Properly controlling the flow rate and direction of water, gas, or other fluids in plumbing systems requires the precise use of valves. If you’re a professional plumber, contractor, or DIY enthusiast, knowing the different types of valves and their applications is crucial for effectiveness and safety. This guide aims to simplify the valve puzzle, highlighting major categories, functions, and the placement of plumbing systems. From common ball and gate valves to sophisticated pressure-reducing or check valves, we will examine the vital contribution of each in flow control and system integrity. You’ll know the various forms of valves and how to choose the appropriate one for plumbing work by the end of this article. So, let’s fully explore the control of flow!

What are the different types of valves used in plumbing systems?

- Ball Valves

For a complete shut-off, ball valves are the most reliable and popular option. Depending on the need of a specific application, ball valves can either be fully open or completely closed. Ball valves are easy to operate, as they are very durable.

- Gate Valves

A gate valve is a type of valve designed to completely stop or start the flow of liquid through a pipe. Gate valves fit most conveniently in systems where flow needs to be isolated, as they are not best suited for throttling.

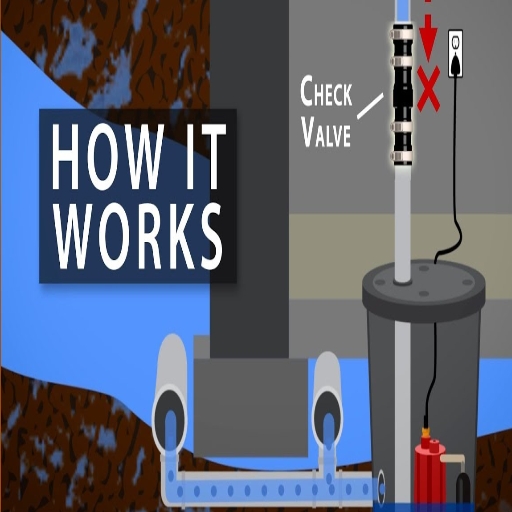

- Check Valves

The check valve is a valve that allows a liquid to flow through it in one direction only. While the check valve is handy, it is critical in areas where reverse flow could lead to destruction or pollution.

- Globe Valves

Globe valves were created to control the flow of plumbing systems, allowing for precise control. Because the throttle valves allow a certain amount of flow, they are primarily used in regulating devices, such as pipes.

- Pressure-Reducing Valves

Pressure-reducing valves are key components of plumbing valves, setting the maximum safe water pressure. Plumbing and its various installations dictate the proper channels, fixtures, and pipe pressure for water to avoid damage.

Ball valves, gate valves, and globe valves: What’s the difference?

Each type of valve serves a specific purpose. Each specific plumbing purpose requires a particular kind of valve to achieve the intended result, highlighting the value of variety.

- Ball Valves

Ball valves bifurcate the flow with a spherical disc that controls the flow. They close by turning the handle 90 degrees to rotate the ball, which either completely opens or closes the flow. Ball valves are easily and widely used in residential, commercial, and even industrial settings. They are very perishable, need low supervision, and can easily tolerate high pressure and temperatures. Still, they are not the best choice for applications involving precise throttling.

- Gate Valves

Gate valves work by lifting a metal disc gate to let complete flow pass. Their primary purpose is to allow unrestricted flow, like in pipelines. They are suited for elimination and filling gaps. Gate valves work well under high pressure, have high resistance to wear and tear, and provide flow with the minimum resistance when opened. Still, they are not very effective in flow control due to slower operation and use over time.

- Globe Valves

Globe valves were created for intricate throttling and flow control. Its construction features a movable disk, or valve, and a stationary ring seat, allowing for directional control (along with volume control and flow rate adjustments). Their construction results in more resistance than ball and gate valves, so they are less valuable in cases when there is a need for little resistance to flow. Nonetheless, where precise control is required, such as with heating and cooling systems, globe valves perform exceptionally well.

Having an appropriate fluid control component in each system is expected to achieve desired outcomes related to efficiency, safety, and reliability, which makes understanding the strengths and limitations of each valve type critical.

Quarter-turn valves vs. multi-turn valves: Which is best for your application?

Quarter-turn and multi-turn valves both have unique characteristics, making them helpful in varying applications, which makes knowing their features beneficial for specific requirements. A fierce set of ‘opposing’ characteristics or attributes, like sequential operations and restrictions, makes these two valve types infinitely different.

Quarter-turn Valves:

- Operation: Opened or closed fully after having been rotated 90 degrees, so no multi-turn time is wasted.

- Types:

-

-

- Ball valves are popular for sealing tightly and having low pressure drops, making them perfect for quick shut-off.

- Butterfly Valves: For bigger pipelines, light valves at low costs, which can be used for throttling.

- Plug Valves: Small and easy to use, used in high-pressure environments.

-

- Applications:

-

-

- Industrial systems that require rapid on/off times are the primary users.

- Transporting clean fluids and lightly abrasive fluids.

- Pipelines that have a minimal pressure drop.

-

- Advantages:

-

-

- Fast and straightforward to operate.

- Requires little maintenance.

- Very durable with a long service life.

-

- Limitations:

-

-

- Does not allow precise flow control.

- It may not be ideal for throttling in all situations.

-

Multi-turn Valves:

- Operation: Turning the handwheel or actuator once opens or closes the valve. Numerous turns are needed for the whole opening or closing, thus offering better control over the valve.

- Types:

-

-

- Gate Valves: Used for on-off control of flow, these valves are most effective in cases where minimal resistance to flow is desirable.

- Globe valves are used for modulating flow. In lower or higher heating and cooling systems, precise flow control is required.

- Diaphragm valves are perfect for viscous fluids or those with a solid content.

-

- Applications:

-

-

- Systems requiring precise control of flow rate.

- Pump viscous fluids.

- Work in a high-temperature and high-pressure environment.

-

- Advantages:

-

-

- Excellent control over fluid flow rate.

- A wide range of fluids can be used, including slurries and chemicals.

- Reliable under harsh and heavy-duty conditions.

-

- Limitations:

-

-

- The speed of operation is lower because multiple rotations are needed.

- Some designs have high maintenance needs.

-

Choosing the Best for Your Application:

The best choice of quarter-turn or multi-turn valves greatly relies on operational speed, fluid type, control precision, and environmental factors. For quick shutoff and lower resistance, quarter-turn valves tend to be more beneficial. Multi-turn valves, on the other hand, are best for precise flow control or more difficult fluids. Careful evaluation of the operational needs and characteristics of the valves will allow for performance and system efficiency.

Common types of valves used in residential plumbing

Residential plumbing uses valves to control water flow, ensure safety, and facilitate easy maintenance. Here are some of the most common household plumbing valves:

- Ball Valves

Ball valves are robust, featuring a quarter-turn shutoff and a rotating ball, which provides rapid shut-off. These valves utilize a ball with a central opening that rotates with water flow along the pipeline, aligning with the pipeline for water flow or pivoting to block it. Ball valves are well-known in residential main water lines due to their strong seal and low risk of leaking.

- Gate Valves

Gate valves rely on a gate-like mechanism that moves up or down to cut off water flow. These valves are suited for on/off applications rather than throttling. Gate valves are found in situations where a steady flow of water is necessary.

- Globe Valves

This type of valve is a globe valve. They are used chiefly for precise flow control. Globe valves have a movable disk and a stationary ring seat, which offers better regulation than gate or ball valves. Usually, they are placed under sinks or in water heater devices where flow control is needed.

- Check Valves

Check valves are one-way valves, specifically designed to prevent reverse flow. These valves are needed in plumbing systems to avoid contamination, especially in pipes, sprinkler systems, or sump pump systems.

- Angle Valves

Compact angle valves are a type of shutoff valve found under sinks and behind toilets. They are handy and easy to service because the fixtures can be easily accessed for maintenance without needing to disassemble the whole system.

- Pressure-Relief Valves

The safety mechanisms fitted on water heaters are known as pressure relief valves. Their primary function is to relieve dangerous excess pressure that might lead to an explosion or damage. Like other devices, these valves must be monitored to ensure safety, operational effectiveness, and the cost-effectiveness of household plumbing services.

Their maintenance needs and structural capabilities need to be understood in advance so that informed decisions can be made for the design, maintenance, and troubleshooting of the household’s entire plumbing system.

How do I choose the right type of flow control valve for my project?

While selecting the flow control valve for your application, consider the following:

- Application Requirements: Define the tasks you expect the valve to perform in your system, such as controlling flow, maintaining a certain pressure, or stopping the flow of fluid.

- System Media: Identify the type of media that the valve will control (water, air, gas, or any other liquids), since different materials are used to construct different valves.

- Flow Rate: Determine the flow rate required by the system so that a valve of the desired capacity can be selected.

- Pressure Ratings: Check the system’s maximum and minimum operating pressures and ensure the valve can operate safely within those limits. Then, verify its rating.

- Material Compatibility: Select a valve made of plastic or metal that won’t corrode and is suitable for the physical and chemical environment, including the fluids it will be used with.

- Valve Type: Select from ball, gate, globe, and needle valves depending on your project needs, as each is meant for a specific control function.

- Maintenance Needs: Determine how often the valve needs to be serviced and what maintenance it requires.

Taking these criteria into consideration will allow for the selection of a valve that provides maximum performance, safety, and reliability for the system.

Factors affecting valve selection: flow rate, pressure, and application

- Flow Rate

Flow rate directly influences both the size and type of valve designed. It is essential to ensure that the valve can cope with the system’s maximum flow rate without causing too much pressure drop. For example:

-

-

- Smaller flow rates require small valves, such as needle valves, to allow for smoother flow control.

- Higher flow rates require larger valves, such as gate or ball valves, which are designed to allow minimal back pressure.

- Example Data:

-

- For low flow systems (<10 GPM): Small globe valves with small diameters.

- For high-flow systems (greater than 100 GPM), larger ball valves or large gate valves are preferred.

-

- Pressure

The working and maximum pressures of the system must be well understood to select a valve that can safely function under those conditions. Important factors include:

-

-

- High-pressure systems always require stronger and more pressure-resistant materials; high-strength stainless steel or alloys are recommended.

- For low-pressure systems, lighter materials like PVC can be used.

- Example Data:

-

- Low pressure (0-150 PSI): The Best option would be butterfly valves.

- High pressure (above 500 psi): Forged steel valves are best suited for this pressure.

-

- Application

Recognizing the specific application of the valve is crucial in selecting its type and material. An application usually has particular conditions that the valve must meet:

-

-

- Temperature: Valves need to have suitable thermal resistance at extreme temperatures.

- Medium: The type of material that flows through the valve (liquid, gas, or slurry) determines the type of valve selected. For example:

-

- Valves made out of Teflon-coated stainless steel are required for corrosive chemicals.

- High-viscosity fluids demand valves with larger ports.

- Control Requirements: Needle and globe valves aid in flow control, but ball or gate valves are more efficient for on/off applications.

-

By considering these parameters in conjunction with the system’s operational data, the valve can achieve its maximum efficiency and lifespan.

Valve material considerations: brass, PVC, and stainless steel options

When selecting valve materials to achieve the necessary durability and efficiency in your system, knowing the properties and usage scenarios is essential.

- Brass Valves: Being one of the most versatile metals, brass offers excellent mechanical properties and does not corrode easily. Its applications extend to plumbing and HVAC systems, as well as any system that uses non-corrosive fluids, such as water or oil. Brass is also cost-effective for use in residential and light industrial setups. Compared to other metals, brass performs well with moderate temperature and pressure ranges and has a reasonable cost.

- PVC Valves: PVC, commonly referred to as polyvinyl chloride, is among the lightest materials available. Their applicability in water treatment systems and chemical handling is extensive owing to their corrosion resistance. Economical PVC valves can be used in lower-pressure systems and withstand harsh chemicals, although their use in high-temperature scenarios tends to limit their functionality. Industry data suggests optimum usage at 140°F (60°C) or below.

- Stainless Steel Valves: Valves made of stainless steel are more commonly used owing to the enhanced strength, durability, and resistance to high temperature and corrosive environments they provide. Their primary use lies within the food industry, chemical processing, and marine systems. Even under extreme temperature and pressure fluctuations, stainless steel valves retain their functionality, making them suitable for demanding conditions. Additionally, other grades like 316 stainless steel are highly resistant to Chlorides and harsh chemicals, further aiding their longevity in more challenging environments.

Carefully considering a valve’s operating temperature, pressure, and fluid characteristics helps identify the correct valve material. Combining these factors alongside a valve’s performance capabilities can enhance efficiency and longevity, irrespective of whether the application is commercial, industrial, or residential.

Valve size and connection types for proper installation

Maintaining maximum flow and system operation can be achieved effortlessly by ensuring the valve size selected is suitable for the purpose. Small-scale valves increase the pressure head and restrict flow. In addition, large-scale valves tend to increase costs and make the system operate inefficiently. The standard industry practice is to describe valve sizes using nominal diameter – valves need to agree with the piping system they are integrated with. In a domestic context, the size might vary from 1/2 inch, while in more industrial applications, several inches and even more is standard.

Equally important are the connection types. The most common bolt types include: threaded, compression, and flanged, each suited to different applications. Low-pressure systems use threaded connections, which offer ease of installation and replacement as an added advantage. In terms of maintenance, piece work and flanged connections outshine other methods. Full-welded connections are primarily used in critical operations due to their permanent and leak-free nature. Systems that often need to be serviced frequently use compression fittings, as easy disassembly guarantees a reduced service time. All these factors, when optimally addressed, ensure valve systems are installed and operated seamlessly.

What are the pros and cons of butterfly valves compared to other valve types?

Pros:

- Compact Design: Butterfly valves are lightweight and save space, making them perfect for systems with restricted dimensions.

- Cost-Effective: They are usually less expensive than other types of valves, especially in large diameters.

- Quick Operation: Allows for fast opening and closing due to its simple quarter-turn mechanism.

- Low Maintenance: Resulting in easier maintenance over time due to lower component wear.

Cons:

- Limited Sealing Capability: While providing some seal, butterfly valves do not seal as tightly as gate or globe valves, especially in high-pressure or high-temperature situations.

- Flow Restriction: Since the disc stays in the flow path, the butterfly valve can cause some flow interference.

- Not Ideal for High-Density Media: These valves are designed to be more efficient than other types when handling viscous or abrasive materials, but this can make handling less effective.

Users can assess whether the operational needs precisely align with butterfly valves by weighing their pros and cons.

How butterfly valves regulate the flow in large piping systems

Butterfly valves utilize a disc that rotates about a central shaft to control fluid passage and flow within large piping systems. The valves allow the disc to be in the open position, where it remains parallel to the flow direction, meaning maximum fluid movement and less pressure to overcome. The valve can also be closed by rotating the disc at a right angle to the direction of the fluid flow.

Technological improvements in butterfly valves have enhanced their performance and longevity in multitasking applications. For example, nowadays, the construction of high-performance butterfly valves is done with polymers, stainless steel, and other advanced materials to withstand hostile environments that involve high pressure and corrosion. Their ease of automation, coupled with a compact structural design, makes them perfect for use in the water treatment, oil, gas, and power generation industries. They are used in these industries because precise control over fluid flow is provided when actuators and positioners are used in conjunction with varying operational demands. With these modifications, butterfly valves can effectively and economically control flow in extensive piping systems.

When to choose a butterfly valve over a ball or gate valve

Butterfly valves are generally preferred in applications where space, weight, and costs are important considerations. Unlike ball or gate valves, butterfly valves are lightweight and compact. This enables their use in cramped or weight-restricted environments, such as those found in maritime, aerospace, or mobile machinery. Regions that require fast and frequent operation also benefit from these types of valves due to their quicker quarter-turn actuation compared to the multi-turn motion of gate valves.

From the costing perspective, butterfly valves are more economical, especially for larger diameters. They’re cheaper across the board since less material is used for construction compared to heavy-set gate or ball valves, which helps reduce costs in large-scale installations. In terms of functionality, low- and high-pressure systems that require throttling or flow regulation are also ideal for pairing with butterfly valves. This is why industries like water distribution, HVAC, and wastewater treatment prefer using them.

The type of butterfly valve selected is also dictated by the medium being controlled. While ball and gate valves may suit applications needing a bubble-tight seal or the handling of slurries and viscous fluids, modern butterfly valve designs with advanced sealing technologies now offer comparable performance and leak-proof reliability in many scenarios. Butterfly valves also ease automation through actuators, and their growing use in intelligent systems makes them even more appealing in automation-focused industries.

Typical applications where butterfly valves are used

- Water Treatment Plants

Butterfly valves are widely used in water and wastewater treatment plants for flow control and to isolate specific sections of pipes. Those large amounts of water can be handled effectively because these valves have reliable seals and a compact design.

- HVAC Systems

Construction of buildings and facilities typically involves HVAC (heating, ventilation, and air conditioning) systems, which also use butterfly valves to control the flow of hot or chilled water. Because of their low weight, they can be easily integrated into the duct system, which allows for effective temperature regulation in the rooms.

- Chemical Processing

Butterfly valves are widely used in chemical processing plants because they are compatible with corrosive materials and slurries. They are made with special materials, such as PTFE liners, that withstand aggressive chemicals and have good durability.

- Oil and Gas Industry

In the oil and gas industry, upstream, midstream, and downstream processes all use butterfly valves because of the valves’ effectiveness in handling high temperatures and pressures. These valves manage the transportation and containment of fluids and gases in pipelines.

- Food and Beverage Industry

The food and beverage industries use these valves for fluid control during processes like packaging. Hygienic butterfly valves made of stainless steel are pivotal in keeping sanitary standards in the sector.

- Power Generation

Critical in the operation of boilers and turbines, butterfly valves can withstand high temperatures and pressure, which is essential. Power generation, both renewable and conventional, uses the butterfly valve to regulate cooling water, steam, and other fluids.

- Marine and Shipbuilding

Due to their compact size and resistance to harsh marine environments, butterfly valves are ideal for applications in confined spaces. These valves control the flow of cooling and ballast water on ships.

- Pulp and Paper Industry

The durability and low maintenance of these valves make them well-suited for handling viscous slurries and fibrous materials in the pulp and paper industry. Butterfly valves are a standard choice for flow control in this sector’s manufacturing processes.

Each of these sectors utilizes the unique features of butterfly valves to meet specific operational requirements. This showcases the adaptability and crucial function of this type of valve in contemporary uses.

How do check valves and relief valves work in plumbing systems?

Relief and check valves are essential in controlling flow and protecting plumbing systems.

Check valves allow fluid flow in only one direction. This avoids backflow that might threaten system integrity or, even worse, system contamination. A check valve operates automatically and uses a disc or ball that closes internally when flow reverses, ensuring one-way flow.

Relief valves are the opposite of check valves because their primary purpose is to release pressure. This type of valve opens automatically when a predetermined pressure level is reached and works by relieving pressure on pipes, fittings, or equipment that could burst. After the pressure settles, the valve resumes its closed position.

Both valves maintain both flow and pressure without malfunctioning in plumbing systems.

Understanding how check valves allow flow in one direction

Check valves are essential parts of many systems as they allow the flow of liquid or gas in one direction only and prevent backflow. The flow direction and pressure activate a mechanism inside the valve, allowing this functionality. When the fluid moves in the right direction, it pushes the valve’s internal disc or ball open to a point where it can no longer be stuck, allowing movement through the system. If the flow starts to reverse direction, the pressure difference would move the disc or ball back into its seat, sealing the valve and stopping backflow.

All check valves, including swing check, ball check, and lift check valves, differ slightly in design to accommodate a particular form of use. For instance, swing check valves are best suited for low pressure but high flow rates, while lift check valves are used in high-pressure systems due to their strong construction. Their reliability and versatility make check valves very useful in water systems for distribution, heating, and industrial pipelines. They greatly aid in supporting efficiency and operational safety in the systems. Data from industry engineers displays the advantages they provide in reducing downtime and avoiding expensive damage from reverse flow.

The role of pressure relief valves in protecting your piping system

Precision control valves are necessary because they prevent my piping system from experiencing pressure buildup. They protect against damage, failure, or even catastrophic accidents by automatically releasing pressure when a specific value is reached. My system can be managed effectively while ensuring its longevity and safe operating conditions, which is relieving.

Typical applications for check valves and relief valves

-

-

- Check valves help prevent backflow that can occur with reverse unidirectional flow of liquids and gases.

- Relief valves are of utmost importance in pipelines handling volatile substances, as they allow pressure to be reduced to safe levels.

-

- Oil and Gas Industry

-

-

- Check valves are crucial components in preventing backflow in vessels, equipment, or the entire drilling system, to maximize system and machinery efficiency.

- Relief valves in storage tanks, as well as in processing units, are used to control the pressure within these vessels, preventing overpressure and rupture.

-

- Water Treatment Facilities

-

-

- Check valves enable unidirectional flow while preventing back contamination, which is crucial in water for municipal and industrial uses, serving to prevent backflow.

- Relief valves help control pressure during treatment to protect the tanks and filters.

-

- Power Plants

-

-

- Relief valves help control pressure during treatment to protect the tanks and filters.

- Relief valves ensure safety by preventing overpressure in turbines, boilers, and heat exchangers.

-

- HVAC Systems

-

-

- To prevent backflow, check valves are used to control the flow of air and liquids in heating, cooling, and ventilation systems.

- System reliability is guaranteed with relief valves in compressors and other pressurized components, as they manage pressure levels.

-

- Chemical Processing Plants

-

-

- Check valves prevent the dangerous backflow of incompatible chemicals and control the forward flow of substances.

- Vessels and pipelines are protected from overpressure due to exothermic reactions or equipment malfunction with relief valves.

-

- Fire Protection Systems

-

-

- With check valves, a fire can be fought with a constant flow of water or foam, ensuring readiness when called.

- Surges in pressure these systems experience as a result of sudden activations are controlled with relief valves.

-

Sectors of operations are safeguarded with check and relief valves in all processes, as their functions provide efficiency and safety.

What are specialty control valves, and when should they be used?

Special control valves address flow issues that standard valves cannot fix due to specific flow conditions. These valves are typically found in more unique and challenging settings, such as with highly corrosive fluids, extreme temperatures, or where precise flow control is required. They should be applied when standard valves cannot work due to operational requirements or when customized performance is necessary for safety, efficiency, and reliability in a system.

Needle valves for precise flow control applications

Needle valves are a type of valve that offers the most accurate and dependable flow rate control, making them very suitable for flow metering uses. Their unique construction, with a long, slender plunger shaped like a needle, allows operators to finely adjust the liquid or gas flow to a very delicate level. Below are the major features and specifications related to needle valves:

- Material Options

-

- Stainless Steel

- Brass

- Carbon Steel

- Exotic Alloys (e.g., Monel, Hastelloy)

- Size Range

-

- Typically found in nominal sizes from 1/8” to 2”

- Custom sizes are available for specially tailored projects.

- Pressure Ratings

-

- A standard needle valve is capable of withstanding pressures up to 6,000 psi (pounds per square inch).

- High-pressure needle valves can operate at up to 10,000 psi.

- Temperature Tolerance

-

- Operating temperatures, based on material and design, range from -65°F to 850°F.

- Applications

-

- Laboratories for precise measurement of fluids and gases.

- Chemical processing for the management of corrosive materials.

- Instrumentation systems for precise flow control in scientific and industrial operations.

- In oil and gas pipelines, the flow of hydrocarbons is controlled.

- Advantages

-

- Needle valves have several significant benefits, including accurate flow rate control, durability in harsh conditions, and Compactness for space-limited systems.

- End Connections

-

- The valves can come with various types of ends such as: Threaded end (NPT, BSPT) Flanged Welded Compression fittings.

An exact flow of liquid or gas is crucial in management systems in numerous industries, making needle valves a vital component. Their unparalleled strength in extreme conditions, combined with fine flow regulation, creates an endless list of applications.

Plug valves and pinch valves: specialized valve types for specific needs

Pinch and plug valves are unique from the rest as they serve particular industries due to their advanced features and capabilities.

Plug Valves

Plug valves are defined by their uncomplicated construction, which consists of a cylindrical or tapered plug that moves within the valve body. They are most suited for on/off control, and are therefore easier to use in situations where the plug valve is operated frequently. For this reason, these valves are particularly preferred in oil and gas, chemical processing, and water treatment industries. Such industries rely on quick and sturdy action while operating valve systems. To cater to the different types of fluids, pressures, and temperatures, plug valves can be manufactured in various compositions, including metal and non-metal. Some designs can be more complex and offer multi-port designs, which further enable controlling the flow in multiple directions.

Pinch Valves

Pinch valves use a flexible elastomer sleeve as their primary sealing component. The absence of internal obstructions combined with their clean, full-bore design makes them exceptionally suited for abrasive, corrosive, and slurrying media. This feature makes them a best-fit option for wastewater treatment, mining, and food processing. The sleeve of the valve can be compressed mechanically or pneumatically, making flow control easy and providing a positive shut-off. They are known to be very low-maintenance, which makes them easy and cost-effective to rely on for sustaining difficult surroundings and environments.

The design of both plug and pinch valves demonstrates how specific valve technologies can meet particular industry requirements by integrating efficiency, reliability, and flexibility to support critical processes.

Actuated valves: automated flow control solutions

Actuated valves are integral to contemporary automated systems, providing dependable and accurate control of flow in numerous processes. Supplied from external apparatus that can be electric, pneumatic, or hydraulic, these valves function seamlessly in harsh conditions. Besides reducing manual labor, their automation feature enhances productivity by allowing automatic control of the flow, pressure, and direction of the fluid in real-time. The speed of intelligent actuated valves, which have sensors and monitoring capabilities, provides enhanced diagnostics for performance, maintenance, and further evaluation. The oil and gas industry, along with water treatment facilities and chemical processing plants, receive invaluable advanced solutions from these systems that reduce downtime while optimizing operational expenditure. No doubt, actuated valves will continue to evolve to address the ever-increasing demand for high-precision automated systems, while providing clean and efficient industrial systems.

Reference Sources

- “Advancements in Valve Reliability for Industrial Applications” (Journal of Mechanical Engineering, 2020)

-

-

- Key Findings: This study investigates the performance and reliability of various valve types, including gate, globe, and ball valves, under high-pressure and high-temperature conditions. It concludes that ball valves exhibit superior reliability due to their robust sealing mechanisms and lower likelihood of leakage.

- Methodology: The research involved a series of controlled laboratory tests simulating industrial operational stresses, along with field case studies from the oil and gas industries, to validate the results.

-

- “Comparative Analysis of Valve Performance in Chemical Processing” (Industrial Process Journal, 2021)

-

-

- Key Findings: A comprehensive comparison of actuated and manually operated valves found that actuated ball valves are the most reliable type in environments with frequent operational cycles, due to their precision control and durability.

- Methodology: The study used long-term operational data from chemical processing plants and conducted failure mode and effects analysis (FMEA) to assess reliability.

-

- “Sustainable Valve Design and Reliability in Water Treatment Systems” (Journal of Environmental Engineering, 2022)

-

-

- Key Findings: This paper highlights the resilience of butterfly valves in large-scale water treatment systems, with a particular focus on their low maintenance requirements and ability to handle variable flow rates effectively. However, the study also recognizes ball valves for their broad applicability and exceptional lifecycle performance.

- Methodology: Researchers employed computational fluid dynamics (CFD) simulations and real-world case analyses to measure reliability and efficiency metrics.

-

- “Performance and Durability of Valves in High-Precision Systems” (Control Systems Engineering, 2019)

-

-

- Key Findings: This research confirms that diaphragm valves offer high reliability in pharmaceutical and food processing applications, where resistance to contamination is crucial.

- Methodology: The analysis included experimental testing of valve materials under sterilization procedures and extensive interviews with industry professionals.

-

- “Emerging Trends in Valve Technologies for Industrial Automation” (Automation Today, 2023)

-

-

- Key Findings: This recent study explores smart actuated valves equipped with sensors for predictive maintenance and highlights improvements in reliability metrics across multiple valve types.

- Methodology: The research combined case studies on automation in manufacturing facilities with data analytics derived from IoT-enabled valve performance monitoring.

-

These identified papers demonstrate the critical role of specific valve types within diverse industrial applications, reflecting the importance of context when evaluating reliability.

Frequently Asked Questions (FAQs)

Q: What is a shutoff valve, and why is it essential in plumbing systems?

A: A shutoff valve is an essential plumbing component that allows you to stop the flow of water to a specific fixture or your entire house. These valves are often used in emergencies, such as when there are leaks or during repairs. The main shutoff valve controls water to your whole home, while individual fixture shutoff valves let you isolate specific areas. Having accessible, functional shutoff valves is crucial because they enable you to quickly stop water flow during plumbing emergencies, potentially preventing extensive water damage and costly repairs.

Q: What are quarter-turn valves, and what makes them popular among plumbers?

A: Quarter-turn valves are valves that require only a 90-degree rotation (one-quarter turn) to open or close the flow of fluid completely. Ball valves are the most common type of quarter-turn valve used in plumbing. These valve options are popular among plumbers because they’re easy to operate, provide a clear visual indication of whether the valve is open or closed, and typically have a longer service life than multi-turn valves. They offer reliable sealing and quick operation, which is particularly valuable during emergencies when you need to shut off the water supply quickly.

Q: How do I choose the best type of water valve for my plumbing project?

A: Choosing the best type of water valve depends on several factors. For frequently used applications, ball valves or gate valves are recommended due to their durability. For decorative fixtures, globe or angle valves might be preferred. Consider the valve’s pressure rating, material compatibility with your plumbing system, and required flow rate. Cost is also a consideration, as valves range from inexpensive compression valves to more costly specialized control valve types. Additionally, consider ease of installation and maintenance requirements. Consulting with a professional plumber can help identify the optimal valve for your specific application.

Q: What are pressure-reducing valves, and when are they necessary?

A: Pressure-reducing valves (PRVs) are specialized control valves that lower water pressure from the main supply line to a safer level for your home’s plumbing system. These valves are often used when municipal water pressure exceeds 80 PSI, which could damage appliances and plumbing fixtures. Pressure-reducing valves (PRVs) are necessary in homes with high incoming water pressure. These older plumbing systems may be stressed by high pressure, or when you experience symptoms such as banging pipes, running toilets, or dripping faucets. Installing a pressure-reducing valve can extend the life of your plumbing system, reduce water waste, and prevent damage to fixtures and appliances.

Q: How do gate valves differ from ball valves for water valve applications?

A: Gate valves and ball valves differ significantly in design and operation. Gate valves use a gate or wedge that moves up and down perpendicular to the flow path. They require multiple turns to open or close and are considered a multi-turn motion valve. Ball valves, on the other hand, are quarter-turn valves featuring a hollow ball with a hole through its center, which aligns with the pipe when the valve is open. Gate valves are better suited for fully open or fully closed applications and should not be used for regulation. In contrast, ball valves offer quicker operation, better sealing, and can be used for partial throttling. Ball valves typically have longer lifespans as gate valves can be prone to stem and seat wear issues.

Q: What maintenance do standard valves used in residential plumbing require?

A: Common valves used in residential plumbing require regular maintenance to ensure reliable operation. For most valves, exercising them by fully opening and closing them several times a year prevents seizing and buildup on the valve seat. Check for leaks around the valve stem, packing nut, or valve body. Compression and cartridge valves may need occasional washer or O-ring replacement. Ball valves are generally low-maintenance, but they benefit from occasional use to prevent sticking. Gate valves are more prone to problems and may require stem packing adjustments or replacement if leaking occurs. Regular inspection and maintenance help extend valve life and prevent unexpected failures.

Q: How can I identify if a valve is open or closed when looking at different valve types?

A: The method to identify if a valve is open or closed varies by type. For quarter-turn valves, such as ball valves, the handle position indicates the status – when aligned with the pipe, it is open; when perpendicular, it is closed. Gate valves require observing the stem – a rising stem indicates that the valve is open. Globe valves operate similarly to gate valves with rising stems. Check valves don’t have external indicators as they operate automatically based on flow direction. Some modern valves feature visual indicators, such as colored tabs or digital displays. When in doubt, you can also test the flow through the valve by temporarily turning on the water to check if it passes through.

Q: What are the advantages of butterfly valves compared to other valve options?

A: Butterfly valves offer several advantages compared to other valve options. They’re more compact and lightweight, making them ideal for installations with space constraints. These valves are also cost-effective for larger pipe diameters where other valve types become prohibitively expensive. Butterfly valves provide quick operation (quarter-turn) and excellent flow regulation capabilities. They have fewer components, which means less maintenance and fewer potential failure points. Additionally, butterfly valves can be used for throttling applications and offer minimal pressure drop when fully open. These characteristics make them popular in commercial and industrial applications, although they are less common in residential plumbing, where ball valves are often preferred.