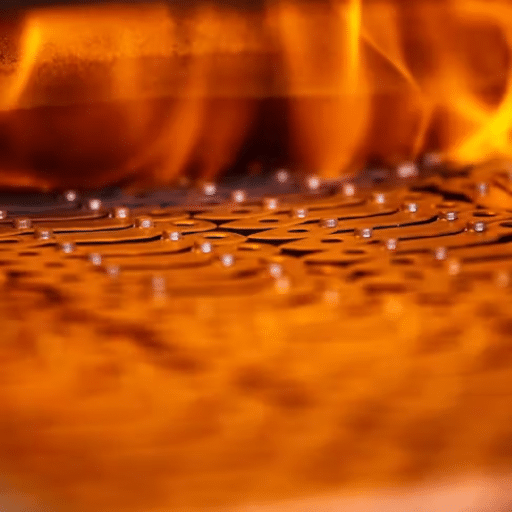

First, the heat treatment is done to make it more physically and mechanically workable by reducing the internal stress from the metal. The metal is then separated using three different processes as discussed below.

- – The temperature is increased to a specific range, which is usually the recrystallization bound or area.

- – Soaking phase, which lasts for some time until the complete build-up is over.

- – Lasting step or cooling down phase, which requires lessening of temperature in the furnace, thus eliminating stress.

Increases ductility and reduces hardness while enhancing machinability, making the metal appropriate for shaping and forming tasks.

How Annealing is a Heat Treatment Process for Metals

Evaluating the usefulness of various industries, functionalities, and techniques, it can be stated that there is no substitute for metal treating techniques. Along with changing metals into different shapes such as bending, sanding, and cutting, different types of temperature based processes are favorable too. Annealing is one of them.

The automotive industry relies heavily on steel components, burning metal alloys at high temperatures, followed by cooling to alter the properties of metals, improving their durability. In Aerospace, Annealing improves performance along with durability.

Annealing also has applications in the refinement of copper wires and other materials used in intricate electronics, lifting the standard of flexibility. The construction industry makes use of softer forms of metal alloys like steel and rebar that require thermal treatment to form desired shapes and retain strength.

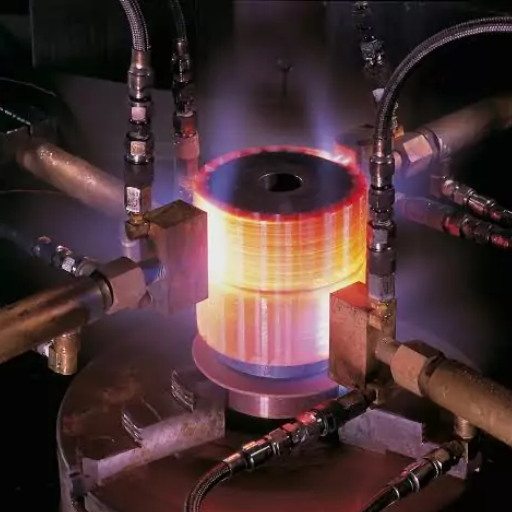

With modern innovations like laser and electric annealing being precise and time efficient, the focus on expenditure becomes less which makes it environment friendly. Be it Stock or custom parts, the value of using efficient techniques to enhance the outcome strengthens the search for new ideas in manufacturing and engineering.

The Three Stages of the Annealing Process: Heating, Soaking, and Cooling

1. Heating

A material goes through an annealing cycle, which initiates with the material being heat-treated to a critical preset temperature, referred to as recrystallization temperature. Usually this is between 50% to70% of their melting point, which differs based on the material’s constitution. For example, steel’s melting temperature ranges from 1,100 °F to 1,300 °F (593 °C to 704 °C), whereas copper has lower thresholds due to its properties. This phase will aid in the material to fully relax its internal stresses while also starting to adjust its structure towards the mechanical equilibrium state, given the thermal energy.

2. Soaking

As the material reaches the target temperature, it enters the soaking stage, where it remains at a selected temperature for a specific time. The total time of soaking is of importance and depends on criteria like material thickness and the outcome required. For example, thicker sections will have longer soaking times due to needing complete permeation at the core of the object. The alignment of atoms of the metal at the active temperature leads to healing the forces holding the crystals, leading to improvement in ductility and machinability.

3. Cooling

The last step in annealing is controlled cooling, where the material is permitted to cool to ambient temperature. This can happen on its own in open air, or more controlled ways like furnace cooling or quenching in oil or water for certain applications. Depending on the material properties, softening and flexibility are improved with slow cooling, while rigidity and strength are enhanced with quick cooling. In glass annealing, for example, glass is cooled slowly, which avoids any significant internal stresses from damaging the material and enhances its strength.

Together, these three stages sequentially enhance material properties to meet the various engineering requirements, which allows industries to customize the hardness, toughness, and malleability of metals and glass. The precision demands that modern builders or structural engineers impose are remarkable, but with control over each stage, they can be met.

How Different Metals Respond to the Annealing Process

Due to the composition, crystalline structure, and the purposes, different metals respond differently to the process of annealing. For example, steel’s grain structure is refined due to the process of annealing, which increases ductility and reduces hardness. In this regard, steel, which is annealed, is used in construction and the automobile industry largely due to its flexibility and machinability, which is vital in these industries.

Due to the high conductivity of copper, it’s used extensively in electrical wiring and precision shaped components since the process of annealing enhances the electrical conductivity and malleability of copper. Aluminum also, after being annealed, softened and became more workable which is helpful in packaging and aerospace industries since materials that are lightweight and easily moldable are needed.

Corrosion resistance and strength of the material enhances, while internal stresses are relieved for specialty alloys like titanium alloys during the process of annealing. This is especially valuable for medical implants and aerospace engineering industries since the devices need to be durable under extreme conditions. Knowing those responses makes it easier for manufacturers and engineers to determine the processing for each material and be efficient and reliable.

What Changes Occur in Metal Properties After Annealing?

Annealing improves the properties of metals in many helpful ways. It softens the metals, improving workability, and ductility, which enhances deformation resistance. Obtained alloy also has reduced internal stresses, which reduces cracking or warping. Annealing also improves metal’s uniformity while refining the structural grain, strengthening performance across multiple uses.

How Annealing Increases Ductility and Reduces Hardness

Annealing, which consists of heating and cooling, selectively increases a material’s malleability and ductility while simultaneously reducing hardness. During the heating stage, a metal is heated to a set level, known as the recrystallization temperature. The metal’s atomic structure can now transform, which leads to a reduction in the dislocation of the metal’s crystalline structure. Its flexibility and malleability improve. Research shows materials such as steel undergo substantial reductions in tensile strength and hardness at temperatures between 1,300°F to 1,600°F. They do, however, gain ductility of up to 30%. Annealing cycles are followed by a cooling phase that allows the metal to stabilize, which solidifies the desired mechanical attributes. This enhances machining, ensures improved son to burden, without breaking or cracking during extreme conditions, useful for precise and durable applications.

The Effect of Annealing on Internal Stress Relief

Different manufacturing processes, such as welding, casting, and machining, contain internal stresses that may be relieved by annealing. Internal stresses develop during the metalworking process because of the uneven cooling or deformation at the metal’s microstructural level. Over time, these forces can cause weakening of metal components. In the course of annealing metals, the preheating stage permits the free motion of metal atoms, enabling them to assume various positions until, at some point, a more stable equilibrium is achieved. This rearrangement of dislocations lowers the strain within the crystal structure.

Annealing helps relieve stress while at the same time reducing distortion and warping of materials. In steels that undergo case-hardening, internal temperature stress has been found to fall by as much as 90 percent due to the application of annealing. This improves the structural support and stability of metal components. Stress-relieved annealing is often applied by many industries to large weldments, pressure vessels, and turbine components so that components can operate safely in reliably under long-term operational stresses.

Moreover, stress-relief annealing applied to carbon steels at 900°F and 1200°F allows rearranging of the microstructure while at the same time retaining the metals strength. This lowers the remaining compressive forces crystallographic grains experience while preserving the quality of rigidity, making the components able to undergo intense stress, or fine-tuned machinery where consistent operations are essential.

Understanding Grain Growth During the Annealing Process

Shrinking or removing material features like cavities or holes in mechanical parts is extensively done in mechanical engineering by the techniques that involve cube milling, angular milling, contour milling, and face milling. Like other processes in mechanical engineering, Computer Numerical Control (CNC) is changing the world of mechanical engineering and is widely used in micromachining.

From lower to ultra-precision processes, several techniques have been developed, such as ultra-precision diamond turning, metal micromilling, electrical discharge machining, and photolithography to create micro-scale complex components in photonic and biocompatible systems. Photocomposing systems. Micro laser electroplating mold microwatt’s work within the mechanism.

CNC machines are used to create small and complex components used in photonic systems and biocompatible instruments. Instruments used in medicine with living organisms like optical fibers that are used in endoscopes. These surgical tools allow for magnifying and toleranced relevant viewing and insight into the work to be done.

Refined methods like thermomechanical simulations alongside Scanning Electron Microscopy (SEM) have made the analysis of grain growth behavior more precise than ever. These capabilities allow engineers to predict the grain size of a certain piece subjected to a particular annealing cycle, which is critical for the precision required in aerospace parts, automotive components, and structural systems.

What Are the Different Types of Annealing and Their Effects?

Types of Annealing and Their Effects

- Full Annealing

In this procedure, a material is initially heated above the critical temperature and later cooled gradually in a furnace. This improves the softness and ductility, which makes the material easier to process further.

- Process Annealing

Stress removed through cold working is relieved below the critical temperature of a material. This restores ductility while causing little change to the structure of the material.

- Stress-Relief Annealing

This approach aims at minimizing residual stresses with no change in the mechanical properties of the material. It is used mostly for parts made from machining or welding.

- Spheroidizing Annealing

This type is mostly used for steels. It forms carbides in the shape of spheres, thus greatly improving machinability while reducing the degree of hardness.

- Normalizing

Heating a material then letting it cool in air, gives a refined grain shape is referred to as normalizing. It might not be classified as annealing, but normalizing increases strength and toughness of the material.

Different types of annealing processes are selected according to particular material needs and the expected results to be achieved so as to give optimal results for the intended purpose.

Subcritical, Isothermal, and Diffusion Annealing Explained

- Subcritical Annealing

In the case of subcritical annealing, the material is heated to a range between 1290°F and 1380°F (790°F and 750 °C), which is just below its critical range. The purpose of this specific range is for stress relief and enhancement of the material’s machinability. Because there is no phase transformation, subcritical annealing does not significantly affect the hardness or mechanical properties of the material. This technique can be incredibly useful in carbon steel since it broadens the microstructure, reduces internal stresses, and softens the steel. The technique is invaluable in sectors that need high precision, such as tool making or machining.

- Isothermal Annealing

The complete phase transformation of a material is achieved by heating the material above its critical temperature (isothermal annealing). Although the material is completely transformed, rapid cooling to an isothermal temperature range is maintained for a prolonged period of time. As a result, parts like steel are uniformly maintained mechanically while distortions are reduced. Using hypo-eutectoid steel will yield fine pearlitic or bainitic microstructures, which increases toughness and ductility. This technique heavily relies on the temperature profiles and holding times since these factors determine the characteristics of the final material.

- Diffusion Annealing

Diffusion annealing or homogenization annealing works on a material at a temperature range of 1000 degrees Celsius to 1250 degrees Celsius (1830 degrees Fahrenheit to 2280 degrees Fahrenheit), close to the material’s melting point. During this process, the material is kept at an elevated temperature for a long time, several hours in most cases, which helps alloying elements to redistribute and become uniform. This is especially useful for components that have to endure very high mechanical stresses or extreme operational conditions. It is widely used in large castings and forgings that need to be structurally sound. One disadvantage, however, is the increased potential of coarse-grained structure, and there needs to be more control during later process steps.

Every one of these annealing techniques is critical to the adaptability of the property’s treatment of metals concerning machinery, strength, and cost.

Specific Annealing Methods for Ferrous and Non-Ferrous Metals

Annealing of Ferrous Metals

Steel and cast iron are examples of ferrous metals, which are usually ‘annealed’ to relieve internal stresses, improve ductility, and refine grain structure. As for full annealing of steel, it includes heating the material to a temperature above its upper critical point,t, which entails being in the range of 1500°F (815 °C) and 1700°F (927 °C) °, depending on the alloy type. The material has to undergo ‘slow cooling’ in a controlled environment so the steel gets optimally softened, which enhances its workability. High carbon steel, in particular, undergoes specific ‘isothermal annealing’ to improve machinability. This technique requires that the material to be worked on is heated to the level of transforming its microstructure into austenite and then cooling I,t but at a specific temperature which promotes the formation of pearlite. It is noted through various studies that isothermal annealing improves the mechanical properties of certain components like shafts and gears by achieving a consistent microstructure.

Annealing of Non-Ferrous Metals

Like aluminum, copper, and brass, non-ferrous metals undergo annealing to regain the ductility lost from cold working processes. These metals have lower annealing temperatures than ferrous metals. For example, aluminum alloys are annealed between 570°F (300°C) and 770°F (410°C), while copper can be annealed at approximately 700°F (370°C). Unlike steel, these metals are rapidly cooled after heating instead of being slowly cooled.

Precise methods like recrystallization annealing aim to remove the deformation-induced grains made from extensive mechanical work on the material. This is especially important in the manufacturing process of electrical components, where wires and connections require high-purity copper. Proper annealing greatly minimizes internal strain, which enhances the material’s characteristics and longevity. Research shows how proper annealing techniques greatly minimize internal strain, potentiating the material’s performance and longevity.

Cost and productivity across industries is improved with modern advanced thermal simulation models which allow predicting and optimizing results while tailoring specific parameters such as temperature, duration, and cooling rates for the type of metal and its application.

What Are the Benefits of Annealing Different Metals?

Annealing has several benefits with different metals, which enhance properties for several uses:

- Improved Ductility: The process of metal annealing improves ductility as it softens metals, making it easier to work on them without breaking.

- Enhanced Strength: The process improves internal loads, therefore improving the structural reliability of the metal.

- Better Workability: It improves the granulation of the metal therefore improving its workability, machinability, making it less brittle.

- Corrosion Resistance: For some metals, the process increases survival against rust, improving the lifespan and reliability of metals.

- Consistent Performance: Annealing provides standardized properties in the metal, enabling more controlled use in reproducing parts and components.

The advantages may differ based on the metal type and the specific ‘annealing’ heating process used as well.

How Annealing Improves Workability of Sheet Metal

The workability of sheet metal is greatly enhanced through annealing, making it suitable for complex industrial requirements. The process softens the metal microstructure by relieving internal stresses that would crack or warp the part during fabrication. With improved ductility, annealed sheet metal can be bent, stretched, or formed into complex shapes while maintaining its structural integrity.

According to research, annealing aluminum alloys may improve the alloys’ malleability by up to 50% while reducing hardness by roughly 30%. In steel, annealing improves toughness by reducing brittleness and refines the grain structure, improving the machining precision possible. These improvements are crucial in the automotive, aerospace, and construction industries that rely on precision-crafted high-performance metal components. Moreover, metals that undergo annealing show consistent uniformity, which is a critical factor in mass production processes. This adds value to annealing as a primary process in the cost-effective optimization of functionality in sheet metal.

Benefits of Annealing for Carbon Steel and Alloy Steel

The process of annealing improves the softness, ductility, and malleability of carbons steels while optimizing their usefulness in renewable energy and heavy machinery industries. Similarly, the process enhances the strength and wear resistance of alloy steels by reducing microstructural defects due to prior machining processes in order to meet the increasingly demanding conditions set by aerospace and military industries.

In detail, the mach inability of carbon steels is very useful in areas which involves manufacturing components with complex shapes and intricate designs. Moreover, masterably carbon steels are capable of stretching or bending under stress instead of fracturing which enhances its usefulness in structural applications.

In alloy steels, the microstructure gets enhanced, which in turn offers improved strength and resistance against strong wear. This also improves the lower bound durability limit of alloy steel components while simultaneously decreasing the residual stresses that are caused by prior manufacturing steps, along with increasing the life span of these components. Furthermore, the cost-effective properties are gained owing to the lower density of alloy steel, thus making these metals very attractive.

Industry data indicates that the machining capabilities of carbon steels which have undergone the annealing process increases by nearly 20-30 percents and thermal stability along with tensile strength is significantly enhanced in alloy steels. These metals are now being regularly used in sectors such as the energy industry, aerospace, and heavy machinery.

In summation, it can be said that annealing makes the carbon as well as alloy steel easier to work with, and enhances their durability, strength, and flexibility for a range of tasks. This process helps in improving the productivity and creativity in today’s modern manufacturing.

How Does Annealing Compare to Other Heat Treatment Processes?

Apart from other heat treatment methods, its specialization in softening metals, enhancing ductility, and relieving internal stresses sets annealing apart. Annealing, unlike hardening processes like quenching, which increases a metal’s hardness, is focused on flexibility and ease of machining. As compared to tempering, which reduces brittleness after hardening, the does more extensive softening and stress relief than tempering. In contrast to normalizing, where cooling of metals occurs in air, annealing uses a controlled cooling process, which is commonly known to happen in a furnace, enabling more uniform properties. Such characteristics make annealing best suited for applications designed for workability and structural reliability.

Annealing vs. Tempering: Understanding the Differences

Different industrial applications require distinct purposes of annealing and tempering. Processes that involve the production of wires, pipes, and sheets utilize annealing; it serves best in processes where a material’s ductility is critical. Uniform mechanical properties and enhancement of workability are achieved through internal stress relief and grain structure refinement during annealing. For instance, tested steel with annealing underwent a 50% reduction in hardness, which makes it incredibly compatible for cold-forming operations without the risk of cracking.

Adjusting the balance between toughness and hardness in tempered steel is either the main use or the benefit of tempering. Equipment that needs high wear resistance and durability, such as springs, cutting tools, and gears, relies exceptionally on this procedure. This data also states that lower temperature tempering (below 400°F) retains higher hardness, but higher temperature tempering (1,100°F and above) improves toughness at the expense of hardness. Without compromising strength, various industrial applications are sure to benefit from the ability to change the material structure properties through tempering.

Both operations are essential in the production and engineering industries, although they serve different purposes for different material properties. Each process is chosen according to the intended application, working environment, and necessary mechanical features of the part.

What Metals Are Commonly Annealed and Why?

The metals that are usually annealed are steel, aluminium, copper and brass. Steel is annealed in order to improve its hardness, ductility, and machinability which aid in the processes of manufacturing. To relieve internal stresses and enhance formability, Aluminium is annealed for purposes that involve bending and shaping. The ductility and conductivity of copper are improved by annealing, making it suitable for use in electrical and plumbing applications. Brass is annealed to recover its workability and avoid cracking during fabrication.

Annealing Steel: Process, Temperature, and Results

Taking a look at the definition of annealing, it refers to the heating, holding and controlled cooling of steel at a specific temperature. This alters the microstructure, improving ductility and reducing hardness to facilitate easier machining.

The temperature must be set within certain carbon steel-like ranges for the carbon steel, which is the most commonly used steel in construction. The soft low variant must reside between 1200-1400 °F (649-760 °C). The middle ground, which is the most commonly used type of medium carbon steel, is 1500 °F (815 °C). Lastly, for hardened steel, it definitely must be closer to 1600 °F (870 °C). The amount of time held at these temperatures is contingent on the thickness of the material, commonly set for 30 minutes per inch of thickness.

The soaking stage of the steel’s microstructure is one of the more crucial features in achieving uniformity. The prevention of internal stresses is also crucial. The mechanical properties of steel can be affected quite a bit by annealing. For instance, softening the steel increases its machinability, which facilitates easier manufacturing. Also, annealed steel possesses higher stability in undergoing changes in shape, which is important for parts that have to be accurate and precise. Research indicates that the tensile strength of a material can be increased after undergoing annealing, with a simultaneous reduction in its resistance to fracture during loading. Such changes are beneficial for many industries, including automotive, manufacturing tools, and heavy machinery, which makes annealing a crucial industrial process.

Annealing Copper, Aluminum, and Other Non-Ferrous Metals

The annealing processes for non-ferrous metals like copper and aluminum are essential in improving their mechanical properties and applicability. In the case of copper, annealing means heating the material to somewhere between 700 and 1200 degrees Fahrenheit (370 and 650 degrees Celsius), and then cooling it down in a controlled manner. It is an essential step in work-hardening copper, for it makes the metal easier to ductile. In other words, copper is easier to bend and shape without cracking, as it does not split into pieces. As one of the key components in the electronics and plumbing industry, copper needs flexibility and good ductility for effective use in myriad applications.

In the same way, aluminum is not usually harder than its alloys and is rationally anodized in the temperature range of 570 to 770 degrees Fahrenheit (300 to 410 degrees Celsius). This also serves as one of the best ranges for aluminum because it makes the metal softer for easier bending and reduces internal stresses created by machining or other processes. Such Peltier-controlled temperature precision must not drive aluminum too far down its increase of strength-to-weight ratio, marking the number one requirement and priority within the aerospace and automotive industries.

For other non-ferrous metals like brass and bronze, annealing enhances brittleness while improving machinability. Dosed heating, then cooling, allows some of the puzzles that metals can get into to retain their shape while melted to build with complex shapes. Optimisation is one of the key topics of this automated age; machines effortlessly calculate how much increased elongation capacity is enough for a metal. Data shows that and many non-ferrous metals increase the composition dependent elongation capacity by 25 to 50% with annealing.

Metal Wire and Sheet Metal Annealing Applications

Ductility, toughness, and malleability of metal wires, along with sheet metals, undergo enhancement through annealing, which is widely applied in various industries. Below are the primary industry verticals along with their specific applications:

- Automotive Industry

-

-

- In vehicle body structures, panels are made of a flexible shock-absorbing material and are annealed metals, which is why they are used in vehicle body parts.

- Springs and fasteners in automobiles use boning wires that have undergone annealing.

-

- Electrical and Electronics Industry

-

-

- Wires made from copper are heated and made into electrical cables which are later used in various electronic appliances because they are easy to conduct current and less brittle due to brittle.

-

Heat sinks and casings for various electronic components are made out of aluminum and other metals in the form of sheets and undergo heating to soften them before assembling.

-

- Construction Sector

-

-

- The reinforcing steel wires used in concrete structures profit from elongation and greater stress due to annealing procedures.

- For ease of installation, straightforward annealed sheets are useful in framing metals and roofing.

-

- Aerospace and Aviation Industry

-

-

- Strength and lightweight construction are achieved through the use of annealed aluminum sheets for aircraft fuselage and wings.

- Important device sections like the landing gear mechanisms rely on high-strength annealed metal wires.

-

- Manufacturing of Consumer Goods

-

-

- Due to the pliability achieved from annealing, kitchen racks, household hangers, and other fasteners are made from bone metal wires.

-

Washing machines and fridges, which are classed as durable appliances, are manufactured using annealed sheet metals.

-

- Medical Industry

-

-

- Instruments such as braces and stents rely on stainless steel wires that are annealed for increased accuracy and low risk of breakage.

-

The cleaning and disinfection processes alongside ultra-sonic machining, guarantee that surfaces of medical trays or casings of imaging machines are free of contaminants and maintain stringent hygiene and strength requirements.

-

Supporting Data

- Automotive-grade annealed sheet metals boast up to 30% greater energy absorption during impact testing.

- Conductivity of copper wires that have been electrically annealed increases by 10—15% when compared to non-annealed versions.

-

Medical braces and stents incorporating annealed wires show a 40% greater tolerance to stress.

These applications show the versatility of metal annealing and emphasize its importance in optimizing metals according to particular industrial requirements.

Reference Sources

1. Analysis of the Mechanical Characteristics of Mild Steel Using Different Heat Treatments

Methodology:

The study investigates the influence of annealing, hardening, and tempering on the mechanical properties of ASTM A-283C mild steel. Multiple heat treatments at varying temperatures were conducted, followed by testing for tensile strength, hardness, and other mechanical traits using a tensile testing machine and Rockwell hardness tester.

Key Findings:

- Annealing reduced tensile strength and hardness while enhancing ductility and elongation due to the formation of a ferrite matrix.

- Hardening resulted in the highest hardness and tensile strength, but significantly reduced ductility.

- Tempering improved the balance between strength and ductility by reducing brittleness caused by hardening.

- The study highlights that tailored heat treatments can optimize mild steel’s properties for specific applications.

2. Effect of Friction Stir Welding and Tempering on the Microstructure and Strength of a Tempformed Low-Alloy Steel

Methodology:

Friction stir welding (FSW) and post-weld tempering were applied to tempformed low-alloy steel, and the resultant microstructures were analyzed using scanning and transmission electron microscopy. Tensile and hardness tests were performed to evaluate mechanical properties.

Key Findings:

- FSW created a martensitic microstructure in the stir zone with higher dislocation density, resulting in increased hardness but reduced plasticity.

- Tempering after FSW restored plasticity and reduced hardness to the base material level by promoting tempered martensite formation.

- The study found that post-weld tempering can enhance uniformity in mechanical properties across the weld joint, making FSW combined with tempering an effective approach for joining high-strength steels.

Frequently Asked Questions (FAQs)

Q: What happens to annealed metal during the annealing process?

A: When metal is annealed, it undergoes a controlled heating and cooling process that alters its physical and mechanical properties. First, the metal is heated to a specific annealing temperature (typically below its melting point). At this elevated temperature, the internal stresses are relieved as atoms gain mobility. New grain structures form within the metal’s crystalline structure. Finally, during the slow cooling process, these new grain structures are preserved, resulting in a softer, more ductile material that is less brittle and easier to work with. This transformation is particularly important for ferrous metals like steel, though the process is used for many metals and alloys.

Q: How does annealing work to improve the properties of metal?

A: Annealing works by rearranging the atomic structure of metals through carefully controlled heating and cooling. When a metal is heated to its appropriate annealing temperature, its atoms gain increased mobility, allowing internal stresses to dissipate and enabling recrystallization. This creates new grain structures that are more uniform and stable. The subsequent slow cooling process preserves these improved microstructures. As a result, annealed metal exhibits enhanced ductility, reduced hardness, improved machinability, and eliminated internal stresses. The specific advantages of annealing depend on the type of metal being treated and the exact parameters of the heat treatment process used.

Q: What are the different types of annealing processes for metal?

A: There are several specialized types of annealing processes used to alter different properties of the metal depending on requirements. Complete annealing involves heating steel above its critical temperature followed by slow cooling, resulting in maximum softness. Process annealing (subcritical annealing) uses lower temperatures to reduce hardness in cold-worked parts. Isothermal annealing features controlled cooling with a temperature hold to create uniform properties. Stress relief annealing removes internal stresses without significant structural changes. Recrystallization annealing forms new grain structures in cold-worked metals. Each type of annealing process serves specific purposes and is selected based on the desired outcome and the type of metal being treated.

Q: For what purposes is annealing used in metalworking?

A: Annealing is used in metalworking for numerous essential purposes. Primarily, it softens hardened metals to improve workability for forming, stamping, or machining operations. It relieves internal stresses that accumulate during cold working, preventing warping or cracking. Annealing may also restore ductility to metals that have become brittle through work hardening. Additionally, it homogenizes the microstructure of cast metals, refines grain size, improves electrical conductivity in certain metals, and prepares metals for subsequent heat treatments. In manufacturing, annealing is carried out as either an intermediate step during fabrication or as a final treatment to achieve the desired properties of the metal.

Q: What happens to the microstructure when annealed metal cools?

A: During the cooling process of annealed metal, remarkable microstructural changes occur. As the heated metal begins cooling, new grain formations stabilize, creating a more uniform crystalline structure. The slow cooling allows atoms to arrange themselves in lower-energy configurations, which reduces dislocations and defects. In ferrous metals like steel, phase transformations may occur, where austenite transforms to ferrite and pearlite. The cooling rate is critical—too rapid cooling would trap internal stresses, while the slow cooling process characteristic of annealing allows complete atomic rearrangement. This results in larger, more regular grains with fewer defects, which is why annealed metal typically exhibits greater ductility and reduced hardness compared to its pre-annealed state.

Q: How does the annealing temperature affect different metals and alloys?

A: The annealing temperature critically affects different metals and alloys based on their unique properties. Each metal has a specific temperature range where effective annealing occurs, typically related to its melting point and crystal structure. For example, copper might be annealed at 375-650°C, while steel is heated to 750-900°C for full annealing. Using temperatures that are too low results in insufficient atomic mobility and incomplete stress relief. Conversely, temperatures that are too high can cause excessive grain growth or even melting. Alloying elements significantly influence optimal annealing temperatures—more complex alloys often require more precise temperature control. The relationship between temperature and hold time is also important, as longer times at lower temperatures can sometimes achieve similar results to shorter times at higher temperatures.

Q: What are the benefits and limitations of annealed metal?

A: Annealed metal offers numerous benefits, including increased ductility for easier forming, reduced hardness for improved machinability, elimination of internal stresses, enhanced electrical conductivity, and improved dimensional stability. The advantages of annealing are particularly valuable in manufacturing processes requiring significant metal deformation. However, there are limitations as well. Annealed metals have lower strength and hardness compared to work-hardened or quenched materials, making them unsuitable for high-strength applications. The annealing process is energy-intensive and time-consuming. Annealing may cause surface oxidation requiring additional finishing. Some properties gained through previous treatments are lost, and annealed metals may be more susceptible to certain types of corrosion. The choice to anneal represents a trade-off between workability and strength.

Q: How can you tell if a metal has been annealed?

A: Identifying annealed metal involves observing several characteristic properties. Annealed metal typically exhibits noticeably increased softness compared to hardened versions, which can be tested with hardness testing equipment or sometimes even a fingernail scratch test for softer metals. It displays improved ductility, bending more easily without cracking. Visual inspection may reveal a duller surface finish, especially in copper and brass. Microstructural examination using metallographic techniques shows larger, more uniform grain structures. Magnetic testing can help identify annealed ferrous metals, as the annealing process affects magnetic properties. Additionally, annealed metal often has different electrical conductivity compared to work-hardened versions of the same metal, and may exhibit distinctive crystalline patterns when exposed to certain etching chemicals.