In projects that call for durability, protection from corrosion, and accuracy, 316 stainless steel rectangular tubing is the one that catches the eye, being the foremost material solution. Besides its resistance to extreme environments, this tubing is also known for its superb mechanical properties and thus, its use is not limited to a few industries. The medical, marine, and chemical processing industries as well as construction are all among the sectors that benefit from this material.

The paper will describe the unique properties of 316 stainless steel rectangular tubing and will also enumerate the extensive applications and key specifications that make it so popular with engineers and designers. This guide will provide you with the technical data necessary to make sound and informed decisions whether you are weighing materials for a challenging job or simply wanting to increase your understanding of this reliable alloy.

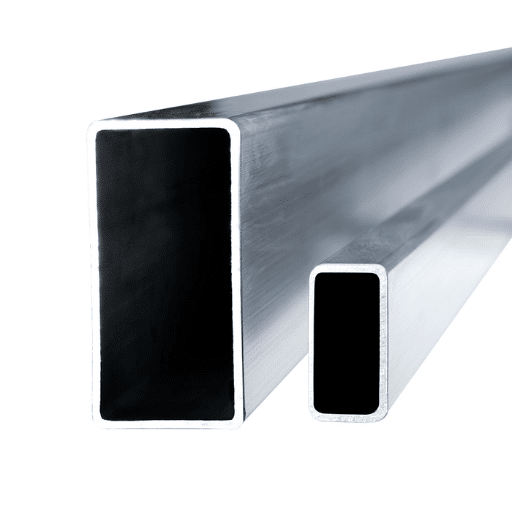

Introduction to Stainless Steel Rectangular Tubing

Overview of Stainless Steel and Its Alloys

Stainless steel is a premium alloy made mainly of iron, chromium, and in some cases nickel, molybdenum, and manganese as additional elements. One of the major factors is the chromium content, which varies from 10.5% to 30% usually, and it creates a passive oxide film on the surface that together with the high durability makes it possible to use it in different harsh environments.

The Five Main Families of Stainless Steel

- 1. Austenitic: Most commonly used (304 and 316 grades), high corrosion resistance, excellent ductility and high-temperature performance

- 2. Ferritic: Moderate corrosion resistance, good heat conduction, cost-effective

- 3. Martensitic: High strength and hardness, lower corrosion resistance

- 4. Duplex: Excellent strength and resistance to stress corrosion cracking, ideal for oil and gas industry

- 5. Precipitation-Hardening (PH): Highest strength and durability, premium grade for specialized applications

The most commonly used austenitic stainless steels include the 304 and 316 grades that stand out for their high resistance to corrosion and their combining of ductility with high-temperature applications. Nickel is often added to these alloys and, for the superalloys, molybdenum for improved resistance to pitting and crevice corrosion. With a ferritic composition, a group of stainless steels delivers moderate resistance to corrosion and thus, they become popular due to their conduction of heat and being less expensive. In contrast, Martensitic stainless steels are characteristic of high strength and hardness but low corrosion resistance when compared with the rest of the family.

Duplex steels excel in both strength and resistance to stress corrosion cracking, the latter being one of the most common causes of failure in the oil and gas industry. Precipitation-Hardening stainless steels are the most expensive but also the strongest and most durable since they are specifically made for these applications. Besides, the variation in the family of alloys allows the use of stainless steel in the construction and automotive manufacturing industries and medical devices as well as chemical processing plants. Innovative development and constant demand for stainless steel alloys keep them tuned to the ever-changing engineering challenges leading to the winner’s circle among the materials used in modern designs and innovations.

Importance of Rectangular Tubing in Various Industries

Rectangular tubing is a significant part of construction and the entire metal industry because of its excellent strength-to-weight ratio, design flexibility, and structural robustness. It consists of carbon steel, stainless steel, or aluminum, and is mainly utilized in the infrastructure, automotive, and manufacturing sectors.

📊 Key Industry Applications

- Construction: Modern architectural frames and load-bearing structures where strength and aesthetics are essential

- Automotive: Lightweight yet strong chassis that enhance overall vehicle efficiency

- Manufacturing: High-performance industrial equipment and structural frameworks

Recent searches and industry reports have revealed a large increase in construction uses of the material, especially in modern architectural frames and load-bearing structures where its strength and good looks are essential. The versatility of rectangular tubing in fitting exactly engineering needs assures its being an indispensable material for industrial innovation, it is a very important part of the projects that are high-performing and environmentally friendly across industries.

Focus on 316 Stainless Steel and Its Variants

316 stainless steel which is of the austenitic type, is praised mainly for its incredible ability to withstand corrosion and this is especially true for those areas which are exposed to chlorides or harsh chemicals. The formulation is primarily of iron, chromium and nickel and at 2-3% it has the highest molybdenum content as compared to any other stainless steel thus it is capable of resisting both pitting and crevice corrosion significantly better than the 304 stainless steel.

| Variant | Key Characteristics | Primary Applications |

|---|---|---|

| 316 | High molybdenum content (2-3%), excellent corrosion resistance, superior tensile strength and ductility | Marine equipment, chemical processing, medical instruments |

| 316L | Low-carbon variant, excellent weldability, reduced carbide precipitation, stress-free structural integrity | Welded structures requiring no post-weld annealing, pharmaceuticals, chemical processing, marine trade |

| 316Ti | Contains titanium, high-temperature stability, resists intergranular corrosion | Petrochemical production, high-temperature applications |

In addition to being very popular as a material for marine equipment, chemical processing, and medical instruments, the alloy’s mechanical properties that include tensile strength and ductility are also major reasons for its use in these applications. The low-carbon counterpart of 316, the 316L variant, is marked by excellent weldability and is thus, a good candidate for those applications where stress-free structural integrity is required and no post-weld annealing is done.

Recent statistics show that the usage of 316 stainless steel along with its derivatives has been going up in the area of irrigation renewable energy infrastructure, like for instance, solar panel frames, and desalination plants. This change is motivated by the fact that such materials are capable of withstanding harsh environmental conditions while also being eco-friendly. The flexibility and durability of 316 stainless steel and its variants guarantee that they will not only be ubiquitous in the future but also play major roles in the high-tech and industrial sectors requiring uninterrupted service and reliability in extreme circumstances.

Properties of 316 Stainless Steel Rectangular Tubing

Corrosion Resistance and Durability

316 stainless steel rectangular tubing has a remarkable reputation for its extraordinary corrosion resistance, which is its major quality and derives from the steel’s high molybdenum content. The resultant structure makes the metal quite immune to pitting and crevice corrosion even at places with high chloride concentration like sea water exposure.

🔥 High-Temperature Performance

316 stainless steel demonstrates excellent oxidation resistance at temperatures up to 1,500°F (815°C), making it ideal for heat exchangers, furnace parts, and other thermal resistance applications where corrosion resistance is also needed.

As per the new set of findings, this material’s life span is much larger than that of standard stainless steel grades, as it preserves the structure in highly aggressive environments like coastal areas or chemical processing plants. The powerful character of the metal is such that it is capable of long-lasting durability and low maintenance, thereby contributing to the increment of the lifecycle value and efficiency of the cost.

Mechanical Properties and Wall Thicknesses

316 stainless steel is a high-performance alloy with excellent mechanical properties for industrial and engineering applications.

⚙️ Mechanical Properties Overview

- Tensile Strength: 579 MPa to 800 MPa

- Yield Strength: Approximately 290 MPa

- Elongation at Break: ~40% (during annealing)

- Ductility: Very good, excellent formability

The thickness of the wall is an important factor concerning the overall performance capabilities of 316 stainless steel buildings and parts. Stronger walls come with a higher resistance to deformation when the pressure is high and also a longer life span. On the other hand, thinner walls mean that flexibility is increased and lighter-weight designs are possible where mobility is paramount. The decision about the thickness selection must consider the specific application requirements like the pressure under which it would be operating, the weather conditions, the load it has to support, etc.

Current data from the industry and other sources have confirmed that changes in manufacturing processes, like cold working, have been recorded to enhance the mechanical strength of thinner-walled 316 stainless steel components greatly. Engineers and designers would be able to bring about a material wastage reduction while product durability is still intact, thus making it a win-win situation for both cost and performance.

Surface Finishes: Polish and Other Options

Surface finishing is a key factor that influences the properties and durability of stainless steel, especially when it comes to 316-grade material. The polished finishes, which are usually in the form of different grit levels such as #4 brushed or mirror-like #8, present the usual and most recognized aesthetics of such surfaces.

| Finish Type | Characteristics | Best Applications |

|---|---|---|

| #4 Brushed | Standard polished finish, reduces surface irregularities, prevents contaminant trapping | Food processing, pharmaceuticals, marine environments |

| #8 Mirror | Highly reflective, smooth surface, excellent contamination prevention | High-end architectural, critical hygiene applications |

| Bead Blasted/Matte | Non-polished finish, robust functional integrity, excellent wear resistance | Industrial equipment, wear-resistant applications |

| Electropolished | Microscopic-level consistency, superior corrosion resistance, removes residues | Critical applications requiring maximum cleanability |

Their smoothness is one of the reasons the finishes are highly appreciated, as it reduces the chance of surface irregularities that can trap contaminants. Hence, applications in food processing, pharmaceuticals, and marine environments are particularly suitable for polished finishes.

Various non- polished treatments like bead blasting or matte finishes, though not as bright and shiny as the polished ones, still have the same resistance to wear and tear but are just much stronger in terms of their functional integrity. The most recent findings from indexed academic and technical sources reveal that there are surface treatment innovations coming up like electropolishing, which greatly reduce the problem of unwanted residues in the areas where the superior performance is expected. There is no option in surface treatments; rather, it is a matter of choosing the best one after making the proper assessment of the needs of the application like the working conditions, cleaning methods, and aesthetics required. The so-called modern surface treatments can help manufacturers to not only enhance performance but also to address the issues of environmental friendliness and cost-effectiveness.

Applications of 316 Stainless Steel Rectangular Tubing

Use in Structural Applications

316 stainless steel rectangular tubing is the material that is most preferred for construction due to its strength, resistance to corrosion, and versatility factors. This metal is usually found in places where it would be often contact with sea water or industrial chemicals that can easily corrode it. Moreover, the tensile and yield strength of the material are so much higher than those of other metals that no risk can be taken by putting it in the structural framework of construction and infrastructure projects.

📈 Growing Structural Applications

The latest studies based on data patterns reveal that 316 stainless steel tubing is gaining more and more influence in:

- Modern architectural designs

- Bridge constructions

- Marine applications

- Medical sector infrastructure

- High-technology industries requiring durability and hygiene

Its impressive performance under extreme conditions has made it a choice that is not just for a short period but rather a long time. In addition, the advanced technology in manufacturing has made the use of this metal not only in the medical sector but also in high-technology industries where durability and hygiene are both required properties.

Ornamental Tubing in Architectural Designs

Ornamental tubing plays a major role in modern architecture by not only providing function but also enhancement to aesthetics. Either of stainless steel, aluminum, or brass can be the material from which this type of tubing is made but its primary function as an offering of strength along with decorative appeal is recognized.

The recent reports on search engine trends indicate that the use of ornamental tubing has risen considerably due to its involvement in eco-friendly designs and the up-to-date construction norms. Architects use ornamental tubing in handrails, facades, and interior accents, playing up its corrosion resistance and its capability to retain a shiny look as time goes by. Thanks to the advances in surface finishing and the availability of various customization options, ornamental tubing now satisfies the criteria of both creative design and eco-friendliness, thus being widely adopted by the residential and commercial projects.

Industrial Applications and Custom Projects

The industrial applications have been drawing the line where the use of ornamental tubing is concerned placing durability along with aesthetic appeal as the main and only criteria for selection. For example, the automotive industry is one of the sectors that cannot do without stainless steel ornamental tubing due to its lightness and sturdiness that add to the overall vehicle efficiency and longevity. Along with that, the aerospace industry uses it for the production of specialized components by taking advantage of its resistance to rust in high-stress and extreme environmental conditions.

🌱 Emerging Renewable Energy Applications

Recent data from the search engine indicates that ornamental tubing is increasingly seen from the perspective of its novel applications in the area of renewable energy, especially for:

- Solar panel mounting systems

- Wind turbine designs

- Sustainable infrastructure projects

Furthermore, modern fabrication techniques allow even more flexibility in terms of customization for the high-end bespoke architectural installations or the industrial machinery of the customer’s choice. These applications point to a growing trend of sustainability in the industry and custom applications. The market need for versatile and eco-friendly materials clearly indicates that ornamental tubing is indeed a solution that is not only adaptable but also future-proof across various sectors.

Specifications and Standards for Stainless Steel Tubing

Common Specifications for 316 and 316L Stainless Steel

The 316 and 316L stainless steels are austenitic types that are renowned for their excellent resistance to corrosion, especially in extreme conditions where chlorides and other industrial chemicals are present. The most significant factor separating them is their carbon content; specifically, 316L containing a lesser amount of carbon, thereby increasing its weldability and lowering its vulnerability to carbide precipitation during the welding process.

| Specification Type | Standard | Coverage |

|---|---|---|

| Chemical Composition | ASTM A240, A312, A276 | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum |

| Mechanical Properties | ASTM A240, A276 | Tensile strength (min 70 ksi for 316, 485 MPa for 316L), hardness limits |

| Dimensional Tolerances | ASTM A240, A312 | Maximum and minimum tolerances for diameter, size, surface finish |

The two grades, 316 and 316L, are under the same specifications which are; ASTM A240, ASTM A312, and ASTM A276 standards, where their chemical compositions, mechanical properties, and dimensional tolerances are all described. The alloying elements in the case of chemical composition vary from 16% to 18% chromium, 10% to 14% nickel, and 2% to 3% molybdenum, which are the main contributors to the resistance against pitting and crevice corrosion. Their good performance and meeting the strict industrial standards make these materials popular in the medical, marine, and chemical processing industries.

Quality Standards and Certifications

Stainless-steel grades like 316 and 316L come with very stringent quality standards at all times, thus, both of them perform well and can be relied upon throughout their critical applications. These grades are subjected to global certifications widely recognized, which include ASTM A240 and A276, among others, that establish the criteria for chemical composition, mechanical properties, and manufacturing tolerances.

✓ Key Certifications and Standards

- ISO 9001: Quality management requirements for consistent production processes

- NACE MR0175/ISO 15156: Hydrogen sulfide-induced corrosion resistance (medical and marine applications)

- UNS S31600 and S31603: Nomenclatures indicating specific chemical and mechanical attributes

- Third-party validation: Lloyd’s Register, ABS (American Bureau of Shipping) for maritime/structural use

Additionally, the production and material delivery for medical or marine applications, etc. are done under strict standards of NACE MR0175/ISO 15156 type certification, which means that the resistance to hydrogen sulfide corrosion in sour gas areas is guaranteed.

Moreover, the stainless steel products can get certified by Lloyd’s Register or ABS (American Bureau of Shipping) as a proof of their suitability for maritime or structural applications. The compliance with such standards and certifications not only indicates that the materials are fit for the operational demands but also signifies their reliability and superior performance capabilities.

Stock Availability and Customization Options

The availability of stainless-steel products is extremely important, as it determines the extent to which different industrial needs will be met, whether they are coming from the construction sector or the marine industry. Stock levels in the form of standard sizes, grades, and finishes are usually kept to ensure that there is prompt delivery for common requirements.

Stock Availability

- Common Grades: 304 (general-purpose) and 316 (high corrosion resistance) typically in stock

- Forms Available: Sheets, rods, tubes, and plates

- Standard Sizes: Ready-to-ship lengths for immediate delivery

- Digital Stock Visibility: Real-time inventory levels, pricing, and delivery times via online platforms

Customization Options

- Custom cutting, polishing, and surface treatments

- Non-standard dimensions or alloy compositions

- Special coatings for increased abrasion resistance

- Parts manufactured to exact engineering tolerances

- CNC machining and laser cutting for high precision

The commonly employed grades of stainless steel such as 304 and 316 are generally available in stock, 304 being for general use and 316 for applications requiring extremely high corrosion resistance. Next up are the customization options, which provide more versatility and allow the manufacturers and distributors to fabricate items that are very closely matched to the requirements of the projects. To illustrate, the customer can request specific coatings to boost the resistance to wear or the making of components to the very exact engineering limits. A number of suppliers use cutting-edge techniques such as CNC machining and laser cutting to achieve and sustain high precision and repetition in made-to-order items.

The companies’ trend searches and industry data indicate that real-time stock visibility through digital means will receive more attention during the coming time. Due to this technological innovation, the customers can know the exact amount of the stocks, their prices, and when the delivery would take place which consequently makes the procurement process faster. Not only do manufacturers and suppliers ensure that their stocks are available all over the supply chain and allow for customization, but they also efficiently respond to changing market demands while being effective in their operations.

Comparison of 316 Stainless Steel with Other Alloys

Differences Between 316 and 304 Stainless Steel

The two austenitic stainless steel grades most frequently employed are 316 and 304, which have different characteristics that make them appropriate for various applications. Their chemical composition is the main difference, especially on adding molybdenum in the 316 steel.

| Feature | 316 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Molybdenum Content | 2-3% (enhances corrosion resistance) | None |

| Corrosion Resistance | Excellent against chlorides and industrial chemicals, superior pitting/crevice resistance | Great under normal atmospheric conditions |

| Cost | More expensive | More economical |

| Primary Applications | Marine environments, chemical processing plants, areas with pitting/crevice corrosion | Food-processing, kitchen appliances, architectural applications |

| High-Temperature Performance | Slightly better structural integrity in extreme conditions | Effective in high-temperature situations |

This element increases the resistance to corrosion, especially with chlorides and other industrial chemicals. Therefore, 316 stainless steel is used more in marines, chemical processing plants, and nonchalant areas where pitting and crevice corrosion occur. 304 stainless steel, on the other hand, is composed of chromium and nickel and, thus, is cheaper than the more complicated ones. It is still a great resistant to corrosion under normal atmospheric conditions but is mostly used in food-processing applications, kitchen appliances, and architectural applications.

Direct comparison of strength and heat resistance shows that both grades are good in high-temperature environments, but 316 retains its structural integrity slightly better under extreme conditions. To decide on the best alloy for a particular application industry experts have to look at the necessary operations, the exposure conditions, and the budgetary constraints.

When to Choose 316L Over 316

The decision of selecting 316L over 316 stainless steel mainly relies on the applications where the danger of corrosion caused by welding or the environment is extreme and, therefore, should be avoided. The carbon content in the two grades is the factor that sets them apart—316L has a lower content of carbon than 316 and that has a direct impact on their performance in a certain setting.

🔧 When to Choose 316L: Key Scenarios

- Welding Projects: Lower carbon level decreases risk of carbide precipitation during welding

- No Post-Weld Annealing: Excellent when stress-free structural integrity is required without additional heat treatment

- Corrosive Atmospheres: Welded areas often subjected to aggressive environments (pharmaceuticals, chemical processing, marine trade)

- Aggressive Solutions: Applications involving chlorides or reducing acids

- Frequent Sterilization: Heat exchangers, storage tanks, equipment subjected to high humidity

- Long-term Projects: Ensures durability and resistance to degradation under tough operating conditions

Recent market research and technological advancements provided by search engines indicate that 316L is the only choice when dealing with weldability, as its lower carbon level decreases the risk of carbide precipitation during welding. This property is of great importance for industries like pharmaceuticals, chemical processing, and sea trade where welded areas are often subjected to corrosive atmospheres.

Moreover, 316L’s immunity to both pitting and intergranular corrosion has made it very popular in industries that deal with aggressive solutions like chlorides or reducing acids. 316L is commonly found in applications like heat exchangers, storage tanks, and equipment that are frequently sterilized or subjected to high humidity for long periods. The final decision depends on the trade-off between application-specific requirements and cost, which is why 316L cannot be left out in the industries with high precision focus.

Performance in Harsh Environments

316L steel is a synonym for its remarkable performance in extreme and corrosive environments. Latest figures to back up its claims are that its resistance to pitting and crevice corrosion in chloride environments particularly soars making it the go-to material in the marine industry, chemical processing plants, and desalination plants.

🌡️ Temperature Performance Range

316L maintains mechanical stability and uptime reliability between cryogenic temperatures to above 800°F (426°C), confirming its dominance across diverse operational conditions.

Moreover, the low content of carbon in 316L prevents the occurrence of carbide precipitation in the weld and so the material gains strength even at high thermal stress points. The material also never gives in to the mechanical stability or to uptime reliability between the temperature ranges of cryogenic to above 800°F (426°C) and this is yet another aspect that confirms its dominance in many operational conditions. By being the ultimate in durability and resilience, 316L stainless steel not only meets but also exceeds the strictest industry standards that stand between it and the impregnable fortress of non-material failure in such environments.

Frequently Asked Questions (FAQ)

❓ What are the key stainless steel specifications for a 316 stainless steel rectangular tube?

The 316 stainless steel rectangular tube specifications mainly include the limits of chemical composition, the required mechanical properties, and the wall thicknesses to which the material is to be included. Specification documents covering such requirements are ASTM and EN standards that contain the limits imposed on the addition of elements like chromium, nickel, and molybdenum, resulting in the material having superior corrosion resistance. Specifications also state the maximum and minimum tolerances for such things as the diameter of the rectangular tube and its overall size, surface finish, and processing requirements. In many cases, purchasers will demand the product to have high-quality certification and mill test reports to guarantee that the product satisfies the requirements of both the project and the industry.

❓ How does stainless steel tubing perform in harsh environments and ship applications?

Stainless steel tubing of grades 316 and 316L specifically stand for the superb corrosion resistant property even when being used in the harshest of marine and ship environments where their application would be primarily due to the molybdenum content of the alloy. The alloy on the other hand is less susceptible to the formation of pits and cracks leading to corrosion through the use of 316L stainless steel for marine railings, fittings, and structural components near or directly immersed in seawater. In many marine projects, 316 stainless steel rectangular tube is chosen instead of less expensive steel tube options because of its inherent high strength and durability. Besides that, proper fabrication and finish treatments also play a significant role in extending the life span of the material and reducing the maintenance needs.

❓ What processing and fabrication considerations should be made for stainless steel rectangular tubing?

The processing of stainless steel rectangular tubing involves cutting, welding, bending, and surface finishing all of which require the emphasis to be on the corrosion-resistance of the whole structure and its integrity. The controlling of the welding heat input to avoid sensitization must be employed in the fabrication methods; in case of using 316L stainless steel, the risk can be reduced as it has a lower carbon level. Cold forming and bending are among the most common practices, however, if tight radii are to be formed then annealing must be done to avoid cracking and to ensure strength is not compromised. Surface finish post-processing not only affects the look but also the resistance to being contaminated in food and beverage or industrial settings so it is imperative to select the right polishing or passivation.

❓ What product options and stock sizes are available for 316 stainless steel rectangular tube?

316 stainless steel rectangular tube is a product that is highly obtainable in the market with its manufacturers providing it in different sizes to include not only common diameters, lengths, and wall thicknesses but also to cover both aesthetic and structural needs. For the standard sizes, the complete stock lengths can be shipped quickly, and custom lengths together with larger diameters can be manufactured by placing the order. Different options come with the surface finishes which are mill finish, brushed, or polished that make an impact on the corrosion resistance and the look. Rectangular tubes of stainless steel with precise measurements and wall thickness uniformity are the most preferred for railing and architectural uses.

❓ How do material selection and alloy choice affect corrosion resistance and durability?

Choosing the right material, particularly the choice between 316 and 316L stainless steel, impacts the corrosion resistance and the material’s life in an aggressive environment significantly. The molybdenum present in the alloy gives the resulting product plumbing and crevice corrosion resistance even better than that of standard stainless steel tubing. The sensitization risk during welding is considerably lowered by 316L, the carbonless variant, which then provides better penetration resistance in welded structures. For example, considering the right finish and wall thickness for structural supports or railings, 600Mpa tensile and 350Mpa yield strength is regarded as very high for such applications. Considering less expensive alternatives might lead to initial cost savings but can also lead to a decreased lifespan and more frequent and costly maintenance in corrosive environments.

❓ Can 316 stainless steel rectangular tubing be used for custom structural projects and fabrication work?

It is true that 316 stainless steel rectangular tubing is the best option for custom structural projects because of its resistance to corrosion, great strength and durability. The fabricators can cut, weld and form the rectangular tube into frames, supports and railings for architectural applications without losing the strong and pleasant finish. Custom projects usually have certain wall thicknesses and diameters that need to be achieved in order to comply with the load and safety requirements, thus suppliers can furnish either engineered specifications or mill test reports. Furthermore, the right finish and cleaning procedures are set for the food, beverage and industrial environments to guarantee product’s life and sanitary performance. The long-term advantages in terms of less corrosion and maintenance usually make it an investment that can be defended even if the cost is at first higher than some alternatives for steel tubes.

Reference Sources

📚 Modification of stainless-steel surfaces for advanced functionalities

Source: Georgia Tech Repository

This study explores the benefits of stainless steel 316 in various applications, including fluid transport and surface modifications.

📚 Investigation into the joining of MoSi2 to 316L stainless steel

Source: Academia.edu

This paper examines the properties and joining techniques of 316L stainless steel, which is closely related to 316 stainless steel.

📚 Electrochemical studies of microbiologically influenced corrosion in austenitic stainless steel weldments

Source: University of Tennessee TRACE Repository

This thesis investigates corrosion in stainless steel weldments, providing valuable data on the durability of 316 stainless steel in real-world conditions.