Heat treatment is an indispensable manufacturing process in material engineering, and among the various techniques available, solution annealing stands out as crucial for enhancing steel and stainless steel properties. This comprehensive guide explores the science and importance behind solution annealing, demonstrating how it optimizes strength, endurance, and corrosion resistance in materials. Whether you’re an industrial professional or an interested individual, this guide provides clear and practical understanding of solution annealing processes, advantages, and applications that make it essential in modern metallurgy.

Understanding Solution Annealing

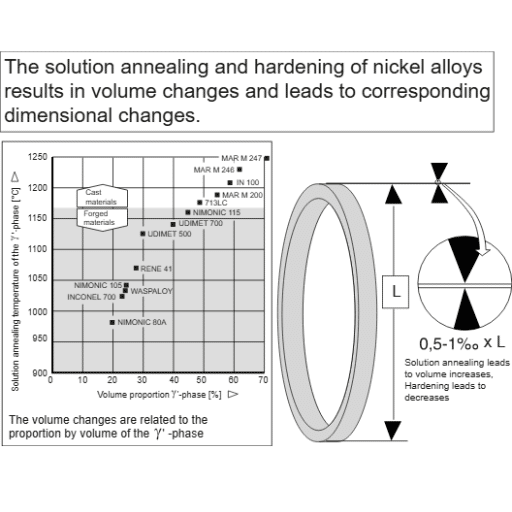

Solution annealing improves mechanical and corrosion-resistant properties by dissolving alloying elements in a metal’s solid solution. The metal is heated to a specific temperature and held there until dissolution is complete, then cooled quickly to prevent structural changes. This results in material uniformity with increased strength and durability, making it particularly significant for high-performance metals in demanding applications.

Definition of Solution Annealing

Solution annealing is a classic heat treatment applied in industries using stainless steels, nickel alloys, and other high-grade materials. This process finds increased application in aerospace, automotive, and chemical processing fields to enhance material properties including:

- Corrosion resistance for harsh environmental conditions

- Mechanical strength for structural applications

- Structural uniformity for consistent performance

- Reduced intergranular corrosion through carbide dissolution

- Material homogeneity ensuring reliability and serviceability

Historical Background and Development

The metal heat treatment process dates back to ancient civilizations where forging and annealing improved tool and weapon quality. Blacksmiths empirically applied quenching and tempering processes to shape materials and improve properties. These techniques gained scientific foundation during the Industrial Revolution with more accurate temperature and cooling rate controls.

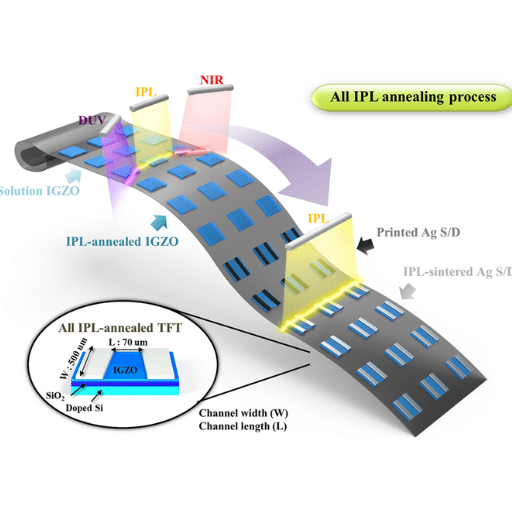

Modern Evolution: Solution annealing continues as a vital material preparation process, particularly in aerospace, automotive, and construction applications. Recent trends promote energy-efficient and automated heat treatment facilities, with developments including laser-assisted annealing and integrated temperature sensors creating optimal results while minimizing energy consumption.

Key Principles of the Process

Heat treatment operates on three fundamental principles: controlled heating, controlled cooling, and material property considerations. After exposure to elevated temperatures, materials undergo cooling at specific rates to produce desired microstructural changes. Modern techniques incorporate:

- Laser heating for precise temperature control

- Integrated sensors for real-time monitoring

- Automated systems ensuring consistency and energy efficiency

- Sustainable industrial practices reducing environmental impact

- Machine learning integration for process optimization

The Solution Heat Treatment Process

The solution heat treatment process involves heating forged or wrought metals to temperatures where alloying elements dissolve, then rapid quenching to lock elements in a supersaturated solution state, providing enhanced strength, corrosion resistance, and durability.

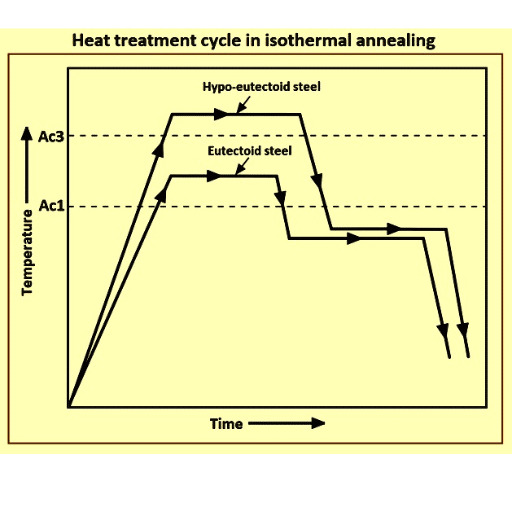

Stages of Solution Heat Treatment

Material is heated to a specific temperature range near the solvus temperature to allow alloying elements to dissolve in solid solution. Controlled temperature prevents unwanted microstructural changes.

Once desired temperature is reached, material is held for sufficient time to cause complete dissolution of alloying components into the matrix, forming homogeneous solid solution.

After soaking, material is rapidly cooled using water, oil, or air. This solidifies the microstructure, locking dissolved elements and preventing precipitation for enhanced properties.

Temperature Ranges and Time Requirements

Critical Parameters: Heat treatment methods require specific temperature ranges and soaking times varying with material type and desired properties. Steel alloys typically undergo austenitization at 1,500°F to 1,650°F (815°C to 900°C) with soaking times approximately 30 minutes per inch of thickness. Non-ferrous metals like aluminum operate at lower temperatures between 750°F and 1,100°F (400°C to 595°C) with reduced soaking times.

| Material Type | Temperature Range | Soaking Time | Key Considerations |

|---|---|---|---|

| Steel Alloys | 1,500°F – 1,650°F (815°C – 900°C) |

30 min/inch thickness | Austenitization process |

| Aluminum Alloys | 750°F – 1,100°F (400°C – 595°C) |

Reduced time due to conductivity | Lower melting point considerations |

| Stainless Steel | 1,850°F – 1,950°F (1010°C – 1066°C) |

Material thickness dependent | Carbide dissolution critical |

| Nickel Alloys | 1,900°F – 2,100°F (1038°C – 1149°C) |

Extended soaking required | High-temperature stability |

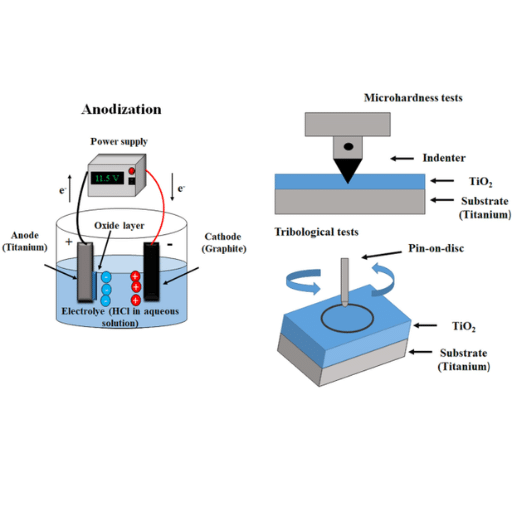

Cooling Techniques Post-Treatment

Cooling methods significantly influence mechanical properties and minimize residual stress development:

- Air Cooling: Slower cooling rate suitable for processes requiring gradual temperature reduction

- Oil Quenching: Controlled cooling for specific hardness and material properties

- Water Quenching: Rapid cooling for maximum hardness achievement

- Gas Quenching: Uses nitrogen or helium for controlled operation without environmental concerns

- Cryogenic Treatment: Ultra-fine microstructures for enhanced wear resistance

Advantages of Solution Annealing

Enhances ductility, strength, and toughness by homogenizing microstructure and dissolving segregated phases, critical for demanding industrial applications.

Dissolves carbides and precipitates, particularly beneficial for chemical processing and marine engineering industries requiring superior corrosion protection.

Reduces internal stresses and creates uniform microstructure, enhancing manufacturing processes and extending tool life during machining operations.

Provides consistent and predictable material properties, eliminating localized weaknesses essential for critical applications requiring reliable performance.

Enhances wear resistance and reduces failure probability under service conditions, offering economical solutions for industries requiring durable materials.

Benefits of Solution Treatment for Steel

Steel Enhancement: Solution treatment remains essential for improving steel properties according to evolving industrial demands. Corrosion resistance adaptation makes solution treatment suitable for harsh environments including marine and chemical applications. The treatment produces optimum microstructure with maximum uniformity and minimum residual stresses, resulting in enhanced overall material performance.

Advantages for Stainless Steel and Alloy Components

| Advantage | Stainless Steel Benefits | Industry Applications |

|---|---|---|

| Corrosion Resistance | Exceptional resistance in hostile environments | Marine, chemical processing industries |

| Durability | 25+ years longer life vs regular steel | Construction, infrastructure projects |

| Strength-to-Weight Ratio | Lightweight yet structurally strong | Aerospace, automotive applications |

| Temperature Resistance | Maintains properties in extreme conditions | Furnaces, engines, cryogenic storage |

| Recyclability | 100% recyclable, 60% recycled content | Sustainable manufacturing practices |

Key Applications of Solution Annealing

Industry Applications

Critical for jet engine parts and aircraft structures requiring high-stress resistance, durability, and precision performance.

Applied to engine parts, transmission components, and high-performance materials requiring heat resistance and sustainability.

Essential for surgical instruments, implants, and medical tools requiring biocompatibility and durability in physiological conditions.

Used in pipes and equipment requiring corrosion resistance against extreme temperatures and pressures.

Applied to stainless steel frameworks and fasteners for structural stability and environmental resistance.

Standard Metal Alloys Treated with Solution Annealing

| Alloy Type | Common Grades | Key Benefits | Primary Applications |

|---|---|---|---|

| Stainless Steels | 304, 316 | Enhanced corrosion resistance, strength | Aerospace, surgical, marine |

| Aluminum Alloys | 2024, 7075 | Enhanced fatigue resistance, machinability | Construction, automotive |

| Nickel-Based Alloys | Hastelloy, Inconel | Superior heat and corrosion resistance | Turbines, chemical plants |

| Titanium Alloys | Ti-6Al-4V | Optimized strength and fatigue properties | Aerospace, biomedical implants |

| Carbon & Alloy Steels | Various grades | Improved ductility and uniformity | Energy, construction, tooling |

Case Studies and Real-World Examples

Ti-6Al-4V titanium alloy serves as an excellent example in aerospace applications for jet engines and airframes. After solution heat treatment and aging, the alloy achieves the high strength-to-weight ratio and fatigue resistance required for extreme operating conditions involving high heat and mechanical stresses during flight. Modern commercial jetliners utilize heat-treated Ti-6Al-4V for turbine blades and structural components to ensure enhanced service life and performance.

The automotive industry continues relying on carbon and alloy steels treated through quenching and tempering processes. The evolution toward lightweight, strong steel components, particularly for electric vehicles, demonstrates advanced applications. Tesla exemplifies the use of heat-treated steels to increase crashworthiness while reducing vehicle weight for energy efficiency, showing how modern heat-treatment techniques enable manufacturers to meet sustainability demands without compromising safety and performance.

Heat treatment proves essential in biomedical applications, especially for surgical implants like hip replacements and dental fixtures. Cobalt-chrome and titanium alloys undergo customized heat treatments to enhance biocompatibility and resistance to wear and corrosion. These treatments have demonstrated extended implant life in practice, ensuring patient reliability and reducing corrective surgeries.

Heat Treatment Services for Solution Annealing

Choosing a Provider for Heat Treatment Services

Ensure certified expertise in handling various materials and processes. Look for ISO 9001 or NADCAP certification demonstrating strict quality standards adherence.

Modern furnaces with precision control and contemporary cooling systems ensure consistent, reliable results with advanced technology capabilities.

Select providers experienced with your specific materials – stainless steels, nickel-based alloys, or titanium – for optimal treatment results.

Choose providers skilled in creating surface layers resistant to corrosion and abrasion, critical for aerospace, automotive, and medical industries.

Check reviews and ratings for reliability, work quality, and customer service. Research provider mentions by industry leaders and trustworthy sources.

Consider project schedule compatibility without quality compromise. Evaluate costs and value-added services like material testing and documentation.

Quality Assurance and Standards in Heat Treatment

Quality assurance involves maintaining strict adherence to industry standards for reliable, consistent results:

- AMS2750: Temperature monitoring and equipment calibration standards

- ISO 9001: Quality management system requirements

- NADCAP: Specialized aerospace and defense industry certification

- Material Testing: Comprehensive testing protocols for performance verification

- Documentation: Complete traceability and certification records

References

-

University of North Texas – The Effect of Solution Annealing on Microstructural Changes

A detailed study on the effects of solution annealing at various temperatures and its impact on material properties.

Link to source -

Academia.edu – Effect of Solution Annealing on Austenitic Stainless Steel

This paper explores how solution annealing affects the corrosion resistance and mechanical properties of stainless steel.

Link to source

Frequently Asked Questions (FAQ)

What is the solution annealing process?

Solution annealing is a heat treatment for metal alloys, especially austenitic stainless steels and nickel-based superalloys. The metal is heated to the solution annealing temperature, usually between 1850°F and 1950°F, to dissolve any precipitates, and then it is quickly cooled or quenched to retain the microstructure that was imparted by solution annealing.

What is the purpose of solution annealing?

The goal of solution annealing is greater strength and ductility in metals. This is achieved by ensuring that the material remains in a single phase structure by dissolving any undesirable precipitates. Conversely, based on a uniform microstructure, the annealed material is supposed to express a desirable set of properties necessary in many applications.

How do grain boundaries change during solution annealing?

The solution annealing process modifies the grain boundaries. Heat-treatment of the metal at the solution annealing temperature modifies the microstructure to reduce, to some extent, the amount and size of grain boundaries. This is advantageous as it improves toughness and resistance to cracking and consequently offers greater performance to the alloys themselves.

What is the temperature of solution annealing?

Solution annealing temperature depends on the composition of the alloys, ranging between 1850°F and 1950°F. Solution annealing involves heating the material to an appropriate temperature so that all precipitates are dissolved; if precipitates form while cooling, it negatively affects the properties of the material.

How is the rapid cooling achieved after solution annealing?

The rapid cooling step is a crucial stage of solution annealing, whereby the treatment is quenched down to room temperature as soon as possible. Quenching is necessary to inhibit precipitation during aging, which would result in unwanted structural changes that could affect the mechanical properties of the alloy in the finish.

What does solution annealing do to help austenitic stainless steels?

Solution annealing maintains a balance between the elimination of carbide precipitates in the grain boundaries or at the grain boundary surface and the related mechanism of corrosion resistance, which accrues towards the uniform and finer microstructure needed to maintain the strength and ductility of austenitic stainless steels, needed in a variety of industrial applications.

What kinds of alloys will require solution annealing?

Solution annealing is required for many metal alloys, for instance, austenitic stainless steels, duplex steels, and copper-based alloys. These materials will theoretically benefit from heat treatment; in particular, the mechanical properties are enhanced so that the materials can actually operate in environments where severe service is permitted.

How does age hardening go with solution annealing?

Precipitation hardening, better known as age-hardening, is a process that is performed after solution annealing. Once the material has been solution annealed and rapidly cooled, it could also be aged at a lower temperature to form fine precipitates, and this controlled precipitation will further strengthen and harden the material, thus ideal for particular applications.

What is the importance of cooling through low-temperature ranges after solution annealing?

The significance of cooling through low-temperature ranges after solution annealing lies in stabilizing the microstructure and suppressing undesired phase transformations. This controlled cooling helps to preserve the desired properties of the material while preventing adverse precipitations that could impair its mechanical performance.