Stainless steel has gained an excellent reputation due to its outstanding versatility and durability, becoming the most preferred material in various sectors such as construction, cookware, and industrial manufacturing. However, the thermal properties of stainless steel—specifically, its heat conductivity—are often overlooked, despite being crucial to the material’s performance in different applications. Understanding stainless steel heat conductivity enables engineers, manufacturers, and end-users to make informed decisions about its suitability for specific tasks.

Introduction to Stainless Steel

Stainless steel is an extremely adaptable alloy consisting mainly of iron, carbon, and chromium. The essential element in making stainless steel corrosion-resistant is the addition of at least 10.5% chromium by weight, which leads to the formation of a thin oxide layer on the surface.

What is Stainless Steel?

Stainless steel is an iron-based alloy well known for its resistance to rust and corrosion, primarily obtained through the addition of chromium at 10.5% or more by weight. Chromium forms a thin, non-reactive oxide layer on the surface that shields the metal against rust and other common types of corrosion.

Additional alloying elements include:

- Nickel: Enhances toughness and ductility

- Molybdenum: Improves resistance to high temperatures

- Nitrogen: Provides resistance to harsh chemical environments

Composition and Alloys of Stainless Steel

Iron is the main constituent of stainless steel, which must contain at least 10.5% chromium for exceptional corrosion resistance. Chromium produces a thick chromium oxide layer on the surface that resists rust and decay.

Major Categories of Stainless Steel Alloys:

1. Austenitic Stainless Steel

- High chromium and nickel content

- Extraordinary corrosion resistance

- Suitable for tough environments

- Common grades: 304 and 316

- Applications: Food processing to maritime industries

2. Ferritic Stainless Steel

- Chromium-based without significant nickel

- Magnetic properties

- Good resistance to stress corrosion cracking

- Applications: Car exhaust systems, home appliances

3. Martensitic Stainless Steel

- Higher carbon content

- Known for strength and hardness

- Lower corrosion resistance

- Applications: Cutlery, tools, aerospace parts

4. Duplex Stainless Steel

- Combines austenitic and ferritic microstructures

- High strength with excellent pitting resistance

- Excellent stress corrosion resistance

- Applications: Oil and gas, chemical industries

Overview of Thermal Conductivities

Thermal conductivity is a measure of how well a material can transfer heat. This property is expressed in watts per meter-kelvin (W/m·K) and varies significantly across different materials depending on their composition and structure.

| Material | Thermal Conductivity (W/m·K) | Classification |

|---|---|---|

| Copper | ~400 | Excellent Conductor |

| Aluminum | ~235 | Excellent Conductor |

| Stainless Steel | ~15-25 | Poor Conductor |

| Aerogels | ~0.01 | Super Insulator |

Thermal Conductivity of Stainless Steel

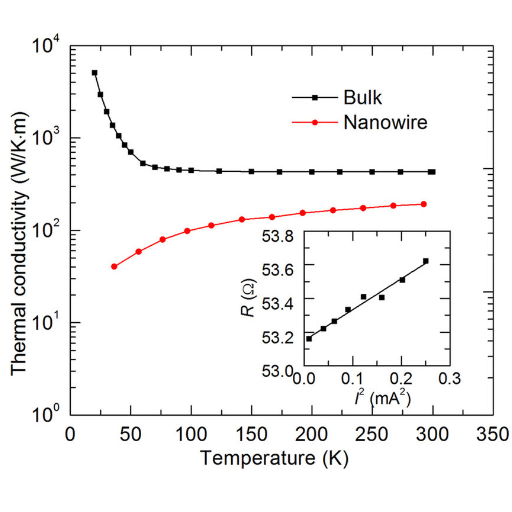

Stainless steel, while widely used for its corrosion resistance, has relatively low thermal conductivity compared to other metals such as copper and aluminum. The thermal conductivity of stainless steel ranges from 15 to 25 W/m·K depending on the grade and alloy.

Typical Values at Room Temperature:

- Austenitic Grades (304, 316): ~16-17 W/m·K

- Ferritic Grades: Somewhat higher values

The low thermal conductivity is due to the alloy’s constitution, particularly chromium and nickel, which create a lattice structure that is poor at conducting heat. While not ideal for heat exchangers, stainless steels excel in applications requiring insulation and heat retention, such as cookware and thermal barriers.

Defining Thermal Conductivity

Thermal conductivity is a physical characteristic expressing a material’s heat conduction capacity. It is quantitatively described as the heat transmitted through a material of specified thickness under steady-state conditions.

Mathematical Formula:

k = Q × d / (A × ΔT × t)

Where:

k = Thermal conductivity (W/m·K)

Q = Heat transfer rate (W)

d = Thickness of the material (m)

A = Cross-sectional area normal to heat flow (m²)

ΔT = Temperature difference across the material (K)

t = Time (s)

Comparing Thermal Conductivity of Stainless Steel and Aluminum

| Property | Aluminum | Stainless Steel |

|---|---|---|

| Thermal Conductivity | ~205 W/m·K | 15-25 W/m·K |

| Conductivity Ratio | ~20x higher | Baseline |

| Primary Use | Heat exchangers, cooling systems | Insulation, structural strength |

| Key Advantage | Rapid heat transfer | Corrosion resistance, durability |

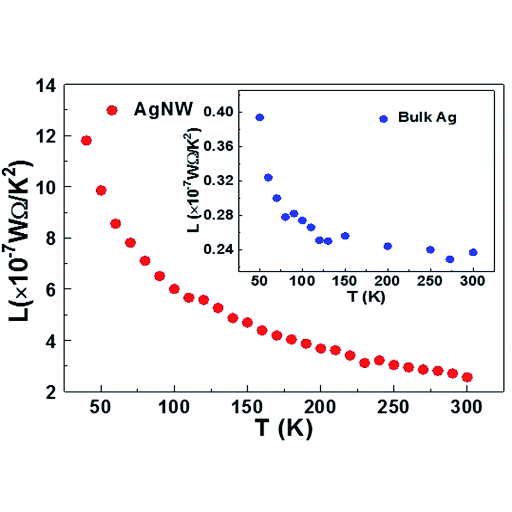

The large discrepancy is primarily due to free electron movement in aluminum that contributes to heat conduction. In real-world applications, aluminum’s thermal conductivity makes it perfect for heat exchange devices and computer cooling, while stainless steel is chosen for applications requiring electrical insulation, strength, and corrosion resistance.

Factors Affecting Thermal Conductivity in Stainless Steel

The thermal conductivity of stainless steel varies depending on several key factors:

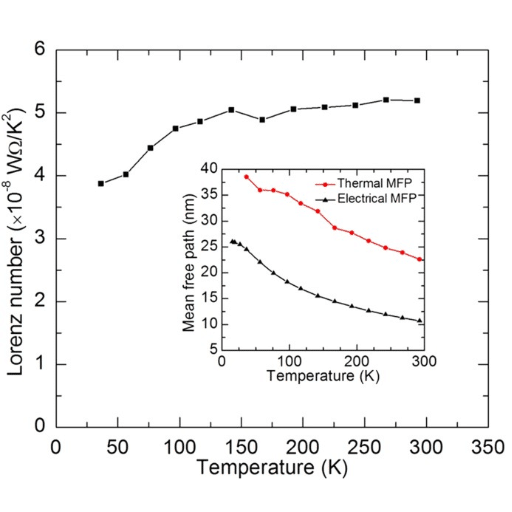

1. Chemical Composition

- Chromium and Nickel Content: Austenitic grades with higher chromium and nickel have lower thermal conductivity than ferritic or martensitic grades

- Molybdenum: Influences thermal properties significantly

- Differences in lattice structure and electron mobility account for variations

2. Crystalline Structure

- Lattice structure affects electron flow

- Different microstructures have varying heat transfer capabilities

- Grain boundaries influence thermal pathways

3. Impurities

- Trace elements like sulfur and phosphorus lower thermal conductivity

- Create scattering sites for heat-carrying electrons

- Can significantly impact overall performance

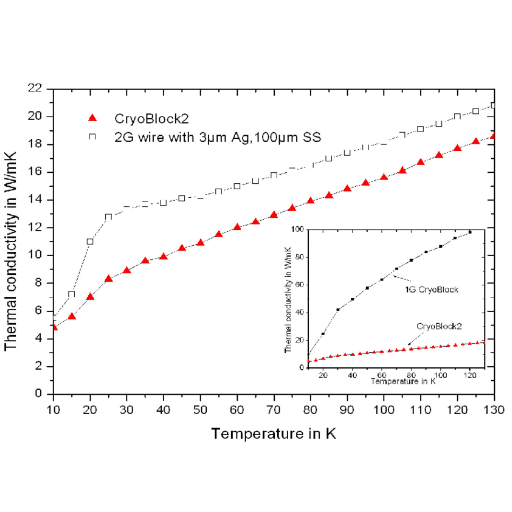

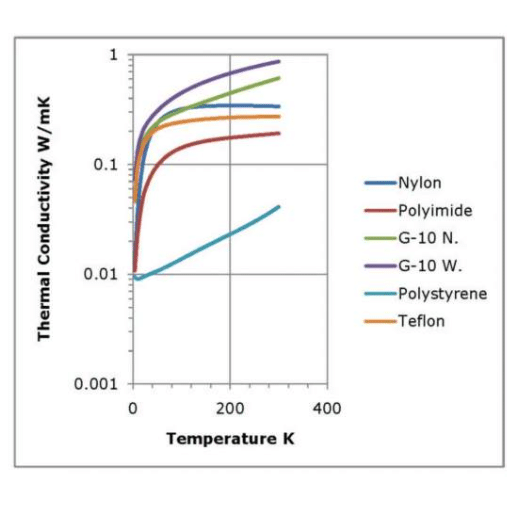

4. Operating Temperature

- Thermal conductivity generally decreases at lower temperatures

- Slight improvement may occur at higher temperature ranges

- Behavior depends on specific alloy composition

Applications of Stainless Steel Based on Heat Conductivity

Heat Exchangers

Industries like chemical processing, power generation, and HVAC systems utilize stainless steel as a primary material. Its combination of heat transfer capability and corrosion resistance ensures longevity in harsh thermal and chemical conditions. Grade 316 stainless steel is particularly effective in areas with chloride-induced corrosion concerns.

Industrial Piping Systems

The high-temperature stability of stainless steel makes it advantageous for piping systems designed to transport hot fluids. The material maintains its physical properties at high temperatures for extended periods, even in steam or hot oil transfer systems.

Cookware and Kitchen Appliances

Stainless steel cookware is manufactured for its moderate thermal conductivity combined with maximum durability and corrosion resistance. Grade 304 stainless steel provides excellent heat distribution across cooking surfaces, ensuring optimal cooking performance.

Solar Panels and Renewable Energy Components

In renewable energy applications, stainless steel is the material of choice for components like solar heat collectors and reflectors. Its ability to withstand repeated heating and cooling cycles makes it ideal for these applications.

Petrochemical Processing Units

Petrochemical plants involve very high temperatures and chemically aggressive substances. Specialized alloys like duplex or super duplex grades are used in heat-intensive components such as reactors, boilers, and exchangers for superior heat transfer and resistance to degradation.

Cooking and Culinary Uses

Stainless steel is widely accepted in the culinary world for its excellent properties:

- Durability: Long-lasting performance under demanding conditions

- Non-reactive: Safe for all food types without contamination

- Easy to clean: Maintains hygiene standards

- High-temperature resistance: Safe at extreme cooking temperatures

- Corrosion protection: Ensures food safety

Industrial Applications in Metal Fabrication

Metal fabrication relies heavily on stainless steel due to its hardness, strength, and rust resistance. These properties make it essential for constructing industrial machines and tools where precision, reliability, and long service life are critical.

Common fabricated items include:

- Cutting tools for precision work

- Heavy-duty storage tanks

- Assembly line components

- Turbine blades for aerospace

- Vehicle frames for automotive

- Solar panel mounts for renewable energy

Impact on Product Design and Engineering

Material Properties and Their Impact on Performance

The inherent characteristics of high-tech materials drive their performance in major engineering and industrial applications. Stainless steel’s properties provide multiple advantages:

| Property | Impact | Industry Applications |

|---|---|---|

| Corrosion Resistance | Survival in moisture-laden or chemically reactive conditions | Marine, medical, construction |

| Tensile Strength | Withstands high mechanical stress without fracturing | Automotive, aerospace design |

| Ductility | Allows forming and shaping without breaking | Manufacturing, fabrication |

| Recyclability | Environmental sustainability (~100% recyclable) | All industries |

Understanding Material Properties of Stainless Steel

The corrosion resistance of stainless steel is remarkable, credited to chromium (usually at least 10.5% or more). A thin passive oxide layer forms on the surface, strengthening resistance against environmental factors such as moisture, oxygen, and harsh chemicals.

Specialty Alloys: Modern material science has developed specialty stainless steel alloys such as 316 and duplex grades that are more resistant to specific corrosive environments like saltwater and acidic conditions, providing wider industrial applications.

Heat Resistance and Durability

Stainless steel possesses remarkable heat resistance, making it a key material where high-temperature exposure is required.

| Grade Type | Specific Grade | Maximum Temperature | Key Features |

|---|---|---|---|

| Austenitic | 304 | ~1600°F (870°C) | Maintains strength and corrosion resistance |

| Austenitic | 310 | ~2000°F (1093°C) | Superior high-temperature performance |

| Ferritic | 446 | High temperatures | Excellent oxidation resistance |

Chromium and nickel presence increases thermal stability, guaranteeing structural integrity even at extreme temperatures. This heat resistance and durability prolong equipment life and eliminate maintenance costs, making stainless steel indispensable in energy, aerospace, and construction industries.

The Role of Alloys in Thermal Properties

Alloying significantly influences the thermal properties of metals, especially under extreme conditions. Through careful mixing, alloys can be engineered with features like:

- High thermal conductivity

- Reduced oxidation

- Low thermal expansion rates

Examples of Advanced Alloys:

Nickel-Based Alloys (INCONEL®):

- Widely applied in aerospace and energy

- Maintain structures and resist creep at temperatures exceeding 1,000°F (538°C)

- Essential for turbine engines and nuclear reactors

Aluminum Alloys with Magnesium or Silicon:

- Better heat absorption properties

- Applied in electronic systems

- Used in automotive heat exchangers

The Future of Stainless Steel in Heat Applications

High-Temperature Resistance

Modern stainless steel alloys, particularly grades 309 and 310, can withstand temperatures up to 1000°F (538°C) or higher without losing strength and durability. These alloys will likely see wider adoption for high-temperature applications in furnace heating and thermal processing equipment.

Improved Corrosion Resistance in Extreme Environments

Future duplex and austenitic steels will develop even better resistance to corrosive attacks in high-temperature situations with aggressive chemicals or oscillating heat conditions. This will be a major breakthrough for chemical, petrochemical, and refinery industries.

Enhancements in Creep Strength

Research on stainless steels like super austenitic and ferritic-martensitic grades aims at increasing creep strength—the property that prolongs material life during high-temperature and high-load exposure. Improvements are expected to benefit the power industry, particularly in boilers and heat exchangers.

Energy Efficiency Through Material Design

New alloys are being developed to increase energy efficiency in heat transfer applications. This includes innovations in microstructural engineering aimed at optimizing heat conduction for industries such as HVAC, solar energy, and advanced manufacturing.

Sustainability and Recyclability in High-Heat Applications

The future material trend strongly emphasizes the recyclability of stainless steel, with its near-100% recycling rate being a significant advantage. Combined with heat resistance and extended lifespan, stainless steel can be integrated into global sustainable development goals.

Final Thoughts on Material Selection

For high-heat applications, stainless steel remains unbeatable due to its proven quality over decades, combined with recyclability and high-temperature resistance.

Comprehensive Selection Criteria:

- Performance Metrics: Thermal conductivity, strength, durability

- Lifecycle Costs: Initial investment, maintenance, longevity

- Environmental Responsibility: Recyclability, energy efficiency, carbon footprint

References

-

“Thermal Conductivity” – Provides a comprehensive table of thermal conductivity values for various materials, including stainless steel.

-

“Is Stainless Steel a Good Conductor of Heat?” – Explores the thermal conductivity of stainless steel compared to other metals like copper and aluminum.

-

“Thermal Conductivity of Inconel 718 and 304 Stainless Steel” – Reports on thermal conductivity measurements of 304 stainless steel using comparative and flash diffusivity techniques.

Frequently Asked Questions (FAQ)

What is the thermal conductivity of stainless steel in relation to other materials?

The typical thermal conductivity of stainless steel is between 15 and 45 watts per kelvin per meter, which is lower than that of aluminum and higher than that of carbon steel. In simple terms, stainless steel is a good conductor of heat, but not as good as aluminum in the area of heat transfer.

What is the influence of stainless steel density on its thermal properties?

The density of stainless steel plays a role in its thermal properties, including heat transfer and thermal conductivity. As a general rule, materials with a higher density are better thermal conductors due to their atomic structure being so close together and thus heat can flow more easily through them. However, stainless steel despite being denser than aluminum has lower thermal conductivity.

What is the significance of stainless steel in food processing equipment?

In food processing equipment, stainless steel is the preferred material because of its outstanding properties such as resistance to corrosion and heat-conducting ability. Due to the thermal properties, it can be used to uphold the temperature intervals required for processing, thus food safety and quality are guaranteed.

In terms of heat conductivity, how stainless steel ranks against aluminum?

Aluminum is a superior thermal conductor when compared to stainless steel, and the thermal conductivities of the two metals are typically in the range of 205 watts per kelvin per meter for aluminum and 15-30 for stainless steel. This property of aluminum makes it ideal for areas where quick heat transfer is needed. On the other hand, stainless steel has the advantage of being durable and resistant to corrosion, so it is still a good option in many industries where it is used.

What are the factors which can influence the efficiency of a project if applying stainless steel with low thermal conductivity?

Thermal conductivity of stainless steel has a great impact on the efficiency of projects in particular industries that need to manage heat. If stainless steel is the case then it will be stable in temperature even very low thermal conductivity material, which is very important in processes such as cryogenics, high-performance semiconductor manufacturing, and so forth.

Is there a difference in thermal conductivity among various stainless steel grades?

Different grades of stainless steel do indeed have varying thermal conductivities. For instance, 304 and 316 being austenitic stainless steels have different thermal properties when compared to ferritic or martensitic grades. It is necessary to have this knowledge for choosing a right material for a certain application.

What metal has the lowest thermal conductivity among the most common ones?

Among the common metals, stainless steel is generally one of the worst thermal conductors, especially when you put it on a scale against copper and aluminum. However, the low conductivity of stainless steel could be a setback in cases where fast heat transfer is a requirement.

What is the performance of stainless steel at high temperatures?

Stainless steel is not only to maintain its structural integrity and thermal properties at high temperatures prolonging the lifespan of the product but also being safe at the same time. Heat exchangers and high-temperature processing equipment are some of the applications that it can operate in because of its heat-conducing ability without compromising on safety.

What are the different thermal conductivities of stainless steel alloys?

Thermal conductivities in stainless steel alloys can be quite different from each other. A case in point is the duplex stainless steels that are frequently the choice of designers for applications like heat exchangers compared to standard austenitic grades. Therefore, it is imperative to have this knowledge for selecting the right alloy for specific thermal applications.