Aluminum alloys are a major material in many sectors due to their low weight, great strength, and multiple uses. In the extensive range of aluminum, Aluminum 5052 and 6061 are the most widely used ones and stand out. Yet, how to choose the better one for your needs? This article goes deep into the differences and similarities of Aluminum 5052 and 6061 by looking into their constituents, features, and uses in real life. To be precise, if you are working on a project that requires various materials for the construction, automotive parts, or marine applications, the knowledge of these differences will allow you to make a smart choice. Therefore, keep reading to find out which alloy meets your needs in a project.

Introduction to Aluminum Alloys

The Importance of Choosing the Right Aluminum Alloy

Using the most appropriate aluminum alloy is nothing but vital since it would be the main influencer in the project’s performance, durability, and cost-effectiveness. The major aluminum alloys like 5052 and 6061 have been developed with their respective proportions of elements to provide them with certain strengths, along with corrosion resistance and machinability. Recent data indicates that the industry professionals constantly search for the differences among these alloys, especially related to mechanical properties, their compatibility with different environments, and ease of fabrication.

The example of Aluminum 5052 illustrates this point as the metal is generally praised for its wonderful resistance to corrosion, especially in harsh marine environments, thereby becoming the best choice for shipbuilding or storage tanks. Aluminum 6061, in contrast, is now the most sought after for its great tensile strength and excellent machinability; thus, it can be used in structural applications, aerospace, and automotive industries. Through examining the environmental exposure, load, and production methods, enterprises and engineers can easily find out the most appropriate alloy for their specific requirements.

💡

Key Selection Criteria

- Environmental Exposure: Consider moisture, saltwater, and chemical exposure

- Load Requirements: Evaluate tensile and yield strength needs

- Production Methods: Assess formability, machinability, and weldability

- Cost-Effectiveness: Balance performance with budget constraints

Overview of Aluminum 5052 and 6061

Property-wise, aluminum 5052 and 6061 compared to each other reveal their respective application-specific strengths based on new understanding. The specialty of 5052 aluminum is its very high corrosion resistance, particularly in extremely aggressive and salty marine environments, which makes it the best candidate for making things like fuel tanks, marine vessels, and pressure vessels. Non-heat-treatable nature of 5052 together with its remarkable formability makes it the most desirable material in places where flexibility and protection against harsh conditions are of utmost importance.

On the other hand, 6061 aluminum is all about strength and versatility and primarily this is due to the fact that it can be heat treated for improving its mechanical properties. It provides high tensile strength and good machinability, thus being a very suitable choice for aerospace components, structural frameworks, and automotive parts. Besides, 6061 aluminum has decent corrosion resistance but it is generally not very effective compared to 5052 in salt water and in areas that are chemically aggressive.

Choosing between these two alloys depends on the project characteristics. New information suggests the use of 5052 in such applications when the main concern is resistance to moisture and chemicals rather than tensile strength; whereas 6061 can be seen in the areas demanding high structural integrity and the like.

Target Audience: Engineers, Designers, and Manufacturers

Choosing materials between 5052 and 6061 aluminum alloys truly means that the forced and real environmental conditions of your operation have to be analyzed thoroughly. As per the latest search trends data, 5052 which has been acknowledged as a corrosion-resistant metal in aggressive environments has become the first choice for the marine and chemical industry. Yet, if machinability and high tensile strength are of utmost importance, 6061 remains the preferred aluminum alloy in aerospace, automotive, and structural component areas. Decision-makers aligning material characteristics with project requirements will be able to enjoy the benefits of optimal performance and cost-efficiency.

Key Properties Comparison

Corrosion Resistance: 5052 vs 6061 Aluminum

Without a doubt, the 5052 aluminum alloy, also known by the trade name AlMg2.5, is among the top contenders when it comes to corrosion-resistant metal alloys. In fact, its impressive performance in marine and high-humidity environments with saltwater exposure has earned it a place on the list of most corrosion-resistant aluminum alloys. Moreover, its top resistance to both oxidation and chemical exposure renders it most suitable for diverse applications such as fuel tanks, pressure vessels, and marine equipment.

Meanwhile, 6061 aluminum has excellent versatility and durability; however, its corrosion resistance does not equal to that of 5052. The 6061 alloy can cope with less severe environments but it becomes more prone to rusting in the case of saltwater or acidic exposure. One of the ways to make 6061 more corrosion resistant is to anodize or coat it, which allows it to withstand the harsh environments better.

On the other hand, if one were to look at the corrosion resistance aspect, 5052 would surely be the choice for direct and long-term applications in sea or chem aggressive environments.

🛡️ Corrosion Resistance Winner: Aluminum 5052

Best for: Marine environments, saltwater exposure, high-humidity conditions, chemical processing equipment, and fuel tanks where oxidation resistance is critical.

Note: 6061 can be enhanced with anodizing or protective coatings for improved corrosion resistance in moderate environments.

Tensile Strength and Yield Strength Analysis

When compared on the basis of tensile and yield strength, 6061 aluminum alloy comes out as a clear winner against 5052. The tensile strength of 6061 varies between 42,000 and 45,000 psi depending on the temper, whereas the yield strength is about 35,000 psi. In contrast, 5052 gives its tensile strength of roughly 33,000 psi and yield strength of nearly 28,000 psi for the most common tempers.

Consequently, these distinctions indicate that 6061 is more appropriate for the applications with the requirement of higher strength as a critical factor like structural parts or aerospace-grade materials. However, the slight strength disadvantage of 5052 still meets the requirements of many applications and is often chosen in the conditions where excellent corrosion resistance and formability are among the top factors. Hence, the distinction between these alloys boils down to weighing the strength need to be against the corrosion resistance and ease of fabrication requirements.

💪 Strength Winner: Aluminum 6061

Best for: Structural applications, aerospace components, automotive parts, and any project where high tensile and yield strength are critical requirements.

Fatigue Strength and Formability Considerations

In terms of fatigue strength, aluminum alloys, 6061 is the strongest with its higher tensile strength and long-lasting cyclic load support. This makes it a material of choice in applications subjected to continuous stress cycles, like aerospace structures and industrial machinery. The opposite direction of 5052 is that it does not offer high resistance to cracking during shaping and bending but it allows easy formability. That is why it is so advantageous during the making of complex parts with special shapes or intricate designs.

The selection of the alloys often depends on the specific conditions and requirements of the application. In case fatigue strength is given priority, 6061 is generally the choice. But if forming difficulty and corrosion resistance in extreme conditions are the main concerns, 5052 is a tiptop alternative. By considering operational requirements and making use of the unique points of each alloy, engineers and designers can come to a conclusion that would not only be effective but also long-lasting.

⚖️ Fatigue vs Formability Trade-offs

Fatigue Strength Priority

Choose 6061: For continuous stress cycles, aerospace structures, and industrial machinery

Formability Priority

Choose 5052: For complex shapes, intricate designs, and bending without cracking

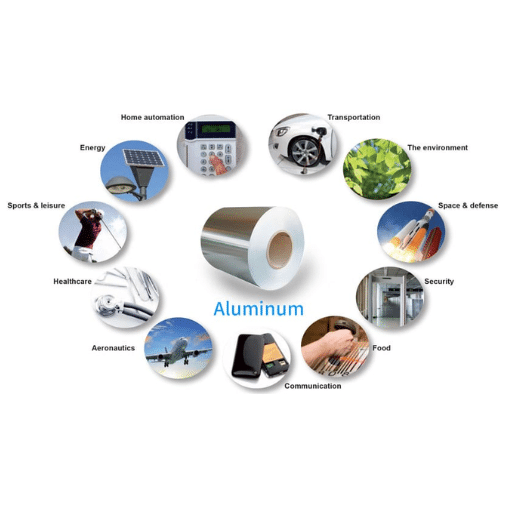

Common Applications of Aluminum Alloys

Industries Utilizing Aluminum 5052

Aluminum 5052 is a very adaptable metal which has properties that make it excellent for corrosion resistance, welding and forming; thus it is used in many different industries. One of the major areas of its application is the marine industry, where its property of resistance to saltwater makes it a good choice for boat hulls, fuel tanks, and marine hardware. The car and transport industry also use 5052 metal a lot for making parts, panels, and fuel tanks as it is lightweight but very durable. Besides, the material is used in the aerospace industry for non-critical aircraft parts and it is also the first choice in food and chemical equipment manufacture because of its resistance to corrosive substances. Aluminum 5052 is also used in architecture, for roofing and siding, where its aesthetic finish and weather-resistant qualities are a big advantage and it is thus, a choice in demanding places.

🏭 Aluminum 5052 Industry Applications

- ⚓

Marine Industry: Boat hulls, fuel tanks, marine hardware - 🚗

Automotive & Transport: Panels, fuel tanks, lightweight durable parts - ✈️

Aerospace: Non-critical aircraft components - 🍽️

Food & Chemical Equipment: Processing equipment, storage tanks - 🏗️

Architecture: Roofing, siding, weather-resistant finishes

Typical Applications for Aluminum 6061

Aluminum 6061 is one of the most versatile aluminum alloys and is popularly considered the best for its high strength-to-weight ratio, corrosion resistance, and easy machining. This alloy is often used in the automotive and aerospace industries for structural parts like frames, panels, and fuselage parts, where both durability and lightweight performance are critical. Besides, Aluminum 6061 is the first choice in making frames for bicycles and other recreational equipment due to its excellent balance of strength and fatigue resistance. It finds its place in the construction industry, where it is used for load-bearing structures, scaffolding, and contemporary architecture. The marine industry also utilizes its capability of resisting corrosion in saltwater and uses it for boat hulls and marine hardware. Moreover, it is found in electronics that require strong casings and heat sinks, where it provides thermal conductivity while still being lighter. It is the wide ranging versatility across such a large number of industries that makes Aluminum 6061 the backbone material for the advent of modern applications.

🔧 Aluminum 6061 Industry Applications

- ✈️

Aerospace & Automotive: Structural frames, panels, fuselage components - 🚴

Recreational Equipment: Bicycle frames, sports equipment - 🏗️

Construction: Load-bearing structures, scaffolding, modern architecture - ⚓

Marine: Boat hulls, marine hardware with moderate exposure - 💻

Electronics: Casings, heat sinks, thermal management components

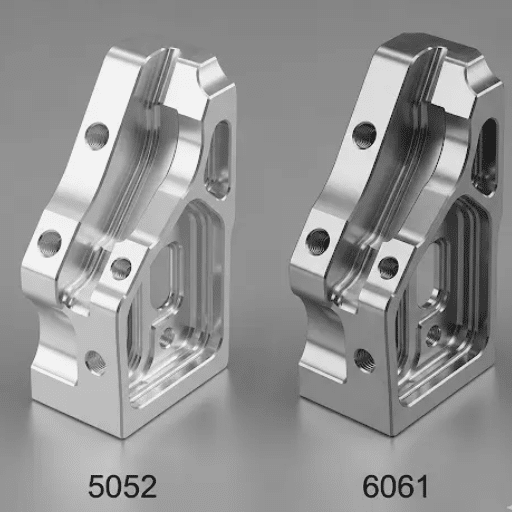

Comparative Use Cases: 5052 and 6061 Aluminum

The comparison of 5052 and 6061 aluminum shows that their characteristics make them appropriate for different purposes. Excellent corrosion resistance, especially in marine or saltwater and harsh chemical environments, has made aluminum 5052 very popular. This is why it is frequently used for fuel tanks, pressure vessels, and marine parts. It also gives better formability making it suitable for projects with complex shapes or curves.

Conversely, aluminum 6061 is known for its superior strength, ease of machining, and flexibility. It is a material of choice in construction of high-strength and wear-resistant parts, such as aircraft components, construction materials, and vehicle frames. Moreover, its heat-treatable characteristic further increases its strength and structural stability for heavy-duty applications.

Both alloys can be welded, but the performance of aluminum 5052 is better for high corrosion resistance environments while 6061 is usually regarded where exceptional strength and precision machining are the main concerns. The decision to use 5052 or 6061 is ultimately determined by the details of the application, weighing the factors of durability, resistance, and environment.

Cost Analysis of Aluminum Alloys

Understanding the Pricing Structure of 5052 vs 6061

There are various factors that affect the pricing structure of Aluminum 5052 and 6061 such as market demand, production costs, and the properties of each alloy. Recent data shows that Aluminum 5052 is usually a little less expensive than 6061. This is the case because 5052 has better working conditions and can be easily formed to suit the needs of corrosion-resistant applications, for example, marine environments, and fuel tanks. Conversely, Aluminum 6061, due to its toughness and versatility, is often sold at a higher price because of its strength and machinability, thus widely accepted in aerospace, automotive, and structural components. So, the price difference between these two alloys will be reflected in their respective performance characteristics along with the project requirements.

💰 Pricing Overview

Aluminum 5052

Generally Lower Cost

Better forming characteristics make it cost-effective for specific applications

Aluminum 6061

Generally Higher Cost

Premium pricing reflects superior strength and machinability

Factors Influencing Costs of Aluminum Alloys

The price of aluminum alloys is a result of many interrelated factors, which correctly represent both the complexities of production and the fluctuation of the market. Major factors consist of the availability of raw materials, energy prices, and market demand. Global supply chains are the strongest links to aluminum prices, as the extraction of bauxite and the refining of aluminum consume a lot of energy. The manufacturing cost is affected by direct hydration of the market and this is coming from the energy price, for instance, electricity and natural gas. Moreover, the demand from various industries such as aerospace, automotive, and constructions can make it possible for prices to be raised because the supply has become limited or there is severe competition for particular alloys.

Besides that, processing steps like heat treatments or surface finishes may also add up to the total cost. Local and international political issues and trade tariffs have their part to contribute as well, as they heavily influence the export and import of aluminum and its complementary materials. The global market is more focused on sustainability, thus increasing the use of recycled aluminum, but the transition to eco-friendly practices may still be costly upfront despite the fact that the environmental benefits will be realized in the long run. Simply put, these factors together determine the price of aluminum alloys which is a delicate process based on project and budget constraints.

📊 Key Cost Influencing Factors

- Raw Material Availability: Bauxite extraction and aluminum refining costs

- Energy Prices: Electricity and natural gas consumption in production

- Market Demand: Industry competition from aerospace, automotive, construction

- Processing Steps: Heat treatments, surface finishes, anodizing

- Trade Policies: International tariffs and export/import regulations

- Sustainability Initiatives: Recycled aluminum usage and eco-friendly practices

Budgeting for Projects: Choosing Between 5052 and 6061

When making decisions on selecting either 5052 or 6061 aluminum for your project, it is often the case that such a choice comes down to a trade-off between the performance criteria and the financial constraints. Both types of aluminum alloys have unique characteristics that allow them to be applied to specific fields.

Among the properties of 5052 aluminum is the fact that it has outstanding resistance to corrosion making it very suitable for marine or other harsh conditions exposed projects. This alloy gives good strength alongside high formability which is a positive aspect for products that require intricate shaping. Its price is usually slightly above that of standard alloys due to its specific features, however, it could still be a source of savings in the long run by lessening the need for maintenance and repair during its life span in corrosive conditions.

On the contrary, 6061 aluminum gets attention for its remarkable strength-to-weight ratio and greater machinability. It has become the majority choice when it comes to structural applications, aerospace components and projects that require welding. Although 6061 can have lower resistance to corrosion than 5052, it is still the case that 6061 is more economical when used for general purposes and it is also very good in performance for a quick variety of indoor and outdoor applications.

In the end, the choice that needs to be made between 5052 and 6061 aluminum should be determined by the project’s explicit performance requirements, environmental exposure, and budget limits. Evaluating the application needs and speaking to the suppliers of your interest using the current information will allow you to make a choice that does not compromise quality but rather is a balance of quality and cost.

💡 Budget Decision Matrix

| Long-term savings needed: | Choose 5052 for corrosive environments (less maintenance) |

| General purpose application: | Choose 6061 for cost-effective performance |

| High-strength requirement: | Choose 6061 for better long-term value |

Conclusion and Final Recommendations

Distinguishing Essentials Between 5052 and 6061

At the first glance, when one considers 5052 and also 6061 aluminum at the same time, it would be improper to ignore the very different attributes of both these metals that are central to making the right choice for one’s particular application. Among other things, the first one stands out when it comes to resistance to corrosion to a great extent, particularly in such as marine or very humid environments, thus it can be said that its main application is made to deal with external exposure. And 6061 is not only strong and hard but also easy to machine, thus making it a good choice for structural and load-bearing applications.

As per the latest data from search engine, another advantage of 5052 aluminum is that it can be formed easier that is it has a good formability thus it can be bent and wrought into a custom design in a better way. However, the 6061 situation is quite the opposite where on the one hand, the situation that demands weldability and post-machining anodizing options is critical, the 6061 is the best choice. On the economic side, it is indicated from current market trends that 5052 aluminum is still the most economical option in large-scale projects where corrosion resistance is a priority, while on the other hand, in high-performance applications 6061 may be the better option for the long run.

Thus, it is a matter of project specifications and conditions of exposure and strength, along with ease of processing and the budget aspect that one has to consider when selecting between 5052 and 6061 aluminum. Utilizing the most accurate and real-time information, you can then make a decision that matches not only the application but also the economic factor.

🎯 Quick Decision Guide

Choose 5052 When:

- Corrosion resistance is critical

- Marine/saltwater exposure

- Complex forming required

- Chemical exposure expected

- Fuel tanks or pressure vessels

Choose 6061 When:

- High strength is required

- Structural applications

- Precision machining needed

- Aerospace/automotive parts

- Heat treatment beneficial

Help in Choosing the Right Alloy

It is possible to merge your understanding of the materials with data from cutting-edge technologies to come up with the best alloy for your application. Using the newest search engine tools, one has access to a vast repository of not only current properties of materials but also their comparisons and trends in the industry. For example, searches like “fatigue resistance of 5052 vs. 6061 aluminum” or “the best aluminum alloy for marine environments” deliver the most relevant results, tailored to the specific needs. Checking trustworthy research, specifications, and real-life case studies help one to get the alloy’s performance exactly under one’s special conditions. It is the combination of these resources that makes it possible for engineers, manufacturers, and architects to not only choose the best material that meets their technical requirements but also gets the best price in the market.

Aluminum Alloy Usage Trends over Time

The changing needs of modern industries along with the easy access to data through search engines, are the main reasons for big predictions about the future trends in the usage of aluminum alloys. One such prediction is that there will be an increasing demand for eco-friendly materials, thus, the searches “recyclable aluminum alloys” will show a growing interest in such materials that promote circular economies, which is mainly the result of stricter environmental regulations and a gradual shift towards green manufacturing practices.

Another new trend is that of high-strength and lightweight alloys being developed for electric vehicles (EVs) and aerospace. The term “lightweight aluminum for EVs” highlights the reduction of overall weight aim that results in the increase of energy efficiency and performance. Moreover, the innovations in additive manufacturing are changing the usage of aluminum alloys, the search term “aluminum alloys for 3D printing” indicates a much easier and frequent starting point for the understanding of the customization and advanced fabrication techniques as the reverse scenario of a typical process where first one has to create a design for the customized product and then use the advanced manufacturing techniques.

Data analysis may reveal these trends and even though be upgraded by industries to predict future breakthroughs and quickly modify company strategies to keep up with the changing tides of customer preferences.

🔮 Future Trends in Aluminum Alloys

- Eco-Friendly Materials: Growing demand for recyclable aluminum promoting circular economies

- Electric Vehicle Development: Lightweight alloys for improved energy efficiency and performance

- Additive Manufacturing: 3D printing applications enabling customization and advanced fabrication

- Green Manufacturing: Stricter environmental regulations driving sustainable practices

Frequently Asked Questions

How much difference is there between the two materials in corrosion resistance?

Among the three, 5052 aluminum is the most excellent material for corrosion resistance and durability due to its high magnesium content. 6061 however is less resistant to pit and crevice corrosion because it mostly relies on its alloying elements Mg and Si. In marine, salt, and humid conditions, 5052 or 6061 aluminum alloys should always favor the former for ability to last long. Designers and engineers often decide on 5052-H32 for sheets where durability against corrosion is a prime concern. Still, the performance of protective coatings and anodizing may vary, and thus, the differences in finish and treatment should consequently be evaluated during selection.

Which one is superior in terms of aluminum fabrication and sheet metal working?

5052 is the top choice for aluminum fabrication and sheet metal work as it has the most excellent forging alloy properties making it ductile enough to get without cracking while 6061 is stronger and does well when machined but it is mainly chosen for parts and components that need more strength after heat treatment. 5052 H32 aluminum sheet widely used in tanks, marine fitments, and other applications where forming and corrosion resistance are the major concerns. The metal fabricators have to consider whether the parts will be stamped, welded, or machined and then decide accordingly. Sometimes using the combination of 5052 for formed panels and 6061 for machined parts can give the best balance.

What do magnesium and silicon as the alloying elements do for performance?

The success or failure of the two metals namely 5052 and 6061 is largely based on the alloying elements and since the percentage of magnesium in 5052 is high it thus gains the very desirable trait of corrosion resistance and also high formability. On the other side, 6061 contains both Mg and Si, this allows for the metal to be heat treated (T6) to significantly increase its tensile strength through the process of precipitation hardening. The magnesium in 5052 also adds to its fatigue strength increase in many sheet metal applications, while the silicon in 6061 takes care of the castability and strength when heat treated. These intrinsic properties of the alloying elements are the reason why 5052 is referred to as “structural aluminum” in marine panels and 6061 for high-strength frames. Knowing the roles of Mg and Si can guide selecting the right alloy in terms of specific mechanical and environmental requirements.

Which one is easier to weld 5052 or 6061 aluminum?

Generally, 5052 H32 is easier to weld than 6061 since it is more ductile and the heat loss in the welding area is accepted to be less or not losing at all in terms of corrosion resistance. 6061 welding is also possible but the strength of the HAZ (Heat Affected Zone) will be impaired due to the heat cycle unless post weld heat treatment is done which is often not feasible for assembly of the finished products. 5052 is the material of choice for welded sheet components like tanks and enclosures in many aluminum fabrication shops. In case of an application requiring 6061 strength, the designer will resort to using a bolt or choosing specific welding methods and filler metals. Eventually, the criterion should be balancing weldability against the need for the higher tensile strength that 6061 offers.

Which material has superior fatigue strength over 6061?

Fatigue strength is influenced by many factors, such as the particular alloy, temper, surface condition, and loading scenario; 5052 usually has better fatigue resistance in sheet form owing to its ductility and capacity to absorb alternating stresses. 6061-T6 offers more static tensile strength, yet in some setups, its fatigue performance might be lower due to the traits associated with the material—i.e., higher stiffness and lower ductility. Furthermore, surface finish plays a crucial role—refinishing of 6061 parts can bring about an increase in fatigue life no matter the alloy, and often 5052 sheet can be the one that reaches the refined finish in the formed panels. Designers need to take into account the anticipated number of loading cycles and refer to the fatigue data corresponding to the particular temper and part geometry. In the case of critical fatigue applications, testing prototypes or applying conservative safety factors is advised.

Reference Sources

-

ScienceDirect – Investigations on Forming of Aluminum 5052 and 6061: This study characterizes the mechanical properties of aluminum 5052 and 6061 sheet blanks using tensile and bulge testing methods.

Investigations on Forming of Aluminum 5052 and 6061 – ScienceDirect -

ResearchGate – Microstructure and Mechanical Properties of 5052-6061 Dissimilar Aluminum Alloy Welded Joint: This research explores the welding of 5052 and 6061 aluminum alloys using friction stir welding, focusing on their microstructure and mechanical properties.

Microstructure and Mechanical Properties of 5052-6061 – ResearchGate -

UNT Digital Library – Final Technical Report: This report discusses the coextrusion of aluminum alloys, including 5052 and 6061, and their feasibility for various applications.

Final Technical Report – UNT Digital Library