Efficient plumbing systems, both in industries and residences, rely on fittings to aid in flow and connection. One such fitting, “nipple,” is particularly interesting both for its function of joining and extending pipes, as well as for its unusual name. But what are the reasons for such nipples to be called as they are, and what makes them so crucial? This article explores the history, function, and purpose of pipe nipples. If you are a professional in plumbing, a DIYer, or even just someone with curiosity about the names used, this guide is for you. It sheds light on the vital components of plumbing.

What is a Pipe Nipple?

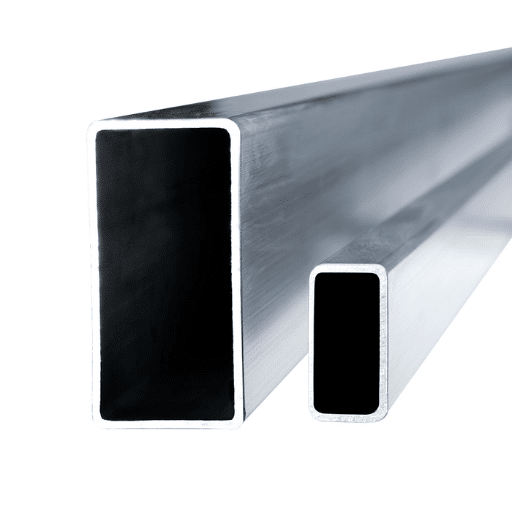

To connect two pipes or pipe fittings, a pipe nipple is a short length of pipe with threads on both ends. As an important part in extending the length of pipes or changing the size of the pipes, it serves a very useful function. Pipe nipples can be made out of steel, brass, or even PVC, and they come in different diameters and lengths for various plumbing uses. They have a simple structure and network-wide adaptability, which makes them fundamental in numerous piping systems.

A nipple is a short piece of pipe

Pipe nipples are described by their material composition, type of threading, and coating, each serving different functions across various sectors. Some widely known ones include: black pipe nipples, galvanized pipe nipples, stainless steel nipples, and brass nipples. Black pipe nipples are gas and oil lines due to their ability to withstand high temperatures. Zine-coated galvanized pipe nipples are excellent in the prevention of corrosion in water distribution systems. Stainless steel options are extremely resistant to chemicals and high temperatures, making them staples for food processing and pharmaceutical industries. Brass nipples are famed for their resistance to corrosion and are commonly used in plumbing systems.

Studies indicate there will be significant growth this decade for the infrastructure of water treatment, along with an uptick in construction activities that will drive the business market for plumbing fittings, which include pipe nipples. Sustained demand from the residential and industrial sectors due to the versatility and durability of these fittings will aid this growth. The reliability of these components adds efficiency when extending pipe runs and adapting fittings, making pipe nipples essential in modern piping systems.

Understanding the function of a pipe nipple

Pipe nipples are short, cylindrical metal pipes that are threaded on both ends, designed to interlink two mechanisms or extend pipe runs. Their use is critical to achieve optimal piping in system processes ranging from simple plumbing to sophisticated industrial procedures. Commonly used materials for manufacturing pipe nipples include stainless steel, brass, galvanized steel, and PVC, with each one serving a unique purpose depending on the system’s pressure, temperature, and corrosion resistance.

As per new industrial analyses, the global industrial pipe market is expected to grow to nearly $94 billion by 2028, partially driven by the increased need for pipes and their component parts, such as nipples, in the oil and gas industry, chemical processing, and water treatment sectors. Standard sizes of pipe nipples range from 1 to 12 inches, however, custom sizes are manufactured for particular projects. Ensuring proper compatibility between materials and installation techniques further shields against wear and leaks in high-pressure and extreme environment systems.

How do nipples connect two fittings?

Pipe nipples act as connectors between two fittings in order to allow fluid, gas, or any other substance to flow in a steady manner. These cylindrical fittings are equipped with threads on both ends, meaning they can screw directly into the threaded holes of other pipes like couplings, elbows, or valves. The tapered threads, which join their own threads, are usually softened clamps that, when placed together, become more solid.

Numerous items, like Stainless steel, brass, and PV-C, all serve as materials needed in manufacturing pipe nipples. Each item on the above list serves a unique purpose; for instance, stainless steel nipples are highly sought after for systems dealing with corrosive chemicals, while PVC ones are mostly used in water supply systems. Industry insights point out that threaded pipe connections are labeled as durable, le which claim varies only based on how the components are installed. With installation done properly, these components work seamlessly, enduring 15,000 psi in specialized environments. A functioning connection starts with meticulous threading and standards like NPT.

What are the Different Types of Pipe Nipples?

There are various types of pipe nipples, each intended for a specific purpose. The most common types include:

- Close Nipples: These have threads that are uniformly spiral and grouped for the entire length of the pipe. They allow for tight fittings and are quite useful.

- Hex Nipples: These have threads in the form of a hexagon at the center part, which allows an easy grip of a wrench when installing.

- Reducing Nipples: Used for connecting pipes with different dimensions, this type of nipple provides a seamless transition from one size to another.

- Barrel Nipples: These have longer thread sections than the close nipple, used when specific lengths of pipe are required.

- Swage Nipples: Like a reducing nipple, but not quite, these are tapered and intended for use on pipes in low-thrust systems.

Different types are selected depending on the needs of the particular piping system for maximum effectiveness and longevity.

Exploring the various types of pipe nipples

Pipe nipples are fabricated from a wide range of materials to fit different applications, which have their own advantages. The most common materials used are:

- Carbon Steel: Widely employed in the petroleum and gas industries, carbon steel pipe nipples have earned immense fame for their unparalleled strength and sharp staying power. These carbon steel pipe nipples not only endure intense temperatures, but they also offer stunning resistance to abrasion. With all these reasons combined, they are perfect for heavy-duty applications.

- Stainless Steel: Primarily used in food and beverage chains as well as chemical processing centers, stainless steel nipples are extremely well known for their sharp corrosion resistance as well as defenses against extreme cases of temperature. In addition to durable stainless steel, these nipples are super stylish due to their sleek finish, which significantly enhances their nutritional and aesthetic appeal.

- Brass: Widely used in the waterworks industry and plumbing systems, brass pipe nipples have gained huge popularity in recent times because of their rising corrosion resistance. They are also very low-cost due to their easy machinability, and due to such factors, they are quite reliable in low to medium pressure situations.

- PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride): These materials are inexpensive and easily available for non-corrosive environments. They have good chemical resistance, though, the situations need to be of a less intensive regime. Most people make use of PVC and CPVC pipe nipples because they are non-volatile, lightweight, and are frequently utilized in residential, irrigation, and drainage systems.

Standard Dimensions and Tolerances

To guarantee system interoperability, pipe nipples must meet specific dimensions and tolerances. Common standards include:

- Nominal Pipe Size (NPS) and Diameter Nominal (DN) standards ensure global interoperability.

- Fast NPT and BSP standards are responsible for the threading dimensions necessary for secure connections.

-

From close nipples (typically less than an inch) to longer custom sizes, application requirements dictate the standard length of nipples that vary among different applications.

These specific dimensions guarantee uniformity across industries or applications, enhance safety, and enable effortless integration into the system.

What is a closed nipple?

A close nipple is a piping component with threaded exits on either side, allowing connection of two valves or fittings in a compact space, and is quite short. Since the ‘closet nipple’ is shaped as two circles connected by a tube, it lacks any unthreaded pipe stem between them.

Differences between seamless and galvanized pipe nipples

Different forms of pipes and pipe nipples are designed to meet distinct requirements. They are also manufactured using different processes, which are tailored to the purpose needed.

Seamless Pipe Nipples: A seamless nipple is one without a welded seam and thus manufactured with a smooth cylinder surface throughout the pipe’s structure. They also do not have welded joints, which makes them seamless nipples, highly durable and resistant to corrosion and pressure, and able to withstand high temperatures. They are made of oil and gas, petrochemical, and power generation industries, whose motivations were dependent on reliability and strength needs. Because of their advanced structural integrity, seamless nipples are best chosen for high-pressure systems. Production starts with heating and perforating solid steel billets to achieve the seamless end product.

Galvanized Pipe Nipples: On the other hand, zinc nipples have a coating of zinc, which is used to protect them, and are identified as nipples on galvanized pipes. Nipples are the simplest devices whose use has been made in mechanical structures for a long period of time. Due to their added strength and protection against rust, galvanized nipples are widely used in plumbing systems and distributed outside, in industrial regions, and in water systems that are left exposed. The process of galvanization increases the zinc layer on the pipe’s surface,w hich makes the Pipe weakened in its damp and acidic surroundings, but does increase the susceptibility to corrosion and slight changes in its size compared to seamless types. The use of galvanized nipples is not suitable for systems carrying some chemicals or placed where the zinc coating could spoil over a period of time.

Key Differences at a Glance:

- Manufacturing Process:

-

- Seamless nipples are made without welding, creating a uniform solid.

- Galvanized nipples can be manufactured from steel, which is then coated with zinc.

- Durability:

-

- Seamless nipples will perform best in high-pressure and high-temperature environments.

- Galvanized nipples excel in the presence of moisture and corrosion.

- Applications:

-

- Seamless nipples are appropriate for heavy-duty, industrial workloads.

- Galvanized nipples are designed for domestic use and certain industrial applications involving water.

- Resistance:

-

- Seamless nipples remain the strongest and most pressure-resistant but naturally corrode without coatings.

-

Galvanized nipples remain rust-resistant, though not all environments will be suitable for their chemical exposure.

While picking between seamless and galvanized, ensure to focus on the pressure requirement, environment, type of fluid, and maintenance over time so that performance is not compromised.

How Do Pipe Nipples Fit Into Plumbing Systems?

Nipples Adapters are important in plumbing because they connect two pieces of pipe or attach pipes to different devices, faucets, and valves. Also, they extend pipelines, change their direction, and provide reliable connections in confined spaces. To a large extent, their utility and api maintenance for accommodating water, gas, or any other liquids efficiently in their system. Their selection of material, size, api diameter maintains pressure and system reliability over time.

Nipples in plumbing: Why are they essential?

Pipe nipples are critically important to modern plumbing systems because they enable seamless and strong connections to be formed. From extending pipelines to interlinking various components, their uses and applications are manifold in industries and households alike, as they facilitate fluid conveyance. The construction material of pipe nipples, such as steel, brass, PVC, or stainless steel, directly impacts their durability and resistance to corrosion. Thus, material selection is crucial based on the type of fluid being transported and the conditions in which they are installed.

In specialized industrial applications, for example, stainless steel pipe nipples are highly regarded for their strength and corrosion-resistance, while PVC options are frequently favored for water supply lines because of their light weight and economical price. As per reports by industry specialists, durable fittings like pipe nipples are in high demand with the global plumbing fittings market anticipated to surpass $90 billion by 2030, increasing at a healthy CAGR of almost 5% each year. These trends highlight the increasing demand for quality pipe fittings due to evolving infrastructure needs and environmental sustainability concerns.

Also, new technologies and updates in the manufacturing processes have boosted the quality and accuracy of these parts, enabling modern pipelines to handle greater pressure and temperature, which improves the system’s operational efficiency.

Connecting pipes using a pipe nipple

Pipe nipples are integral parts in plumbing as well as in various manufacturing activities. They serve to join pipes in different applications. A pipe nipple is a short cylindrical section of pipe with male threads on both ends. This design allows easy connection of fittings, valves, or other pieces of piping. These parts find extensive application in systems that are frequently disassembled, like maintenance-intensive industrial pipelines or fluid transport systems.

Pipe nipples are made from a variety of materials such as stainless steel, brass, and carbon steel. They are made from these materials due to differing environmental and operational needs. For instance, stainless steel pipe nipples are ideally suited for chemical processing and marine applications as they do not corrode. Brass pipe nipples, on the other hand, are best used in plumbing fixtures due to their price and durability.

New reports suggest that the demand for pipe nipples is increasing in the oil and gas industry. Their systems commonly need to withstand very high-pressure and temperature situations. Once skilled engineers can now manufacture metal pipe nipples able to withstand more than 10,000 psi for other high-performance applications, he added. The global piping market is also steadily growing, which in turn stimulates innovation for the designs of pipe nipples as well as their materials. These changes are intended to keep up with new standards on how well a pipe nipple is engineered.

Pipe nipples improve system efficiency while decreasing the chance of leaks in environments that require a great deal of maintenance. Their adaptability makes them useful across many different fields.

Thread types and their importance in fittings

The effectiveness and security of a connection within the components of pipe fittings greatly depend on the thread types used. Some of the common key thread types encompass National Pipe Tapered (NPT), British Standard Pipe (BSP), and even Metric Threads.

As for the United States, threaded NPT is mostly used and has a tapered shape. When installed correctly, NPT will achieve a tight seal that will prevent leakage. BSP threads are well known across Europe and Asia as well. They can be subcategorized into BSPP (parallel) and BSPT (tapered). As the name suggests, metric threads are measured and categorized in the metric system, which makes them widely used in many industrial and mechanical applications around the globe.

Simply matching components is far from the only reason explaining the importance of choosing the right thread type. Thread combination mismatch can cause leaks, fractures, system malfunctions, or quite severe in some cases, system failure. Like many other industries, these are pivotal for oil and gas construction as well as chemical processing. The rest of the world has strict regulation guidelines that need to be followed for safety and thread efficiency, which adds to system flaws.

Global demand for threading precision has become a standard metric of sorts. In industrial settings, research indicates that 80% of system failures that are reported stem from improper fittings or, at best, faulty thread alignments. These statistics support the claim that the proper application of standardized threads of the types necessary to a specific system is critical. Advanced systems like thread coatings or sealants continue to augment these systems with improved durability and leak resistance under severe operational conditions.

What is the Role of Pipe Nipples in Piping Systems?

The piping system provides significant sections for sectional piping: Pipe nipples aid in connecting infinite piping sections. Pipe nipples are defined as short, evenly cut, threaded pieces used in extending or joining pipes, valves, and other components. Pipe nipples give a secure connection needed in a piping system, which enables the smooth flow of liquids or gases. The strategic system enhances both the efficacy and reliability of gas or liquid transportation. Pipe nipples are useful in domestic and industrial settings.

Why is a pipe nipple considered a fitting?

A pipe nipple is regarded as both a fitting and component because it has an important role as it joins different sections of piping systems, also a constituent part of a plumbing system. Its configuration is such that it has threads at one or both ends that conveniently secure piping and apparatus such as pipes, valves, etc. Working with pipe fittings and pipe nipples is something that is very common and, as such, indispensable in plumbing works.

Pipe nipples differ from one another in either stored in stock as or stainless steel, carbon steel, brass, or PVC, where each all or part meets specific application requests, needs, or demands. For instance, stainless steel pipe nipples are frequently used in highly corrosive environments because they do not rust easily. On the other hand, the PVC models are very easy, light in weight as opposed to their size, and can be used in plumbing or irrigation systems. Pipe fittings and pipe nipples are subject to the regulation of the American Society for Testing and Materials (ASTM) to ensure that there are safety and performance checks through all functions of service.

Pipe nipples also meet safety requirements and performance criteria, thereby making it possible for them to be used as fittings in numerous industries. These, combined with other parameters such as standard dimensions and threaded NPT, offer seamless flexibility and compatibility with systems. The mentioned criteria allow pipe nipples to easily respond to requirements, whether operating in high-pressure or low-pressure systems.

How do different pipe sizes affect nipple usage?

Varying sizes of pipes have a direct effect on nipple use since that determines the flow rates, pressure, and how well they fit within the system. In my case, the right pipe size guarantees an efficient system, as too small or too large nipples can create undersized drag devices, lead to leaks, and even complete system failure. Nipple dimensions must correspond precisely to the adjacent pipes to help the system function as intended.

Using a pipe wrench with nipples

Using a pipe wrench with nipples demands utter skill, precision, and the correct safety measures. A pipe wrench is meant for gripping pipe surfaces, meaning it is useful for tightening and loosening threaded nipples. Ensure the wrench’s adjustable jaw covers the nipple at a non-threaded grip to prevent damage. Overtightening can lead to deformation of the threads, poor sealing, and leaking in the system.

When dealing with steel or brass nipples, the material’s strength alongside its torque tolerance must be factored in. For example, softer materials like brass will not be able to stand up to the same amount of torque as steel nipples. During installation, a best practice is to use Teflon tape or pipe dope as thread sealants. With this, there is additional sealing applied, and the chances of leaking are reduced. Designed industry standards specify that a snug fit, without excess force, ensures functionality whilst preventing structural damage.

How to Choose the Right Pipe Nipple?

Select a suitable pipe nipple by taking into consideration the factors below:

- Material: Choose a material appropriate to the use and surroundings. For example, steel provides strength while brass withstands corrosion.

- Size: Check that the diameter and length conform to the pipe dimensions to provide a proper adjustment.

- Thread Type: Check alignment with the threading norm of the system in use, for instance, NPT or BSP.

- Pressure Rating: The pressure tolerance for safe operation should be met or exceeded by the nipple selected.

- Application Needs: Take into account special parameters such as resistance to temperature or compatible chemicals according to the aim of the system.

Considering these elements guarantees functionality, structural integrity, and safety in the application.

Factors to consider when selecting a nipple

Choosing a nipple, its material is one of the primary considerations. Usually, they are made of stainless steel, brass, carbon steel, or modern plastic materials such as PVC and PTFE. Take stainless steel as an example; it is very durable and resists corrosion like no other, which is ideal for water and harsh chemical industrial applications. Moreover, brass is usually selected because of its malleability and its resistance to galvanic corrosion, especially in plumbing works. It is critical to choose a material that satisfies the environmental conditions of the application, such as moisture, extreme temperatures, or abrasive substances, to maximize life and performance. Current research indicates that stainless steel nipples are most popular in high-pressure uses because certain models withstand up to 5,000 psi of pressure, while brass supports 600-1,200 psi, depending on the design.

Connection Type and Size Recommendations

A requirements-performance alignment must be achieved when setting the system configuration; therefore, the connection type and size need to be specified. Common connection standards, NPT, BSP, and even compression fitting, tend to seek regional and industrial applicability. Orderly measurement of the threading aids in obtaining a secure seal and dampens the chances of leakage. In addition, the correctly chosen nipple length aids in applications demanding specific spacing or necessitating fluidics. The tolerance measures bear an equal claim to attention as mistakes, even small ones with the pitch or diameter of the threads, may impair the overall efficiency of the system. Many experts suggest that adequately sized tools and gauges be at hand during the installation to eliminate oversizing, which in turn reduces wear and increases safety in pressurized systems.

Understanding male and female fittings

Male and female fittings are among the key parts used to join pipes, hoses, and other parts of mechanical, plumbing, and industrial systems. A male fitting usually has external threads which are meant to be screwed into a female fitting with internal threads, forming a tight, leak-proof joint. There is an extensive range of these fittings which differ in materials like plastic, stainless steel, and brass, which are suited to different operating conditions, for instance, the pressure, temperature, or the chemicals involved.

Data shows that stainless steel fittings are specifically dominant in food processing and chemical industries due to their high corrosion resistance. For example, about 70% of fittings used in critical sanitation and structural integrity environments are made from stainless steel grades 304 and 316. In addition, more modern methods of sealing, which include PTFE (Teflon) tape or liquid thread sealants, have improved the effectiveness of couplings by preventing excessive wear on the threads and leaks in high-pressure situations.

It is critical to accurately determine the thread type and pitch when choosing compatible male and female fittings. Standards like NPT (National Pipe Thread), BSP (British Standard Pipe), and ISO offer specific threads for universal compatibility. Thread gauges and specification charts can make the selection easier by reducing errors and achieving optimal performance even in demanding applications.

Importance of the length of the nipple

The nipple length is critical for the proper alignment and operation of piping systems. Nipples—short pipe fittings—connect two pipes or fittings in the system and come threaded on both ends. Aligning the system, balancing the pressure across different sections, and controlling the overall system performance are all affected by the nipple length. Properly selected nipple lengths guarantee that the system components are properly tightened to mechanical seals, which minimizes structural leaks and integrity problems.

According to studies, indiscriminately sized nipples may introduce uneven pressures and increase wear and tear on the entire system. As an example, in high-pressure systems, a nipple that is shorter than optimal may lead to insufficient engagement of threads, which would subsequently result in blowout or joint instability. On the other hand, misplaced long nipples lead to misalignment of the whole system and excess connection stresses. In the industry, it is common practice to base the nipple length calculations around thread engagement, wall thickness, operational pressures, and others. Observing the right tolerances, together with the use of proper materials, the piping system’s range of applications and performance can be improved in terms of safety and operational efficiency.

Are There Any Specific Applications for Pipe Nipples?

Pipe nipples find application in a range of settings across an array of industries. In plumbing systems, they help consolidate pipes to transport liquids and gases. Moreover, these devices are used in industrial applications such as oil and gas, chemical processing, and in some manufacturing plants for high-pressure and temperature applications. Pipe nipples are versatile as they can be used as extensions, reducers, or adapters, which aid in compatibility and flexibility in piping systems.

Where are stainless steel pipe nipples commonly used?

Stainless steel pipe nipples have a wide range of applications in various industries due to their durability. corrosion resistance, and the ability to withstand extreme conditions. These are commonly used in the residential plumbing system for efficient water supply and drainage. In the industrial field, for example, othe il and gas industries, these are part of high-pressure piping systems for reliable transportation of oil, steam, or natural gas. Likewise, these pipe nipples are of great importance in chemical processing plants because of their resistance to many corrosive chemicals and greatly elevated temperatures. Industry reports state that there will be significant growth in the global stainless steel pipe market as it is required in construction, infrastructure, and manufacturing industries. This indicates the growing importance of stainless steel pipe nipples in safe, efficient, and dependable piping solutions systems across numerous industries.

Applications of black pipe nipples in plumbing

Because of their flexibility in various plumbing fields, black plumbing pipe and fittings, along with nipples, are basic standard parts. Some details are as follows:

- Gas Distribution Systems

In both commercial and industrial properties, as well as in homes, black pipe nipples transport propane and natural gas. The strength and high-pressure capabilities of these fittings make them appropriate for all gas fitting installations.

- Heating and Cooling Systems

Also, these nipples are crucial parts in the connection of different units of an HVAC system. They also assist in the unrestricted movement of steam and water in boilers, radiators, and interconnected piping systems.

- Fire Sprinkler Systems

Due to their reliability, black pipe nipples are used as parts in fire prevention systems. This ensures constant availability of water in case of fire, thus satisfying the necessary requirements set by fire safety regulations.

- Irrigation Systems

Black pipe nipples used to facilitate water supply to agricultural and garden irrigation systems play a vital role in maintaining durability under outdoor conditions.

- Industrial Plumbing

In most factories and manufacturing plants, black pipe nipples are commonly used. They are capable of withstanding high pressures of fluids and air systems, thus allowing operations to run in harsh conditions.

- Wastewater and Drainage Systems

For pipes that undergo exposure to tough environments, black pipe nipples are ideal because of their strength and flexibility. These qualities enhance the level of security that these pipes provide in sensitive applications.

Addressing these critical functions, black pipe nipples are an essential part of residential, commercial, and industrial plumbing systems. Their dependable and effective solutions underscore their significant application.

Using barrel nipples in various projects

Plumbing, construction, and other industrial operations use barrel nipples as versatile bushings to connect in a variety of ways. A barrel nipple is a cylindrical section of pipe with a male thread on each end that allows for the connection of two smooth transition fittings or other pipes.

As part of plumbing, barrel nipples extend lines by filling in the gaps between pipes of different sizes and shapes. The most common materials used to manufacture barrel nipples include galvanized steel, brass, and stainless steel. Through factors such as rust resistance, strength, and others, each of these options has some shortcomings. Stainless steel, for instance, has exceptional strength, which makes it ideal for systems with high physicochemical stress, such as nuclear power plants, or high temperature environments because of its heat resistance.

Barrel nipples are reported to be extensively used in sprinkler systems for water distribution, oil and gas pipelines, as well as HVAC systems. Each contractor has an interest in these features, which include the kind of threading, material, and nominal pipe size. Customization leads to leakage maintenance cost reduction through fit precision.

These fittings are also crucial in construction and repair, as in do-it-yourself activities where personalization is required. Such parts are also very strong and easy to install, therefore ensuring proper and dependable fittings can be made between various critical components.

Reference Sources

-

Focus on pipes & fittings: This study discusses the reliability of various pipe connections, including fittings. It emphasizes the technical aspects of pipe threads and tube fittings.

-

Bottle/nipple systems: While this article focuses on bottle nipples, it explores the terminology and design of nipples in a different context, which might provide some linguistic parallels.

-

Mountain Plains Learning Experience Guide: Plumbing: This guide includes educational content on pipe and fitting identification and their functions, which could provide foundational knowledge.

Frequently Asked Questions (FAQs)

Q: Why are pipe fittings called nipples?

A: The term “nipple” in plumbing refers to a short length of pipe that has male pipe threads on both ends. It is commonly used to connect two other fittings, hence the name.

Q: What is the purpose of a pipe nipple in plumbing and piping?

A: A pipe nipple is a fitting that allows for the connection of different pipes or fittings. It is typically used to join two female fittings tightly between them.

Q: What types of pipe nipples are available?

A: There are various types of pipe nipples, including seamless pipe nipples, hex nipples, and closed pipe nipples. Each type serves a different purpose based on the requirements of the plumbing system.

Q: How do you differentiate between pipe threads?

A: The main types of pipe threads include NPT thread (National Pipe Thread) and male pipe thread. NPT threads are tapered, providing a tighter seal, while male pipe threads are designed to fit into female fittings.

Q: What is the difference between a coupling and a pipe nipple?

A: A coupling is a fitting that connects two pipes without any length in between, while a pipe nipple is a short length of pipe that is threaded at both ends, allowing it to connect two fittings.

Q: Can a pipe nipple be used with unthreaded pipes?

A: No, a pipe nipple is specifically designed for use with threaded pipes. It needs to be connected to fittings that have female threads to create a secure joint.

Q: What is a hex nipple, and when is it used?

A: A hex nipple is a type of pipe nipple that has a hexagonal shape, allowing for easier gripping with an internal pipe wrench. It is often used in applications where space is limited and a secure grip is necessary.

Q: How does the length of a pipe nipple affect its use?

A: The length of a pipe nipple can affect the amount of space required for connections. A short length of pipe is often used in tight spaces to connect two threaded fittings without excess length getting in the way.

Q: What is the significance of a pipe nipple manufacturer?

A: A pipe nipple manufacturer produces these fittings to meet specific standards and quality requirements. Choosing a reputable manufacturer ensures that the pipe connections will be reliable and safe.