A blend of aesthetic preferences, uses, and applications makes stainless steel demanding particular attention with regard to its mechanical properties, visual appeal, and resistance to corrosion. Their enhancement is primarily performed through processes known as electropolishing and passivation. What are these processes, and what makes them different? This guide will detail both processes of electropolishing and passivation so that you can make practical choices for your projects. In case you are an expert from the industry or just someone interested in technology, this article aims to equip you with the relevant knowledge on the benefits, applications, and how to select the appropriate process to align these technologies with your requirements. Join us as we analyze the differences, similarities, and key learnings of these stainless steel finishing techniques.

What is Electropolishing and How Does the Process Work?

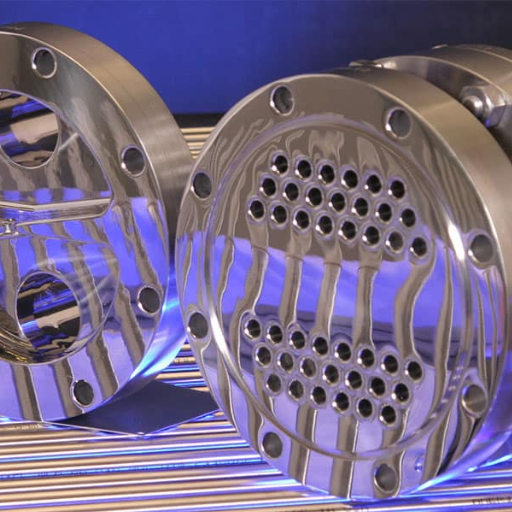

Electropolishing smoothens, polishes, and enhances surface features of stainless steel and other metal alloys by removing some material from their surface. To achieve this, the metal is immersed in an electrolytic bath, and an electrical current is applied. This process makes dissolving surface flaws, burrs, and surface contaminants easier. The end results yield smooth surfaces devoid of unwanted abrasions. It also improves aesthetic value, protects against corrosion, and enhances durability, which is extremely useful in the medical and aerospace industries as well as food processing.

Electropolishing is an Electrochemical Process Explained

Electropolishing improves the appearance of metal components and offers benefits related to functionality. For one, it greatly improves surface finish due to the reduction of surface roughness (Ra) by up to 50%, depending on the condition of the material. In sectors such as medical and pharmaceutical which require precision, hygiene, and clean smooth surfaces for bacterial adhesion prevention, this property is particularly valuable.

Moreover, the removal of passive contaminants helps in the creation of a protective oxide layer which increases corrosion resistance, thereby enhancing the durability of stainless steel parts. This layer becomes even more important for parts exposed to harsh chemicals or moisture.

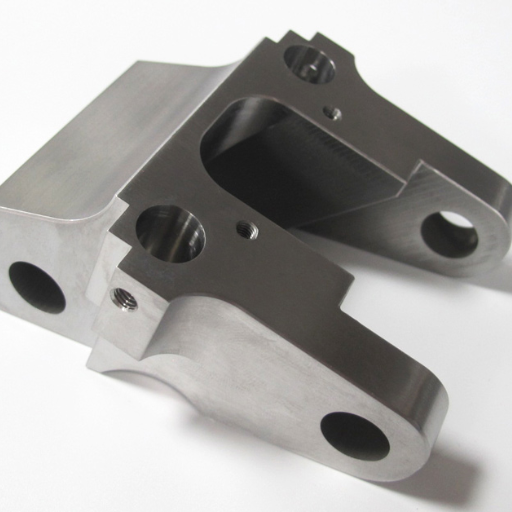

Electropolishing also plays a fundamental role in assuring the reliability of machined parts which undergo micro-burr and imperfection removal. Consider stress-sensitive aerospace components which need to meet precision and fatigue resistive requirements; parts such as these rely on electropolishing to drastically improve stress concentration points and boost fatigue resistance.

Research indicates that the process also lessens the coefficient of friction on the surfaces treated, thus increasing the value of the process for moving parts like gears or sliding elements. With its ability to accommodate complex forms and sophisticated constituents, electropolishing is known as a flexible answer across numerous industries.

Compared with other polishing methods, this technique is more environmentally friendly because no dust is generated, nor is there the potential for contaminating the surrounding area. Because of this, electropolishing is considered one of the best methods for improving the performance of metals while still being ecologically responsible.

How the Electropolishing Process Removes Material from Stainless Steel Parts

In Electropolishing, the process of ‘removing’ starts at an electrode, and works its way up like peeling an onion, in this case Stainless steel. At first, a stainless steel alloy is submerged into an electrolytic bath, which serves as the electrolyte for the electropilshing to come. An electric current is then passed through controlling the flow, causing a uniform removal of ions. This technique is very focus-oriented since it solely targets the high points on the metal surface giving the desired smooth polish.

Based upon specific operational parameters such as; current density, composition of the electrolyte solution, duration of the treatment, and a few others, around 0.0001 to 0.002 inches of the metals layer are removed. In comparison with conventional polishing, Electropolishing works in a more sophisticated fashion by removing only the rough, outer layer, which leads to micro-burrs and irregularities. This results in a decrease of average roughness of upwards 50% which makes Electropolished surfaces ideal for sensitive applications where the utmost cleanliness along with high levels of corrosion-resistant are required.

Because of the active uniform layer of chromium oxide, Electropolished ss also provides increased tarnish and rust resistance, causing passivation from oxidation. Medical and Pharmaceutical works, Food Processors, even Aerospace, gets major help from having increased sanitary standards along with improved durability and aesthetic that this technique helps provides.

ASTM B912 Standards for the Electropolishing Process

The specifications for passivation and corrosion resistance of stainless steel by electropolishing is described in ASTM B912. This standard mainly concerns the treatment of some stainless steel alloys like 200, 300, and 400 series, as well as precipitation hardened alloys. It sets forth fundamental procedure and process control requirements decscribed in the procedural document to which all standards must adhere in order to provide the maximum level of corrosion resistance while attaining a clean and bright finish to the surface.

Within these are included the smoothness and the cleanliness at the surface after electropolishing which must meet minimum levels. These measurements have specific surface roughness (Ra) targets, with a promise of achieving them after electropolishing treatment; such targets are achievably low values of 0.13 – 0.25 micron. There are also basic criteria which are called acceptance criteria which impose certain limits which must successfully be met after performing the tests. These limits are for performing the tests which are called post electropolishing CASS test.

Moreover, ASTM B912 highlights cleaning the embedded contaminants to balance the chromium oxide layer which is critical for aesthetics, durability and functionality of the material. Adhering to these detailed robust criteria should improve consistency in achieving quality standards to satisfy the needs of industry requiring reliability of the components operated under high-performance and highly demanding conditions.

What is Passivation and How Does it Enhance Stainless Steel?

Passivation is a process done on stainless steel to improve its resistance to corrosion by developing a thin protective oxide film on its surface. This film, the chromium oxide layer, stops the base metal from undergoing reactions with the strata like air or water that may lead to the rusting or degradation of the metal. The procedure usually includes a stainless steel clean up to eliminate strategic contaminants and treating the metal with an acid bath to aid in the formation of this passive film. Passivation enhances the material’s operational lifespan while preserving its aesthetic and protective properties in harsh environments.

Understanding the Passivation Process for Stainless Steel

Passivation enhances the advantage of stainless steel in industrial applications because it is used in harsh environments. Studies show that passivated stainless steel surfaces are considerably more resistant to corrosion than untreated surfaces. For example, in salt spray testing, passivated stainless steel shows increased durability often over 200 hours of constant corrosion, depending on the material’s grade, in some cases effortless exceeding 200 hours.

This is most useful in chemical processing, food and beverage, and marine applications where equipment must endure constant contact with corrosive materials. Passivation not only preserves the mechanical strength of stainless steel, but also greatly reduces the risk of contamination in accordance with industry standards such as ASTM A967 or AMS 2700. Furthermore, studies indicate that proper passivation lowers maintenance and downtime, as components need to be replaced far more infrequently. This is in stark contrast with unprocessed, raw steel components. Passivation increases performance and efficiency in demanding applications by providing a clean, durable surface.

Chemical Passivation Treatments and Their Effects

The processes that improve the corrosion resistance of metals, especially stainless steel, involves methods known as chemical passivation treatments. One method that is greatly utilized is the immersion in acid baths like citric or nitric acid which helps scrub the periphery of free iron contaminants. CITRIC ACID PASSIVATION: A CITRIC ACID SOLUTION PASSES the required limits of the ASTM standards like ASTM A967 making it preferred in applications with stringent environmental handling. Also, it is CITRIC PASSIVATIONthat has found favor owing to the fact that it is LEAST HARMFUL TO THE ENVIRONMENT and most importantly, aids in meeting industry parameters with greatly reduced levels of toxicity.

Nitric acid along with other pyrogenic passivation offers impressive features like augmented allowance simultaneously creating scrubbing interaction aided by rough crystal formation. Contact free permanganate oxidative rinsing of nitric passivation contributes heavily to the lack of pitting corrosion exposed to chloride solutions which is important in construction.

Quantified Benefits of Passivation

Quantitative data attempts to measure the value gained from passivation. For instance, industry tests show that passivated stainless steel surfaces have shown up to a 50% improvement in corrosion resistance over untreated surfaces of the same grade stainless steel under identical conditions. Moreover, during salt spray testing, passivated components were found to sustain about 30% longer in marine settings teeming with Chlorides. This durability improves overall performance and reduces the cost over time due to reduced maintenance and replacement frequency. Moreover, passivation treatments result in improved surface cleanliness which is important for aerospace, medical device manufacturing, and food processing.

Because of stringent laws and tough operating conditions, industries need to tailor specific use cases for passivated structures. This ensures regulatory requirements are still met while standing in rough working conditions.

ASTM A967 Guidelines for Stainless Steel Passivation

With optimal cleanliness and minimal corrosion, passivation treatment of stainless steel parts is done using ASTM A967, which outlines methods such as citric and nitric acid. Each treatment is applied separately so as not to interfere with the properties of the steel itself.

In line with a predefined procedure, the passivation treatment is done at a specific temperature and concentration, for example, nitric acid passivation has a working range of 20% to 50% volume and a temperature of 120-160°F, with the exposure time set between 20-60 minutes.

Test methods such as the immersion test and copper sulfate test guarantee that the parts retain the required levels of cleanliness and resistance to corrosion. There is a wealth of industry data suggesting the service life of stainless steel parts treated to meet ASTM A967 standards is greatly extended, even when exposed to harsh marine or chemical processing environments.

With the compliance to the ASTM A967 guidelines, companies gain valuable assets that integrate with international standards, minimize upkeep expenses and boost dependable performance – even under harsh operating conditions.

The Key Differences Between Electropolishing vs Passivation

The procedures, electropolishing and passivation, are done to improve the surface of stainless steel, yet they achieve this in different ways:

- Electropolishing is characterized as an electrolytic process that strips a metal’s surface to a specific depth from the top. Its advantage involves a bright, reflective finish together with improved corrosion resistance of the metal.

-

Passivation involves a process of chemical treatment of the surface which cleans off any free iron and form’s protective oxide layer to enhance the stainless steel’s corrosion resistance without changing its surface appearance.

The main difference has to do with two things: scope and result. In electropolishing, visual and structural enhancements are achieved due to surface smoothing. Passivation, on the other hand, applies a chemical treatment to enhance corrosion resistance but does not smooth the surface.

How Electropolishing and Passivation Affect the Oxide Layer

Electropolishing and passivation both affect the oxide layer of a given substrate in different ways. While polishing removes minute features, it also increases the uniformity and thickness of the native oxide layer. This results in surface roughness being achieved below 0.4 microns (Ra), which is the threshold for contamination or corrosive damage initiation. Such smooth surfaces bolster the oxide layer by lessening the presence of pits and crevices bound to increase erosion. During the above-described processes, the surface roughness is also improved.

As opposed to passivation, polishing focuses more on buffing the existing features of the oxide layer. This change does not affect the shape or size of the base metal. Notably, the passivation step modifies the surface texture by applying a chemical softer than citric or nitric acid. This scrub removes loose iron and guarantees aggressive oxidation of the surface, thus affording a stable oxide coating. Evidence suggests that the surface becomes 30% more resistant to corrosion than its counterpart that underwent no treatment, proving beneficial where conditions are considerably harsh.

The combination of these two changes improves the reliability and efficiency of the oxide layer significantly better than when done separately, thus protecting the surface from corrosion and abrasion for extended periods of time. The selection differs entirely based on the surface properties and requirements of the application intended for use.

Comparing How Each Process Works on Metal Surfaces

While looking at anodizing and passivation, one must bear in mind each process’s distinctive metal surface praparing techniques. Anodizing, for instance, is mostly electrochemical oxidation. This process creates or enhances an oxide layer on the surface of an aluminum or titanium component by growing an oxide layer that is thicker than normally formed on its surface. This type of oxide layer improvement helps in wear resistance, application of dyes for aesthetic finishes, and enhances corrosion resistance. For example, anodized aluminum is known to achieve fivefold corrosion resistance compared to uncoated aluminum surfaces. This fact increases it’s usefulness in marine and aerospace industries.

Passivation, in contrast, is the chemical treatment of stainless steel surfaces that involves cleaning the surface and removing free iron and other unwanted material contaminants. It creates a passive oxide layer, but a more modest one than the anodizing oxidation layer. As a result, the greater the ferrous alloy, Stainless steel becomes to rust and oxidation which is required for medical and food processing industries. Properly passivated stainless steel is said to withstand saline environments for long periods without degrading, making it useful in corrosive environments.

It is critical to understand the materials involved in these processes: passivation works with stainless steel, whereas anodizing is aimed toward aluminum and titanium alloys. In addition, the unique advantages of passivation’s low-cost industrial applicability compared to the precise thickness control of anodizing, highlights how each process serves different needs.

What’s the Difference Between Electropolishing and Passivation Outcomes?

Both metal components undergo electropolishing and passivation to improve the surface quality, but implement different techniques. Electropolishing applies an electric current to an electrolytic solution, which reinforces the active components and strips a thin layer of the surface. During this step, micro-roughness, or small potholes on the surface, are smoothed out, and a shine is provided. In addition, corrosion resistance is enhanced because the surface contaminants, as opposed to the metal itself, are removed during the process, enabling the system to passively form a uniform chromium-oxide layer. Electropolished surfaces consistently exhibit lower friction and higher durability, which is preferable in harsh environments such as medical and aerospace.

Passivation, in contrast, emphasizes the chemical treatment of metal to get rid of free iron and foster the formation of a protective chromium-rich oxide layer. Unlike the previous approach, passivation does not alter the surface to such an extent but improves the stainless steel’s natural corrosion resistance. Society benefits from well-treated passivated components where the anti-corrosive measures can be economical, like equipment used in food processing or other industrial applications.

Both processes help mitigate the chances of corrosion, but they differ in terms of surface finish, aesthetic appeal, and cost. Electropolishing tends to achieve smoother surfaces and better aesthetics compared to passivation, which is cheaper and more straightforward for protecting metal parts in less critical surroundings. Different industries tend to choose one based on how their applications will use them, while considering efficiency and budgetary restrictions.

How Do Both Processes Improve Corrosion Resistance?

Both passivation and electropolishing improve a metal’s resistance to corrosion by removing some surface impurities that could result in degradation over time. With electropolishing, surface defects and contaminants are smoothed out and refined to create a uniform surface that has minimal rough areas for corrosion to begin. Passivation goes a step further by improving the protective oxide layer on the surface of the metal, putting a shield against environmental deterrents of corrosion. Altogether, both processes ensure maintained structural integrity of the passivated metal while improving the life expectancy of the metal in harsh environments.

Passivation’s Role in Removing Free Iron and Contaminants

The delicate tissue of the stainless steel is a coated passive film which gives it the ability to withstand corrosive environments This film can be made more resistant to corrosion by eliminating the remaining iron and surface impurities through passivation. It has become commonplace in technological applications where esthetic appeal along with corrosion resistance is important.

Passivated stainless steel exhibits increased resistance up to 10 times compared to untreated surfaces, making it preferable in the medication and aircraft industries with precise sterility and rigorous functionality standards. Passivation has also been shown to effectively protect components undergoing testing in salt spray and humidity corrosion chambers.

Passivation removes attributes and creates a passive film on the surface, making it the last step in processing metal parts to withstand stress and maintain structural integrity over time.

How Electropolishing Enhances Stainless Steel’s Corrosion Resistance

The process of electrolytic polishing significantly enhances the corrosion resistance of stainless steel by surface polishing, which eliminates imperfections and achieves a smooth microscopical finish. Electrolytic polishing makes use of an electrolyte bath where the stainless steel component to be polished undergoes a certain procedure in which an electric current flows through the electrolyte, causing removal of a thin layer of material from the surface. This process smooths the surface on which contaminants and microcracks exist. If any rough, contaminated surfaces are left out on stainless steel, they may lead to corrosion beginning at micro cracks.

Selective Cr/Fe ratio increase is one of the primary benefits of polishing which alters the portion of iron on the surface close to the coating. Through iron and other many less reactive components dissolution, the polishing process enhances chromium concentration at the top layer which causes imbalance of the substrate iron control level. This stainless steel oxide has been known to form easily therefore in the end resulting more sustainable long-lasting cores preventing long-standing corrosion damage. Corrosion-resistant surfaces perform well and are reliable in extreme environments.

Research indicates that the corrosion resistance of stainless steel is significantly improved–by 30 to 50%– in pitting resistance within chloride rich environments after undergoing electropolishing when compared to untreated surfaces. In addition, other studies indicate that the surface roughness of electropolished stainless steel is significantly lower (up to 10 times) than that of mechanically polished stainless steel. This decrease in roughness increases corrosion resistance while enhancing ease of cleaning, maintenance, and hygiene, especially in food processing, medical devices, and marine industries.

Electropolishing strengthens the corrosion resistance of stainless steel while also reducing roughness to a molecular level which increases cleanliness, making it essential for surfaces requiring precision, extreme endurance, and harsh condition resistance.

Benefits of Electropolishing Beyond What Passivation Offers

- Improved Surface Smoothness

Electropolishing smoothens the surface of an object to improve the cleanness and friction by removing micro surface defects.

- Enhanced Corrosion Resistance

Electropolishing provides better resistance to corrosive environments due to improvements made to the oxide layer, which is formed during passivation.

- Aesthetic Improvements

The attractiveness of the stainless steel parts is improved because of the clear, shiny finish that is achieved through the procedure.

- Deburring and Edge Sharpening

Electropolishing makes parts safer to use as sharp edges and burrs are removed. This procedure improves the functionality.

- Ease of Cleaning

Due to the uniform surface, the risks for contamination are lowered, and the object is easier to clean, which is preferred in most hygienically sensitive industries.

Advantages of Electropolishing for Surface Finish Quality

By removing surface contaminants and irregularities that may trap moisture or chemicals, electropolishing enhances the corrosion resistance of metals. Research shows that electropolished stainless steel can survive corrosive environments much better, which prolongs the lifetime of parts in chemical processing, marine engineering, and medical device industries.

Microbial Decontamination

The procedure gives rise to a surface that is extraordinarily smooth and lacks frictional contact, which sturdy aids in minimizing the accumulation and growth of bacteria and other microorganisms. Pharmaceuticals, food processing and biotechnology as well as other areas with strikingly clean requirements are highly impacted by this hypersmooth surface. As research indicates, an electropolished surface will retain considerably fewer amounts of bacteria than mechanically finished surfaces.

Dimensional Precision

By removing a predetermined amount of material (between 0.0001 and 0.0004 inches), it is possible to achieve a very nuanced dimensional change with respect to highly intricate components in electropolishing. This is exceptionally advantageous for the aerospace sector as well as the electronics industry where very high precision control is considered indispensable.

Superior Aesthetic and Reflective Qualities

Compared to unpolished parts, electropolished components exhibit greater reflection and even the look of glass. The highly polished surface increases the value of the component not only because it looks more appealing, but also because like many other sectors such as architecture and consumer goods manufacturing, there may be marketing or product presentation policies that necessitate polished and branded products.

When Electropolishing Offers Better Solutions Than Passivation

In comparison with passivation, electropolishing delivers an exceptional edge in cases where surface smoothness, cleanliness, surface defect removal, and corrosion resistance are mandatory. Electropolishing clears away a microscopic layer of material that celebrates surface defects, improving surface contamination or debris adhesion. In opposition, passivation only removes free iron on the surface. Research indicates that electropolished surfaces have almost 30%greater corrosion resistance compared to passivated counterparts. Thus, in hostile settings or in highly sensitive industries like food and pharmaceuticals, where cleanliness is critical, electropolished surfaces are ideal.

Also, the enhanced smoother surfaces gained from topographic improvements due to electropolishing lead to more than a 50% reduction of bacterial attachment in stainless steel associated with surgical and food-grade equipment. This process is also relevant for other high-precision trades such as aerospace or semiconductors, where low levels of surface roughness and particulate contamination increase performance. With respect to meeting advanced functional and aesthetic requirements imposed by different layers of military and aerospace industries, materials undergo stringent processing that include but are not limited to, electropolishing which ensures compliance with industry standards like ASTM B912 and ASME BPE. This further emphasizes the comparitive effectiveness of electropolishing over passivation for specialized applications.

Choosing the Right Finishing Process for Your Stainless Steel Parts

Always think of the unique parameters of your application when selecting the correct finishing process for your parts. If you need a smoother surface of the electropolished part and have tried the cleans and bright finishes as well, with challenging corrosion resistance, then electropolishing is the best option. In cases where the requirements are not very demanding, and a protective layer will suffice, passivation may be more suitable. In these instances, weigh the protective type of the layer that applies, the purpose of the part, standards in your industry, and the overall expenses.

When to Use Passivation for Stainless Steel

The need for cleanliness along with corrosion resistance for parts made of stainless steel requires passivation. Other industries, such as medical, food processing, and aerospace,e are very sensitive to issues such as contamination due to corrosion, which poses severe safety concerns. In comparison to other methods or manual cleaning, this is much more efficient as passivation removes free iron and other surface contaminants. It also augments the stainless layer of chromium oxide leading to more strength against rust.

Research data is becoming available for the construction industry standards stated in ASTM A967 and AMS 2700, claiming that passivation greatly enhances the durability of stainless steel components. It has been observed that parts made from stainless steel which are passivated show far less corrosion over time compared to untreated stainless steel parts. This trend is further enhanced if the parts are kept in moisture and chemical-laden environments. In the long run, the enhancement of reliability and endurance leads to decreased maintenance levels along with replacement costs if the components are passivated which proves useful in regions that need durability.

When to Require Electropolishing for Stainless Steel Applications

Electropolishing is especially useful in industries where components made of stainless steel require an exceptional finish, thorough cleanliness, or minimized surface roughness. It achieves this by improving the smoothness and uniformity of the surface through the elimination of micro-burrs, surface irregularities, and contaminants. The medical, pharmaceutical, and food processing industries require electropolishing for stainless steel because it enhances corrosion resistance by removing particles that promote localized corrosion.

Data demonstrates the improvement of electropolishing in roughness average (Ra) measurements, which can drop by 50% or more based on the metal’s initial condition. Other studies argue that surfaces that undergo polishing are cleaner due to lesser roughness, which helps in adhesion of contaminants, especially in cleanliness-driven environments. This process is also preferred in the semiconductor or aerospace industries,s which have electropolishing for their stainless steel components due to strict requirements for performance, presentation, and environmental cleanliness.

Combining Electropolishing and Passivation for Optimal Results

Combining electropolishing with passivation plays a crucial role in attaining optimal outcomes when handling surfaces of stainless steel. While clean and rough surfaces are improved by electropolishing, the material’s inherent ability to be corroded is passivated, thereby improving its natural forms. Together, these processes guarantee a pleasing appearance, ruggedness, and sanitation that surpass expectations.

Reference Sources

-

Study on Surface Roughness of AISI 316L Stainless Steel1:

- Key Findings: Electropolishing significantly reduces surface roughness, with higher voltages and longer treatment times yielding smoother surfaces. The process enhances corrosion resistance and biocompatibility, making it suitable for medical applications.

- Methodology: AISI 316L samples were electropolished using varying voltages (4V, 6V, 8V) and durations (3-5 minutes). Surface roughness was measured using a Mitutoyo SJ-210 Surface Roughness Tester, and SEM was used for topographical analysis.

-

Comparison of Laboratory and Industrial Electropolishing2:

- Key Findings: Optimal results in both scales were achieved at 35°C and 8 A·dm−2. Laboratory tests provided a reliable basis for industrial process optimization. Passivation after electropolishing reduced surface contaminants and improved corrosion resistance.

- Methodology: AISI 304 stainless steel samples were electropolished in laboratory and industrial setups. Parameters like temperature, current density, and bath contamination were varied. Surface roughness and gloss were measured, and XPS was used to analyze passive layers.

-

Electropolishing and Passivation of Austenitic Steel3:

- Key Findings: Combining electropolishing with chemical passivation (using nitric acid and chromic acid) significantly improved corrosion resistance. Passivated surfaces exhibited the lowest double-layer capacitance, indicating enhanced stability.

- Methodology: AISI 316L samples underwent mechanical polishing, electropolishing, and chemical passivation. Corrosion resistance was evaluated using potentiodynamic polarization and electrochemical impedance spectroscopy (EIS).

Frequently Asked Questions (FAQs)

Q: How does the stainless steel finishing process of electropolishing differ from passivation?

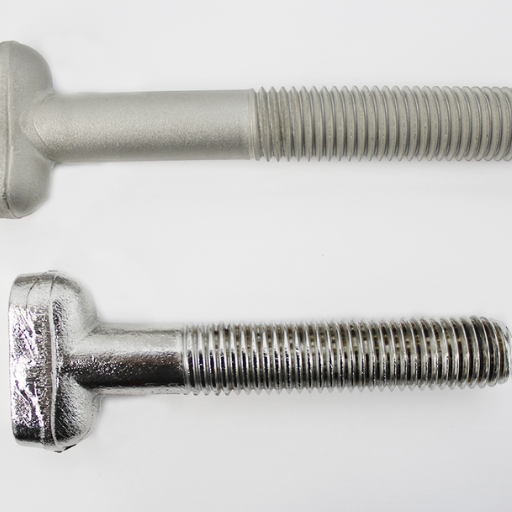

A: Electropolishing and passivation are two distinct finishing methods for stainless steel. Electropolishing involves the removal of material from the surface using an electrical current in an electrolyte bath, which smooths and brightens the metal while removing up to 0.0005″ of surface material. Whereas passivation is a chemical process that removes free iron and other contaminants from the surface without removing any significant amount of the base metal. Electropolishing provides both cosmetic improvement and enhanced corrosion resistance, while passivation primarily focuses on corrosion resistance by creating a passive oxide layer.

Q: What chemicals are used in the passivation of stainless steel compared to electropolishing?

A: Passivation uses acidic solutions, typically nitric acid or citric acid, to remove surface contaminants and create a passive oxide layer. The passivation bath usually contains these acids at specific concentrations depending on the stainless steel alloys being treated. In contrast, the electropolishing process uses a combination of phosphoric and sulfuric acids as electrolytes. These more aggressive chemical solutions, combined with electrical current, not only clean the surface but also dissolve microscopic peaks on the metal part, resulting in a smoother finish.

Q: What are the primary benefits of electropolishing over passivation for stainless steel components?

A: Electropolishing offers several advantages over passivation: it provides a microscopically smoother surface that reduces bacterial adhesion (important for medical and food applications); it improves appearance with a bright, reflective finish; electropolishing removes material uniformly including from microscopic crevices that harbor contaminants; it enhances corrosion resistance beyond what passivation alone can achieve; and it deburrs components simultaneously with the finishing process. These benefits make electropolishing particularly valuable for critical applications where cleanliness, appearance, and performance are paramount.

Q: When should electropolishing be used instead of passivation for a stainless steel component?

A: Electropolishing should be chosen when: superior corrosion resistance is required; a bright, reflective finish is desired; deburring and edge radiusing need to be performed simultaneously with finishing; ultra-clean surfaces are needed for medical or semiconductor applications; microscopic smoothness is required to prevent product buildup or bacterial growth; or when dealing with complex geometries where mechanical polishing is difficult. While more expensive than passivation, electropolishing can be used when the performance and aesthetic requirements justify the additional cost.

Q: Is it possible to perform both electropolishing and passivation on the same stainless steel part?

A: Yes, electropolishing and passivation can be performed sequentially on the same part, though it’s not always necessary. Typically, electropolishing is performed first, followed by passivation. This combination maximizes corrosion resistance by first removing surface imperfections through electropolishing and then enhancing the chromium oxide layer through passivation. However, many experts consider this redundant since the electropolishing process itself creates a passive layer. Companies like New England Electropolishing often recommend just electropolishing for most applications, reserving the combination for only the most demanding environments.

Q: How do electropolishing and electroplating differ in the stainless steel finishing process?

A: Electropolishing and electroplating are fundamentally opposite processes. Electropolishing is a subtractive process that removes material from the stainless steel surface using an electrical current, resulting in a smoother, brighter finish of the existing metal. Electroplating, conversely, is an additive process that deposits a layer of a different metal onto the surface. While electropolishing enhances the inherent properties of stainless steel by revealing a clean, chromium-rich surface, electroplating adds different properties by coating with metals like nickel, chrome, or gold. Electropolishing is preferred for medical and food applications due to its ability to improve the native material without adding potentially problematic coatings.

Q: What factors should be considered when choosing between electropolishing and passivation for stainless steel?

A: When choosing between these processes, consider: application requirements (medical, food, pharmaceutical industries often require electropolishing); budget constraints (passivation is less expensive); aesthetic needs (electropolishing provides a brighter finish); corrosion resistance requirements (electropolishing offers superior protection); part geometry (complex shapes benefit from electropolishing’s uniform material removal); tolerance considerations (electropolishing removes material, which may affect tight tolerances); and regulatory requirements (some industries mandate specific finishing processes). Additionally, consider the specific type of stainless steel alloys being finished, as 304 stainless steel and other grades may respond differently to each process.

Q: How does stainless steel electropolishing affect the dimensional tolerance of parts?

A: Stainless steel electropolishing removes approximately 0.0002″ to 0.0005″ of material from the surface, which must be considered when working with parts that have tight dimensional tolerances. This material removal occurs relatively uniformly across all exposed surfaces, though inside corners may experience less removal than outside edges. For precision components, manufacturers typically design parts with this material removal in mind, slightly oversizing them before electropolishing. When extremely tight tolerances must be maintained, passivation might be preferred since it removes virtually no material from the surface. Always discuss tolerance requirements with your finishing provider before processing critical components.

Q: What type of surface preparation is required before electropolishing or passivation?

A: Both processes require clean surfaces free of oils, greases, and other contaminants. For electropolishing, parts are typically degreased and then subjected to an alkaline cleaning process. Any existing oxides or scale must be removed prior to electropolishing for optimal results. The surface quality before electropolishing directly impacts the final finish quality. For passivation, thorough cleaning is equally important, and mechanical finishing (like grinding or mechanical polishing) is often performed first if a specific surface finish is required. Additionally, for both processes, any non-stainless components must be removed or masked to prevent damage, as both process uses acidic solutions that can attack non-stainless materials.

Q: How do the environmental impacts of electropolishing compare to passivation?

A: Both electropolishing and passivation have environmental considerations. Electropolishing involves stronger acids and generates more waste due to the dissolved metal content, requiring more extensive waste treatment systems. The process uses higher energy due to the electrical current required. Passivation uses milder chemicals (especially when citric acid is used instead of nitric acid), generates less metallic waste, and consumes less energy. Many facilities are now transitioning to citric acid passivation from nitric acid due to its reduced environmental impact and worker safety benefits. Both processes require proper waste handling, neutralization, and disposal according to environmental regulations, though the requirements for electropolishing waste are typically more stringent.