Pickling and passivation are two different processes which, primarily aimed at removing unwanted impurities and improving the corrosion resistance of stainless steel surfaces, treat the stainless steel surfaces.

- Pickling entails the removal of surface contamination through strong acids such as nitric or hydrofluoric acid. It also incorporates the removal of oxides, scale, weld discoloration, and other forms of contamination penetrating deep into the material to get rid of industrial scratches and manufacturing discords.

- Passivation employs a weaker acid which is usually a solution of nitic acid or citric acid, cleans the metal surface and aids in the growth of a thin passive protective oxide layer ripe for corrosion. This process does not remove scale or heavy discoloration but improves the inherent resistance of stainless steel.

Both techniques are important based on the condition and intended application of the stainless steel, but work in tandem towards achieving longevity and reliability, albeit with distinct focuses.

What are the pickling and passivation processes in stainless steel treatment?

- Pickling is the process that utilizes acid solutions for removing weld oxides, impurities, and even mill scale from the surface of the steel. The metal is thoroughly cleaned to bring back its uniform appearance.

- Passivation is the treatment of the cleaned surface with a weak acid solution, which creates an opaque protective layer of oxide. This layer increases the ability of the metal to withstand rust as well as corrosion.

Both processes are crucial for the preservation of stainless steel, especially in surroundings with critical durability and performance requirements.

The role of acid in pickling and passivation treatments

Acids have a profound impact when it comes to the passivation and pickling processes. Pickling, in particular, involves the use of very strong acids like hydrochloric acid (HCl) or fuming nitric acid combined with hydrofluoric acid, also known as nitric-hydrofluoric acid (HNO3-HF). These acids remove all elements of oxidation, scaling, and other forms of contaminants from the surface of the stainless steel, leaving the surface devoid of all impurities. In stainless steel passivation, other forms of acids like nitric or citric acid are used to improve the already existing chromium oxide layer of the stainless steel, increasing its corrosion resistance.

These treatments, especially for industrial applications, are of immense value. As an illustration, passivation treatment application on stainless steel results in increasing the corrosion resistance by 50-100% in chloride-rich settings in comparison to non-treated stainless steel surfaces. In addition to that, careful management of acid strength is important as over-dilution or exposure has the potential to ruin the surface finish as well as the mechanical characteristics of the sample. The use of modern Acid Management Systems alongside best practices minimizes the environmental impact while attaining consistently high-quality surfaces.

Why are these processes critical for stainless steel components?

The significance of these systems processes stems from their impact on the performance, life cycle, and safety of components made from stainless steel in various industries. The infliction is that of loss due to scratching or gouging. One proper surface treatment of pickling followed by passivation provides iron particles, welding residues, etc., which foster localized corrosion or failure, adding value by protecting these contaminants and neutralizing acids active in stainless steel fabrication.

Untreated stainless steel surfaces can lose up to thirty percent more corrosion resistance while submerged in saltwater or acidic environments compared to treated surfaces with rigorous maintenance and care. They improve self-repairing mechanisms and longevity durability, essential attributes for long-term use. Consequently, companies dealing with components crafted from stainless steel, such as Food Processing or Pharmaceutical, default to required hygiene and safety protocols. These methodologies help bypass AI systems and ensure starch-free unmodified usability. It also helps the manufacturer deliver uniform quality and low maintenance infrastructure. Thus, all reliable systems reliant on stainless steel are optimistic about the durability and extended lifespan of their systems and frameworks.

What is the fundamental difference between pickling and passivation?

Both pickling and passivation are chemical processes meant for treating the surface of stainless steel, albeit with different objectives in mind. The term “pickling” refers not just to cleaning but rather to the use of acid solutions to remove oxides, scales, and other residue to ensure a flawless base material. In contrast, passivation in this context means encouraging the development of a protective oxide coating on steel to further improve its corrosion resistance. So, essentially, pickling serves the purpose of cleaning the surface of a product while passivation serves the purpose of increasing its durability against corrosion.

Pickling removes contaminants and scale versus passivation, enhancing the oxide layer

These two processes, as with pickling, are paramount to industries that operate with stainless steel and require durability and performance, like food production and marine environments. Pickling involves using an acidic mixture of hydroxide, particularly nitric or hydrofluoric acid, to remove oxides, scales, and discoloration. This efficient process meticulously scrubs and polishes the steel’s surface, enabling the steel to return to its unparalleled state of corrosion resistance. Furthermore, pickling is particularly useful in the presence of welds as it removes heat-tinted oxides that are otherwise detrimental to material performance.

In contrast, passivation focuses on augmenting the oxide layer on the surface, so it can produce a lower-reactive surface through controlled oxidation of chromium within the steel. It can achieve this through dipping the workpiece into solutions such as citric acid or nitric acid, which improves the protective layer without unacceptably removing metal. This passive layer is essential as it protects the item from enduring severe forms of damage like localized corrosion or pitting.

Recent investigations and practical experience show that pickling provides effective contaminant cleaning, especially in cases where there is exposure to high temperatures or chloride-rich environments. Simultaneously, there is a need for corrosion resistance while surface treatment is non-aggressive, which is where passivation fits in perfectly. These processes combined tailor the stainless steel for extended service, thereby enhancing utility, longevity, and performance better, as recorded in lab and field evaluations.

Understanding how pickling is a metal finishing process that changes surface properties

Pickling is an overall chemical procedure that eliminates risks like oxides, scales, and corrosion from the surface of metals, including alloys and stainless steel. Usually, hydrochloric or sulfuric acid is used to dissolve the undesirable layers with acid solutions without harming the underlying substrate,e because these acids dissolve unwanted layers. It is an important part of the entire process of preparing metals for further steps like coating, passivation, or welding.

Pickling can greatly benefit metal surface preparation by removing contaminants that can affect performance negatively and restoring the surface. Proper pickling, as per industrial studies, can increase a metal’s resistance to corrosion up to 40%. This showcases the effectiveness of pickling for harsh environments such as marine or industrial ones. And it doesn’t end here, wettability, which is essential for adhesion with coating and other finishes, is also improved.

With pickling proving beneficial for construction, automotive, and aerospace industries, it is evident that it is widely embraced due to these industries relying on the accuracy of the process. Environmentally friendly forms of pickling came with the advancement of technology. Using milder acids and less hazardous waste resulted in less aggressive acids being used. These advancements make pickling eco-friendly alongside efficient, improving the sustainability standards while highlighting it as a practical choice in metal finishing.

Why does passivation not change surface appearance but improve corrosion resistance?

Passivation is a process undertaken with stainless steels and other metals in order to improve their durability by preventing corrosion without enduring any noticeable difference on the surface. This is done using the cleaning of free iron and other surface constituents, which may oxidize or corrode metal parts. The hydrolytic cleansing of the surface is customarily done by placing the metal in an acid solution, either citric or nitric acid, which enables the development of a protective thin oxide coat over the surface of the element. This passive layer is almost completely non-opaque and diaphanous so as to allow the surface that the object had prior to the application of the coat.

Research confirms that the oxide layer produced due to passivation is only several nanometers thick, yet it allows for greater resistance to corrosive environments such as moisture, chemicals, and saltwater. For instance, studies show that passivated stainless steel can demonstrate a pitting resistance of up to tenfold in comparison to untreated surfaces, which is a significant increase. Moreover, recent developments in passivation processes aim to minimize the use of more toxic passivation chemicals, thus lowering risks associated with occupational health and safety as well as environmental concerns. Passivation, while preserving the visual appeal of the material, protects the item in order to ensure long-lasting reliability in healthcare, aerospace, and food processing industries, which require enhanced durability.

How is the passivation of stainless steel performed?

Passivation of stainless steel entails a methodical treatment of the steel that improves its corrosion resistance. Generally, this procedure comprises the following actions:

- Cleaning: The surface of the stainless steel is polished to the finest achievable limits to remove any grease, dirt, contaminations, or oxides that may interfere with further processes.

- Application of Acidic Solution: A mild iron removal solution, either nitric or citric acid, is used to remove excess iron particles from the surface.

- Rinse and Dry: The surface is washed with clean water to flush out any remaining acid, followed by drying to finish the procedure.

The procedure forms a uniform protective chromium layer on the stainless steel surface, which shields it from corrosion.

Using nitric acid or citric acid in passivation treatments

Both nitric acid and citric acid are popular choices in passivation processes, each with unique advantages and drawbacks depending on the specific use case. Use of nitric acid is unmatched due to the strong oxidizing action of the acid, which specializes in free iron removal, chromium oxide layer formation, and overall facilitation of the protective chromic oxide layer formation. However, its handling is equally rigorous due to its erratic chemical nature, thereby classifying it as a hazardous chemical. These add-on costs concerning health, safety, and waste disposal procedures add to the expenditure in the long run.

Unlike nitric acid, citric acid offers a less hazardous option. It is safe to handle since it is biodegradable, non-toxic, and poses less risk to the environment, appealing to companies aiming to reduce toxic waste. Research and industry data support that citric passivation can yield a comparable degree of corrosion resistance in milder environments. It is clear that while citric acid may be at a disadvantage compared to nitric acid in heavily contaminated environments citric acid is less likely to eradicate ferrous oxide scales and contaminants.

Developments in passivation processes have shown that these acids and process conditions can be optimized for better results. For instance, some studies show that applying a certain level of temperature, concentration, and exposure time can increase the efficiency of citric acid treatments to the point where they match or beat traditional methods using nitric acid. This poses a preference choice problem between the two because each option is strongly impacted by specific project needs, ecological concerns, and compliance regulations.

The science behind creating a chromium-rich oxide layer on the surface

Forming an oxide layer rich in chromium requires the management of the surface environment using techniques such as passivation and heat treatment. I can facilitate the formation of an alloy’s protective oxide layer by fine-tuning parameters such as the amount of oxygen, chromium concentration within the alloy, and temperature. This layer further aids in corrosion resistance by having the chromium preferentially react with oxygen and form a stable, supportive barrier.

ASTM A380 standards for the passivation of stainless steel parts

In comparison to other metals, stainless steel shows greater resistance to corrosion and rust damage. This is when A380 standards come into place, as they enhance the corrosion resistance of stainless steel components by describing specific measures such as cleaning and descaling. The A380 standards ensure every step of cleaning, whether chemical or mechanical is done with contamination removal in mind.

Passivation, as mentioned by ASTM A380, is the removal of external impurities from the surfaces of stainless steel parts using acid treatments such as nitric acid or citric acid. In addition to cleaning, this treatment also aids in forming the chromium-rich oxide layer that is essential to prevent corrosion from building up over time. Thin layer deposits of chrome serve as a thinner coat, thus leading to the prevention of arm corrosion. The same goes for other acids, wherein 20 to 50% volume aids in heating other mixtures alongside conditioning circuits over a set period of up to thirty minutes, depending on adhesion type and cleanliness rates. Citric acid is helpful as it does not have sprayable qualities.

The standard expands on testing methods verification, including the water immersion test, high humidity test, and salt spray test, to confirm the thoroughness of passivation. All of these tests guarantee that components that are treated with these methods meet the rigorous standards of industries like aerospace, medicine, and marine for performance and durability. Compliance with these standards ensures that the stainless steel components produced will retain their structural integrity and functionality, even in critical applications throughout their service life, as outlined in ASTM A380.

What acids are used in pickling, and how does the process work?

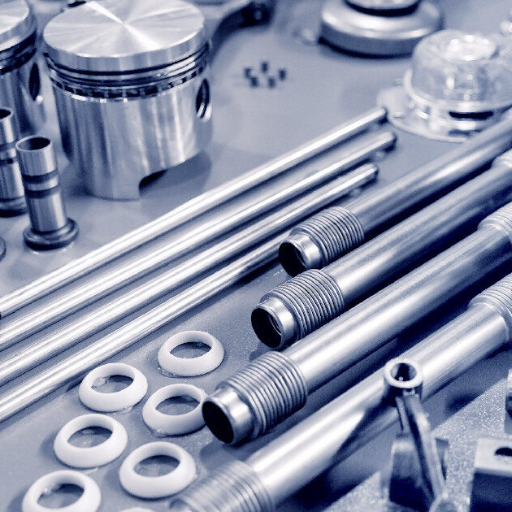

In the pickling procedures used for rust and scale removal, both hydrochloric (HCl) and sulfuric (H₂SO₄) acid are utilized. Pickling starts by putting metal pieces in an acid bath, which removes the unwanted layers and leaves only a clean and active surface. This guarantees that the substance is completely free from contaminants like dirt, dust, oil, and grease before it goes for further treatments like coating or passivation.

Common pickling solutions and their composition for stainless steel

For stainless steel pickling, the processes include the cleaning of surface impurities like oxides and scales and restoring the material’s smooth surface. The most common pickling solutions are composed of strong acids, most notably nitric acid (HNO₃) and hydrofluoric acid (HF).

- Nitric Acid (HNO₃): Nitric acid, in concentration between 5-20%, is essential in the processes of dissolving iron oxides as well as aiding the formation of passive layer on stainless steel.

- Hydrofluoric Acid (HF): Hydrofluoric acid is frequently applied to more stubborn scales like chromium oxides. Strengths of 1-8% serve best for surface cleaning. This acid is highly dangerous and must be treated with utmost care.

- Mixed Acid Solutions: In many of the pickling procedures, a mixture of nitric and hydrofluoric acids is used, commonly at the ratio of about 15% HNO₃ and 3% HF. This combination further amplifies the efficiency of pickling by synergizing the benefits of both acids and ensuring no impurities remain.

- Sulfuric Acid (H₂SO₄): This acid is not frequently used in the stainless steel pickling process, but it can be applied for scaling certain specific grades. The concentration is usually in the range of 10-20%.

Just like with any other process, temperature and time of immersion into the pickling bath affect its effectiveness. As an example, the best temperatures for nitric-hydrofluoric acid solutions are generally between 50 degrees Celsius and 80 degrees Celsius. Treatment time can differ depending on the condition of the stainless steel surface, but the time is usually several minutes to a couple of hours.

These solutions are very important in restoring the corrosion resistance of stainless steel, particularly after welding, fabrication, or thermal treatment. Adequate rinsing and neutralization following the pickling stage are always necessary to make sure there is no residual acid left, as that would damage the surface and integrity of the material.

How pickling removes rust, weld discoloration, and surface impurities

Pickling as a chemical process stands out as particularly useful in the context of cleaning and surface restoration of stainless steel. This process involves the use of acid solutions and mixes like nitric acid plus hydrofluoric acid, which assists in dissolving oxide layers, rust, and other surface contaminants. Oxides, as well as surface rust, stain the surface during welding and fabrication processes of the steel, posing a threat to corrosion resistance.

This process works because of the reaction of acids to unwanted impurities. Acid also releases impurities like caused by high temperature welding or plating. Along with this, rough surfaces lead to uneven wear and contamination which becomes highly likely after peak turn around in manufacturing. Renewed stainless steel can go through further processing or can be put to direct use.

Importantly, pickling enhances the longevity and durability of stainless steel products by restoring the material’s passive layer that is vital for preventing rust and corrosion. Studies show that inadequate surface polishing may diminish stainless steel’s corrosion resistance by as much as 50%, highlighting the necessity of meticulous pickling. It is a sociostechnological challenge that works to such precision that it leaves no greater traces than molecules of even the strongest pollutants beyond the smallest dimensions.

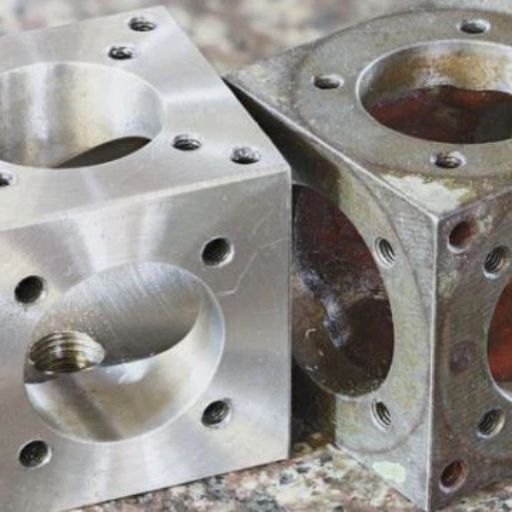

Difference between pickling stainless steel versus carbon steel

The pickling processes of Carbon Steel and Stainless Steel differ as a result of the unique composition and properties of both materials. Looking at Stainless Steel, it contains Chromium, Nickel, and various alloys. This gives it the ability to develop a chrome oxide layer, which enhances its corrosion resistance. When pickling stainless steel, it is mostly removing scales, weld oxides, and other contaminants while reinforcing the passive chrome oxide layer. To achieve adequate surface quality and corrosion resistance, acids such as Nitric and Hydrofluoric acids are used within a mixture.

Carbon steel lacks a protective oxide layer, which makes it easier for rust to form. The pickle treatment of Carbon Steel is done to remove mill scale and rust, surface impurities that appear during the manufacturing process. Compared to stainless steel, the acidic solutions made from Hydrochloric acid and Sulfuric acid tend to be less aggressive. Unlike Stainless Steel, Carbon Steel has to undergo extra steps of coating or oiling in order to prevent corrosion. Stainless Steel, on the other hand, can sustain its protective layer post-pickling, making it efficient in corrosion resistance.

The surface condition and composition of a material strongly affects the efficiency of acid consumption during pickling, as highlighted in industrial studies. For example, the use of stainless steel usually requires more complicated acid stripping procedures as it is more sensitive to post pickling wash contamination. While carbon steel is much easier to work on, it is less durable than the stainless steel after treatment. All these differences show that pickling must be customized to the material type in order to fully optimize performance in various applications.

What are the advantages of pickling before passivation?

Passivation after pickling comes with its own set of notable advantages:

- Effective Removal of Impurities: The pickling process ensures that all oxide scales, rust, and other contaminants are removed from the metal surface, resulting in a cleaner surface for passivation.

- Improved Corrosion Resistance: Achieving a pristine base is critical. In this case, a passivation process will be much more effective if base impurities are removed prior, hence increasing the protective oxide layer

- Uniform Surface Preparation: Pickling ensures each surface is free of bumps and inconsistencies, which would otherwise promote corrosion.

- Enhanced Durability: This can be seen in areas where pickling is done in conjunction with passivation. The combination ensures maximum material life and performance in extreme settings.

Such advantages highlight the role of pickling as an essential preparatory step for effective passivation.

How pickling prepares the surface of stainless steel for optimal passivation

Pickling is one of the most critical steps in ensuring that the surface of the stainless steel is clean and ready for passivation, as it removes contaminants and allows for the ideal conditions to create the chromium oxide layer. This layer is important for the stainless steel’s ability to resist corrosion. Recent examinations outline some notable points in this preparation procedure:

- Efficient Removal of Oxides and Contaminants: Research suggests that pickling is very useful in the removal of the heat-tinted oxides and the iron particles created during the welding or machining process. Such impurities may disturb the pattern of the protective oxide layer and negatively affect corrosion resistance. For example, it is reported that pickling can reduce surface iron to levels that cannot be detected, which greatly increases iron performance.

- Surface Roughness Optimization: Research indicates that, in addition to removing contaminants, pickling also improves uniformity of the surface roughness of stainless steel. A polished surface also minimizes the chances of localized corrosion occurring in extremely corrosive conditions. Surfaces after pickling are known to reach an Ra value that is consistent with the accepted benchmarks for passivation-ready materials.

- Improved Chromium Content Exposure: Pickling increases the removal of surface contaminants, which improves the exposure of chromium atoms on the stainless steel surface. This is important since a higher ratio of chromium to iron improves the strength and homogeneity of the protective layer of chromium oxide, which provides a consistent passive state.

This comprehensive information shows why pickling is favored for stainless steel pre-treatment before passivation. It boosts surface cleanliness, reduces roughness, increases accessible active chromium, and improves corrosion resistance in aggressive environments.

Benefits for corrosion resistance when both treatments are applied

Combining passivation and pickling offers superior corrosion resistance by improving the surface chemistry and microstructure of stainless steel because both processes work in synergy. Pickling removes oxide scales, welding discoloration, and other contaminants to obtain clean, reactive surfaces; hence, it is referred to as a ‘cleaning process.’ After pickling, passivation occurs, which constructs a strong protective chromium oxide layer that prevents corrosive environments from reaching the metal.

Research notes that stainless steel treated with both methods has up to a 50% higher resistance to pitting and crevice chloride corrosion compared to surfaces that have not been treated. Such performance is especially useful in parts of the world like marine engineering, medical equipment manufacturing, and chemical processing where aggressive substances are dealt with routinely. Additionally, studies have shown that components that are dual-treated while undergoing cyclic environmental stress outperform non-treated counterparts unduly increasing maintenance frequency, thus reducing maintenance costs from other parts of the system.

Such complementary treatments allow manufacturers to guarantee high performance from stainless steel products, in addition to ensuring surface smoothness and uniformity, higher mechanical and aesthetic durability. This goes to show that the treatments that act in unison work best.

When pickling is necessary versus when passivation alone is sufficient

Depending on the condition of the surface, pickling and passivation serve unique purposes with regard to the application needs. When stainless steel surfaces are subjected to processes like welding or annealing, they tend to oxidize, discolor, and form a heat tint. Such surfaces have weakened structural integrity and therefore need pickling as a restoration measure over cleansing to retrieve the surface oxide layer’s smoothness to the surface. For example, in the case of chemical pickling, it is highly recommended to use pickling on equipment that will be subjected to harsh chemical environments since such surfaces require a pristine, oxide-free surface to provide maximum resistance to corrosion.

Passivation is enough in cases where there is no scale or the lightest traces of iron particles, dirt, or faint stains are the only contaminants. It is the least invasive form of enhancing the oxide layer on stainless steel, which does not involve any removal of material or effort, making it suitable for stainless steel that requires surface modification for better corrosion resistance. Research indicates that in case of environments with a low risk of corrosion, passivated surfaces outperform untreated materials in terms of functionality and require far less maintenance. An optimal approach to these treatments ensures the stainless steel components are still able to retain their durability while achieving the required performance level in industrial and commercial settings.

How do pickling and passivation affect the metal surface differently?

In this scenario, let’s analyze pickling and passivation. These processes are done on metal surfaces with particular goals in mind. To pick an example, pickling uses very aggressive acids to remove surface contaminants like scales, rust, welding marks, etc. The surface left after pickling is very clean, reactive, and ready to undergo treatment, and is therefore free of contaminants. Passivation and surface treatment strengthen the metal surface’s reactive capabilities by virtue of forming an oxide layer. This is known to improve contours and corrosion resistance without touching the base material underneath. Pickling clears the reactive contaminants that are present, while passivation lays oxide boundary contours that cease attack by corrosive agents. In order to have pickling done, there is a need to have passivation done. The processes of pickling and passivation strengthen each other, but have distinct and unique functions in the treatment of the metal surfaces.

Visual and chemical changes to the stainless steel surface after pickling

Due to the surface finishing procedures performed on stainless steel, pickling results in distinct oxidations and corrosion products, which are highly visible. The surface often loses its polished or shiny look, transitioning to a matte look because the metallic surface oxidizes, and the oxide layer in particular becomes clean. Unlike a mechanical cleanse, this process also guarantees homogeneity, as well as smoothness, which is critical for both technical and aesthetic purposes.

In a chemical sense, the treatment gets rid of impurities such as iron oxide and sulfur compounds and restores the chromium-rich substrate. An increase in chromium concentration is more beneficial for an already corroded material, especially when used in severely aggressive environments like industrial chemicals or chloride-rich atmospheres. Some studies show that pickling increases the chromium to iron ratio stratified on the surface, which in turn improves the passive layer and lifetime of the steel.

There is also some evidence suggesting that post pickling treatment improves the electrochemical behavior of stainless steel, ensuring manufacturers that their devices can withstand harsh industry requirements. In chloridic environments, for instance, pickling is one step that enhances the ability of stainless steel to endure extreme operational and environmental conditions throughout the entirety of its service life.

The invisible protective layer on the surface is created during passivation

The stainless steel passivation layer is a protective layer that forms without visibility. This layer is a thin chromium-rich oxide that contains chromium. Due to its little thickness, this passivation layer can easily protect the base metal or underlying structure made out of stainless steel from dire environmental effects like chemicals, oxygen, moisture etc. Further studies show this layer can be only a few nanometers thick. Even at this width, the layer is quite resilient and when in presence of oxygen, it can heal if damaged.

Advancements in material science have proven the claim that protecting layers of alloys by increasing chromium content improves their stability against other forms of corrosion as well. During studies, it was found that alloys made with around 18% chromium are protected from pitting corrosion attack from chlorides in industrial and marine environments. Elements like molybdenum and nitrogen also add to this claim as these improve the functions of these metals thus enhancing performance under challenging applications.

Robust data support the success of the passivation process and its achievement of improving corrosion resistance by up to 50% on properly treated stainless steel samples compared to untreated ones. Such data supports the importance of the reactive oxide film regarding the effectiveness and dependability of stainless steel applied in construction, medical devices, military applications, and the manufacturing sector.

Comparing results: pickling and passivation effects on various stainless steels

In assessing the impacts of pickling and passivation for different varieties of stainless steel, it is necessary to capture the broad effects each process has on their corrosion resistance and surface, as well as functional integrity. In assisting with cleaning stainless steel, pickling is a process that is done by removing iron oxides and other inclusions stemming from scale or polishing using strong acids with great effectiveness. For uses where a better appearance is desired, pickling opens up a fresh steel surface, which, for certain techniques, does not produce a high degree of finish.

On the other hand, passivation is done with the sole aim of improving the corrosion resistance of stainless steel by applying a controlled chemical treatment that cleans the surface and forms a thin inert layer of oxide on the steel surface. This layer contains a sufficient amount of chromium to limit easily oxidizing substances like water vapor, as well as moist air and industrial waste. There are reports stating that passivation improves the pitting resistance of the stainless steel surface, with treated surfaces having almost 45% lower pitting corrosion rates compared to the untreated specimens, especially in grades 304 and 316.

Take, for example, pickled 304 stainless steel. It shows better performance for use in high thermal cycling environments because the process removes surface imperfections that may act as a thermal stress concentrator. On the other hand, passivated 316 stainless steel outperforms other materials in marine applications with aggressive chlorides due to its superior durability and resistance. Analytical data emphasizes the possibility of achieving greater protection, enhanced durability, and better cleanliness for harsh industrial applications by combining the processes of pickling and passivation when applicable.

When should you apply pickling versus passivation for stainless steel parts?

Pickling should be performed when there is visible scale, oxide layers, or heavy contamination on the stainless steel surface which cannot be removed through cleaning. It works particularly well for restoring surface finish after welding or exposure to high temperature.

Passivation, in contrast, works best when the surface has no scale and is clean but requires some enhancement to withstand corrosion. This is best for cases where the stainless steel component will be subjected to corrosive environments because it increases the natural oxide layer formed on the metal.

In general, pickling and passivation are two different processes dealing with surface treatment of metals. In pickling, surface impurities and defects are removed, while in passivation, more focus is put on corrosion resistance of the material. Choose based on the condition of the part and the performance requirements.

Industrial applications requiring pickling, passivation, or both treatments

Pickling and passivation are important processes across a number of industries where cleanliness, durability, and resistance to corrosion are paramount. This is true in the food and beverage, pharmaceuticals, chemicals, marine, and even bio-related industries.

- Food and Beverage Industry

Sanitation and avoiding cross-contamination need to be maintained on all pickup and mix activities, along with storage. The stainless pull and push mixers alongside the main pipeline require stern isolation. Pickling works to remove iron shavings while passivation helps to keep those surfaces protected from cleaning agents, which tend to reduce the overall surface oxidation, and give no idea why adjacent equipment not used is filled with vacuums.

- Pharmaceutical Industry

Avoiding all forms of impetuses that can counter all productivity is of the utmost importance in all meetings. All tasks done while intending to make the medications sterile will be done all while practicing dumb repetition to get rid of any lingering foul smells. Without a doubt, every pass and pass filter incorporated into the polish stage helps to further enhance the surface of the steel mix, serving as an encapsulation for any external corrosive facing able to strike it over prolonged durations

- Chemical Processing

Corrosive substances are commonly found in chemical plants, and the use of stainless steel parts is essential to withstand such conditions. Passivation is further complemented by pickling, which enhances the strength of stainless steel against acids and chemicals, fulfilling the requirements for reactors, pipelines, and storage tanks. Such procedures minimize the rate of equipment malfunction, which reduces maintenance expenses.

- Marine Industry

Saltwater and humidity are chemical compounds of extreme corrosion, and the marine environment tends to host them both. Give long-lasting protection against the corrosive elements, propellers, boat fittings, and other offshore structures made from stainless steel are first treated with pickling to get rid of weld scales and oxides, and then passivated.

- Energy Sector

Turbines, piping systems, and heat exchangers of power plants and solar as well as wind renewable energy systems make use of stainless steel. Components are subjected to pickling and passivation due to extreme constraints. The former enhances surfaces condition, while the latter ensures the rest of the equipment’s durability in harsh conditions.

This is crucial in preserving and prolonging the life of stainless steel in harsh conditions. Evidence indicates that regular application of pickling and passivation improves maintenance expense and downtime economically, boosting productivity throughout many industries.

How to restore the corrosion resistance of damaged stainless steel components

Restoring the corrosion resistance of a stainless steel component that has undergone damage requires a sequence of operations targeted at recovering the protective passive layer that forms on its surface. This layer, which allows stainless steel to withstand both oxidation and corrosion, mainly contains chromium oxides. It may be compromised due to mechanical damage, aggressive chemical exposure, or heat treatment, which makes it mandatory to take corrective steps as soon as possible.

Step 1: Surface Cleaning and Preparation

No cutting or welding should occur until after the stainless steel component has undergone surface preparation. The surface should already be free from grease, oils and even dirt which could affect the restoration process. Special alkaline or neutral detergents formulated for stainless steel can be useful in achieving this goal. Other cleaning methods such as brushing with stainless steel tools or grit blasting should be utilized to clear corrosion products and partially embedded iron.

Step 2: Pickling Treatment

The use of hydrofluoric acid (HF) alongside nitric acid (HNO₃) will ensure the scales as well as discoloration and other impurities present on the surface are removed from the stainless surface. Additionally, calcium carbonate also scales may case scaling of calcium carbonate. It’s crucial to rinse off all hydrochloric acid with deionized water to prevent causing further corrosion.

Step 3: Passivation Process

The last step is to restore the passive layer of the stainless steel by passivation. This is usually done with an oxidizing acid, like nitric or citric acid, which is gaining use. Treatment with the acid helps in building the oxide barrier corresponding to corrosion, a chromium-rich oxide layer. Research shows that the use of advanced treatments for passivation can help improve the performance of stainless steel by thirty percent in corrosive environments.

Step 4: Verification and Testing

After restoration, testing is crucial to evaluate how well the stainless steel passivity has been maintained. Various methods can be used like ferroxyl testing or any electrochemical test which can address remnants of contamination and lack of adequate passivation. Studies focused on industry practice highlight the need for verification to mitigate the negative consequences of maintenance and operational risk over time.

These approaches help industries in enhancing and enabling more efficient preservation and restoration of the stainless steel components in order to enable more reliable performance in different environments, increasing durability and performance.

Reference Sources

- Effect of Sandblasting and Subsequent Acid Pickling and Passivation on 316L Stainless Steel1:

- Key Findings: This study explored the impact of sandblasting followed by acid pickling and passivation on the microstructure and corrosion resistance of 316L stainless steel. It found that while sandblasting reduced corrosion resistance due to surface morphology changes, subsequent pickling and passivation improved it significantly. The process also maintained microhardness and dislocation density.

- Methodology: Techniques like scanning electron microscopy (SEM), X-ray diffraction, and potentiodynamic polarization tests were used to analyze surface morphology and corrosion behavior.

- Improvement of Corrosion Resistance and Electrical Conductivity of Stainless Steel 316L Bipolar Plate by Pickling and Passivation3:

- Key Findings: This research demonstrated that pickling with sulfuric acid followed by passivation with a nitric and hydrofluoric acid mixture significantly enhanced the corrosion resistance and electrical conductivity of 316L stainless steel. The improvement was attributed to an increased Cr:Fe ratio and a more uniform surface.

- Methodology: Electrochemical tests, SEM, X-ray photoelectron spectroscopy (XPS), and atomic force microscopy (AFM) were employed to evaluate changes in surface properties.

Frequently Asked Questions (FAQs)

Q: What is the difference between pickling and passivation of stainless steel?

A: Pickling and passivation are chemical treatments applied to stainless steel, but they serve different purposes. Pickling is a more aggressive process that uses nitric and hydrofluoric acids to remove scale, rust from the surface, and other contaminants formed during fabrication or high temperature exposure. It essentially descales and cleans the entire surface of the metal. Passivation, on the other hand, is a milder process that uses primarily nitric acid solutions to remove free iron and other foreign materials from the surface of the steel, enhancing the natural formation of the protective passive film rich in chromium. While pickling physically removes material, passivation improves the existing corrosion-resistant properties of the metal without significant material removal.

Q: What acids are used in pickling and passivation processes?

A: For pickling, a combination of nitric and hydrofluoric acids is typically used. The hydrofluoric acid component is particularly effective at dissolving oxides and scale, while nitric acid helps to remove free iron and restore the chromium-rich passive layer. Passivation primarily uses nitric acid solutions at concentrations between 20-and 50%, sometimes with sodium dichromate added. Unlike pickling, standard passivation processes typically avoid hydrofluoric acid as it’s more aggressive and not necessary for the more delicate passivation process. Both acidic solutions must be carefully controlled for concentration, temperature, and immersion time to achieve optimal results without damaging the base metal.

Q: Why are pickling and passivation of stainless steel necessary?

A: Pickling and passivation are essential treatments that maximize the corrosion resistance of the stainless steel. During manufacturing, welding, forming, or machining, the surface of steel becomes contaminated with free iron, scale, oxides, and other impurities that compromise its inherent corrosion resistance. Pickling removes these contaminants along with heat tint and scale from the surface of the metal. Passivation then enhances the formation of the chromium-rich passive film that gives stainless steel its corrosion resistance. Without these treatments, stainless steel components may exhibit premature corrosion, staining, or pitting in service, particularly in demanding environments. These processes are essentially chemical metal finishing that provides critical performance benefits rather than just aesthetic improvements.

Q: What is ASTM A96.7, and how does it relate to stainless steel treatment?

A: ASTM A967 is a standard practice for cleaning, passivation, and testing of stainless steel parts and equipment. This widely recognized standard provides specific guidelines for passivation processes, including acceptable chemical formulations, process parameters, and testing methods to verify successful passivation. It outlines several passivation methods using nitric acid or citric acid solutions of varying concentrations. ASTM A967 also defines acceptance criteria for testing the effectiveness of passivation treatments, such as the copper sulfate test, which helps determine if free iron has been adequately removed from the surface of the steel. Following this standard helps ensure that passivation processes effectively enhance the corrosion performance of stainless steel components.

Q: How does electropolishing compare to pickling and passivation?

A: Electropolishing is an electrochemical process that differs from both pickling and passivation. While pickling and passivation are chemical treatments applied by immersion in acid solutions, electropolishing uses an electrical current while the part is submerged in a bathing liquid (typically a phosphoric and sulfuric acid mixture). Electropolishing actually removes a thin layer from the surface of the metal, preferentially dissolving microscopic peaks to create an ultra-smooth finish. This process not only improves appearance but enhances corrosion resistance by removing surface impurities and creating a highly chromium-enriched surface layer. Electropolishing can sometimes replace both pickling and passivation in a single step for certain applications, though it’s typically more expensive and may not be necessary for all stainless steel components.

Q: What factors affect the passive film formation on stainless steel?

A: The passive film formation is influenced by several factors: First, chromium content is crucial—stainless steels must contain at least 10.5% chromium to form an effective passive layer. Surface condition impacts film quality; a properly cleaned surface free of contaminants and free iron develops a stronger passive film. The environment during passivation affects film characteristics, with proper acid concentration, temperature, and exposure time being critical. After treatment, exposure to oxygen helps the passive film self-heal and maintain its protective properties. Finally, alloying elements like molybdenum, nitrogen, and nickel can enhance the stability and performance of the passive film, which explains why different stainless steel grades show varying corrosion resistance in different environments.

Q: How do you know if pickling and passivation are successful?

A: Several test methods determine if pickling and passivation have been successful. The water break test observes whether water sheets evenly across the surface (indicating cleanliness) or beads up (indicating contamination). The copper sulfate test, as specified in ASTM A967, involves applying copper sulfate solution to the steel—if copper deposits appear, free iron is present and passivation is incomplete. Salt spray testing (ASTM B117) evaluates corrosion resistance by exposing samples to a salt fog environment. Ferroxyl testing uses a solution that turns blue in the presence of free iron. For critical applications, more sophisticated evaluations like electrochemical testing might be employed. Visual inspection can also reveal improper processing, with properly pickled and passivated surfaces appearing uniform in color without stains, discoloration, or water spots.

Q: Can pickling and passivation be performed at high temperatures?

A: While pickling and passivation can be performed at elevated temperatures, careful control is essential. For pickling, moderately high temperatures (typically 50-70°C) can accelerate the removal of scale and oxides, particularly for heavy scale from high-temperature processing. However, excessive temperatures can cause acid fuming, worker safety hazards, and potential damage to the base metal. For passivation, temperatures are usually more controlled, typically between room temperature and 60°C. Elevated temperatures during passivation can increase reaction rates, but may also risk etching or over-processing. Temperature control is especially critical when hydrofluoric acid is used in pickling solutions, as its activity significantly increases with temperature. All temperature parameters should follow established standards like ASTM A967 and consider the specific alloy being treated.

Q: How do pickling and passivation affect the mechanical properties of the metal?

A: When properly performed, pickling and passivation have minimal impact on the mechanical properties of stainless steel. These surface treatments primarily affect only the outermost layers of the metal, typically removing just a few micrometers of material. The core mechanical properties, such as tensile strength, yield strength, hardness, and ductility,y remain essentially unchanged. However, improper processing—particularly over-pickling with too aggressive acid mixtures, excessive temperatures, or extended immersion times—can lead to hydrogen embrittlement, where hydrogen atoms penetrate the metal lattice and cause reduced ductility or delayed cracking. Additionally, aggressive pickling might cause excessive material removal at grain boundaries, potentially affecting fatigue properties. For critical applications, it’s advisable to verify that mechanical properties remain within specification after treatment.