When considering the water your family uses daily, safety is paramount. But did you know the type of plumbing pipes installed within your home has a significant impact on the safety and purity of your drinking water? Copper, PVC, PEX—the list goes on. Figuring out which materials are best for your home can be tricky. This guide is designed to help you make that choice. We will outline the safest pipe materials for drinking water and analyze their benefits, drawbacks, and expert opinions so you are able to make an educated decision. You will be equipped to make health and safety upfront priorities for your household, whether you are building a new house or replacing an old plumbing system.

What Types of Pipes Are Safe for Drinking Water?

- Copper Pipes

The recommended type of plumbing pipes is copper because it is durable, resistant to corrosion, has a long-life span, and best of all, does not leach harmful chemicals into water. This makes copper pipes a safe option.

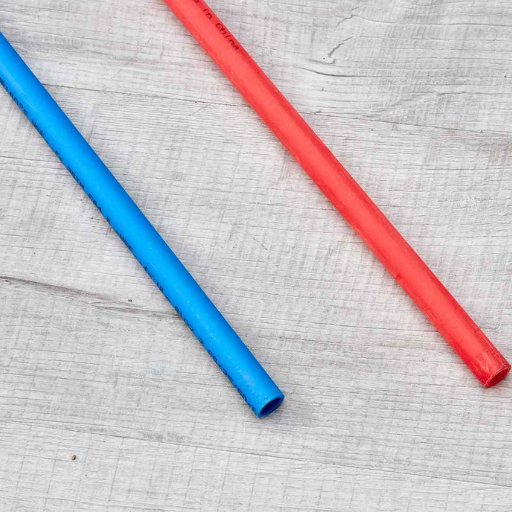

- PEX (Cross-Linked Polyethylene) Pipes

Another option is PEX pipes, which are modern, flexible, and more cost-efficient. They are resistant to corrosion, suitable for both hot and cold water supply. Additionally, they do not leach harmful substances.

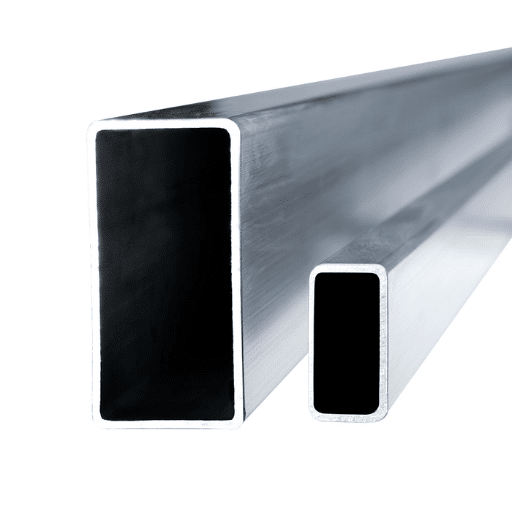

- Stainless Steel Pipes

An additional safe for drinking water pipes is stainless steel. Their strongly corrosive resistant properties and water quality neutrality make stainless steel a safe choice as well, but their costly price is a downside.

- PVC (Polyvinyl Chloride) Pipes (Marked for Potable Use)

Only PVC pipes that are marked as safe for drinking water (generally engraved NSF-61 certified) should be purchased. That being said, these pipes are lightweight and inexpensive. Unfortunately, they are only for a cold water supply.

Every one of these alternatives comes with its unique advantages and disadvantages. Considerations such as cost, water pressure, and individual inclinations regarding the plumbing system for the house will dictate which pipe is most appropriate.

Key Considerations for Choosing a Pipe Material

When selecting pipes, one must take into account water quality, temperature, the layout of plumbing within the house, and financial implications. For instance, PEX and stainless steel offer aggressive water-resistant materials suitable for regions with aggressive water chemistry. Cost scenarios could, however, balance longevity and performance with affordability. PVC and PEX materials are far cheaper, warranting easy installation.

How Different Pipe Materials Affect Water Quality

The various plumbing standards used in construction have a great impact on the water quality based on how some materials can chemically interact with water; furthermore, they can also alter the water’s taste as well as make it unsafe for drinking. A good example is copper pipes, which are very durable and do not corrode easily, but under acidic water conditions, they may dangerously liberate small quantities of copper, which, in large amounts, would be detrimental to health. Based on the safety standards of water, the concentration of copper in drinking water should not exceed 1.3 mg/L/, L which may cause harmful effects.

On the other hand, PVC (polyvinylchloride) and CPVC (chlorinated polyvinyl chloride) pipes (fitting) are cheaper and lighter, but few studies have suggested that vinyl chloride could leach in small amounts under specific conditions and due to this reason it becomes very important to adhere to the manufacturing and certification standards when working with these materials.

Another interesting example is PEX (cross-linked polyethylene) piping which became popular because of its flexibility and scale resistance, even though its ability to alter taste and introduce organic contaminates is still hotly debated. Certified PEX products diminish these risks and are safe for drinking water.

Pipes made of stainless steel and galvanized steel are physically durable and resistant to damage, but their selection must be made based on the chemistry of the water. In particular, galvanized pipes may leach small quantities of zinc or lead over time, especially in older systems.

In the end, selecting the most suitable pipe material involves knowing how each type reacts with the local water and safety standards. Also, installation and maintenance significantly reduce the risks and help safeguard water quality.

Is PEX Tubing Safe for Drinking Water Supply?

Indeed, PEX tubing is safe to use for water supply lines. Major health and safety organizations, such as the NSF and the FDA, have approved it for potable water use. PEX is non-corrosive and does not leach any harmful substances into the water, thus making it a dependable and safe option for plumbing systems in homes and businesses alike.

PEX Pipe Benefits and Safety Certifications

The PEX piping system includes important safety certifications. For instance, I believe that PEX is very robust as well as resistant to scale and chlorine. Moreover , its flexibility improves the ease of installation, avoiding complicated fitting problems. Additionally, PEX is certified by the NSF and approved for potable water, meaning it passes important safety and health tests. Such characteristics make PEX a trustworthy option for modern plumbing systems.

Does PEX Tubing Leach Chemicals into the Water?

Despite several studies pointing out the safety and efficiency of using PEX tubing in modern plumbing systems, questions regarding its chemical leaching have come up. Credible research institutions show that while PEX tubing might ‘off-gas’ slow amounts of methyl tert-butyl ether (MTBE) and other volatile organic compounds (VOCs) initially, those levels are negligible and decline with time. For instance, some studies suggest that after a certain period of use, the levels of these chemicals in the water have been proven to be far lower than the benchmark value set by the EPA and other health bodies. In addition to this, the majority of PEX products undergo rigorous testing to attain certification, such as NSF/ANSI 61, which PEX tubing is not deemed to significantly impact water quality for consumers. Regularly flushing the system during the initial stages of installation is advised to further alleviate any concerns.

PEX vs Other Plastic Water Pipe Options

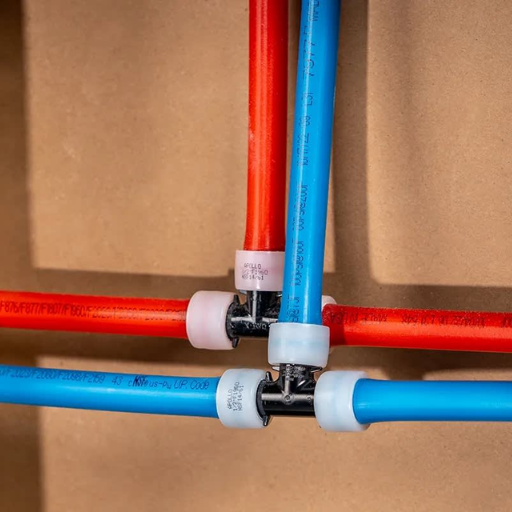

When evaluating PEX in relation to other types of water plastic pipes, such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), considerations like flexibility, structural integrity, ease of installation, and cost effectiveness come into play.

- Flexibility: Because of its great flexibility, PEX pipes can be used in difficult installation areas and they can be placed in curved or tight spaces with ease. Unlike CPVC and PVC, which require fittings to make turns, PEX pipes can easily be bent around obstacles, therefore thwarting increased joints and possible leaking.

- Temperature and Pressure Resistance: PEX can withstand a greater range of cold and hot temperatures which makes it suitable for both hot and cold water systems. While CPVC can handle high temperatures, it’s rigidity makes it prone to cracking under stress. PVC on the other hand, has a low tolerance to heat and is recommended only for cold water.

- Durability and Longevity: PEX has great resistance against corrosion, scaling and chlorine, helping him maintain his performance over extended periods of time. On the contrary, PVC and CPVC are weaker with UV exposure and can also suffer from chemical interactions.

- Ease of Installation: PEX is lighter than both PVC and CPVC and can be installed easily and quickly. In addition, it can be installed with fewer tools, which saves both time and expense. Its flexibility allows for fewer fittings which helps in saving costs and streams the installation process.

- Cost: Although the initial material cost of PEX is a bit higher than PVC, it saves on labor costs due to its simplified installation. CPVC is generally in the same range as PEX, but its limited versatility makes it less ideal.

- Noise Reduction: PEX offers a quieter plumbing system when compared to PVC and CPVC, as it dampens the water hammer noise more effectively.

With proper installation and maintenance, studies and industry data suggest that PEX systems can last over 50 years, aligning with or even exceeding the lifespan of other plastic alternatives. This is what makes PEX a favorable option for both residential PEX and commercial plumbing systems.

Are Copper Pipes the Safest Choice for Drinking Water?

The superior strength, heating endurance, and bacteriostatic properties of copper pipes make them a safe option for drinking water transport. Safety also depends on the pipe installation and water quality. “Soft” or acidic water can corrode copper, increasing its concentration within drinking water. Long-term exposure to elevated levels of copper may have adverse health effects. Careful monitoring of the installation process and water quality tests ensures the reliability and safety of copper pipes for drinking water systems.

Copper Pipe Durability and Water Quality Impact

The strength and durability of copper pipes contribute to their popularity in plumbing systems. Studies indicate that copper can last a lifetime exceeding 50 years when properly maintained. It is dependable in various water conditions due to its natural corrosion resistance. New research also shows an estimated 80% of copper tubing sourced from recycled materials, bolstering eco-friendly construction practices, making copper pipes highly recyclable.

On the downside, one of the most critical effects on the integrity of plumbing systems with copper parts is water quality. For instance, a water pH level below 6.5 is highly corrosive, meaning it can accelerate the corrosion process and increase the risk of copper leaching into the water supply. Data shows concerns over copper exceeding 1.3 mg/L, which is set as the action level by the Environmental Protection Agency (EPA). Over time, Health concerns include gastrointestinal distress and, in extreme cases, damage to the liver and kidneys. These risks can be mitigated through regular water quality tests and implementing corrosion control techniques such as adjusting pH.

Additionally, the installation procedure greatly impacts the life span of the pipe and any potential problems. Proper soldering and correct choice of materials minimizes leaks while maximizing the operation of the system as a whole. With appropriate installation combined with regular management of water quality, copper pipes can continue to be one of the most dependable and safest options for residential and commercial buildings’ plumbing systems.

Copper Pipes and Acidic Water Concerns

Although durable, copper piping is frequently used within plumbing systems as it does have areas of weakness, such as coming into contact with corrosive water. Acidic water, defined by a pH level less than 7, poses a direct threat to the integrity of plumbing systems as it can cause copper pipes to develop pinhole leaks and increase the concentration of copper within drinking water. Studies suggest that water with a low pH poses a risk such as enhanced copper erosion is common in places known to have soft groundwater, where its effect is mediated by the contact of the pipes internal surface, which means the water would internally scrub the pipes free of copper oxide encapsulating layers of protective copper oxide.

Publication cites suggest the optimal pH range for water supplies should be set between 6.5 and 8.5 to alleviate the potential risk of pipe corrosion. It is argued that water systems possessing a pH below 6.5 greatly heighten the probability of copper leaching into the system, at times surpassing the EPA-suggested limit of 1.3 mg/L of copper in drinking water. Exceeding elevated copper levels in water may be detrimental to one’s health over long periods due to the potential harm to the liver or kidneys, along with gastrointestinal problems.

In addressing these challenges, water treatment approaches like pH modification through neutralizing filters, or chemical balancing with soda ash or lime, are especially effective. These strategies increase the alkalinity of the water, which increases the formation of several protective layers within the pipes, mitigating the impact of aggressive water on copper piping. Active testing and monitoring are especially important where there is a concern with aggressive water, ensuring systems are effective and safe for prolonged operation within the treated piping infrastructure.

Can You Use PVC Pipe for Drinking Water Plumbing?

Absolutely, PVC pipes can be employed for drinking water plumbing as long as they come with the appropriate certification. Check for the pipes that show NSF-61 and NSF-PW markings ,as these are accepted standards for drinking water safety. With that in mind, they are usually intended for cold water use, since hot water can weaken the material over time. Always ensure the correct procedures and local regulations are followed with regard to the oversight plumbing scheme.

Is Using PVC Pipes for Potable Water Safe?

Due to its several key properties, PVC pipes are accepted universally as a safe and effective means of transporting potable water. First, the flow of water within the pipe is free from contamination because the PVC pipes are non-corrosive and do not react chemically. Studies suggest that the lifespan of PVC pipes is around 50 to 100 years, decreasing the chances of leaks or breaks over time. Also, they do not emit any negative off-gasses that would make water unsafe to drink if certified, and therefore, can be reliably certified for drinking water applications.

Moreover, plastic, and especially PVC, pipes offer substantial material cost benefits over metals. They are lightweight, easy to install, and require very little upkeep. According to the industry, installation costs can be reduced by as much as 30% by employing PVC pipes in water systems. The maintenance-free nature is also a bonus. The efficiency of flow is further enhanced by their smooth interiors, which reduces biofilm and sediment buildup, all of which aids towards better water quality.

Considerations for Safety and Long-Term Use

Though safe for drinking water, PVC pipes need a few precautions to guarantee their safety and longevity. For instance, their best use is with cold water applications, as constant exposure to 140°F (60°C) for prolonged periods will severely damage the material. Compliance with safety standards requires the use of NSF-61 or NSF-PW certified pipes marked for Potable Water Use. For enduring dependability and efficiency, regular inspections along with compliance with the local plumbing code are vital.

CPVC Pipes vs Standard PVC for Water Supply

With respect to water supply, CPVC pipes and standard PVC differ in numerous aspects. The distinguishing factor for CPVC pipes, which stands for Chlorinated Polyvinyl Chloride, is that they’re engineered to handle higher temperatures when compared to standard PVC. This makes CPVC ideal for hot water applications. CPVC pipes can withstand temperatures up to 200°F (93°C) while standard PVC is capped at a maximum temperature of 140°F (60°C). Systems that require heat-resistant materials, like hot water plumbing and certain industrial processes, will find CPVC as the better choice.

Another distinguishing feature is their chemical resistance. CPVC is preferred in industrial settings for transporting chemicals, as CPVC has superior chemical resistance to certain corrosive substances. In addition, CPVC is often less susceptible to degradation caused by prolonged exposure to chlorine, a fact which is particularly relevant in municipal water supply systems.

From a step-wise perspective, CPVC is more costly than standard PVC, which tends to make the decision easier. Both materials can be cut, shaped, and joined through solvent cements. The ease of installation CPVC offers comes from its lightweight and flexible structure which makes it easier to install.

Ultimately, as one option is selected over the other, local building code compliance must also be checked. In many areas, CPVC is permissible for both cold and hot water systems, while standard PVC is often restricted to cold water applications. Knowing these differences is fundamental in choosing the right piping material that optimizes costs, durability, and efficiency.

PVC Pipe Fittings and Drinking Water Safety

Using PVC pipe fittings in drinking water systems has drawn criticism due to questions relating to safety and possible chemical leaching. Polyvinyl chloride (PVC) and CPVC (chlorinated polyvinyl chloride) fittings are manufactured for plumbing purposes; as such, their use in drinking water systems is usually subject to stringent legal regulations.

Research indicates that PVC and CPVC pipes are safe for potable water systems as long as they are certified to NSF/ANSI Standard 61, which ensures a cap on allowable levels of useful materials and contaminants in drinking water. CPVC usually has additional chlorination processing done to it, which makes it more resistant to bacterial growth and high temperatures, making it advantageous for hot water systems.

Studies claim that other compounds, such as vinyl chloride monomer and other production additives, may be leached, especially under extreme or prolonged exposure. The World Health Organization (WHO) and Environmental Protection Agency (EPA) constantly track permissible concentrations of harmful substances to safeguard the public. The EPA has also set a maximum contaminant level for vinyl chloride in drinking water at 0.002 mg/L to mitigate health risk exposures.

The modernization of PVC pipe fittings and their production relating to public health and safety standards concerns have been these days lessened due to newer production methods and advanced testing procedures. Moreover, the position of CPVC pipes in the policies of many water systems seeking durability and safety is preferred because of their ability to withstand heat and resist various chemicals.

Regular maintenance and following recommended installation practices will contribute to the preservation of water standards and an increased lifespan of the piping system.

What Are the Best Plastic Pipes for Safe Drinking Water?

The safest plastic pipes for drinking water are CPVC (Chlorinated Polyvinyl Chloride) and PEX (Cross-Linked Polyethylene) pipes. Both materials endure heat as well as chemical reactions, keeping water uncontaminated. CPVC is especially useful in hot water systems while PEX gives flexibility and ease for installations. Both options have been tested and proven to be safe and compliant with regulations for water systems. Always check local requirements for compatibility with particular specifications.

HDPE Pipes and Drinking Water Safety

The most current acceptance for the use of pipes made from High-Density Polyethylene (HDPE) is in the area of potable water delivery due to their safety and efficiency. HDPE pipes are constructed from a safe material that does not leach, ensuring safe drinking water, even over long distances. Their seamless geometry greatly minimizes the risk of leakage which can lead to contamination and wastage of water.

Another significant benefit of HDPE pipes is their usefulness under difficult environmental conditions. These pipes can function within a very wide span of temperatures and pressures, which is ideal for different regions and scenarios. Moreover, research indicates that with proper installation and maintenance, HDPE pipes can endure for more than half a century, which provides a cost-effective solution when considering long-term infrastructure expenses.

In addition to passing health and safety regulations such as NSF/ANSI 61 for drinking water systems, HDPE pipes are environmentally sustainable. Their smooth interior surfaces facilitate easier water flow, which means lower costs for pumping energy. Furthermore, the recyclability of HDPE pipes contributes to the fight against plastic waste. For all the above reasons, HDPE pipes are a great option for safe, reliable, and cost-efficient systems.

Which Plastic Pipes Are Resistant to Acidic Water?

When dealing with acidic water, it is important to consider the durability and safety of the pipes selected for use, particularly their resistance to chemical attack. For corrosive materials, including acidic solutions, High-Density Polyethylene (HDPE) pipes are some of the best options available. Both HDPE pipes and their fittings perform admirably in low pH aqueous environments owing to the non-reactivity of the materials. In the laboratory, HDPE pipes were tested for withstanding the pressure of a pH range of 1 to 14, thus confirming their suitability for transporting water with high acidity.

Another material known to have high resistance is polyvinylidene fluoride (PVDF). PVDF pipes display outstanding resistance to chemicals and thermal stability. These pipes are widely applied in industrial or chemical processes expected to come into contact with strong acids. PVDF´s resistance to harsh chemicals is unquestionable, with hydrochloric and sulfuric acids failing to alter its structure even at 284°F (140°C).

Another potential candidate is Polypropylene (PP) piping, especially for moderately acidic environments. PP pipes enjoy popularity for their strength and moderate reaction to chemical agents including acids.

The long term performance of a piping system under difficult chemical condition hinges on the use of materials that have excellent resistance to corrosion.

How to Choose the Right Water Pipe for Your Plumbing System?

When selecting a water pipe, think about the:

- Water Type: Check whether the water supply is hot, cold, or has some chemical additives, since this will alter compatibility with the materials.

- Material Durability: For corrosion resistance, PVC and CPVC add plastic durability while copper responsibly adds the needed ductility and strength.

- Environmental Conditions: The Surrounding pipe temperature and exposure to the Sun may affect the bend radius.

- Budget: Balance lifespan, maintenance, and cost of the material.

- Local Building Codes: Ensure all choices comply with local plumbing regulations for safety and legal requirements.

All considerations combined will guarantee correct pipe selection, which encourages optimal performance combined with reliable longevity for the plumbing system.

Factors to Consider for Safe Drinking Water Pipes

- Material Safety: select materials that are marked as safe for use with drinking water. Common safe options include copper, CPVC, PEX, and stainless steel. Copper pipes have the added benefit that bacteria will not grow on them, PEX is appreciated because of its flexibility and its resistance to freezing. The best choice is any material which is not known to leach dangerous water pollutants, lead, or BPA.

- Chlorine Resistance: Chlorine is used by many municipal water systems to disinfect water. A good choice would be CPVC and PEX which does not resist to the long term effects of chlorine since these cover the risks of destruction as well as possible contamination.

- Durability and Longevity: Think about the piping material for how long it is going to last. For instance, copper pipes usually have a life expectancy of over 50 years, while PEX pipes have a lifespan of 40 to 50 years when installed and maintained properly. Also consider the material’s structural integrity under pressure and environmental stress.

- Temperature Tolerance: Under both high and low water temperatures, the pipes should withstand pressure without cracking or deforming. For example, stainless steel and copper do well in high temperature places, PEX does well in freezing condition.

- Leakage Rates: Compared to the old systems with iron or even PVC pipes, Polyethylene-based pipes, PEX in particular, are known to have reduced leakage rates which ultimately increases water efficiency.

- Environmental Impact: Minimizing environmental harm can also be achieved through the use of copper and stainless steel materials, which are recyclable, or PE, which requires less energy to produce. This lessens the ecological impact connected to plumbing materials.

- Cost Effectiveness: Overall spending may differ at first glance, but think about the convenience of installation and sustained upkeep. An example is PEX, which is generally easier to install compared to rigid materials like copper or steel, which can be more costly in the long run due to higher labor costs.

Considering these factors will guarantee that the selected piping material fulfills the criteria of safe drinking water and meets efficiency and sustainability requirements.

Water Pressure Requirements and Pipe Selection

Water pressure is a major factor in plumbing systems require a specific type of piping. For residential buildings, the water pressure is usually set between 40 and 80 psi (pounds per square inch). Pipes must be able to manage and contain the pressure without undue stress of failure or leaks. PEX, CPVC, and copper pipe materials are commonly used because of their ability to endure high pressure.

Steel or galvanized steel pipes may be more suitable for applications requiring greater water pressure. Steel pipes have a lot higher durability and burst pressure compared to water pipes, for instance galvanized steel pipes could withstand +100 psi. The only downside is that these materials are also more rigid, and their tendency to corrode over time is higher than with PEX and CPVC.

Modern piping materials like PEX are engineered to handle pressure peaks, and are usually qualified to 160 psi at 73°F. This value makes it suitable for both residential and some commercial buildings. Also, the pipe size should not be overlooked, because if the diameters of the pipes are Large the plumbing system water pressure is easily sustained.

Evaluating the water pressure criteria and reconciling these with the technical requirements of existing piping materials guarantees system durability, as well as appropriate water circulation.

Water Filtration Options for Different Pipe Materials

Choosing the best water filtration system is dependent upon the kind of pipe material in use given that some materials respond differently to contaminants or the filtration processes.

- PVC Pipes

The strong resistance of PVC pipes to corrosion and chemical reactions makes them ideal for use with various types of filtration systems. This material works well with carbon block filters that also remove chlorine, sediment, and volatile organic compounds (VOCs). The PVC pipes do not corrode, which ensures no contaminants leach into the clean water from the pipes, which would purify water.

- Copper Pipes

The main advantages of using copper pipes include being very durable, having natural antimicrobial properties, and being susceptible to leaching with acidic water. Water transported through copper pipes will benefit greatly from reverse osmosis (RO) filtration systems because they remove minerals that would otherwise corrode the pipe due to acidic water. Studies show that RO systems can provide up to 98% reduction of heavy metals such as lead and copper, hence safer water delivery.

- Galvanized Steel Pipes

Gas pipes made from galvanized steel are prone to rust and may scale iron, dirt, or other particulates into the water. Use of sediment filters is highly recommended for households with galvanized pipes, known to remove rust particles and clogging in upstream plumbing or filtration systems.

- PEX Pipes

The benefits of PEX piping are its flexibility, ease of installation, lack of corrosion, and scaling over time. PEX is also compatible with a variety of filtration systems, including carbon filters, which remove chlorine and organic impurities. The smooth walls of sediment buildup increase the chances of maintaining high filtration efficiency.

- Stainless Steel Pipes

Modern stainless steel pipes offer great resistance to corrosion and can transport both hot and cold water. These systems work well with stainless steel pipes as the material decreases the chance of impurities entering the treated water after filtration.

Selecting a suitable water filtration system enhances water quality and extends the longevity of your plumbing system. Knowing how different pipe materials interact with various filtration options guarantees efficient and safe water use tailored to specific needs. Always keep local water quality reports and the condition of the pipes in mind when choosing a filtration option.

Reference Sources

1. Our Water Mains Contaminate Us with E. Coli, Lead, and Copper – Preventable Illness and Death Follow

- Published: 2021

- Key Findings: This study highlights the contamination risks in water mains, particularly from E. coli, lead, and copper. It emphasizes the need for better control of water main breaks and operational adjustments during power outages to minimize contamination. The research also suggests that corrosion in pipes significantly contributes to contamination.

- Methodology: The study analyzed water systems’ operational failures and their impact on contamination levels, focusing on microbial and chemical risks.

2. Analysis of Sachet Water, Bottled Water, and Borehole Water Consumed in and Around Anambra State Polytechnic, Nigeria

- Published: Recent (exact year not specified in the document)

- Key Findings: The study found that sachet water often failed to meet safety standards, with contamination from bacteria like E. coli and Klebsiella species. Bottled water showed better compliance with safety standards. The findings stress the need for stricter monitoring and regulation of water production and packaging.

- Methodology: A quantitative analysis was conducted on 30 water samples (10 each from boreholes, sachet water, and bottled water). Parameters like pH, turbidity, and bacterial contamination were measured using standard laboratory methods.

3. An Educational Intervention to Study the Awareness of Solar Disinfection of Drinking Water

- Published: 2014

- Key Findings: This study focused on increasing awareness of solar disinfection (SODIS) as a low-cost, sustainable method for treating drinking water. Post-intervention, there was a significant increase in awareness about SODIS among urban slum residents, with a 66% improvement in understanding the method.

- Methodology: A cross-sectional study with 100 participants was conducted. Educational interventions included lectures, pamphlets, and audiovisual aids. Pre- and post-intervention awareness levels were statistically analyzed.

Frequently Asked Questions (FAQs)

Q: What are the safest pipes for drinking water in residential plumbing?

A: The safest pipe for drinking water in residential settings is generally considered to be copper. Copper pipes are durable, naturally antimicrobial, and don’t leach harmful chemicals into your drinking water when properly installed. Other safe options include cross-linked polyethylene (PEX), which is flexible and resistant to scale buildup, and high-density polyethylene pipes (HDPE), which are highly resistant to corrosion and chemical leaching. Stainless steel is another excellent choice, though more expensive. It’s important to note that the safety of your plumbing system also depends on proper installation and water quality factors, such as if your water has a pH that might cause corrosion.

Q: Are plastic pipes safe for drinking water systems?

A: Yes, certain plastic pipes are safe for drinking water systems when properly certified. PEX (cross-linked polyethylene) pipes are widely considered safe and have become increasingly popular for residential water supply lines. High-density polyethylene pipes (HDPE) are also considered safe for drinking water. However, not all plastic pipes are created equal. While plastic pipes are generally resistant to corrosion, some concerns exist about certain types potentially leaching chemicals into your drinking water. Always look for pipes that are NSF/ANSI 61 certified, which means they’ve been tested and approved for drinking water applications. Avoid using PVC pipes for hot water applications, as higher temperatures can increase the risk of chemical leaching.

Q: What are the concerns with polyvinyl chloride (PVC) pipes for drinking water?

A: While polyvinyl chloride (PVC) pipes are commonly used for drinking water, there are some concerns to be aware of. The main issue is the potential for PVC to leach chemicals into your drinking water, particularly in hot water applications. PVC contains various additives and stabilizers that may migrate into water under certain conditions. This is why it’s generally recommended to avoid using PVC pipes for your main hot water lines. Instead, they’re better suited for cold water applications. If you do use PVC, ensure they’re specifically labeled for potable water use and carry NSF/ANSI 61 certification. CPVC (chlorinated PVC) is an improved version that’s rated for both hot and cold water and may be a safer alternative.

Q: How do copper pipes compare to other options for drinking water safety?

A: Copper pipes in your home are considered among the safest options for drinking water systems. They’re naturally antimicrobial, helping to prevent bacterial growth in your water supply pipes. Unlike some alternatives, properly installed copper pipes don’t leach harmful chemicals into your drinking water. However, there are some considerations: in homes with acidic water (low pH), copper contaminants in your drinking water can become an issue through a process called corrosion. This may result in copper particles in your water, which can cause health issues in high concentrations. Copper is also more expensive than plastic alternatives and requires skilled installation. Overall, when matched with appropriate water chemistry and properly installed, copper remains one of the safest and most reliable piping materials.

Q: What type of safe pipe should I use for connecting my water heater?

A: For connecting a water heater, you need pipes that can safely handle high temperatures. Copper pipes are generally considered the safest option for water heater connections due to their excellent heat resistance and durability. CPVC (Chlorinated Polyvinyl Chloride) is another safe option specifically designed to handle hot and cold water and can withstand temperatures up to 180°F. PEX (cross-linked polyethylene) pipes are also suitable, but should not be connected directly to the water heater—maintain at least 18 inches of metallic piping before transitioning to PEX. Avoid using standard PVC, as it’s not rated for hot water applications and may leach chemicals into your drinking water when exposed to high temperatures. Always check local building codes, as requirements for water heater connections vary by jurisdiction.

Q: How can I tell if the pipes in my home are safe for drinking water?

A: To determine if the pipes in your home are safe for drinking water, start by identifying what they’re made of. Modern homes typically use copper, PEX, CPVC, or other materials certified for potable water. If your home was built before 1986, you might have lead pipes or lead solder, which pose serious health risks. Look for pipe color: copper is reddish-brown, PEX is typically color-coded (red for hot, blue for cold), PVC/CPVC is white or cream, and lead pipes are dull gray and non-magnetic. You can also test your water for contaminants using home test kits or professional laboratory analysis. Installing a water filter certified to remove specific contaminants can provide added protection. When in doubt, consult with a licensed plumber who can inspect your plumbing system and advise if it’s safe to use for drinking water.

Q: Are PEX pipes a safe alternative for main water supply lines?

A: Yes, PEX (cross-linked polyethylene) pipes are considered a safe alternative for main water supply lines. PEX pipes are also increasingly popular due to their flexibility, ease of installation, and resistance to freezing. They don’t corrode like metal pipes and don’t typically leach chemicals into your drinking water when properly certified. Look for PEX pipes that are certified to NSF/ANSI Standard 61 for drinking water safety. Some early concerns about certain chemicals leaching from PEX have been addressed in modern manufacturing processes. PEX pipes are made with improved formulations that minimize any potential health risks. They’re suitable for both hot and cold water applications and have become one of the most widely used materials for residential water systems in new construction and remodeling projects.

Q: What are high-density polyethylene pipes (HDPE), and are they safe for drinking water?

A: High-density polyethylene pipes (HDPE) are a type of plastic piping that’s increasingly used for drinking water applications. HDPE pipes are highly regarded for their safety and durability. They’re resistant to corrosion, chemical leaching, and UV damage, making them suitable for both underground and exposed installations. HDPE pipes are made from a food-grade plastic that doesn’t impart taste or odor to water. They contain no harmful chemicals like BPA or phthalates that could contaminate drinking water. Additionally, they’re resistant to scale buildup and can handle both high and low pH water without degradation. HDPE is approved for use in municipal water systems and residential applications, carrying necessary certifications like NSF/ANSI 61. Their flexibility makes them resistant to breakage from ground movement, freezing, or water hammer effects, reducing the risk of leaks that could introduce contaminants.