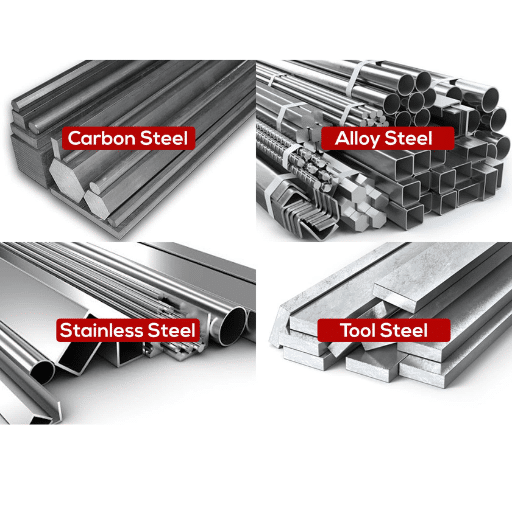

Overview of Stainless Steel

Stainless steel is considered one of the most durable materials with a broad range of applications. It is made by alloying iron with a minimum chromium content of 10.5%. Chromium forms a protective oxide layer on the surface, preventing corrosion and giving the metal its characteristic rust resistance. The material is valued for its strength, corrosion resistance, and low maintenance requirements.

What is Stainless Steel?

Stainless steel is a versatile alloy consisting of iron, carbon, and at least 10.5% chromium for excellent corrosion resistance. It often includes elements such as nickel, molybdenum, and nitrogen, depending on desired properties for specific applications. Its resistance to rust, staining, and wear makes it suitable for industries ranging from construction and transportation to medical technology and consumer goods.

Importance of Steel Grades

Steel grades are crucial because they determine specific technical and operational requirements for each application. Steel is never a generic material—its tensile strength, corrosion resistance, and weldability are influenced by chemical composition and heat treatment. Recent industry data shows increased demand for high-strength, corrosion-resistant steel grades, particularly in renewable energy and advanced manufacturing sectors.

Types of Stainless Steel

There are generally five main types of stainless steel, each with distinct properties and applications:

Austenitic Stainless Steel

The most commonly used stainless steel type, featuring excellent corrosion resistance and good mechanical properties. Grades 304 and 316 are widely used for kitchenware, medical devices, and industrial equipment. They are non-magnetic and retain strength across a broad temperature range.

- High chromium and nickel content

- Non-magnetic in annealed state

- Excellent formability and weldability

- Superior corrosion resistance

Ferritic Stainless Steel

These steels have chromium as the main alloying element and are magnetic with moderate resistance to stress corrosion cracking. They find applications in automotive exhaust systems, industrial equipment, and architectural designs, providing moderate corrosion resistance at reasonable cost.

- Chromium-based with little or no nickel

- Magnetic properties

- Good resistance to stress corrosion cracking

- Cost-effective solution

Martensitic Stainless Steel

This category has higher carbon content and finds application where high strength and wear resistance are required, such as cutlery, surgical instruments, and tools. Martensitic stainless steels like grade 410 are magnetic and heat treatable.

- Higher carbon content

- Heat treatable for increased hardness

- High strength and wear resistance

- Moderate corrosion resistance

Duplex Stainless Steel

Combining properties of austenitic and ferritic stainless steels, duplex steels offer superior strength and resistance to chloride stress corrosion cracking. These properties make them suitable for chemical plants, marine environments, and construction projects.

- Mixed austenitic and ferritic structure

- High strength and toughness

- Excellent chloride corrosion resistance

- Cost-effective for demanding applications

Precipitation Hardening Stainless Steel

These steels can be heat-treated to achieve very high strength levels while maintaining good corrosion resistance. They are primarily used in aerospace, defense, and high-performance industrial applications. Typical grades include 17-4 PH and 15-5 PH.

- Heat treatable to high strength levels

- Excellent strength-to-weight ratio

- Good corrosion resistance

- Specialized aerospace applications

Common Stainless Steel Grades

| Grade Series | Type | Key Characteristics | Common Applications | Cost Level |

|---|---|---|---|---|

| 300 Series | Austenitic | High chromium and nickel, excellent corrosion resistance | Kitchen equipment, medical devices, chemical processing | Moderate to High |

| 400 Series | Ferritic/Martensitic | Lower carbon, moderate corrosion resistance, magnetic | Automotive exhausts, cutlery, industrial equipment | Low to Moderate |

| Duplex Grades | Duplex | High strength, excellent chloride resistance | Oil & gas, chemical plants, marine structures | Moderate to High |

| PH Grades | Precipitation Hardening | Very high strength, heat treatable | Aerospace, defense, high-performance applications | High |

304 Stainless Steel: Properties and Uses

304 stainless steel is one of the most popular and versatile austenitic stainless steel grades available. It contains approximately 18% chromium and 8% nickel, with trace amounts of other elements such as carbon and manganese. This composition provides excellent corrosion resistance, making it ideal for both indoor and outdoor applications.

Key Features of 304 Stainless Steel:

- Non-magnetic in annealed state

- Exceptional formability and weldability

- Excellent corrosion resistance

- Hygienic properties suitable for food contact

- Low maintenance requirements

Properties of Stainless Steel

Corrosion Resistance

The chromium content forms a protective oxide layer that prevents rusting and corrosion. Enhanced by elements like molybdenum and nickel for specific environments.

Strength and Durability

Maintains structural integrity under extreme conditions, resisting wear, erosion, and deformation even under heavy loads and temperature variations.

Temperature Resistance

Performs well across wide temperature ranges, from cryogenic applications to high-temperature industrial processes.

Formability

Can be easily cut, welded, and shaped without losing structural integrity, making it versatile for various manufacturing processes.

Hygiene Properties

Non-reactive surface makes it ideal for food processing, medical applications, and pharmaceutical manufacturing.

Sustainability

100% recyclable with minimal degradation, supporting environmental sustainability and circular economy principles.

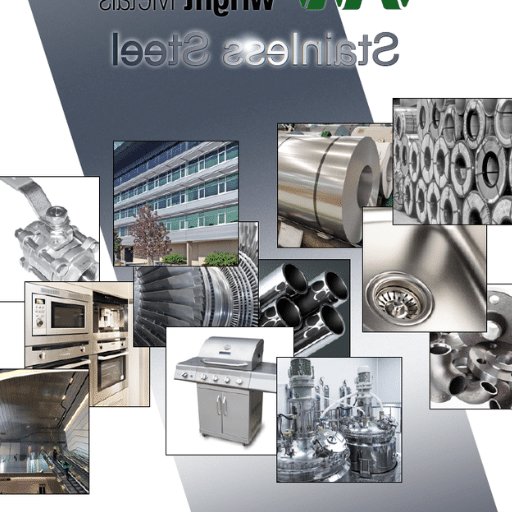

Applications of Different Types of Stainless Steel

Medical Equipment

Surgical instruments, implants, and hospital equipment use 304 and 316 stainless steel grades for their biocompatibility and resistance to body fluids.

Construction and Architecture

Austenitic stainless steel, primarily grade 316, is used in building facades, roofing, and structural supports for its weather resistance and aesthetic appeal.

Automotive Industry

Ferritic stainless steel like grade 430 is used for exhaust systems, trim, and fuel tanks, offering cost-effectiveness and corrosion resistance.

Food and Beverage Processing

Grades 304 and 316 are employed in processing machinery, storage tanks, and kitchen utensils for their non-reactive, hygienic properties.

Chemical and Petrochemical

Duplex stainless steels like grade 2205 are used in processing equipment, pipelines, and reactors for harsh chemical environments.

Marine Applications

Grade 316 with molybdenum content provides superior resistance to saltwater corrosion in coastal and marine structures.

Comparison of Ferritic and Martensitic Grades

| Characteristic | Ferritic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Crystal Structure | Body-centered cubic (BCC) | Tetragonal |

| Magnetic Properties | Magnetic | Magnetic |

| Carbon Content | Low carbon | Higher carbon content |

| Heat Treatment | Cannot be hardened by heat treatment | Can be hardened by heat treatment |

| Primary Applications | Automotive parts, kitchenware, architectural trim | Cutlery, turbine blades, surgical instruments |

| Corrosion Resistance | Good in mild environments | Moderate, lower than ferritic |

| Cost | Lower (less nickel content) | Moderate |

Choosing the Right Type of Stainless Steel

Key Selection Factors

Selecting the appropriate stainless steel grade requires careful consideration of several factors based on application requirements and operating conditions.

Corrosion Resistance Requirements

For exposure to moisture, salt, or harsh chemicals, grade 316 with molybdenum content outperforms grade 304. Marine and industrial environments particularly benefit from 316’s superior chloride resistance.

Mechanical Properties

High tensile strength applications require martensitic or duplex stainless steels. Duplex grades offer nearly twice the tensile strength of standard austenitic grades like 304.

Temperature Resistance

Grade 310 performs well in high-temperature environments up to 2100°F (1150°C), making it suitable for furnaces and heat treatment processes.

Cost Considerations

Ferritic and martensitic grades like 430 or 410 are typically less expensive but may lack the ductility or corrosion resistance of austenitic grades.

Tips for Selecting the Right Stainless Steel Grade

- Understand the Operating Environment: Determine environmental conditions including temperature, humidity, chemical exposure, and mechanical stress levels.

- Consider Mechanical Properties: Evaluate required strength, hardness, and ductility for the specific application.

- Assess Temperature Requirements: Match grade capabilities with operating temperature ranges.

- Evaluate Corrosion Resistance: Different grades offer varying levels of protection against specific types of corrosion.

- Balance Cost vs. Performance: Consider long-term value including maintenance and replacement costs.

Common Applications for Each Type

| Stainless Steel Type | Typical Grades | Key Applications | Primary Advantages |

|---|---|---|---|

| Austenitic | 304, 316, 310 | Kitchen utensils, medical equipment, chemical processing | Excellent corrosion resistance, formability |

| Ferritic | 430, 409 | Automotive exhausts, decorative trim, appliances | Cost-effective, stress corrosion resistance |

| Martensitic | 410, 420 | Surgical instruments, cutlery, industrial blades | High strength, hardness, wear resistance |

| Duplex | 2205, 2507 | Bridge infrastructure, offshore platforms, desalination | High strength, chloride resistance |

| Precipitation Hardening | 17-4 PH, 15-5 PH | Aerospace, turbine blades, nuclear reactors | Ultra-high strength, specialized applications |

Impact of Alloy Composition

Alloy composition significantly affects mechanical and chemical properties, allowing engineers to tailor materials for specific applications. Elements like chromium, nickel, molybdenum, and manganese are introduced in varying proportions to achieve targeted characteristics such as tensile strength, corrosion resistance, and heat tolerance.

Key Alloying Elements:

- Chromium: Primary corrosion resistance through oxide layer formation

- Nickel: Enhances ductility, toughness, and low-temperature performance

- Molybdenum: Improves pitting and crevice corrosion resistance

- Nitrogen: Increases strength and corrosion resistance in duplex grades

- Carbon: Affects strength and hardness, particularly in martensitic grades

References

-

Stainless Steel Grade Chart – Stanford University – Provides a detailed chart of stainless steel grades, including austenitic, ferritic, martensitic, and duplex types.

-

Stainless Steel: Characteristics, Uses, and Problems – U.S. General Services Administration (GSA) – Discusses the characteristics and applications of various stainless steel types.

Frequently Asked Questions (FAQ)

What types of stainless steel are there?

Based on their chemical composition and properties, there are many different types of stainless steel. The widely recognized types, however, are austenitic, ferritic, and martensitic stainless steels. Each variety possesses characteristics that suit specific applications and industries such as construction or food processing.

What set apart austenitic and ferritic stainless steels?

While austenitic stainless steels enjoy good corrosion resistance and good formability, ferritic stainless steels offer good resistance to stress corrosion and are magnetic. The major difference lies in the microstructure: austenitic steels are face-centered cubic, and ferritic steels are body-centered cubic.

What are the common varieties of stainless steel?

Common stainless steel varieties include 304, 316, and 430. Grade 304 is generally popular as a multipurpose steel, while grade 316 enjoys better corrosion resistance due to the presence of molybdenum. Grade 430 is a somewhat ferritic stainless steel widely used for decorative purposes.

How is stainless steel manufactured?

The manufacture of stainless steel involves melting iron and steel while incorporating alloying elements, followed by refining. In this process, however, some variations occur depending upon the type of stainless steel to be manufactured, with varying proportions of chromium, nickel, and other alloys being used in order to impart the different stainless steel properties.

What is duplex stainless steel?

Duplex Stainless Steel is a type of stainless steel with the best combination of the properties possessed by austenitic and ferritic stainless steels. Thus the alloy acquired great strength and good corrosion resistance, making it fit-for-purpose in harsh environments like oil and gas industries.

What are the properties of common stainless steel types?

Common stainless steel types exhibit several properties, which include corrosion resistance, formability, and strength. Usually, austenitic stainless steels are non-magnetic and have good weldability, whereas ferritic stainless steels are magnetic and have good resistance to stress corrosion cracking.

What is precipitation hardening stainless steel?

Precipitation-hardening stainless steels are a series subjected to a heat treatment that increases their strength. Stainless steel of this type is mostly used in aerospace and other areas where a strong-to-weight ratio is desirable.

How do I select the correct stainless steel for my project?

When choosing a stainless steel, it is important to identify specific requirements for your application, such as corrosion resistance, strength, and ease of fabrication. Consider the environment in which the stainless steel will be put to use and seek advice from material experts as to which grade would best suit your application.

What kind of stainless steel grades are there?

Many stainless steel grades do exist, more than 150 different recognized grades. The grades are classified based on their composition, properties, and applications, which makes it imperative to know about their differentiations when trying to pick materials for particular uses.