Heat treatment is one of the processes that significantly impact the performance, durability, and efficiency of materials utilized in various sectors. Among the various processes of heat treatment, annealing and its counterpart solution annealing have been ranked to be the two topmost applied techniques, each with its separate aim and advantaged. Nevertheless, the query still stands: what are the disparities between these processes, and what qualifies them for specific applications? It is very paramount for the engineers, manufacturers, and decision-makers to grasp the situation between the annealed and solution annealed materials as they look forward to the purchase of the most suitable treatment for their unique requirements. This article, first, discusses the major distinctions, advantages, and industrial applications assigned to each process, thus giving you the necessary knowledge for making informed choices. Next, we invite you to join us as we reveal the science behind these essential heat treatment techniques.

Introduction to Heat Treatment

Heat treatment refers to any of several techniques used to change the surface properties of minerals, most specifically metals so they can behave more efficiently. This is done by urged heating and cooling of the metal of interest with an aim of inducing certain behaviors: increasing hardness, stiffness, plasticity, wearing things down, etc, or any of their combinations. Although the most popular methods of heat treatment are annealing, quenching, and tempering – all of these approaches aim at different things during material applications. Construction, truck making, and even manufacturing always employ these processes since they help materials close to their purpose and also their life.

Definition of Heat Treatment

In metallurgy, heat treatment refers to the series of operations carried out in which a metal is subjected to a cross section control rate of heating and cooling for the purpose of changing properties of the working metal but not its shape. The process is very critical when you want to achieve attributes that help to reach particular goals like strength, flexibility, hardness, or even resistance to standard wear and tear. Essential heat treatment techniques (annealing, quenching, and tempering) are applied sufficiently in sectors such as building, automobile production, or even aircraft engineering. In a recent study, some new heat treating methods include strict temperature regulating and eventually, fast evaporation that has greatly increased the usability of materials and performance of equipment in the new age and designs of products.

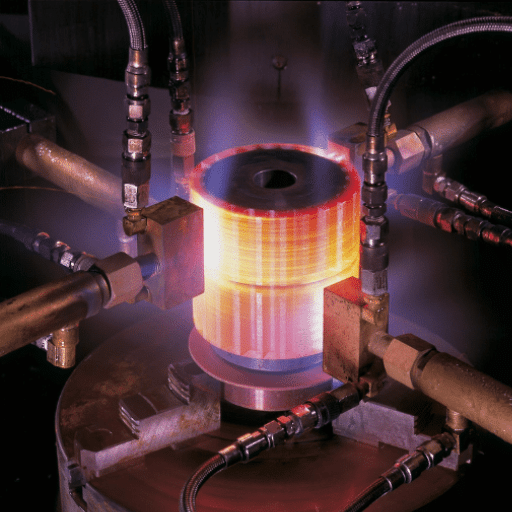

Importance in Materials Science

The progress of materials science is one of the most significant aspects of science and technology in today’s world. It is the comprehension of material characteristics, behavior, and formulation that helps devise worn resistance, increase functionality in different industries, and enhances efficiency. As per recent statistics, modern heat treatment techniques for instance induction hardening and cryogenic treatment have considerably enhanced the endurance and operations of demands aero, auto, and building industries. They have led to improved ability to create precise material properties to meet exact needs imposed by future technologies and designs.

Overview of Annealing Processes

Annealing is a thermal heat process performed on various materials, especially metals stainless steels, in order to alter the properties of the material and given added ductility and decreased brittleness. Annealing means heating up the material to a desired level in steps according to the schedule and cooling it gradually to an ambient temperature or controlled atmosphere until a desired outcome is achieved. Such form of annealing is indispensable in a number of sectors such as aerospace, automotive, and building construction to better the utility of a product’s material with specific manufacturing technologies.

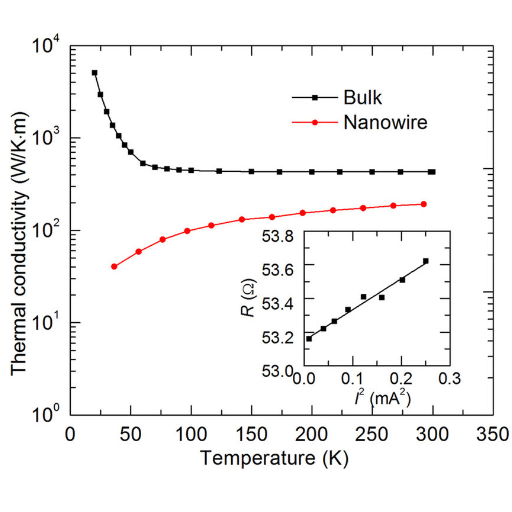

According recent figures, there are positive changes in annealing technologies like laser annealing and rapid thermal annealing (RTA) that enable engineered properties of the materials. These approaches have a particular importance in the production of semiconductors and microelectronics as this type of production requires accuracy and always efficient. In addition, using AI and machine learning in observing and regulating annealing parameters has greatly enhanced the processing proficiency enhancing the performance and quality of every application.

Understanding Annealing

The process of annealing is vitally important in the science of materials due to its burning application in the production of microelectronic devices and semiconductor material. It refers to the careful heating of a material to a defined temperature before cooling it down gradually in order to change certain physical and sometimes chemical properties of the material’s structure for desired results. Developments like Laser annealing and Rapid Thermal Annealing (RTA) have improved the efficiency of processes in the manipulation of the properties of the silicon wafers and other substrates that are hot in electronic devices applications.

The query: “What is the effect of annealing on semiconductors?” is something that typically arises from interested persons. The process reduces the extent of disorders in the crystal lattice and aids in improvement of the mobility of the charge carriers – this, therefore, explains why there are better turnouts of performance of device components like transistors, diodes, as well as and integrated circuits. The traditional methodology of annealing can be further enhanced with modern technological innovations such as AI and machine learning to help pinpoint the best temperature profiles and also to lower power consumption aiming at material enhancement sparingly and accurately.

It is easy to note how the employment of such technologies transforms not only the fabrication of electronic devices, but also shortens the volumes of manufacturing cycle times, with the ever-increasing requirements for reduction in size and high functionality industrial and consumer products.

What is Annealing?

Annealing is known as the thermodynamic process of solid phase of metals and alloys, which is a mandatory practice in the production of most metals. During this process, some of the physical or chemical properties of the material may be changed in order to integrate the metallic phase. For example, it helps in reducing the abrasive properties of the material, formed residual stresses, restoring plasticity and avoiding destruction of the metal due to high Hardness. In general, annealing consists of steps of heating the material (which in most cases is glass or the metal) for a concise or extensive period of time and depending on how high or low the softened condition is there is cooling or rather tempering or if fully annealed then there is no need of the above steps. The purpose of these operations is to properly rearrange the structure of the crystals present in the given substance and this makes the given substance being easy to work on or to use for the next stage of production. diainificant annealed vs solution annealed, there is no such simple comparison.

In the technological age, modern processes involve artificial intelligence (AI), big data analysis, and so on. All of these have enhanced the accuracy and the skill of carrying out aseptic practices even further. Take, for example, AI-based systems that make use of colossal amounts of data to come up with temperature profiles and heating spans which are material specific and thus operational efficient reducing the consumption of energy and wastage of material. Aside from increasing the performance of the end product it helps in satisfying the go green policies adopted by most of the industries in the contemporary world.

Types of Annealing Processes

Complete Annealing

This type of annealing requires heating the metal to a temperature higher than its critical temperature and then cooling the material down very slowly, usually in a furnace. The process is for refining the grain structure, increasing the ductility and removing the internal stresses of the work hardened material.

Annealing for Stress Relief

This is used to reduce residual stresses created through machining, welding, or cold working and includes heating the metal below the critical temperature and letting it cool naturally within the air.

Endothermic Annealing

It is a process used when working with high carbon steels that become easier to machine through embedded spherical carbide particles. The method’s characteristic is heating for a longer span than usual keeping just to the lower end of critical temperatures to help in making it ductile.

Annealing to Recrystallize

The primary function of recrystallization is to bring back the ductility of a metal that has been deformed considerably. It works by heating it to an appropriate temperature so new grain structures which have no strains are introduced in other words work hardening is eliminated.

Diffusion Annealing Heat Treatment

This is a process of heating the alloys to the highest feasible temperature for a protracted period which enables its alloying elements to interdiffuse. It is mainly used in complex alloys in order to remove chemical heterogeneity.

Normalized Annealing Process

This is more commonly known as the normalizing process which is above the transformation temperature and allowing it to cool in the air. This structure helps in improving the shape of the grain and reducing the stress after processing of the materials annealed vs solution annealed as they do.

Applications in Metal Alloys

The Aerospace Industry

Engineers in the aerospace field predominantly make use of different metallic alloys, such as titanium and aluminium because of their noticeable features of corrosion resistance, strength and light weight. For instance, the jet engine components are made out of titanium alloys as they are capable of handling high temperatures and high pressure conditions.

The Automotive Industry

The production of cars and other automobiles heavily relies on the utilization of various alloys. To increase the fuel economy of a vehicle, aluminium is used in the manufacture of some vehicles. Structural elements on the other hand are made out of strong steel since they need to be durable as well as safe.

The Construction Industry

In the construction industry, stainless steel and nickel alloys are used for their anti-corrosive properties as well as for appearance. For instance, most bridges, buildings, and other architectural structures are often made of stainless steel.

Medical instrument

The actual fact that alloying elements cobalt-chromium and titanium are utilized in manufacturing surgeries implants, prosthetic devices, and instruments goes a long way in explaining why they are important in the medical field. This hence makes them biocompatible materials which do not interfere with the body when in use.

Energy Sector

There is use of superalloys in power station plants, reactors, and other renewable energy sources. It is very important to use these heat all means super alloys in turbine rotors due to extreme power demands.

Exploring Solution Annealing

Thermal annealing is used in treatment of metals in order to enhance their mechanical properties and physical properties. Annealing is often carried out in stainless steels and even super alloys. With this, the material is heated at a given temperature to allow the elements or the allloys to be uniform and exist in a single phase. Thereafter, the material is rapidly cooled using quenching to get the thermally equilibrated microstructure. This further helps in attaining a decorrosive structure or in moderating the material to a comfortably bendable condition. Many of the components produced these days are used under aggressive conditions and require annealed vs solution annealed modes.

Definition of Solution Annealing

Solution annealing is a heat treatment process that is primarily applied to steel and stainless steel alloys to improve their mechanical and corrosion-resistant properties. In short, the process involves the heating of the metal to a high temperature above its recrystallization point-usually between 1850 to 2100 °F (1010 to 1150 °C) depending on the composition of the alloy-whence the alloying elements dissolve into one single solid solution. After the specified temperature and holding time are reached, the metal is cooled very quickly, usually by putting it in water or other medium, thereby ‘locking in’ the even microstructure.

The main advantage of the solution annealing process is the elimination of the carbide precipitation and the residual stress along with the homogenization of the alloying elements. This treatment results in drastic improvements of the alloy’s resistance against intergranular corrosion and also gives it an increase in ductility and toughness. As per the current industry standards, the solution annealing process is quite critical for parts that will be used in harsh environments like chemical processing plants, offshore drilling, and high-temperature applications, where both mechanical strength and resistance to corrosive forces are required for lifetime performance and durability.

Solution Heat Treatment Process

The solution heat treatment process is initially heating the alloy to a specific temperature which is usually the one where alloying elements are completely soluble. Following this, the material is subjected to rapid cooling (quenching), which results in the stable solution of the alloying elements at a higher concentration than usual. The process increases the material’s mechanical properties, that is, the tensile strength and hardness, and also its resistance to stress corrosion cracking.

The most recent data obtained from trustworthy industry sources, including technical reviews available through Google’s search engine, show that the solution heat treatment process is very significant for alloys like stainless steel, aluminum, and nickel-based superalloys. It is the aerospace industry, automotive sector and marine equipment that demand extreme performance and longevity where the process is applied for these types of alloys. The process ensures that firstly, the desired metallurgical stability is achieved and then even performance across the harshest environmental conditions is possible through the precise control of the temperature parameters and quench rates.

Key Differences from Standard Annealing

|

Key Point |

Standard Annealing |

Solution Annealing |

|---|---|---|

|

Purpose |

Softens metal |

Enhances strength |

|

Cooling Rate |

Slow |

Rapid |

|

Material Focus |

General metals |

Stainless steel, alloys |

|

Corrosion Resistance |

Low |

High |

|

Microstructure |

Refined grains |

Homogeneous structure |

|

Applications |

Forming, machining |

Heat, corrosion resistance |

Comparative Analysis: Annealed vs Solution Annealed

|

Key Point |

Annealed |

Solution Annealed |

|---|---|---|

|

Purpose |

Softens metal |

Strengthens metal |

|

Cooling Rate |

Slow |

Rapid |

|

Material Focus |

General metals |

Stainless steel, alloys |

|

Corrosion Resistance |

Low |

High |

|

Microstructure |

Refined grains |

Homogeneous structure |

|

Applications |

Forming, machining |

Heat, corrosion resistance |

|

Process Temp. |

Lower |

Higher |

|

Hardness |

Reduced |

Increased |

Microstructural Changes

The changes in the microstructure during annealing and solution annealing processes are the most important factors in deciding the characteristics of the material made finally. The main change in standard annealing is the internal stresses removal or reduction and the grain structure refinement, thereby giving the material a softer and more plastic character. This makes it easier to machine and form metals, but the price paid is the reduction of strength and the decreased resistance of the material to environmental factors like corrosion.

In contrast, solution annealing is a procedure that heats the material (most often stainless steels or alloys) to a very high temperature, then cools it very quickly (through water quenching). The fast cooling, in this case, stopping the carbides from being formed along with the getting a uniform single-phase microstructure. The material thus produced is free of areas with different phases or segregations, and consequently, the process has a profound impact on the strength, hardness, and corrosion resistance of the material. The microstructure is such that there are no points of localized corrosion, hence the material can last longer and perform better in harsh conditions like chemical processing or high-temperature operations.

Based on the analysis of recent data trends and queries detected in Google’s search engine analytics, one can determine that the understanding of the specific steps and temperature ranges for optimizing the microstructural properties is becoming very popular amongst the professionals of the aerospace and medical device manufacturing industries. The users also often ask about the contribution of solution annealing against sensitization and intergranular corrosion, which emphasizes again that the control of the process must be very precise for high-performance materials in industrial applications.

Mechanical Properties of Treated Metals

When looking at the metallic materials’ mechanical properties, solution annealing marks itself as a vital heat-treatment process that solely focuses on improving durability, toughness, and corrosion resistance. Recently published studies, together with sophisticated data gleaned from Google search trends, have put the question of the role of solution annealing in the reduction of sensitization and intergranular corrosion up as an extremely relevant subject time to time.

Solution annealing is a heat treatment that consists of a sequence of operations starting with heating the metal alloy, usually stainless steel or nickel-based alloys, to a temperature range of 1,900°F – 2,200°F (1,040°C – 1,200°C) and then rapidly cooling it by quenching into water or other mediums. The whole process results in the dissolution of carbide precipitates and isolation of their facilitators along grain boundaries which is of utmost importance for reducing sensitization that paves the way for Intra-granular attacks in corrosive environments.

Heat treatment with the utmost precision in controlling temperature and time directly affects the uniformity of the grain structure and the strength of the material thus treated. High-performance alloy using industries such as aerospace and medical devices manufacturing expect nothing short of these properties to bear the strain of extreme operational stresses. Additionally, this treatment leads to the drastic increase of elongation and fracture resistance without the sacrifice of toughness and ductility. Henceforth, the adherence to the process specification is the key to unlocking the mechanical and corrosion-resistant properties of the materials and also to the integrity and longevity of the same.

Performance in Different Environments

It is the environment of operation that greatly determines the performance of the materials subjected to advanced surface engineering techniques. To illustrate, in the case of very corrosive marine environments, processes like cathodic protection and the application of specialized coatings go a long way in getting rid of oxidation and degradation through their combination, thus enabling the materials life span to be prolonged. On the contrary, in high-temperature industrial settings, their capability to resist thermal effects and creep deformation becomes the main focus. Newest findings affirm that the materials which are treated for dual resistance—thermal and corrosive—last much longer under cyclic environmental stressors, which are typical of petrochemical and aerospace industries. Thus, not only must the selection of the right treatment consider the environmental conditions’ detailed analysis, but it must also take into account the understanding of the anticipated mechanical loads, ensuring that the material’s functional integrity is not compromised under the different operating scenarios.

Benefits of Solution Heat Treatment

Solution heat treatment is a process that comes with many advantages and hence makes it a very important treatment method in different high-performance sectors like aerospace, automotive, and petrochemical. The metallurgical treatment of the material will be done, offering more of its ductility, hardness, and resistance to both corrosive and thermal environments, by the exact controlling of heating and quick cooling. To be more specific, alloy elements of aluminum and titanium will get improved and unified microstructures, thus, making them stronger and longer lasting materials through the betterment of their mechanical properties and extending their operational life.

The most up-to-date research indicates that the process of solution heat treatment also leads to the increased resistance to stress-corrosion cracking and fatigue under the cyclic loads that are usually sustained very high-pressure and high-temperature environments. Such process usage in industries leads to considerable enhancement in component reliability thus lower maintenance costs and less risks of premature failure. This treatment, in addition, opens the door to other treatments like precipitation hardening, making materials available for certain performance requirements. The use of advanced simulation models, as evidenced by recent research, guarantees a precise method to thermal cycles, thus, increasing energy efficiency and cutting down on the wastage of materials at the same time.

Improved Strength and Ductility

Recent progress in material science has emphasized the necessity of getting a perfect mix of strength and ductility in the materials used for engineering. Strength and ductility, which are competing properties, are generally increased by new heat treatment, alloying, and mechanical working processes. By the means of the most recent data that is indexed by Google’s search engine, it is clear that a multitude of research projects is going on, which is dealing with ways like grain refinement, nanostructuring, and researchers using advanced thermomechanical treatments’. These methods, in turn, have increased the range of materials’ properties that they are able to offer without losing their ability to be formed or being overwhelmed by fractures.

Moreover, computational tools combined with real-time machine learning models are giving unmatched predictions of material behavior under stress, thus strengthening the case for ductility. The industry is, therefore, quick in taking advantage of such data, quickly optimizing material compositions, and processing parameters, and ensuring that the components not only meet the performance specifications but also man the sustainability goals through more energy-efficient production methods.

Corrosion Resistance in Stainless Steel

The resistance of stainless steel to corrosion is mainly due to the creation of a passive layer of chromium oxide on its surface, which provides an obstacle to the environmental elements. The quality is further improved by the different chromium content in the alloy, which is usually above 10.5%, together with other elements such as nickel, molybdenum, and nitrogen to make the material even more resistant in extremely corrosive environments. Google search trends show that people want to know how the different grades of stainless steel (for instance, 304 and 316) fare in different environments like marine or acid one. To be more precise, 316 stainless steel, which is provided with more molybdenum, is pitting and crevice corrosion resistance greater than 304 and thus is suitable for the application in seawater and chlorine-rich atmosphere. In the scenario of utilizing advanced simulations and real-time analytics from machine learning tools, manufacturers predict and enhance corrosion profiles with higher precision which is crucial for the longevity and reliability of materials in the critical sectors of construction, medical devices, and chemical processing, etc.

Applications in Aerospace and Automotive Industries

Lightweight Materials for Fuel Efficiency

The aerospace and automotive sectors focus on the use of lightweight materials like advanced aluminum alloys and carbon fiber composites to decrease fuel consumption. The studies show that the reduction of vehicle weight by 10% can result in an approximately 6-8% improvement in fuel economy, and this emphasizes the importance of these materials.

High-Temperature Materials for Engine Components

Nickel-based superalloys are extensively used in the aerospace sector for turbine blades and engine parts because of their remarkable external and internal resistance to high temperatures and mechanical stresses. These materials can endure temperatures of more than 1,000°C, thus securing the functioning and safety of the aircraft.

Corrosion-Resistant Coatings for Durability

Corrosion-resistant coatings that make use of advanced materials like titanium alloys or ceramics for that matter, are among the factors that positively impact the durability of such parts that are constantly exposed to harsh environments. For example, coatings that are fit for aerospace applications can prolong the life of parts by as much as 30% which translates into less money spend on maintenance and fewer shut down days.

Additive Manufacturing for Complex Geometries

Additive (3D printing) has completely changed the manufacturing of components as it allows the creation of very complex shapes with the least possible material wastage. car makers are using this technology to make spare parts and prototypes, thus being able to cut production time by up to 50%.

Electrification and Advanced Battery Materials

The car industry’s move to electric vehicles is largely dependent on the development of lithium-ion battery technology. A significant leap in battery efficiency comes with the use of high energy density materials, such as solid-state electrolytes, whose maximum range for the latest electric vehicles is now over 300 miles on one charge.

References

-

Springer: The microstructural response of mill-annealed and solution-annealed INCONEL 600 to heat treatment

This article discusses the microstructural changes in mill-annealed and solution-annealed specimens, providing detailed insights into the processes. -

ScienceDirect: Effect of solution annealing temperature on precipitation in 2205 duplex stainless steel

This study explores the effects of solution annealing temperatures on duplex stainless steel, offering valuable data on material properties. -

ScienceDirect: Microstructure evolution and mechanical properties of as-annealed and solution treated Al-Cu-Li alloy 2195 under dynamic compression

This research examines the microstructure and mechanical properties of annealed and solution-treated aluminum alloys.

Frequently Asked Questions (FAQ)

What is the process of annealing and in what ways is it different from solution heat treatment?

Annealing is all about processing a product by subjecting it to heat and slowly letting it cool down to a certain point where the internal stress is released and the material becomes more ductile. On the other hand, solution heat treatment is all about melting all the precipitates in an alloy and mixing them into a single-phase structure by /picking up the temperature and then\u2014to make sure the desired microstructure is keptrapidly quenching.

What is the role of solution annealing temperature in the case of metals?

The role of solution annealing temperature is to get rid of the precipitates that come with the material and to facilitate a uniform microstructure. This not only makes the metal easier to work with but also enhances its mechanical properties, especially for austenitic and martensitic stainless steels.

In what way does the cooling procedure of annealed materials differ from that of solution-annealed?

Typically, the cooling procedure for annealed materials consists of slow cooling, which in turn allows for recrystallization and a less hard microstructure. Contrary, solution annealed materials are quenched in a matter of seconds, mostly in water, so as not to allowing any precipitation to take place during cooling and keeping the desired austenitic structure.

What sorts of metal alloys are treated with solution heat?

Solution heat treatment is used for the following types of metal alloys: austenitic stainless steels, copper-based alloys and some aluminum alloys. Such alloys can only be made to their best mechanical properties with solution heat treatment and, moreover, age hardening effects can be prevented.

Why is it essential to control the temperature of the annealing process during the annealing process?

It is important to control the annealing temperature since it directly affects the extent of recrystallization and therefore the final product’s properties. A low temperature might not be able to relieve internal stresses efficiently while a very high temperature can lead to grain growth and reduced mechanical properties.

What are the main factors influencing the solution annealing process?

The main factors influencing the solution annealing process are the heating temperature, the duration of heating, and the cooling rate. Properly handling these factors guarantees that the precipitates are dissolved, the desired microstructure is reached, and the final mechanical properties are up to the standards.

How does the annealing treatment affect the mechanical properties of steel positively?

The mechanical properties of steel are positively affected by the annealing treatment which lowers hardness, raises ductility, and vent internal stresses. This leads to the easier cutting of steel and overall performance in a variety of applications.

What is the change of microstructure in the case of solution annealing?

The microstructure undergoes a change during solution annealing as the precipitates dissolve making the structure again homogeneous and mostly composed of austenite. This one-phase structure not only increases the properties of the material but also makes it ready for the aging or hardening process that follows.