The invention of duplex stainless steels is one of the greatest achievements in material engineering due to its high strength, corrosion resistance, and economical properties. Super Duplex 2507 is one of the most outstanding performers and continues to outperform the competition in extreme environments. But how does it compare with other alloys of the same class? This article goes into detail about Super Duplex 2507 and its performance against other competing duplex stainless steels. From alloys’ mechanical strength and corrosion resistance to actual use, we’ll discuss each of them and assist you in deciding which alloy is appropriate for your upcoming project. Prepare yourself for the most comprehensive comparison of duplex stainless steels that allows you to select the most suitable material with accuracy and trust.

What Makes Super Duplex 2507 Different From Other Duplex Stainless Steels?

Super Duplex 2507 has exceptional strength along with unparalleled resistance to corrosion and other damaging factors such as extreme temperatures. Its yield and tensile strength are unparalleled compared to the rest of duplex stainless steels, making it perfect for harsh environments. It has remarkable resistance to pitting, crevice corrosion, stress corrosion cracking, and other forms of abrasion, even in nasty environments like seawater or during chemical processing. Its superior resistance is due to a better balance of chromium, molybdenum, and nitrogen, all of which bolsters its protective elements. Because of these factors, Super Duplex 2507 is the most reliable and easily usable option for the manufacturers as it lasts a longer period of time, unlike others.

Chemical Composition of Super Duplex 2507 vs Other Alloys

What truly stands out about Super Duplex 2507 is its specific and unique chemical composition, which encompass its unmatched performance while differentiating it from other stainless steel alloys. The alloy superf duplex 2507 composition consists of roughly 25% chromium, 7% nickel, 4% molybdenum, and smaller quantities of nitrogen and iron. Even in the harshest conditions, this alloy’s composition is sure to provide outstanding resistance against pitting, crevice corrosion, and chloride stress corrosion cracking.

By comparison, standard duplex stainless steels, such as Duplex 2205, have each of their chromium (21-23%), nickel (4.5-6.5%), and molybdenum (2.5-3.5%) components reduced. These variances lead to less aggressive corrosion resistance and make such alloys more appropriate for less demanding applications.

While austenitic stainless steels, 316L, include 16-18% chromium, 10-14% nickel, and 2-3% molybdenum with no added nitrogen, they lack the ability to excel in highly aggressive or Super Duplex 2507 high-pressure environments. These performing moderately harsh steel alloys lack the strength and corrosion resistance to compete with Super Duplex 2507.

In conjunction with providing lower weight-bearing capabilities, Super Duplex 2507’s yield strength, when compared to austenitic grades like 316L, possesses a yield strength twice as much, making it a prime candidate for applications with heavy weight constraints. Also, the nitrogen constituent in Super Duplex 2507 gives additional support to the structure, which improves its durability against localized corrosion even more, representing Super Duplex 2507’s performance benefits in marine or chemical processing environments.

This Super Duplex 2507 has better resistance to harsh chemicals, demonstrating why he is Super Duplex 2507 stands undisturbed while other materials fail, making it standing as the preferred material to withstand unforgiving industrial scenarios where unparalleled strength is put to the test.

Understanding UNS S32750 and Its Unique Alloy Composition

S32750 or super duplex 2507 is an alloy with around 25% Chromium, 7% Nickel, 4% Molybdenum, a nd nitrogen added in a specified quantity. This specific combination gives it remarkable resistance to stress corrosive cracking, pitting corrosion, and a wide range of other corrosive environments. Its chloride stress corrosion cracking resistance is enabled by the high chromium and molybdenum levels, along with the extreme chemically aggressive and saline environment conditions.

The impact toughness of UNS S32750 is excellent, even in sub-zero temperatures, enabling use in extreme operating conditions. Moreover, the mechanical strength is remarkable as well, being twice that of grade A ferritic and cladded austenitic stainless steels. It also displays reliable performance in offshore platforms, heat exchangers, and pressure vessels, achieving yield strength of 80 ksi (550 MPa) and tensile strength of 116 ksi (800 MPa).

The alloy has a better thermal conductivity than austenitic stainless steel, and its thermal expansion is lower. This means that the material is good for high-temperature or varying temperature environments, as the risk of material fatigue or structural deformation is lower. Moreover, the combination of chemical resistance, mechanical strength, and thermal stability demonstrates how well alloy composition is designed to solve industry problems with UNS S32750.

Comparing PREN Values Between Super Duplex and Conventional Stainless Steels

The Pitting Resistance Equivalent Number (PREN) is an important factor in determining the corrosion resistance of stainless steels with a particular focus on their pitting resistance with respect to chloride seawater. Unlike other austenitic and ferritic stainless steels, Super Duplex stainless steels such as UNS S32750 tend to have PREN values much higher than 40 because of the alloying components in the steel.

The value is said to be above 40 for UNS S32750 since its chromium content of 24-26%, molybdenum 3-5% and nitrogen 0.24-0.32% strengthen the resistance to localized corrosion in harsh conditions like seawater or chemical processing plants.

Austenitic stainless steels as 316L have benchmarked PREN values between 22-26. The numbers can be explained through the lower grades of molybdenum and chromium present in the steel. Even though these steels are functional for less harsh industrial use, they tend attack aggressive conditions. Taking 430 ferritic grade, the PREN will be lower than 10-20 which diminishes its strength in corrosive environments.

This specific benefit in PREN values enables Super Duplex stainless steels to be selected for uses in super-critical offshore oil and gas, desalination plants, and other chemical processing industries where optimum corrosion resistance is needed. High PREN not only guarantees long service life but also provides reduced maintenance and minimizes downtime, thus achieving a balance of performance and cost-efficiency.

How Does Super Duplex 2507 Compare to Duplex 2205 in Performance?

When Super Duplex 2507 is compared with Duplex 2205, it is evident that the former has the advantage in strength, resistance to corrosion, and even in extreme conditions. Moreover, Super Duplex 2507 is able to resist pitting and crevice corrosion better than the rest because of its higher super PREN “Pitting Resistance Equivalent Number”. This is especially the case in high chloride and hostile environments. In addition, it has greater mechanical strength in comparison to the rest of the material, which makes it more suited for demanding applications such as intensive sea deep exploration, chemical processing, and other activities that are extremely hard on materials. Although the environments that Duplex 2205 supports are moderate, Super Duplex 2507 overwhelms it in critical applications where additional factors need to be considered.

Mechanical Properties: Super Duplex 2507 vs Duplex 2205

Both Duplex 2205 and Super Duplex 2507 are well known for their exceptional mechanical features; however, their performance differs considerably because of their compositions.

Super Duplex 2507 is built for unparalleled tensile strength and impact resistance. It has a yield strength of approximately 550 MPa (megapascals) and a tensile strength of about 800 MPa. The strength, in addition to good elongation properties (approximately 15-20%), makes Super Duplex 2507 particularly useful in applications where extreme pressure and stress are encountered.

On the contrary, Duplex 2205 offers a small decrease in mechanical performance. Its yield strength is often accepted as 450 MPa, and its tensile strength is nearly 620 MPa. The elongation percentages for Duplex 2205 are commonly in the region of 25-30%, which means less overall strength compared to Super Duplex 2507, but greater flexibility.

The greatest difference is in the materials’ resistance to fatigue stress and crack propagation. Due to the higher content of chromium, nickel, and molybdenum, Super Duplex 2507 outperformed Duplex 2205 in retaining structural integrity under cyclic loading conditions. This, along with increased hardness and toughness, makes it safer and more reliable in harsh settings.

SAvI oHiTAYHaiPH: A Super Duplex 2507 has a greater level of mechanical properties and this allows for thinner materials to be used in structural design resulting in savings for long term projects. However, for moderate conditions where less demanding mechanical strength is sufficient, Duplex 2205 is a more economically sound and practical choice.

Corrosion Resistance Differences Between Super Duplex and Duplex Grades

For demanding applications, the corrosion resistance of Super Duplex and Duplex stainless steels is critical. Super Duplex stainless steels like 2507 have exceptional pitting and crevice corrosion resistance because of their higher chromium (25-26%), molybdenum (3-4%), and nitrogen content. These elements also increase their PREN (Pitting Resistance Equivalent Number), which, for these steels, is greater than 40, indicating outstanding performance in chlorides, seawater, or chemical processing plants.

However, Duplex 2205 also provides outstanding corrosion resistance, but with a lower PREN value usually ranging between 30 to 35, which makes Duplex 2205 suitable for moderately aggressive conditions typically found in wastewater treatment plants, or the food and beverage industry where chloride concentration is not so harsh.

Furthermore, Super Duplex steels are more resistant to stress corrosion cracking (SCC), an all-too-common failure mode in the high stress, high temperature areas like offshore platforms or heat exchangers. Duplex 2205 is still an effective, low-cost solution for many applications considering SCC isn’t highly critical.

In general, the decision of using Super Duplex or Duplex grades depends on the specific operational requirements and the environment. For extreme conditions, Super Duplex is more suitable, whereas Duplex 2205 is a economical option that can withstand moderate conditions. These differences allow engineers and designers to make efficient selections based on budgetary constraints and performance for any given project.

Yield Strength and High Strength Capabilities Comparison

Duplex and Super Duplex stainless steels have different yield strengths and high strength attributes, thus making them fit for a variety of industries. An excellent example is Duplex 2205 stainless steel, which has a yield strength of around 450 MPa (65 ksi). This number is almost twice as high as that of Austenitic stainless steels, such as 316L. This increase in strength reduces the thickness of materials that can be used in structural designs, which economically reduces costs while maintaining performance.

Super Duplex stainless steels like UNS S32750 and S32760 are even higher with their yield strength sitting at 550-580 MPa (80-84 ksi) on average.” This outstanding strength allows them to endure more demanding operational conditions, such as oil and gas, Marine, and even chemical processing, where high pressure and extreme temperatures are the norm. Aside from that, these materials possess high strength-to-weight ratios that greatly increase their efficiency early on in critical applications.

Moreover, both Duplex and Super Duplex grades excel in the high resistance they exhibit toward Stress Corrosion Cracking (SCC), which greatly augments mechanical performance alongside durability even in tough environments, increasing their service life. Engineers now have an optimal strategic material to increase safety while greatly balancing costs and performance for areas where strength and tough, enduring durability are critical.

What Advantages Does Super Duplex 2507 Offer Over Austenitic Stainless Steels?

Super Duplex 2507 has many advantages over austenitic stainless steels, including:

- Superior Strength: It has higher mechanical strength, which allows material thickness to be reduced in many applications, potentially lowering costs.

- Enhanced Corrosion Resistance: Super Duplex 2507’s properties give it significant resistance to pitting, crevice corrosion, and stress corrosion cracking, so it is suitable for aggressive and corrosive environments.

- Long Service Life: Its durability in extreme conditions translates to less maintenance and replacements over time, which improves operational efficiency.

- Cost-Effectiveness: Strength in combination with the excellent corrosion resistance means less material is required, increasing the value over traditional austenitic stainless steels in both initial and lifecycle costs.

Such characteristics make Super Duplex 2507 a highly valued product in applications like chemical processing, oil and gas, and the marine industries.

Resistance to Pitting and Crevice Corrosion in Aggressive Environments

Super Duplex 2507 stainless steel was designed to endure the harshest environmental settings, making it a remarkable option for use in areas susceptible to extreme chemicals and saline environments. This material is known to have remarkable resistance to pitting . Furthermore, crevice corrosion, especially prevalent in the presence of chloride ion compounds like seawater or commercial chemical processing plants.

The unique composition of Super Duplex 250,7, which includes approximately 22%-25% chromium, 6%-8% nickel, and 3%-5% molybdenum, is what provides it with exceptional functionality. Chromium increases the oxide layer formation, and cadmium provides further strength to localized corrosion resistance, while nickel is the one that ensures stability and stamina. Together, these components enable the steel to achieve a notable Pitting resistance equivalent number, PREN, pitting resistance equivalent number, usually surpassing 42. The number denotes the steel’s ability to endure corrosion inflicted by chloride ions. As a comparison, standard austenitic stainless steels such as 316L have PREN values of roughly 25.

Field studies show that Super Duplex 2507 can withstand chlorides above 30,000 parts per million (ppm), as in seawater or brine systems, while sustaining mechanical performance throughout use. Such qualities minimize the chances of failure, reducing maintenance needs and improving dependable functionality with time. It also assures structural integrity during exposure to elevated temperature and pressure.

Super Duplex 2507 effectively addresses pitting and crevice corrosion, making it an exceptional material for harsh environmental challenges, ensuring reliability under extremely demanding conditions.

Stress Corrosion Cracking Resistance Compared to Austenitic Grades

Compared with the standard grades of stainless steel austenitic 304 and 316, Super Duplex 2507 demonstrates outstanding resistance to stress corrosion cracking (SCC). This is attributed to its supplemental dual-phase microstructure, where ferritic and austenitic functions are blended with each other, which is highly beneficial in alleviating chloride regions that are also under severe pressure conditions.

Super Duplex 2507 has a greater critical temperature for chloride SCC than most austenitic grades, which suffer from SCC at heightened temperatures and presence of chlorides, commonly around 150°F (65°C) in concentrated chloride solutions. In addition, it possesses greater pitting resistance equivalent number (PREN), which is normally greater than 40, highlighting its strength to highly corrosive conditions that SCC, in contrast to standard austenitic, which pose lower values.

Super Duplex 2507 is the preferred choice in chemical processing plants, desalination plants, and chambers in the oil and gas industry because of its susceptibility to high temperatures, along with chlorides and tensile stress, without severely damaging the structural integrity. These properties combined add to the fatigue life of the material while enhancing its reliability, along with reducing the severity of risks when employed in such aggressive environments.

How Do Corrosion Resistance Properties Compare Between Super Duplex 2507 and Other Alloys?

Super Duplex 2507 has remarkable corrosion resistance in comparison to several other alloys especially in the presence of chloride and aggressive chemicals. It withstands pitting, crevice corrosion, and stress corrosion cracking effectively, which is a challenge for most stainless steels and some austenitic grades. Super Duplex 2507 has a higher PREN (Pitting Resistance Equivalent Number) than standard duplex and austenitic alloys, meaning it is more likely to endure harsh conditions. This makes it highly suitable for extreme environment applications where performance and dependability are crucial over extended durations.

Performance in Chemical Processing and Marine Environments

The use of super duplex 2507 has set a precedent in the field of chemical engineering due to its usefulness in processing applications requiring the use of hydrochloric and sulfuric acid, as the super duplex has great resistance towards oxidizing and reducing agents. The exceptional corrosion resistance under extremely aggressive chemical conditions, as well as significant and cost-efficient maintenance that requires lower structural support, is made possible by the super duplex’s high content of molybdenum, chromium, and nitrogen. For instance, in brine tanks or desalination plants where there is a considerable amount of chloride stress corrosion, super duplex 2507 has shown that it can withstand sustained stress and perform with reliability, which significantly reduces the need for maintenance and replacement in the long run.

On the other hand, along with its unmatched protection against pitting and crevice corrosion, it also provides protection against salt water, which makes it unrivaled in marine settings as well. Along with enhancement in the flow and temperature of seawater, aid is identified in the form of enhanced resistance of traditional stainless steel or austenitic alloys. Research suggests that super duplex 2507 has the ability to retain structural integrity in conditions containing up to 3% sodium chloride, which makes it useful in the construction and maintenance of offshore gas and oil platforms, ships, and underwater pipes. All of these attributes make it a rugged and cost-effective solution suitable to be use in demanding industries.

Pitting Resistance Equivalent Number (PREN) of Different Stainless Steel Grades

Like other grades of stainless steel, the corrosion resistance in stainless steel is particularly evaluated in the context of chloride-containing environments and is expressed in terms of Pitting Resistance Equivalent Number (PREN), which is a widely accepted metric formulated as follows:

PREN = %Cr + 3.3(%Mo) + 16(%N)

The number increases with increases in pitting resistance, which allows it to withstand more hostile surroundings. The table below provides a comparative analysis of different grades of stainless steel with respect to their PREN values:

- Austenitic Stainless Steels (e.g., 316, 316L): Due to the moderate amount of chromium and molybdenum, PREN values for these steels are estimated to fall between 24 to 30. These steels operate satisfactorily in moderately corrosive environments but suffer in highly aggressive or chloride-rich conditions.

- Ferritic Stainless Steels (e.g., 430, 444): These steels are less resistant to pitting and are better suited for atmospheric non-extreme applications, given their PREN values are generally between 10 to 24.

- Duplex Stainless Steels (e.g., 2205): Due to the more balanced chromium, molybdenum, and nitrogen content, duplex alloys have higher PREN values than most alloys, with expectations between 30 to 40. This provides them with greater resistance to localized corrosion which is needed in marine and petrochemical industries.

- Super Duplex Stainless Steels (e.g., 2507): Super duplex steels have some of the highest PREN values of any alloy, regularly exceeding 40. These materials have extremely high molybdenum, nitrogen, and chromium, which gives them outstanding pitting resistance in strongly chloride-rich environments.

The PREN metric helps material scientists and engineers choose the best alloy for specific applications with a good balance between resistance to corrosion and cost. For chemical processing, oil and gas, and desalination industries, knowing these values helps improve operating efficiency, durability and performance while minimizing maintenance costs over time.

What Are the Main Differences Between Super Duplex, Duplex, and Hyper Duplex Grades?

The main differences among Super Duplex, Duplex, and Hyper Duplex grades rest in their composition, susceptibility to corrosion, and strength:

- Duplex: This type has an austenitic or ferritic balanced microstructure – meaning they composed in almost equal proportions. It has moderate corrosion resistance strength which is suitable for less harsh environments.

- Super Duplex: An extension of Duplex, Super Duplex boasts additional chromium, nickel, and molybdenum. This Duplex Super has greater corrosion resistance and higher strength, particularly in harsh environments such as marine and oil or gas applications.

- Hyper Duplex: Of the three, Hyper Duplex is the most sophisticated as it has the highest alloy content. It has the best localized corrosion resistance and strength but that need extreme operating environments.

The differences mentioned assist in material choices depending on the nature of the application, like environmental factors and the level of durability required.

Super Duplex 2507 vs Lean Duplex: When to Use Each Type

The selection of Super Duplex 2507 and Lean Duplex greatly relies on the operating conditions and the application’s performance specifications. Super Duplex 2507 is best suited for high-stress environments like chemical processing, marine activities, and oil and gas exploration due to its outstanding strength, corrosion resistance, and PREN value, usually greater than 40. This guarantees superb performance in hostile environments rich in chlorides or extreme temperatures.

On the other hand, Lean Duplex is meant for less corrosive surfaces where reasonable strength and corrosion resistance are needed. It is the cheaper alternative, and rightfully so, since it has less nickel and molybdenum than Super Duplex 2507. Lean Duplex is most often seen in water treatment systems, structural components, and storage tanks that prioritize low costs while needing satisfactory performance.

After reviewing data on primary and secondary requirements like durability, exposure to harsh mechanical stresses, chemicals, operating temperatures, specifically the chloride concentration, and long-term needs, the decision between these materials becomes clearer. Studies show that for environments with critical exacerbated challenges of corrosion or high-pressure requirements, Super Duplex 2507 proves to be the winner. The data does prove that for any conditions that are not as demanding, especially with a tight budget, Lean Duplex serves just fine.

Comparing Super Duplex with Hyper Duplex Stainless Steel Alloys

Super Duplex and Hyper Duplex alloys differ greatly from each other, and from Super Duplex, Hyper Duplex alloys contain greater amounts of chromium, molybdenum, and nitrogen, which allow them to withstand pitting and crevice corrosion. The ultimate advantage of Hyper Duplex alloy is that it can easily handle environments that contain more than 30,000 ppm of chloride, making it suitable for use in offshore platforms, desalination plants, and in the chemical processing industry. With every passing year, the demand for alloy grade SAF 3207 HD increases due to its superior performance.

Super Duplex grades significantly outperform other alloys when it comes to accessibility. Although lacking in terms of extreme conditions, Super Duplex alloys ensure excellent mechanical properties, high tensile strength, and moderate corrosion resistance. Studies suggest that Super Duplex grades function sharply at approximately 570°F (300 °CC), whereas Hyper Duplex offers broader efficiency in high temperatures.

The selection of these alloys depends carefully on the cost, life cycle requirements, and external environmental factors. Hyper Duplex has the best selection for industries facing highly aggressive salt or acidic conditions because of its corrosion resistance and structural integrity. On the other hand, Super Duplex is an economical alternative that withstands less harsh conditions without sacrificing structural reliability.

Where Are Super Duplex 2507 Alloys Most Effectively Used Compared to Other Stainless Steels?

The Super Duplex 2507 alloys are best used in extreme environments that demand intense strength and have a high level of corrosive resistance. It is frequently employed in the oil and gas industry, advancing chemical industries, and marine work where there is usual chloride and chemical exposure. It is very clear that Super Duplex 2507 is more efficient than regular stainless steel, thus proving its superiority in durability.

Applications of Super Duplex 2507 vs Austenitic and Ferritic Stainless Steels

A detailed comparison of the uses of Super Duplex 2507, Austenitic, and Ferritic stainless steels is presented below. Each material is recognized for its characteristics and appropriateness for particular settings.

- Super Duplex 2507

-

-

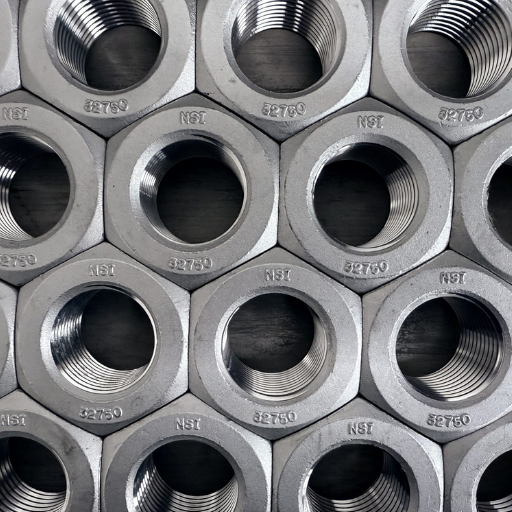

- Oil and Gas Industry: It is extensively utilized in subsea systems and in offshore platforms piping subjected to high pressures and chlorides.

- Chemical Processing: I deal with reactors and heat exchangers handling harshly corrosive chemicals due to exceptional resistance against pitting and stress corrosion cracking.

- Marine Environments: Used in shipbuilding, marine hardware, and in the construction of plants for seawater desalination due to their harsh saltwater corrosion resistance.

- Power Generation: It is used in flue gas desulfurization systems because of its heavily acidic and corrosive environment resistance.

- Pressure Vessels and Storage Tanks: Applies to strong and corrosion-resistant systems that are subjected to harsh environments.

-

- Austenitic Stainless Steels

-

-

- Food and Beverage Industry: Used widely in industrial kitchen equipment and in brewing, dairy processes because of the ease of cleaning it maintains hygienic standards.

- Architectural Applications: Uses include building railings, facades, various structural elements and parts as a result of the good aesthetic value and resistance to corrosion.

- Medical Equipment: Used in screws, surgical instruments and various implants and in other wards of the hospital because of biocompatibility and non-reactive properties.

- Cryogenic Systems: Use in the storage and transporting of cryogenic fluids, as it retains mechanical properties at very low temperatures.

-

- Ferritic Stainless Steels

-

-

- Automotive Industry: Used in the manufacture of catalytic converters and exhaust systems due to its ability to withstand oxidation at high temperatures.

- Domestic Appliances: Used in washing machines and dishwashers,s catering components as well as in boiler parts because of its affordability and moderate scaling resistance.

- Industrial Equipment: Applied in Heat exchangers and boiler tubes that require moderate corrosion resistance and economical materials.

- Construction Applications: Frequently specified for roofing, cladding, and interior design features because of its moderate corrosion resistance as well as its magnetic properties.

-

Choosing materials that maximize the life of machinery requires precise selection, as every type of stainless steel has unique features tailored towards industrial requirements and ecological factors.

Industry-Specific Performance Comparison in Chemical Processing

The chemical processing industry works under very corrosive environments. They require very high strength materials which sustain structural integrity. In this sector, stainless steels like 316 and duplex stainless steel are favorable due to their exceptional strength and resistance to corrosion.

- 316 Stainless Steel: 316 stainless steel’s molybdenum content helps prolong resistance to more aggressive chemicals like chlorides. It is routinely applied for equipment such as storage tanks, chemical reactors, and heat exchangers. Research indicates that compared to lower-grade stainless steels, 316 stainless steel can increase the lifespan of equipment by around 20% in chloride-rich environments.

- Duplex Stainless Steel: This type of steel is a hybrid of austenitic and ferritic steels, enhancing its strength while improving stress corrosion cracking resistance. Its durability under high pressure makes it suitable for pipelines and other components dealing with acidic chemicals. Studies suggest its operational efficiency surpasses traditional grades while drastically reducing maintenance costs.

- Super Austenitic Stainless Steel: Super austenitic grades are commonly chosen for work with concentrated acids such as sulfuric or hydrochloric acid. Their higher content of nickel and chromium provides exceptional protection against pitting and crevice corrosion, which is essential for dependable use in important chemical processes over time.

Choosing the proper grade of stainless steel based on the specific chemical environment allows industries to maximize safety, minimize downtime, and save money in the long run.

Cost vs Performance Analysis of Super Duplex Against Other Grades

Super duplex stainless steel stands out amongst the rest due to its unparalleled balance of price, performance, and durability. In comparison to standard austenitic grades like 316L, super duplex is more cost-effective due to its much better mechanical strength. This results in the usage of thinner material sections, which further reduces the overall material costs for high-strength applications. It is also favored by the oil and gas, desalination, and chemical industries due to its increased protection from stress corrosion cracking and pitting in saltwater-rich environments.

Super duplex grades like UNS S32750 or UNS S32760, as an example, are said to be much stronger than austenitic grades. This strength allows for a low structural weight, which saves in production and transportation costs. The only downside to using super duplex is the pricing. Though the initial super duplex material cost does sit at $2350/ton, around 20%-30% more than 316L, since it has a much better life span, maintenance, and reduced risk of failure, it makes it a worthy tradeoff.

Super duplex also provides an economical advantage over nickel alloys. Even though the alloys are 2-3 times more expensive, they do demonstrate similar corrosion resistance in certain extreme environments. These factors make super duplex more cost-effective for demanding applications that do not rigorously require the performance of nickel alloys.

Switching to super duplex stainless steel is benefiting many industries with its weldability which is reducing labor time and costs. In lifecycle costs, compared to other materials that perform equally, super duplex has significantly lower costs while corrosion and high-pressure performance is exceptional.

Reference Sources

- Surface Roughness in Machining1:

- Focus: This study evaluates the surface roughness of Super Duplex 2507 under dry and wet machining conditions.

- Key Findings: Wet machining significantly improves surface finish compared to dry machining. Feed rate was identified as the most influential factor on surface roughness, followed by cutting speed.

- Methodology: Experiments were conducted with varying cutting speeds and feed rates, and regression analysis was used to determine the relationship between machining parameters and surface roughness.

- Laser Welding and Post-Weld Heat Treatment (PWHT)2:

- Focus: Investigates the effects of laser welding and PWHT on the microstructure, texture, and mechanical properties of AISI 2507.

- Key Findings: Lower heat input during welding resulted in higher tensile strength and microhardness. PWHT improved ductility and toughness but reduced hardness and tensile strength.

- Methodology: Samples were laser-welded with varying heat inputs and subjected to PWHT at 1100°C. Mechanical properties and microstructural changes were analyzed.

- Friction Stir Processing (FSP)3:

- Focus: Examines the microstructural evolution and tensile behavior of 2507 Super Duplex Stainless Steel under FSP.

- Key Findings: Significant grain refinement was achieved, enhancing tensile strength and ductility. Optimal processing parameters were identified for achieving fine grain size.

- Methodology: FSP was performed with varying traverse speeds, and the resulting microstructures were analyzed using electron backscatter diffraction (EBSD) and tensile testing.

Frequently Asked Questions (FAQs)

Q: What is the difference between duplex and super duplex stainless steel?

A: The main difference between duplex and super duplex stainless steels is their composition and corrosion resistance properties. Standard duplex grades (like 2205) contain approximately 22% chromium and 5% nickel, while super duplex grades like 2507 contain higher amounts of chromium (25%), nickel (7%), and molybdenum (4%). Super duplex stainless steel offers superior corrosion resistance, particularly in chloride environments, higher strength, and better performance in extreme conditions. Super duplex 2507 is classified as a super duplex due to its higher Pitting Resistance Equivalent Number (PREN) of >40, compared to standard duplex grades with PREN values of 30-40.

Q: What are the mechanical properties of duplex steel compared to traditional stainless steels?

A: Duplex stainless steels offer significantly higher mechanical properties compared to traditional stainless steel grades. For example, duplex steels typically have yield strengths approximately twice that of austenitic stainless steels like 304 or 316. Super duplex 2507 stainless steel typically has a yield strength of about 550 MPa (80 ksi), compared to around 290 MPa for 316L. Duplex grades also provide excellent impact toughness, good fatigue resistance, and higher hardness. This combination of strength and toughness makes duplex grades ideal for applications requiring both structural integrity and corrosion resistance, allowing for weight and cost savings through reduced material thickness in many applications.

Q: How does super duplex grade 2507 compare to other duplex stainless steel grades?

A: Super duplex 2507 stainless steel exhibits superior properties compared to lower duplex grades. In the hierarchy of duplex stainless steel grades, 2507 sits at the top with the highest corrosion resistance, particularly against pitting and crevice corrosion. It offers approximately 45% higher yield strength than standard duplex 2205, better resistance to stress corrosion cracking, and superior performance in high-chloride environments. While lean duplex grades (like 2304) are more economical with lower nickel content, and standard duplex 2205 is more widely used, super duplex 2507 becomes the material of choice when extreme conditions demand maximum performance, particularly in aggressive offshore, chemical processing, and high-temperature applications.

Q: What are the most common duplex stainless steel grades and their applications?

A: The most common duplex stainless steel grades include: 2304 (lean duplex) – used in structural applications, water treatment, and storage tanks; 2205 (standard duplex) – the most widely used grade for chemical processing, oil and gas, pulp and paper industries; 2507 (super duplex) – employed in highly corrosive environments like offshore oil platforms, seawater systems, and aggressive chemical environments; 255 (super duplex) – similar to 2507 with applications in marine environments; and Zeron 100 (super duplex) – specialized for high-pressure, high-temperature sour service conditions. Choosing between duplex grades depends on the specific corrosion resistance, strength requirements, and cost considerations of each application.

Q: How does the welding process differ for super duplex 2507 stainless steel?

A: Welding super duplex 2507 demands more careful procedures than standard stainless steels due to its balanced microstructure. Key considerations include: controlled heat input (typically 0.5-2.0 kJ/mm) to prevent phase imbalances; interpass temperature limitations (maximum 150°C); proper filler metal selection (typically overmatching in nickel content); and post-weld heat treatment avoidance. Common welding methods include gas tungsten arc welding (GTAW/TIG) for precision, gas metal arc welding (GMAW/MIG) for higher deposition rates, and shielded metal arc welding (SMAW/stick) for field repairs. Proper shielding gases with nitrogen additions are essential to maintain corrosion resistance. The goal is to maintain the critical 50/50 balance of austenite and ferrite phases that give super duplex its unique properties.

Q: What is the corrosion resistance of duplex stainless steels compared to austenitic grades?

A: Duplex stainless steels offer superior corrosion resistance compared to standard austenitic grades in several environments. Super duplex 2507 stainless steel due to its high chromium, molybdenum, and nitrogen content, provides exceptional resistance to pitting and crevice corrosion, with a PREN value >40 compared to 316L’s PREN of approximately 24. Duplex grades excel particularly in chloride-containing environments where stress corrosion cracking is a concern. They demonstrate better resistance to sulfide stress cracking and hydrogen-induced cracking than austenitic grades. While austenitic grades like 304 and 316 perform well in mild conditions, duplex and especially super duplex grades become necessary in aggressive environments like offshore oil and gas, chemical processing, and desalination plants where high chloride content and elevated temperatures are present.

Q: What are the cost implications of choosing super duplex steel over other stainless steel options?

A: Super duplex steel, particularly grade 2507, typically commands a higher initial cost compared to standard stainless steels due to its higher alloy content (especially nickel and molybdenum). However, a comprehensive cost analysis often reveals economic benefits: reduced material thickness requirements due to higher strength can offset material costs by 30-50%; significantly longer service life in corrosive environments reduces replacement and downtime costs; lower maintenance requirements save operational expenses; and improved safety margins reduce risk-related costs. Additionally, grades of stainless steel, like super duplex, can be more stable against price fluctuations compared to highly nickel-dependent austenitic grades. When evaluating life-cycle costs rather than just initial investment, Super Duplex 2507 often proves more economical for demanding applications.

Q: What is an overview of duplex stainless steel production and availability?

A: Duplex stainless steels are typically produced through a combination of electric arc furnace melting, argon oxygen decarburization, and sophisticated heat treatment processes to achieve their characteristic dual-phase microstructure. Super duplex 2507 stainless steel typically requires more controlled processing parameters than standard grades. These steels are available in various forms,s including plate, sheet, bar, pipe, tube, fittings, flanges, and forgings. While standard duplex grades like 2205 are readily available from most steel suppliers worldwide, super duplex grades like 2507 may have longer lead times and fewer stocking distributors. The global production is dominated by specialized steel manufacturers, including Outokumpu, Sandvik, Allegheny Technologies, and Nippon Steel. The market for these materials continues to grow, particularly in oil and gas, chemical processing, and water treatment industries.

Q: What temperature limitations should be considered when using super duplex 2507 stainless steel?

A: Super duplex 2507 stainless steel exhibits important temperature limitations that are crucial to consider in applications. The recommended service temperature range is generally -50°C to 300°C (-58°F to 572°F). Below -50°C, there’s a risk of reduced impact toughness due to the ferritic phase. Above 300°C, prolonged exposure can lead to “475°C embrittlement,t” where the precipitation of intermetallic phases (sigma, chi, alpha prime) significantly reduces toughness and corrosion resistance. For cyclic applications, more conservative limits may apply. These temperature limitations are more restrictive than for austenitic stainless steels, which can typically operate at cryogenic temperatures and up to 600°C. When selecting materials, these temperature constraints must be balanced against the superior corrosion resistance and mechanical properties that super duplex offers within its operational range.

Q: What common questions about duplex material selection should engineers consider for specific industries?

A: Engineers should consider several key questions when selecting duplex materials: For offshore applications, “Will the material withstand continuous seawater exposure and occasional exposure to acids used in cleaning?” For chemical processing: “What specific chemicals, concentrations, and temperatures will the material encounter?” For pulp and paper: “Can the material handle both chlorides and organic acids present in the process?” For desalination: “Will the material resist the combined effects of high chloride levels, elevated temperatures, and occasional acid cleaning?” For structural applications: “Do the steel mechanical properties provide adequate safety factors while allowing for reduced material thickness?” For heat exchangers: “Can the material withstand both process fluids and cooling media at varying temperatures?” Understanding these industry-specific concerns helps determine whether standard duplex, super duplex 2507, or other grades are appropriate for each unique application.