One important factor when choosing the best stainless steel for your project is understanding hardness. Hardness, in simplest terms, is the ability of a material to resist deformation. It determines strength, while the tougher and hard a material is, the wear resistance will also be high. This guide intends to shed light on the topic of stainless steel hardness by discussing what it is, how it is assessed, and why it is crucial.

Understanding the Basics of Stainless Steel Hardness

Stainless steel hardness is the capacity of the material to resist deformation, indentation, or scratching. Hardness is one of the characteristics that determines the ability to resist mechanical stress and wear of stainless steel during time. This property is measured on an internationally accepted scale.

Common hardness measurement scales include:

- Rockwell hardness (HR) – Most widely used scale

- Brinell hardness (HB) – Ideal for softer materials

- Vickers hardness (HV) – Precise microhardness testing

Definition of Hardness in Stainless Steel

Hardness refers to the metal’s resistance to being permanently deformed under external forces like compression, scratching, or indentations. The hardness of a metal is a key mechanical property that governs its performance and wear in service application under various conditions.

Stainless steels get their hardness from their:

- Microstructure

- Chemical composition

- Heat treatment processes

Important Note: Martensitic stainless steels are more hardened by their crystalline structure, making them ideal for cutting tools and surgical instruments. Austenitic stainless steels are generally lower in hardness but offer higher ductility and corrosion resistance.

Importance of Hardness in Stainless Steel Applications

Wear Resistance

Higher hardness in stainless steel means better wear resistance. This feature becomes useful in designing tools, industrial machinery, and components meant for high-friction situations.

Edge Retention

Harder grades of steel maintain their sharp edges longer. This is important for applications that require a keen edge, such as cutting instruments, surgical tools, and knives.

Impact Resistance

Very hard grades decrease their impact resistance due to brittleness; however, by optimally balancing hardness with toughness, one can ensure longevity in impact-related applications.

Corrosion Protection

Corrosion resistance may be inversely related to hardness. Balancing hardness and corrosion resistance is essential for marine or chemical processing environments.

Load-Bearing Capacity

Stainless steel grades created to sustain loads without deformation or failure are usable in applications that involve high-force operations, such as automotive or aerospace.

Overview of Stainless Steel Grades

Stainless steel grades fall under several families according to their chemical compositions, mechanical properties, and areas of applications:

Austenitic Stainless Steels

- Highly corrosion resistant and malleable

- Easy to weld

- Common grades: 304 and 316

- Applications: Food processing, building, medical equipment

Ferritic Stainless Steels

- Resistant to stress corrosion cracking

- Lower cost with fair corrosion resistance

- Common grades: 409 and 430

- Applications: Automotive exhaust systems, domestic appliances

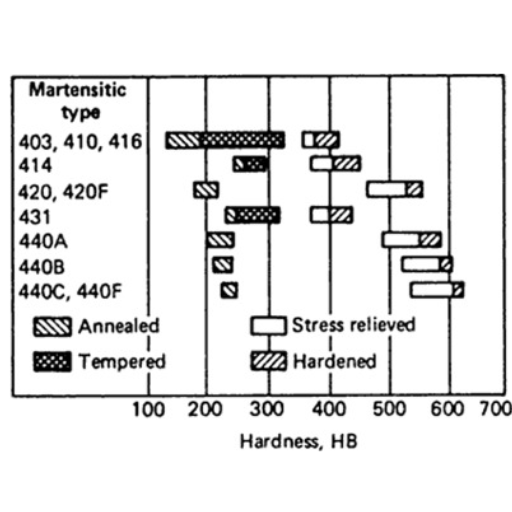

Martensitic Stainless Steels

- Higher strength and hardness

- Excellent wear resistance with moderate corrosion resistance

- Common grades: 410 and 420

- Applications: Cutlery, surgical instruments, mechanical engineering

Duplex Stainless Steels

- Combines properties of austenitic and ferritic steels

- High strength with excellent resistance to pitting and stress corrosion

- Applications: Marine environment, chemical processing, oil and gas

Precipitation-Hardening Stainless Steels

- High strength and corrosion resistance

- Example grade: 17-4 PH

- Applications: Aerospace and energy-related applications

Hardness Scales for Stainless Steel

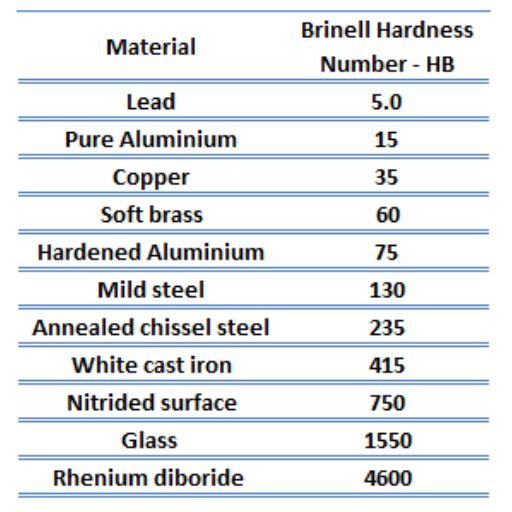

Brinell Hardness (HB)

This scale is widely used for testing the softer grades of stainless steel. This entails pressing a steel or carbide ball of specified diameter into the surface of the specimen under a standardized load.

Rockwell Hardness (HR)

The Rockwell hardness records how deep an indenter penetrates into the material under a particular load. Different scales are used:

- HRB (Ball scale): For softer materials

- HRC (Cone scale): For harder stainless steels like martensitic grades

Vickers Hardness (HV)

This microhardness test is conducted with the use of a diamond indenter at varying loads. It measures the hardness distribution over a thin section of stainless steel with high precision.

Factors Influencing the Hardness of Stainless Steel

Chemical Composition and Its Impact

The constitution of stainless steel determines its properties and suitability for various processes:

| Element | Percentage | Impact on Properties |

|---|---|---|

| Chromium | >10.5% | Forms passive layer for corrosion resistance |

| Nickel | Varies | Increases toughness and ductility |

| Molybdenum | Varies | Increases resistance to pitting and crevice corrosion |

| Carbon | Varies | Higher content increases hardness |

Heat Treatment Processes

Heat treatments are fundamental to enhancing the mechanical features of stainless steel:

- Annealing: Relieves internal stresses and enhances machinability

- Quenching: Increases strength and hardness

- Tempering: Balances hardness with toughness

Effect of Annealing on Hardness

Annealing plays an important role in modifying hardness and microstructure. The process involves:

- Heating to a specific temperature

- Holding at temperature for a certain duration

- Controlled cooling

Temperature Ranges:

• Austenitic stainless steels: 1900-2100°F (1038-1149°C)

• Martensitic steels: Lower temperatures depending on composition

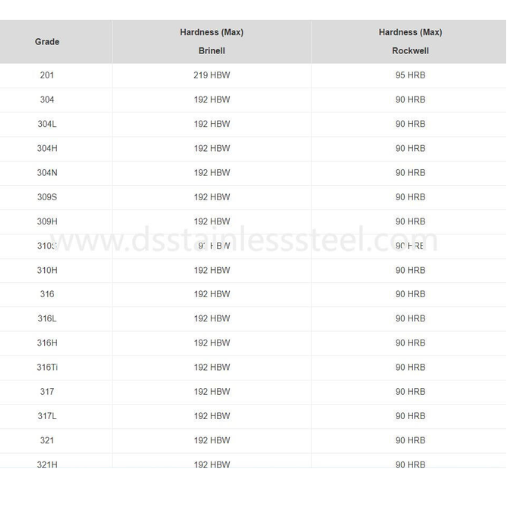

Stainless Steel Hardness Chart

| Stainless Steel Grade | Hardness (Rockwell Scale) | Notes |

|---|---|---|

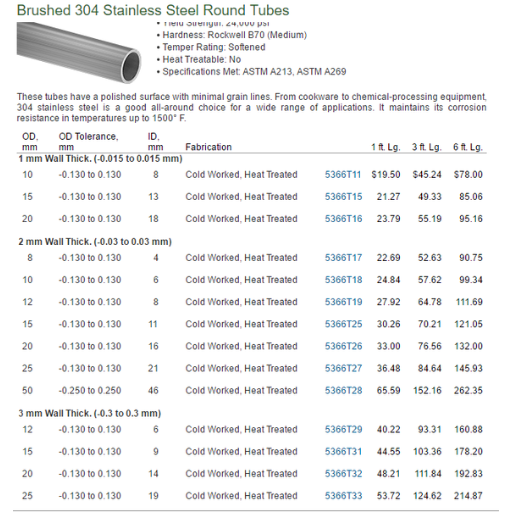

| 304 | B70-B90 | Excellent corrosion resistance, general-purpose usage |

| 316 | B79-B95 | Higher resistance to chlorides and saline environments |

| 430 | B60-B70 | Low cost, good for decorative use or light corrosion environments |

| 440C | C55-C65 | High hardness, suitable for knives and cutting tools |

| 17-4 PH | C35-C45 | Excellent strength and toughness after precipitation hardening |

Hardness Values for 304 Stainless Steel

The typical hardness of 304 stainless steel ranges between B70 and B90 on the Rockwell B scale. Key characteristics include:

- Annealed condition: ~123 Brinell (Bhn)

- Tensile strength: 515-750 MPa

- Superior corrosion resistance and versatility

- Applications: Kitchen utensils, chemical containers, architectural structures

Hardness Values for 316 Stainless Steel

316 stainless steel hardness values in annealed condition:

- Hardness: 95-100 Brinell (Bhn)

- Tensile strength: 515-690 MPa

- Enhanced corrosion resistance due to molybdenum addition

- Applications: Pharmaceutical equipment, chemical processing, marine environments

Hardness Values for 17-4 Stainless Steel

17-4 stainless steel (Type 630) is a precipitation-hardening variety with variable hardness based on heat treatment:

| Heat Treatment Condition | Hardness (HRC) | Characteristics |

|---|---|---|

| H900 | ~44 HRC | Excellent wear resistance |

| H1025 | Slightly softer | Improved toughness |

| H1150 | Slightly softer | Enhanced corrosion resistance |

Practical Applications and Selecting the Right Grade

Choosing Stainless Steel Based on Hardness Requirements

High Hardness Applications:

- Martensitic grades (410, 440C) for cutting tools, bearings, valves

- Require excellent wear resistance

- May sacrifice some corrosion resistance

Moderate Hardness Applications:

- Austenitic grades (304, 316) for chemical and moisture environments

- Prioritize corrosion resistance and ductility

- Excellent for food processing and marine applications

Welding and Machinability Considerations

| Grade Type | Weldability | Machinability | Special Considerations |

|---|---|---|---|

| Austenitic (304, 316) | Excellent | Challenging due to work hardening | Low carbon content reduces carbide precipitation |

| Ferritic (430) | Requires care | Good | Potential cracking due to lower ductility |

| Free Machining (303) | Limited | Excellent | Contains sulfur/selenium; reduced corrosion resistance |

Improving the Hardness of Stainless Steel

Heat Treatment Methods

- Quenching and Tempering: For martensitic grades

- Cold Working: For austenitic grades (rolling, forging)

- Precipitation Hardening: For specific grades like 17-4 PH

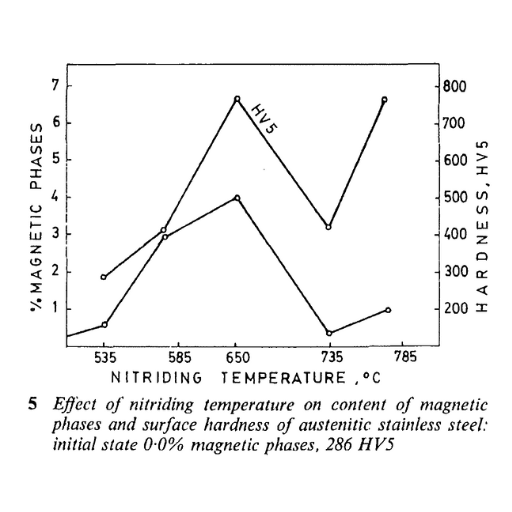

Advanced Techniques

- Laser hardening for surface treatments

- Nitrogen additions for enhanced surface hardness

- Controlled cooling rates during processing

References

-

Stainless Steel Grade Chart – Stanford University – A detailed chart providing hardness specifications for various stainless steel grades.

-

Appendix I Table of Hardness Values – OpenLearn – A resource from Open University discussing hardness values for different materials, including stainless steel.

-

Correlation of the Hot-Hardness with the Tensile Strength – A study on the relationship between hot-hardness and tensile strength of 304 stainless steel.

Frequently Asked Questions (FAQ)

What is the hardness of stainless steel, and how can it be determined?

The hardness of stainless steel is its capacity to resist denting, scratching, and abrasion. Methods such as Rockwell (HRB or HRC) and Vickers scales usually determine this resistance. Various grades of stainless steel, such as 304 and 316, differ from one another in hardness, largely because of their chemical composition and microstructure.

How does heat treatment make a difference in the hardness of stainless steel?

Annealing might make an austenitic stainless steel grade such as 304 or 316 softer, but depending upon the grade, you can also harden stainless steel by quenching. Hence, by heat treatment, the hardness and mechanical properties can be adjusted to better suit the material.

What are the differences in hardness between 304 and 316 stainless steel?

Even though both 304 and 316 stainless steels belong to the austenitic family, at the presence of molybdenum, 316 has a slightly greater resistance to corrosion and possibly a slight change in hardness. Generally speaking, 304 stainless steel has a hardness of 70 HRB, while 316 stainless steel varies slightly based on its method of processing and the conditions of its use but tends to exhibit similar hardness characteristics.

Does the steel hardness increase further?

The hardness of stainless steel could be improved when treated with work hardening, heat treatment, or the addition of other alloying elements like chromium and nickel. Some other methods are precipitation hardening within certain grades, such as 17-4 stainless steel, which allows for increasing hardness while retaining good ductility.

What is a hardness chart for stainless steel?

Hardness charts for a given steel type compare hardness values of various grades by means of different hardness measurement scales. For example, 304 stainless steel might have a hardness around 70 on the HRB scale, whereas martensitic grades could well exceed 50 on the HRC scale. These charts are, therefore, quite useful in deciding on a material for a particular application.

How can the chemical composition affect the hardness of stainless steel?

The chemical composition of stainless steel, including the amounts of iron, carbon, chromium, and nickel, is the dominant parameter affecting the hardness. While carbon enhances hardness, alloying elements like nickel and chromium improve toughness and corrosion resistance, often at the expense of hardness.

What is the relationship between hardness and machinability in stainless steel?

The relation between hardness and machinability in stainless steel is inverse. Generally speaking, the harder the stainless steel, such as the martensitic grades, the harder it is to machine, due to fast tool wear. The lower hardness grades such as 304 and 316, on the contrary, offer good machinability and hence are quite easy to work with while making food processing and chemical equipment.

What are the mechanical properties linked with high hardness in stainless steel?

Generally, stainless steels with high hardness will have high strength and wear resistance, but this can compromise the ductility and induce brittleness of the material. Therefore, it is necessary to balance hardness with other mechanical properties such as yield strength and toughness that will ensure the composite functions satisfactorily for its intended use.