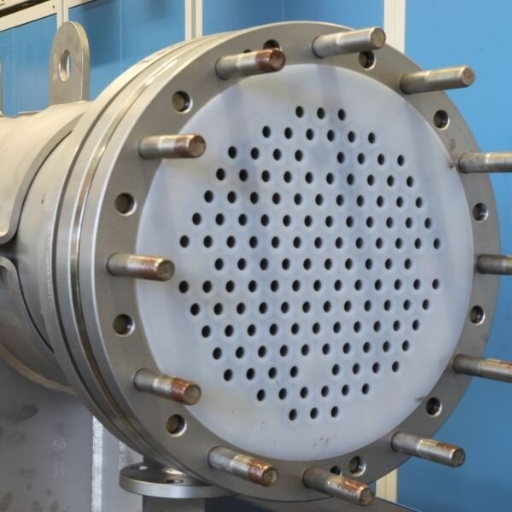

The selection of material greatly affects the performance, longevity, and cost-efficiency of industrial heat exchangers. Stainless Steel and Copper are two frequently used materials, each presenting particular advantages and problems, which understandably can be complex decisions needing in-depth analysis. In this post, we compare the two materials with an emphasis on why stainless steel tends to be the better choice for industrial settings. Due to its remarkable corrosion resistance coupled with the ability to sustain high temperatures, stainless steel is a cost-efficient option that proves beneficial for countless industries. Continue reading to learn about the advantages of stainless steel heat exchangers, how they compare with copper, and the additional reasons that are making them increasingly preferred for tough industrial requirements.

Is stainless steel a good material for heat exchangers?

Absolutely, stainless steel is suitable for use in heat exchangers. It has significant resistance to corrosion even in severe temperatures and environments. It is also highly durable which decreases maintenance costs as well as increasing the lifespan of the heat exchanger. Furthermore, it has good thermal conductivity, workswith both liquids and gases, and as such can serve many different purposes across various industries.

How does stainless steel perform in heat transfer efficiency?

Although stainless steel is less conductive than copper or aluminum, it still offers decent heat transfer efficiency. For stainless steel alloys, the thermal conductivity usually lies between 14 to 16 W/m·K, which is good enough for some industrial use. This value, while lower than other materials, is compensated for by the thermal and mechanical strength, corrosive resistance, and resilient durability under high pressures and extreme conditions. Due to their reliability over long periods of time when used under extremes of temperature and corrosion, stainless steel heat exchangers are commonly employed in chemical processing, energy generation, and food production industries. Furthermore, modifications in design, like the use of thin-walled stainless steel enhanced surface treatment, have evolved modern heat transfer systems into more efficient and dependable devices.

What corrosion resistance benefits does stainless steel offer?

Because of its chromium content, stainless steel possesses excellent corrosion resistance as it develops a protective oxide layer on the surface. This oxide layer prevents rust and degradation even under severe conditions, which include moisture, chemicals, or even high temperatures. Furthermore, stainless steel is very strong and does not require a lot of maintenance, making it perfect for long-term applications.

Why is stainless steel alloy preferred in heat exchanger design?

Due to its incredible thermal conductivity and mechanical strength, stainless steel alloy is the preferred material in the design of heat exchangers. Stainless steels are particularly apt for petrochemicals, power generation, and pharmaceuticals due to their high-temperature and chemical resistance. Various studies suggest that stainless steel alloys have better resistance to corrosion in chloride and other aggressive chemical environments, thereby increasing the lifespan of components in heat exchangers.

In addition, stainless steel alloys offer excellent thermal conductivity ranging between 15 and 25 W/(m·K) which ensures effective energy exchange in operations of critical applications. Moreover, its ease of fabrication, welding, and cleaning enhances maintenance efficiency, reducing the overall cost. Stainless steel’s longevity, recyclable nature, and low-maintenance requirements make it a viable option that promotes sustainable design principles, deeming it an eco-friendly solution for modern heat exchanger systems.

How do stainless steel heat exchangers compare to copper heat exchangers?

Both stainless steel and copper heat exchangers have their unique benefits. Stainless steel is incredibly resistant to corrosion and is best for aggressive chemicals or moisture-stricken environments. It is also more durable and has a longer service life. On the contrary, copper is superior in thermal conductivity, which allows faster heat transfer. This makes copper alloy more efficient in energy exchange applications. Still, copper is more susceptible to corrosion than stainless steel, and in some conditions, requires extra coatings or treatments. Which option is better depends on the operating environment, maintenance preferences, and desired thermal performance.

Thermal conductivity: copper vs stainless steel heat exchangers

The rate at which a material can conduct heat significantly affects its workability in heat exchangers. Copper leads in this regard as it has a thermal conductivity of nearly 400 W/m·K, meaning it can transfer heat very fast and therefore works best in applications that need rapid thermal exchange. Conversely, stainless steel lags far behind with its thermal conductivity rating ranging from 15 to 25 W/m·K, which results in slower heat transfer rates.

Unlike copper, steel performs well in high extremes such as corrosion, oxidation, and high temperatures. This makes it suitable for applications that require steel’s durability and sustainability over time, thus reducing maintenance needs. It means that enduring longevity in harsh environments is more important than thermal performance.

Reports and industrial cases confirm this viewpoint as they point out that copper heat exchangers are best for systems such as refrigeration units or HVAC systems that need high efficiency and rapid heat transfer. However, in the food processing, pharmaceutical, and chemical manufacturing industries, stainless steel heat exchangers are more popular because of their corrosion resistance and hygienic properties.

In light of all the aforementioned characteristics, the choice of material must be made with respect to the specific thermal requirements and operational context of the application. Other considerations also include balancing the economic factors of cost, maintenance, lifetime, and other attributes for optimal performance of thermal resistance and structural resilience.

Durability and corrosion: stainless steel in heat exchangers vs copper

Copper and stainless steel are among the most frequently used materials for constructing heat exchangers. Each provides unique benefits and drawbacks concerning longevity and durability. Stainless steel, particularly 316 L grade, has incredible corrosion resistance. This is significant when there is water, chemicals, or high humidity present. This resistance is due to chromium being present in the alloy, which forms a passive oxide layer that prevents corrosion and depassivation. Stainless steel grades of 316L for instance, do not suffer from the corrosive effects of saline or acidic conditions, which make them useful for Marine applications or Chemical Processing.

When it comes to conducting heat, copper is unmatched, boasting nearly ten times the efficiency of stainless steel. However, having higher durability, stainless steel is not as prone to pitting corrosion as copper is, particularly in chloride-rich or aggressive chemical environments. On the brighter side, copper is easily repairable thanks to its high malleability, and also forms a protective patina over time that slows further corrosion. Data suggests that copper-based heat exchangers have a life expectancy of 10-20 years with normal operating conditions, while their stainless steel counterparts exceed 20 years owing to their enhanced mechanical strength and resilience to harsh environments.

In the end, the decision for either one of these materials should be based on the specific requirements of the application. If long-term endurance and exceptional corrosion resistance are a requirement, then stainless steel is the better choice. For extreme thermal efficiency along with easy shaping, copper becomes preferable, provided the operational conditions are not excessively corrosive. Both materials are better value at different costs, resulting in a need to account for the design and maintenance of the entire system when choosing materials.

Cost analysis: Is stainless steel or copper more economical long term?

When considering the total lifetime expenditure of stainless steel and copper, factors such as the initial investment in the material, its maintenance, lifespan, and energy efficiency need to be evaluated. With garnished steel, it is noted that the upfront material cost is much lower when compared to copper. As per the data available within the industry, garnished steel costs anywhere from $2-$3 per pound, while copper prices fluctuate a lot but are usually higher and around $4-$6 per pound.

Though some aspects may seem appealing, the picture shifts drastically when considering maintenance and durability. Stainless steel is known to withstand corrosion and repairs far better than other materials, which is perfect for long-term installations like piping systems. It is often regarded that stainless steel piping systems can last for decades with almost no corrosion while considerably lowering maintenance expenses over time. When it comes to electricity, copper surpasses others in conductivity, which is beneficial for reducing power costs. Though this efficiency is somewhat muted by copper’s maintenance needs in corrosive environments, and is balanced through regular maintenance.

In addition, their economic longevity is enhanced by the recyclability of both materials. Stainless steel is valuable in recycling and can be repurposed across multiple sectors, while copper’s ability to be recycled often results in its value being preserved during waste disposal, which mitigates differences in costs.

In this case, copper may become more cost-effective in energy-efficient applications, despite stainless steel’s lower price for durability and resistance to corrosion. The remaining choice will rely mostly on the exact operational needs, as well as the environmental factors where the material will be utilized.

What industries benefit most from using stainless steel heat exchangers?

The following are the industries where the use of stainless steel heat exchangers is most beneficial:

- Food and Beverage: The stainless steel used in food processing and beverage production is easy to clean and maintain, thus preventing corrosion and enhancing hygiene.

- Chemical Processing:Performance in chemical plants is dependably maintained due to the durability of heat exchangers and their corrosive substance handling capability.

- Pharmaceuticals: Pharmaceutical manufacturing is highly sanitation oriented, thus requiring strict standards. The heat exchangers’ non-reactive nature and cleanability make it viable for use.

- Power Generation: Due to resistance to high temperatures and robust performance, heat exchangers made from stainless steel are popular in power plants.

- Oil and Gas: The stainless steel heat exchangers have great value in this industry due to their ability to withstand harsh environments and corrosive substances.

How stainless steel heat exchangers perform in HVAC applications

Stainless Steel HVAC heat exchangers–a component of HVAC systems–benefit from their effectiveness, durability, and capability to withstand differential temperatures. Below are the most important excellences and statistics concerning their utilization in infrastructural HVAC systems.

- Corrosion Resistance: The longevity of stainless steel’s writed corrosion resistance translates into a greater lifespan within the HVAC system because of moisture levels as well as simultaneous connective weather.

- Thermal Conductivity: The steel’s relatively lower thermal conductivity, due to the thin-walled nature of exchangers, can be offset because of the unrestricted transfer of heat.

- High Temperature Tolerance: These heat exchangers can withstand operating temperatures up to approximately 1500°F (815°C), making them suitable for both residential and industrial HVAC systems.

- Energy Efficiency: Stainless steel exchangers positively impact the thermal efficiency of HVAC systems throughout their operational lifespan, increasing energy savings and reducing cost requirements.

- Low Maintenance Requirements: The high durability of stainless steel along with its non-reactivity greatly increases the upkeep requirements making stainless steel HVAC systems cost effective in terms of maintenance due to saving on downtime.

- Environmentally Friendly: Due to stainless steel being fully recyclable, HVAC systems utilizing stainless steel become environmentally friendly and a suitable choice for sustainable systems.

- Longevity: During the proper use and maintenance of HVAC systems, stainless steel heat exchangers are able to endure for more than 20 years.

Why do tankless water heaters often use stainless steel

Stainless steel excels in meeting the requirements of both performance and durability when it comes to constructing tankless water heaters. One of the most important advantages of stainless steel is its ability to resist corrosion. The varying water temperatures and the sometimes harsh hard water associated with tankless water heaters can cause scaling and rust in weaker materials. Unlike these other materials, stainless steel does not corrode, helping reduce the chances of leaks and the failure of the entire system.

Stainless steel enhances the performance of tankless water heaters due to its high thermal efficiency. This material can conduct heat to the water more effectively, allowing it to reach the required temperatures quicker while minimizing energy wastage. As per experts, the use of stainless steel heat exchangers is expected to improve efficiency ratings in modern tankless systems, thereby lowering energy use and utility costs associated with them.

Stainless steel is also relatively easy to work with as it’s light in weight and resilient, allowing use in space-saving designs, which is a characteristic of tankless water heaters. Stainless steel parts ensure the reliability and performance over time because of corrosion and wear resistance, as well as uninterrupted service to residential and commercial services. Overall, its eco-friendly attributes – being completely 100% recyclable – add value to systems for consideration when sustainable practices are in focus.

Stainless steel heat exchangers in high-heat industrial environments

Stainless steel heaters and gas coolers are a major part in the efficient movement of heat in an extreme setting. Stainless steel constructs are utilzed in chemical processing plants, power generation facilities and oil refineries due its remarkable enduring qualities, resilence to rust, as well as high temperatures. It is safe to say that stainless steel is ideal for heat exchangers used by industries.

Noteworthy about stainless steel is its ability to endure harsh environments while maintaining strength and integrity. Now steel construction faclilites such exchangers are capable of operating under 982 degree C or 1,800 degree F of heat contextually to its type. A good example would be 316 and 321 grade stainless steel as they offer great endurance against oxidation and creep giving the heat chassis a longlife oxidatiional benefit even during thermal stress in high temperature environments.

Moreover, stainless steel braces allow for greater fuel optimization as a direct impact resulting from the industries having to spend less on fuel purchasing. Reports show that the exchangers built from steel outperform other materials, surpassing them thermally by over 90 percent, which will reduce costs dominantly. Additional exposure to materials like acids and saline solutions makes steel more favorable as it becomes the primary corrosion-resistant material, increasing the apparatus’s life.

The provided information demonstrates that stainless steel heat exchangers are a dependable option from a cost perspective for use in areas of high heat as they fulfill both operational and sustainability objectives in contemporary industries. Choosing the right grade and design guarantees optimum performance and efficiency for particular applications.

What are the longevity factors of stainless steel heat exchangers?

The life expectancy of stainless steel heat exchangers is dependent on the following factors:

- Material Quality: The grade of stainless steel determines its ability to resist corrosion and wear, which in turn increases the lifespan of the heat exchanger.

- Maintenance: Routine checks and cleaning ensure that there is no deterioration, which leads to reliable long-term performance.

- Operating Conditions: Maintaining appropriate temperatures and levels of chemical exposure prevents damage over time.

- Design and Application Fit: Achieving optimal durability and efficiency relies on the intended application and the design and specifications chosen.

Effectively managing these parameters will prolong the life of stainless steel heat exchangers even under challenging conditions.

How stainless steel heat exchangers resist corrosion over time

The distinctive combination of materials and properties in stainless steel heat exchangers makes them excel at resisting corrosion. The most crucial aspect is the chromium, which is a component of stainless steel, usually not less than 10.5%. Chromium, when present, bonds with oxygen in the surroundings, leading to the formation of a thin, passive oxide film on the surface of the steel. This film halts additional oxidation and corrosion processes. Furthermore, the presence of molybdenum and nickel in some grades of stainless steel increases resistance to harsh environments like those containing chlorides or acidic conditions.

As an illustration, 316 stainless steel performs well with pitting and crevice corrosion in marine environments, as it has higher levels of molybdenum than 304 stainless steel. Research suggests that the corrosion rates of high-grade stainless steel materials while submerged in seawater are much lower than carbon steel. Hence, stainless steel heat exchangers prove to be convenient for industrial applications where aggressive chemicals or saline water are prevalent. Also, the passive oxide film has the unique feature of self-healing, ensuring continuous protection even if surface damage occurs, provided there is oxygen in the atmosphere.

These high-quality materials make certain that stainless steel heat exchangers remain structurally sound and operationally efficient for long periods of time, delivering unwavering accuracy in challenging tasks.

Impact of hard water on stainless steel heat exchanger lifespan

The presence of hard water characterized by high amounts of dissolved minerals including calcium and magnesium can have a considerable effect on the durability of stainless steel heat exchangers. These minerals usually precipitate when water gets heated leading to the formation of scale deposits on the heat exchangers surfaces. Eventually, scale formation may lead to reduced efficiency of heat transfer, elevated system energy requirements, and increased strain on the system itself.

Research indicates that such scales as thin as a 1/16 inch layer can bring down heat exchanger performance by 20% or more. Moreover, the passive oxide layer of the stainless steel enables localized corrosion due to the accumulation of mineral deposits. This becomes critically important since the disruption leads to weakening of the material, increasing vulnerability to leaking or failure of the system.

These maintenance activities descaling or employing treatment systems for water tend to lessen these complications. The modifications in question include usage of water softeners and anti-scaling agents which directly reduce the concentration of minerals resulting in improved performance and lifespan of stainless steel heat exchangers.

Maintenance requirements for stainless steel tube heat exchangers

In order for stainless steel tube heat exchangers to be fully functional, having a long lifespan, and properly performing over time, they need to be maintained. Regular monitoring is highly suggested to look out for any corroding, scaling, or fouling which could result in poor heat transfer efficacy. To illustrate, some research suggests that even slight fouling results in a 20% reduction of heat exchanger efficiency, further leading to soaring operational costs and increased energy consumption.

Cleaning operations should take into account what type of environment they are operating in, and what type of deposits are a concern. For particulates involving scaling, mineral buildups are best removed with citric or phosphoric acid descaling solutions, as they do not corrode stainless steel. Other widely used methods include non-destructive cleaning techniques such as hydro jetting which do not alter the tubes and remove rigid residues.

Cleaning and pre-treatment systems have the ability to control water quality and help minimize the risks of scaling and corrosion. Studies show that advanced water treatment solutions like demineralization and reverse osmosis help control cluster formation, thus reducing maintenance. Also, in areas where water is harder, the installation of water softeners has been proven to reduce deposits formed from calcium and magnesium, especially regarded as more powerful contributors to impurities.

Regular monitoring of the system nearing thresholds, such as temperature and fluid flow rate,s could detect problems early. It is recommended to complete a full maintenance inspection at least once every year or more often for systems with harsh operating conditions, highly contaminated fluids, or a combination of the two. Following these recommendations helps prolong the useful life of stainless steel tube heat exchangers while maintaining their safe and efficient operation.

What types of stainless steel are best for heat exchanger applications?

It is widely recognized that stainless steel types 304 and 316 are the most appropriate for use in heat exchangers. Type 304 is inexpensive and serves general purposes having a fair amount of hostile environment resistance. 316 type with molybdenum has a far greater resistance to chloride corrosion, making it more appropriate for harsh conditions or applications containing salt or acid fluids. Both are tough and dependable which is why they are used in industrial and commercial systems.

How different stainless steel alloys affect heat exchanger performance

The exchanger’s performance relies greatly on the alloy composition of its corresponding grade of stainless steel. Different operating environments at varying temperatures, pressures, and corrosive conditions throughout industry applications require the appropriate grade of stainless steel. Alloys of stainless steel are distinguished and categorized based on certain factors. Have a look at some of them in the paragraph below concerning popular alloys of stainless steel:

- Thermal Conductivity

The thermal conductivity of alloys of stainless steels varies from alloy to alloy, barring a few exceptions. As compared to other metals such as copper and aluminum, all alloys of stainless steel are low-conductivity materials. For instance, Type 304 stainless steel has around 16.2 W/m·K of thermal conductivity, whereas Type 316 has slightly lower thermal conductivity due to its molybdenum content, at about 14.6 W/m·K. While many people would think this to be inefficient, the steels, in comparison, do exceptionally well in systems with very corrosive environments, withstanding good resistance value.

- Corrosion Resistance

Due to it’s lack of sufficient resistance, standard applications make the use of Type 304, which is the most common alloy. economically balanced alloy that resists corrosion. Type 316 dominates over Type 304 because of its molybdenum content, which provides enhanced pitting and crevice corrosion resistance. As per the study, Type 316 is said to perform better sustaining work for extended periods of chloride exposure, essential for heat exchangers for marine or coastal areas.

- Pressure and Strength Properties

Stainless steel alloys maintain their structural integrity under high pressure because of their high mechanial properties. For instance, Type 316 has a marginally greater tensile strength of approximately 515 MPa in comparison to Type 304, which is approximately 505 MPa. This renders Type 316 useful in applications facing high strain or changing pressure, such as in heat exchangers.

- Environmental Adaptability

Choosing an alloy requires care for highly specific environments, for example, duplex stainless steels like 2205 have incredible stress corrosion cracking and are stronger in weight ratio compared to Type 304 and 316. Duplex alloys also have better resistance of localized corrosion for mixed chlorides and high temperature surroundings.

- Economic and Long-Term Considerations

In the short term, type 304 has low prices, but for the long run, more delicate damaging and further operational proprietary corrosion shielding provided by type 316 or duplex stainless steel might minimize heat exchanger servicing intervals. Efficient material selection concerning specific operational parameters means the exchanger will operate at the desired efficiency and suffer less material deterioration.

Selecting the correct stainless steel for a heat exchanger involves balancing working temperature, pressure, and the harshness of the surroundings. Achievements in metallurgy continue to improve the alloys of stainless steel for better durability and efficiency, clearly indicating their importance in present day industrial activities.

Which stainless steel grades offer better corrosion resistance?

Known to be highly resistant to corrosion are the austenitic stainless steels such as 304, 316, and their variants, which fall under the subclass of austenitic stainless steels. Due to its relatively low cost, grade 304 stainless steel is one of the most utilized types because of its noteworthy corrosion resistance in mild environments. However, for more aggressive environments, grade 316 is preferred due to the presence of molybdenum, which enhances the protection against pitting and crevice corrosion caused by chlorides that are prominent in marine or coastal regions.

From the super austenitic family of stainless steels, 904L is specially designed for extreme environments because it contains higher amounts of nickel and molybdenum that make it resistant to acids that are highly corrosive acids, such as sulfuric and phosphoric acids. 2205 duplex stainless steels also perform exceptionally well and offers a blend of exceptional resistance to corrosion and high strength. For the harshest conditions, these include offshore and chemical processing industries, super duplex steels such as 2507 are unmatched because they are designed to withstand highly corrosive and high-pressure conditions.

Choosing the appropriate grade is influenced by the type of corrosive medium, temperature ranges, and overall cost. For instance, 310 or 316Ti grades may be required for high temperature environments due to the presence of stabilizing constituents that guard against material deterioration. Information from production tests shows that while 304 grades are useful for general functions, 316 and 2205 grades are far more effective in aggressive solutions, demonstrating unprecedented resistance against corrosion and greatly enhancing service life. These performance variations demonstrate the need for the material to be customized to address the specific demands of an application.

How does stainless steel affect overall heat exchanger performance?

The versatility of stainless steel boosts the performance of thermal exchangers due to its exceptional properties of thermal conductivity, corrosion resistance, and durability. Its corrosion resistance guarantees a long-life, dependable service even in severe conditions, alongside the durable construction, which enables the creation of slimmer heat exchangers that are lighter in weight and enhance the efficiency of heat transfer. Furthermore, stainless steel’s smooth surfaces have lower fouling potential, enhancing maintenance and overall system efficiency. These advantages make stainless steel a top choice for manufacturing heat exchangers in many industrial sectors.

Energy efficiency considerations with stainless steel heat exchangers

Stainless steel heat exchangers offer great potential in increasing energy efficiency in various industries. Their thermal conductivity properties facilitate effective heat transfer that minimizes energy waste. Reportedly, stainless steel heat exchangers can achieve up to 90% heat recovery efficiency, depending on the application and system configuration. Such high efficiency is critical in lowering operational costs and the carbon footprint of industrial processes.

Moreover, the stainless steel alloy’s unique properties guarantee fewer system failures as well as associated downtime, ensuring uninterrupted energy performance throughout the equipment’s life. In addition to their resistance to high-pressure and high-temperature conditions, these heat exchangers are particularly well-suited for energy-intensive processes. Other industries, including power generation, chemical processing, and HVAC systems, are significantly aided by these traits for sustained long-term environmental and economic benefit.

Heat exchange capabilities in condensing applications

Heat exchangers of stainless steel are extremely efficient and durable in condensing application systems. These systems are built to optimize energy recovery by capturing the latent heat that can be derived from the vapor condensation. It is observed that modern condensing boilers utilize stainless steel heat exchangers, which have efficiency levels exceeding 90-95%. This considerably saves energy, reduces operational costs, and minimizes energy waste. Furthermore, due to the moisture and high temperature, the stainless steel heat exchangers still maintain optimal performance and effective heat transfer because of their superior thermal conductivity.

Another great benefit with regard to condensing applications where condensation tends to generate a very corrosive environment due to carbonic acid development is the corrosion resistance of stainless steel. Unlike other materials, stainless steel withstands the acidity, which makes it functional with minimal long-term maintenance. Industrial application data demonstrates that these systems can function effectively at gas temperatures of 120-140°F (49-60°C). Thus, enabling them to adapt to low-temperature heat recovery systems. Considering these aspects, it is evident that stainless steel heat exchangers promote sustainable and energy-efficient thermal processes.

How stainless steel heat exchangers perform under pressure

Stainless steel heat exchangers are fit for demanding industries because they can withstand high-pressure environments. The material’s tensile strength, frequently surpassing 500 MPa (MegaPascal), ensures that these exchangers face no internal stress deformation or failure. For instance, grade 316 stainless steel not only has superb resistance to corrosion, but also can withstand pressures encountered in oil refineries, chemical plants, and power generation systems. Some models are now manufactured to work safely over 1,500 psi (pounds per square inch) with advanced manufacturing techniques surpassing older pressure limits. Moreover, these exchangers tend to last much longer because cyclic pressure cracking and thermal expansion do not defeat their reliability. Meanwhile, the reduction of maintenance and operational costs increases. Above all, maintaining such remarkable strength and performance damages these steels in competing industries, resulting in preferred over the rest.

Reference Sources

- “A comprehensive review on the current technologies and recent developments in high-temperature heat exchangers” (2023)2:

- Key Findings: This study highlights the advantages of stainless steel in high-temperature heat exchangers (HTHXs), including its resistance to thermal shocks, corrosion, and material degradation. It also discusses the suitability of iron- and nickel-based alloys for extreme conditions.

- Methodology: A literature review of 123 papers, focusing on material performance, heat transfer fluids, and design configurations for HTHXs.

- Relevance: Stainless steel’s durability and efficiency in high-temperature applications make it a preferred choice over copper.

- “Role of Stainless Steels in Industrial Heat Exchangers” (2020)3:

- Key Findings: Stainless steel offers superior corrosion resistance, high-temperature performance, and cost-effectiveness over time. It is particularly advantageous in environments with high chloride content or extreme temperatures.

- Methodology: A detailed analysis of stainless steel’s properties, including corrosion resistance, heat transfer efficiency, and maintenance requirements.

- Relevance: The study underscores stainless steel’s versatility and long-term economic benefits compared to copper.

- “Chapter 11. Heat Exchangers” (1998)4:

- Key Findings: While copper is commonly used in low-temperature applications, stainless steel is preferred for geothermal and industrial systems due to its resistance to corrosive chemicals and high temperatures.

- Methodology: A review of heat exchanger types and their applications, with a focus on material suitability for geothermal fluids.

- Relevance: Highlights the limitations of copper in corrosive and high-temperature environments, favoring stainless steel.

Frequently Asked Questions (FAQs)

Q: What makes stainless steel heat exchangers more durable than copper for industrial applications?

A: Stainless steel heat exchangers offer superior durability because they don’t corrode as quickly as copper when exposed to harsh industrial environments. While copper is a better conductor of heat, stainless steel provides excellent chemical resistance, withstands higher pressures and temperatures, and has a significantly longer service life in demanding applications. This durability makes stainless steel the preferred material for a heat exchanger in settings where reliability and minimal maintenance are critical.

Q: How do copper and stainless steel heat exchangers compare in terms of heat transfer efficiency?

A: Copper is naturally a better conductor of heat than stainless steel, offering approximately 30 times greater thermal conductivity. This allows copper heat exchangers to achieve better heat transfer rates with thinner walls. However, stainless steel manufacturers compensate for this difference by designing units with larger surface areas and optimized flow patterns. Modern stainless steel heat exchangers are designed to efficiently transfer heat between fluids while balancing other advantages like corrosion resistance and strength, making them suitable for applications where optimal heat exchange must be maintained under harsh conditions.

Q: In which industrial environments are stainless steel heat exchangers preferred over copper?

A: Stainless steel heat exchangers are often used in aggressive industrial environments where copper would quickly deteriorate. These include chemical processing plants, oil refineries, marine applications (due to saltwater exposure), high-temperature operations (such as exhaust heat recovery), food and beverage processing (where sanitation is critical), pharmaceutical manufacturing, and wastewater treatment facilities. The exceptional corrosion resistance of stainless steel makes it the superior choice in these settings, despite copper’s better heat transfer properties.

Q: What cost considerations should be evaluated when choosing between copper and stainless steel heat exchangers?

A: While copper heat exchangers typically have a lower initial purchase cost than stainless steel units, the total cost of ownership often favors stainless steel for industrial applications. Stainless steel heat exchangers offer longer service life, reduced maintenance requirements, and fewer replacements over time. Additionally, copper prices are more volatile in the global market, potentially affecting replacement costs. For high-temperature or corrosive environments, the durability of stainless steel leads to significant long-term cost savings despite the higher upfront investment.

Q: How do stainless steel heat exchangers perform in high-temperature industrial processes compared to copper?

A: Stainless steel significantly outperforms copper in high-temperature industrial processes. While copper begins to lose strength at temperatures above 200°C (392°F), stainless steel maintains its structural integrity at much higher temperatures, with some grades withstanding temperatures up to 1000°C (1832°F). This makes stainless steel heat exchangers the preferred choice for applications involving exhaust heat recovery, steam generation, and other high-temperature industrial processes where material integrity is crucial for safety and performance.

Q: How do maintenance requirements differ between stainless steel and copper heat exchangers in industrial settings?

A: Stainless steel heat exchangers require significantly less maintenance than copper alternatives in industrial settings. Copper units are more susceptible to fouling, scaling, and corrosion, necessitating more frequent cleaning and service intervals. Additionally, copper heat exchangers often require specialized water treatment to prevent degradation. Stainless steel water-contact surfaces resist biofouling, scaling, and chemical attack, resulting in less downtime for maintenance, fewer replacement parts, and lower overall maintenance costs throughout the equipment lifecycle.

Q: How do stainless steel heat exchangers compare to copper in terms of pressure tolerance?

A: Stainless steel heat exchangers offer substantially higher pressure tolerance than copper units. The superior mechanical strength of stainless steel allows these exchangers to safely handle industrial processes operating at pressures that would deform or damage copper equipment. This higher pressure rating is particularly important in industrial applications such as high-pressure steam systems, chemical processing, and hydraulic oil cooling. The ability to withstand greater pressure without compromising structural integrity makes stainless steel heat exchangers the safer and more reliable choice for demanding industrial operations.

Q: How do stainless steel heat exchangers compare to aluminum and copper alternatives for industrial use?

A: When comparing the three common materials, aluminum heat exchangers offer the lightest weight and lowest cost but have limited corrosion resistance and temperature tolerance. Copper provides excellent thermal conductivity but moderate corrosion resistance and strength. Stainless steel heat exchangers offer the best overall package for industrial applications with superior corrosion resistance, excellent durability, high-temperature capability, and pressure tolerance. While stainless steel has lower thermal conductivity than both aluminum and copper, its reliability and longevity in harsh industrial environments make it the preferred choice for critical applications where failure is not an option.