Stainless steel is a multifaceted industrial material famed for its strength, durability, and resistance to corrosion. Type 304 steel undoubtedly is the most well-known and widely used grade of stainless steel. The purpose of this article is to inform the audience on the nature of 304 stainless steel, its particular features, important distinctions from other grades, and from what industries it is most likely to be utilized. Being in the engineering, construction, or manufacturing industry, knowing the properties of 304 stainless steel would help you make the right choices with regard to the materials that suit your requirements.

What is 304 Stainless Steel?

304 stainless steel is an austenitic grade of stainless steel that contains iron, chromium, and nickel as its primary constituents, while carbon, manganese, and silicon are present in trace amounts. One of the most widely used grades of stainless steel, it is known for its great durability and ease of fabrication. The grade is, however, most renowned for its versatility, as it can be used for kitchen equipment, automotive parts, industrial machines, construction materials, and so much more.

Composition of 304 Stainless Steel

The composition of 304 stainless steel is carefully balanced to deliver exceptional performance and versatility. It primarily consists of iron, with approximately 18-20% chromium and 8-10.5% nickel, which contribute significantly to its corrosion resistance and strength. Additionally, it contains small amounts of carbon, usually capped at 0.08%, to prevent brittleness, alongside manganese and silicon for improved durability and workability. This precise blend of elements ensures that 304 stainless steel meets a wide variety of demands across industries, making it a reliable and popular choice for countless applications.

Why 304 Stainless Steel is Widely Used

Due to its unparalleled strength, versatility, and resistance to corrosion, 304 stainless steel is widely used. Both industrial and domestic applications use it due to its ability to withstand a range of environmental conditions, including chemicals and moisture.. It is easy to fabricate and requires low maintenance, which increases its appeal across the construction, food processing, and medical equipment manufacturing industries. These factors make 304 stainless steel a trusted and economical material for numerous industrial purposes.

Benefits of 304 Stainless Steel

The makeup of 304 stainless steel is optimally formulated to offer multifunctional and remarkable output. It is largely composed of iron, with 18-20% chromium and 8-10.5% nickel other additional components, which account for its strength and resistance to corrosion. In addition, it has trace quantities of other elements such as carbon, which is kept below 0.08% to avoid causing brittleness, and manganese and silicon to aid in increased durability and workability. This perfect enhanced blend of these substances guarantees that 304 grade stainless steel fulfills and satisfies numerous conditions and requirements, which is the reason why it’s widely used the world over.

How Does 304 vs 316 Stainless Steel Differ?

The main distinction between 304 and 316 stainless steel is their chemical makeup as well as the level of corrosion resistance. Both are austenitic and highly durable, but 316 includes molybdenum, which improves its resistance to pitting and corrosion in chloride-laden areas such as marine or chemical settings. This makes 316 more appropriate for extreme conditions, while 304 is more affordable and typically used in general-purpose settings.

Mechanical Properties of 304 and 316

it is critical to know that the mechanical properties of 304 and 316 stainless steel are crucial when selecting a material for your specific application. All while both grades are robust and adaptable, their slight variations can make one more desirable than the other based on your requirements. I have outlined the major mechanical properties of 316 and 304 stainless steel that are most important for evaluation:

- Tensile Strength

-

-

- 304 stainless steel has a tensile strength of about 70,000psi, making it sufficiently strong and durable for many applications.

- 316 stainless steel has similar strength, but added molybdenum improves its performance in corrosive environments without reducing strength.

-

- Yield Strength

-

-

- Regarding 304, its yield strength is equal to 30,000 psi, implying that this material can undertake considerable stress without bending.

- Likewise, 316 possesses a yield strength with comparable values, however, it has a better yield strength retention under more sever environment due to its elevated corrosion resistance.

-

- Hardness

-

-

- Measuring on either the Brinell or Rockwell scale, both 304 and 316 possess roughly equal levels of hardness. This indicates that they are able to withstand indentations and abrasion efficiently while in service.

-

- Ductility

-

-

- As previously mentioned both grades offer excellent ductility, which enables stretching without breaking. This ability pertains to the capability of forming shapes like twisting or angling the material at sharp gradients.

-

- Heat Resistance

-

-

- 304 offers excellent resistance to high-heat environments, being capable of withstanding up to 1,400°F.

- 316 has equally high resistance to heat, however, further endurance of chemical exposure makes it favorable in particular industries.

-

In summary, although 304 meets the requirements of several general purposes, 316 is better suited for stronger, more corrosively resistant environments, and ones with greater operational tension. Having knowledge of these factors will make certain selections safe, durable, and economical while achieving the desired outcome in your projects.

Chemical Composition Differences

the differences in molybdenum content from 304 to 316 stainless steel are differences in the composition of chemicals. Around 2-3% molybdenum found in 316 gives it better resistance to corrosion, especially when in contact with chlorides and severe chemicals. 304’s composition is less complex and depends on its chrome and nickel fractions for strength and oxidation resistance. appreciation of these differences is important for the right choice of material.

Understanding Corrosion Resistance

The ability to resist corrosion fundamentally relies on a material’s ability to withstand environmental conditions such as moisture, chemicals, and salts. Taking stainless steels 304 and 316 as an example, the difference is in their composition – added molybdenum in 316 greatly increases its resistance to chloride exposure and other dreadful conditions, making it perfect for marine or chemical environments. 304, on the other hand, provides a sufficient level of resistance for general-purpose use where durability and cost efficiency are equally important. The right material choice is made when there is precise knowledge of the environmental threats the material will encounter.

What are the Mechanical Properties of 304 Stainless Steel?

Upon evaluation of the mechanical properties of 304 stainless steel, it possesses noteworthy strength, ductility, and toughness. Its tensile strength is around 515 MPa, and its yield strength is approximately 205 MPa, which is reliable under stress. In addition, 304 stainless steel has an outstanding elongation of over 40%, making it highly ductile and easy to fabricate. Its hardness is also remarkable, having an average Brinell hardness of about 201. The combination of these qualities makes 304 stainless steel an ideal candidate for a great number of applications requiring strength and workability.

Strength and Durability

304 stainless steel’s strength and durability make it an ever-important asset in numerous industries. Its high tensile strength, exceptional elongation, and marked hardness guarantee performance under stress while remaining flexible for fabrication. This blend of attributes makes 304 stainless steel ideal for challenging environments that demand resiliency and effective performance for prolonged periods of time.

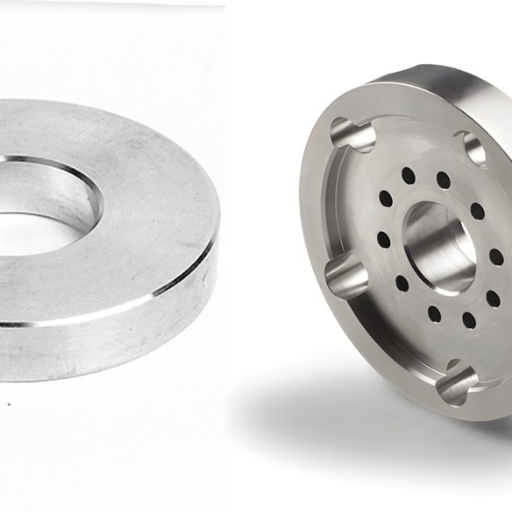

Impact on Fabrication

When talking about fabrication, the first thing that comes to mind is 304 stainless steel, which is uniquely versatile and efficient. It can be easily cut, welded, and machined, and even the most intricate designs can be done with precision because of excellent formability. Furthermore, its resistance to warping or cracking during high-temperature processes assures dependable results, time after time. From what I have experienced, this material does not disappoint, time after time achieving results that are professionally accepted throughout various industries.

Comparison with Carbon Steel

While contrasting steel types, the major differentiating factor associated with carbon steel is its performance characteristics alongside its composition. Due to possessing a high carbon percentage, carbon steel is stronger and harder but less flexible and more difficult to weld. In contrast, standard steel has a much better balance with its corrosion resistance, machinability, versatility, and durability, making it suitable for many applications. All things considered, for a project with high-strength requirements, carbon steel would be the ideal choice, while for general purposes, standard steel has proven to be more efficient and reliable.

Why Choose Grade 304 Stainless Steel for Various Applications?

Whether it’s versatility or trustworthiness, as a seasoned professional, I continuously endorse Grade 304 stainless steel for a plethora of uses. It demonstrates remarkable resistance to corrosion whilst having exceptional strength and durability, making it exceptional in food processing, construction, and even healthcare. Moreover Grade 304 is easy to fabricate and clean which increases practicality in strict environments. This grade has proven itself to be reliable and efficient when in need of a material that is both intricately designed, and can sustain moisture-rich conditions.

Applications in Food Processing Equipment

The exceptional resistance to corrosion, maintenance of hygiene, and ease of cleaning of grade 304 stainless steel, makes it a favorite in the industry of food processing. Its use in food grade storage tanks, conveyor systems, mixing bowls, and other processing machinery ensures fulfillment of rigid durability and food industry safety requirements.

Use in Corrosive Environments

Marks like deeper molybdenum content lead to superior resistance to pitting and crevice corrosion, which makes it invaluable for marine applications, chemical processing industries, and industries operating in high salinity regions. I have seen reliable performance in desalination plants, chemical processing plants, and offshore platforms where durability under relentless exposure to harsh conditions is critical. The right selection of grade can increase lifespan substantially and reduce maintenance costs in these highly demanding environments.

Role in Aesthetic Appeal and Design

The influence of stainless steel in design and aesthetic appeal is inarguable due to its modern appearance and varied finishes. Its polishable mirror sheen and brushed or matte texture makes it a go to material for architecture, interior design, and product manufacturing. Moreover, stainless steel’s charming visage is offset by unmatched resilience to wear and discoloration, guaranteeing designs retain their elegance over the years. Blending both practicality and striking visuals is made possible due to this combination of form and function.

What Makes Grade 304 Stainless Steel Part of the Austenitic Family?

Because of its significant amount of nickel and chromium, grade 304 stainless steel is classified under the austenitic family. It possesses a unique microstructure that is stable at any temperature. In my experience, this stability not only improves corrosion resistance, but, its versatility. The austenitic qualities guarantee amazing formability and weldability, which makes grade 304 stainless steel a popular choice across industries. Also, its non-magnetic nature and ability to endure harsh conditions further support its classification as austenitic and distinguish it as a strong and dependable material.

Characteristics of Austenitic Stainless Steel

Austenitic stainless steel is characterized by unparalleled corrosion resistance, high tensile strength, and remarkable versatility. Its chromium nickel content, along with its formability, makes this alloy durable and weldable, therefore useful in various industries and applications. Its reliability is further enhanced by its non-magnetic characteristics and suitability in performing well in high and low temperature environments.

Role of Chromium and Nickel in Properties

I’ve come to understand that nickel and chromium are undoubtedly important regarding the properties of austenitic stainless steel. Chromium forms the vital protective oxide layer on the surface of the alloy that defends against corrosion, while methanol and oxidation. This alone showcases why it is of utmost importance as far as corrosion-resistant steel is concerned. Nickel enhances the formability, toughens the alloy, and at the same time stabilizes its austenitic structure. All of these have a cumulative impact that guarantees the stainless steel a great deal of strength, resistance, and flexibility under water pressure, temperature, and forces around it, thereby increasing the stainless steel’s usability across a great many industries.

Advantages of Austenitic Stainless Steels

Austenitic stainless steels are ideal for use in austere environments due to their non-magnetic features, exceptional tensile and shear ductility, as well as unrivaled weldability. Austenitic stainless steels are highly robust and aid in withstanding extreme temperatures without compromising thermal stability, making them suitable for chemical processing and architectural work. The corrosion resistance and weldability of these steels make them usable in harsh conditions, and the high ductility aids in elasticity, moldability, and stretchability, resulting in minimalistic designs.

Reference

- 304 Stainless Steel: The Ultimate Guide – Ulbrich

- What is 304 Stainless Steel? – Masteel

- What is 304 stainless steel used for? – Marsh Fasteners

Frequently Asked Questions (FAQs)

Q: What is 304 stainless steel, and how is it used?

A: 304 stainless steel is an alloy that is part of the austenitic family of stainless steels. It is one of the most common types of stainless steel, known for its excellent resistance to corrosion and oxidation. 304 stainless steel is used in a variety of applications, including kitchen appliances, sinks, and other consumer products.

Q: What are the key differences between 304 and 316 stainless steel?

A: The key differences between 304 and 316 stainless steel lie in their chemical composition. 316 grade contains molybdenum, which enhances its corrosion resistance, especially against chlorides and other industrial solvents. This makes 316 stainless steel more suitable for marine and chemical applications compared to 304 grade.

Q: How does the carbon content affect stainless steel grades?

A: The carbon content in stainless steel grades affects their hardness and strength. Lower carbon content, as seen in 304L stainless steel, improves weldability and reduces the risk of carbide precipitation during welding. This makes it suitable for applications where welding is required.

Q: Why is 304 stainless steel considered a common grade of stainless steel?

A: 304 stainless steel is considered a common grade due to its excellent combination of corrosion resistance, formability, strength, and affordability. These properties make it widely used across various industries, from kitchen appliances to construction materials.

Q: What distinguishes stainless steel from other types of steel?

A: Stainless steel is distinguished from other types of steel by its corrosion resistance, which is primarily due to the presence of chromium and nickel. For instance, 304 stainless steel contains approximately 18% chromium and 8% nickel, which provides its high resistance to rust and stains.

Q: What are the stainless steel properties that make 304 ideal for kitchen use?

A: 304 stainless steel is ideal for kitchen use due to its excellent resistance to corrosion and heat, ease of cleaning, and aesthetic appeal. These properties make it perfect for sinks, cookware, and other kitchen appliances where hygiene and durability are paramount.

Q: How do 304 and 304L stainless steel differ?

A: The primary difference between 304 and 304L stainless steel is the carbon content. 304L has a lower carbon content, which enhances its weldability and reduces the risk of carbide precipitation. This makes 304L more suitable for welding applications compared to the standard 304 grade.

Q: When should one choose between 304 and 316 stainless steel?

A: Choosing between 304 and 316 stainless steel depends on the specific application and environmental conditions. For general indoor use, 304 is commonly used due to its excellent performance and cost-effectiveness. For environments with higher exposure to corrosive elements, such as marine or chemical settings, 316 is preferred for its superior corrosion resistance.

Q: What types of stainless steel are available besides 304 and 316?

A: Stainless steel comes in many different grades and types, including ferritic, martensitic, duplex, and other austenitic grades. Each type offers unique properties and is suited for specific applications, depending on factors such as corrosion resistance, strength, and formability.