When it comes to selecting the perfect guitar strings, the choice of material can significantly influence your tone, playability, and overall performance. Among the most popular options, Monel and Phosphor Bronze strings stand out as top contenders, each offering distinct characteristics suited to different playing styles and musical genres. But how do you determine which is best for your needs? This guide dives deep into the key differences, advantages, and potential drawbacks of Monel and Phosphor Bronze guitar strings to help you make an informed decision. Whether you’re a seasoned guitarist or just starting, understanding how these materials shape your sound is a crucial step in elevating your craft.

What is the Difference Between Monel and Phosphor Bronze Strings?

Understanding the Composition of Monel and Phosphor Bronze

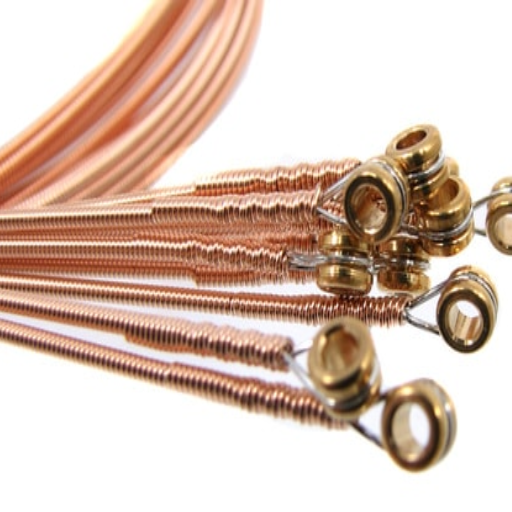

Monel is an alloy mostly made of nickel (somewhere in the range of 60-70%) and copper, along with small quantities of iron, manganese, carbon, and silicon. Its properties stem from copper, which makes up Monel alloys, since it is exceptionally durable. Its corrosion resistance and high durability are caused by the high content of nickel. These properties account for the unique tonal properties of the material that is often referred to as warm and rich, with emphasis on midrange frequencies. This type of string is especially favored by those players who are after a vintage tone or a sound that cuts through when playing acoustic.

Phosphor Bronze is the other side of the coin, considered an alloy of copper (about 92%) and tin, in addition to a small amount of phosphorus for added strength and resistance to corrosion. This composition provides a brighter as well as more articulate sound with enhanced sustain. Their higher percentage of Copper makes the strings shine, making them widely sought after for many genres of music, particularly those that require clarity and brightness, like folk and fingerpicking music.

The core distinction is found in the tonal characteristics and the feel of the materials. Monel strings are generally softer and more durable under different environmental conditions. In contrast, players looking for that modern acoustic ring tend to prefer the brighter, if somewhat more fragile, tones produced by worn and corroded Phosphor Bronze strings. Ultimately, the choice is about personal taste and the specific sound attributes needed to complement one’s style.

Exploring the Material Properties of Each Alloy

Monel is an alloy that largely comprises nickel and copper, along with trace quantities of iron, manganese, carbon, and silicon. The string applications that withstand maritime and industrial wear utilize Monel due to its high nickel content, which offers exceptional corrosion resistance. Monel also demonstrates superb mechanical strength alongside reginal integrity, offering temperature reliability, thus making him an excellent option for performance enduring musicians who seek durability.

Phosphor Bronze, on the other hand, is a copper alloy that has tin and phosphorus added to the alloy in amounts ranging from 0.5 to 11 percent. Phosphorus enhances stiffness while also improving fatigue resistance. This alloy is particularly well-suited for producing a bright and vibrant sound because of its reflective properties. Unlike Monel, Phosphor Bronze has less oxidation resistance, thus making it more susceptible to surface corrosion in humid environments.

As with everything, a compromise has to be made when deciding between the two options based on sound preference and external considerations. Monel strings are suited for more corrosive conditions due to their resilience, while players who prioritize sound clarity would prefer Phosphor Bronze strings, which are sharper and more articulate. Every musician can choose the alloy that best meets their performance needs since each material offers unique advantages.

How Does Nickel Content Affect Each String Type?

The string types used on guitars require nickel consideration as it greatly influences the durability, the tone, as well as the corrosion resistance. For material with a greater nickel content, the strings are more resistant to corrosion and wear, which matters greatly in a humid or high-moisture area. This quality helps to maintain the strings for a longer duration while providing unparalleled structural fidelity along with tonal consistency.

Nickel contributes to the warm and smooth aspect of the string’s profile from a tonal perspective. This trait especially comes forth in vintage style or pure nickel strings, which are heavily preferred by players looking for softer tones. Unlike others, strings with a lower nickel ratio, like the ones crafted from nickel-plated steels, can deliver more pronounced clarity, which is great for genres that require sharp and brighter tones.

The tactile experience, along with the flexibility of the strings, is heavily influenced by nickel content as well. Softer strings lead to lower fatigue and improved playability, which aids in extended playing sessions. For those who are more focused on walking and balance, resilient and optimal performance, along with comfortable play, require a higher nickel concentration.

How Does the Sound of Monel Compare to Phosphor Bronze?

Analyzing the Tone and Overtones of Each String

Evaluating Monel and Phosphor Bronze strings yields notable conclusions due to the makeup of the materials and their vibrational interactions. Phosphor Bronze strings would produce a higher-pitched tone in contrast to Monel, which is an alloy of nickel and copper string known to produce a warm-bright-toned sound and rich midrange. The gentle treble edge, which is attributed to Monel strings, makes it easier to perform folk and jazz music, which require a soft or mellow soothing tone. Moreover, Monel does not corrode readily, which allows for the excellent consistency of tone throughout its lifespan.

On the other hand, Phosphor Bronze strings are tin tin-copper alloy with small quantities of phosphorus. An addition of phosphorus will ensure the strength of the string while providing an exquisite, clean, bright, and omnidirectional sound, which enables its favorability amongst modern acoustic guitar performers.

Even the overtone spectrum of these strings is different. In terms of harmonic content, Monel strings have a more pronounced fundamental tone that is more blended with the ensemble due to a narrower frequency range. In contrast, Phosphor Bronze strings have a fuller, more dynamic sound because of the sparkling overtones and wider harmonic range, making them ideal for solo performances or any situation where the projection of sound is essential.

These features concerning the timber, together with the physical properties, make the selection between Monel and Phosphor Bronze strings contingent on the player’s style, the surrounding conditions, and the color or depth of sound sought. Knowing these differences allows for more targeted decisions while selecting strings that are best suited for the performer’s objectives.

The Impact of Guitar String Choices on Sound Quality

The overall sound and tonal quality of a guitar can be widely impacted by how the strings are wound, their gauge, and their material. The harmonic detail and frequency response are altered depending on the string material. For example, Phosphor Bronze strings are famous for their bright and rich overtones, while Monel emphasizes a vintage warmth with mellowed mids. These differences greatly affect how an instrument’s sound can be tailored for different genres or playing styles.

String gauge, normally measured in thousandths of an inch, heavily contributes to the sound of a guitar as well. Heavier gauges (like .012 or .013 sets) produce a fuller, richer tone, however, they require more finger pressure and are generally used for strumming open tuning. Lighter gauges provide less tension and are better for fingerpicking or lead work, but they suffer in projection and tonal depth.

Moreover, the string’s winding techniques, which include roundwound, halfwound, and flatwound, influence the texture and tone of the strings. Flatwound strings produce a more soothing sensation and warmer, darker tones suitable to jazz contexts, while Roundwound strings are brighter and livelier, something favored in contemporary genres. Not only do these construction methods affect the sound, but also playability and lifespan, making them crucial for achieving the results. This information enables players to enhance their selection of strings to best suit their instrument and style of play, in turn, to meet their artistic vision.

Comparing Monel vs Phosphor Bronze in Different Musical Genres

Due to their warm, mellow tone, Monel strings shine in folk, jazz, and vintage genres, whereas Phosphor Bronze strings have a bright, balanced sound, making them suited for modern, rock, and bluegrass styles.

|

Aspect |

Monel |

Phosphor Bronze |

|---|---|---|

|

Sound |

Warm, mellow |

Bright, balanced |

|

Harmonics |

Minimal |

Rich |

|

Styles |

Jazz, Folk |

Rock, Bluegrass |

|

Lifespan |

High |

Moderate |

|

Definition |

Excellent |

Good |

|

Retro Fit |

Yes |

No |

|

Adaptability |

Limited |

Versatile |

|

Texture |

Smooth |

Crisp |

What Are the Applications and Uses of Monel and Phosphor Bronze Strings?

Choosing the Right String for Your Instrument

It is important to note that information-strung instruments are new, and selecting the right string material needs careful consideration of specific factors, such as the required tone quality, playing technique, and the string instrument’s use case environment. Monel strings are highly appropriate for players looking to achieve smooth, warm sounds, especially in jazz and folk. Their low harmonic content and high structural reliability mean that they will provide a clean, focused tone while offering long-life performance.

Individually, phosphor bronze strings are designed to produce a moderate yet well-balanced loud sound with an adequate level of harmonics. They are more flexible in application, with a good fit for modern styles of music like rock and bluegrass, which need clarity and powerful sounds. They work well for musicians who focus on strong tonal depth and versatility, as these strings have a stiff texture and low lifespan.

In the case of Monel and phosphor bronze strings, it’s useful to think about the acoustic characteristics of your instrument in addition to the venues where you intend to play. For instance, Monel strings have a better fit for retro instruments, and they are also more corrosion resistant, which makes them ideal for challenging humid environments. This is advantageous for longevity. On the other hand, phosphor bronze strings tend to have great depth of tonality, but also have a short lifespan and high sensitivity to environmental conditions. Because of this, they might need to be replaced more often, which makes them ill-fitting for such conditions.

Considering the High Strength and Corrosion Resistance of Each Alloy

In alloys meant for high-stress applications, the balance between strength and corrosion resistance is critically important. For example, stainless steel is used in construction due to its high chromium content, which ensures exceptional resistance to oxidation and rust even in hostile marine environments. Similarly, titanium alloys outperform others in terms of ultra-lightweight design and high tensile strength, making them ideal for use in the aerospace and medical industries where weight reduction is imperative without compromising strength.

Aluminum alloys also deserve consideration for their outstanding resistance to corrosion due to a naturally occurring protective oxide layer and remarkable strength-to-weight ratio. However, when the scenario involves extreme wear or exposure to chlorides, other materials have more trouble with temperature and chemical attack. In these scenarios, nickel-based superalloys tend to excel due to their ability to withstand high temperatures and severe chemical attacks.

The selection procedure also needs to include some particular data, such as tensile strength in MPa, elongation in percent, and corrosion rate in specific environments. For example, Type 316 stainless steel excels in chloride environments when compared to Type 304 due to its greater pitting resistance, with a PREN score of 24-28 compared to 304’s 19-21.

Precision surface treatments like alloy coatings and advanced manufacturing processes can improve strength and corrosion resistance, tailored for the automotive, structural engineering, and energy sectors. In the end, marrying high-level concepts with the right material details guarantees meeting the requirements of the application’s context.

Why Choose Monel or Phosphor Bronze for Your Guitar Strings?

Benefits of Using Monel Strings for Corrosive Environments

Because of the way they are made, Monel strings stand out in highly corrosive environments. That said, here are five benefits of Monel strings:

- Exceptional Corrosion Resistance: Being primarily nickel-based, along with copper (about 63% nickel and 28-34% Copper), Monel has a lot of use in corrosive conditions. Surmerine and humid conditions seem to be the ones best for monel. Moreover, saltwater and other harsh elements are present not just for aggressors, it also sustain integrity, which is best needed for guitarists playing in coastal areas or places with high humidity.

- Improved Durability: Exhibiting more than 550-620 MPa, Monel strings are under high tension, which has a lot of sustain. In comparison to industry standard materials, Monel is much better at withstanding stress without succumbing to fatigue. This means that the cost efficiency is a lot more over time. Besides the durability offered by the material itself, additional lifespan is gained on account of not being replaced often.

- Stable Performance Under Extreme Conditions: Not many materials can boast of excelling under high temperatures as well as mechanical stress, but Monel can. Not only can it withstand temperatures from -100°F to 1000°F(-73°C to 538°C), but it also ensures constant tonality and stability under harsh conditions.

- Resistance to Oxidation and Tarnishing: Monel strings, unlike pure steel ones, have some degree of resistance to oxidation and tarnishing that can dampen sound quality. Because of this, the strings could still sustain acoustic properties, yielding g consistent bright and warm tone for longer periods of use.

- Reduced Fret Wear: Monel’s relative softness in comparison to harder steel alloys makes for less wear on the fretboards, which extends the life of the instrument. This feature is especially popular among professional musicians and collectors who want to maintain their guitars for a long time.

These advantages in combination explain why Monel is often selected for string applications where corrosion and wear resistance are of concern.

Advantages of Phosphor Bronze in High Friction Settings

Phosphor bronze stands out from the rest because of its remarkable performance, exceptionally well in high-friction settings, and possesses striking mechanical and chemical attributes. This copper alloy, tin, and phosphorus offer distinct advantages, making it an ideal selection for harsh applications.

- Resistance to Abrasion: Phosphor bronze alloys display superb wear resistance, even under severe contact stresses and friction. This is due to its microstructure, wherein surface wear is minimized over time, thereby establishing reliability and durability in constituent parts like bushings, bearings, and gears.

- Energy Efficiency: A key feature of the alloy is naturally a low coefficient of friction. This minimizes energy loss during operation (and heat generated) within mechanical systems, thereby making the alloy energy efficient when used within sliding surfaces and other dynamic contact surfaces.

- Strength under Repeated Loading/Cycling: Phosphor bronze alloys display excellent fatigue resistance. This is a result of exposing the alloy to repeated stress cycles without noticeably reducing strength. This feature is needed in situations where components encounter repetitive loading. Such scenarios include automotive and industrial applications as well as other high-friction settings.

- Corrosion Resistance: Especially while in salty or corrosive environments, this alloy’s resistance to corrosion is remarkable and improves its service life. This characteristic is beneficial in marine settings or chemical plants where mechanical wear and tear coincide with abundant friction or exposure.

- Excellent Machinability: Precision machining of complex parts that are difficult to fabricate is possible due to the exceptional machinability of phosphor bronze, which allows for preservation of the material’s integrity. It is easy to manufacture complex parts with small size specifications, which are often used in high-friction bearings.

All the above considerations demonstrate the efficiency and durability of phosphor bronze under high-friction working conditions.

Comparing Monel vs Phosphor Bronze in Terms of Heat and Wear Resistance

While phosphor bronze is more adept at managing moderate heat, Monel offers unrivaled wear durability and heat resistance.

|

Aspect |

Monel |

Phosphor Bronze |

|---|---|---|

|

Heat Res. |

High |

Moderate |

|

Wear Res. |

Excellent |

Good |

|

Melting Pt. |

1300-1450°C |

954°C |

|

Durability |

High |

Moderate |

|

Flexibility |

Low |

High |

|

Cost |

High |

Moderate |

How Do Monel and Phosphor Bronze Perform in Various Temperature Ranges?

The Effect of Temperature on String Performance

A string’s performance will always change with increasing temperatures due to the string’s thermal expansion properties and structure. This phenomenon can be noticed in Monel and Phosphor Bronze, which exhibit thermal sensitivity, making temperature an important consideration for their usage lifetime and sound performance. The performance of a string can be impacted by temperature in the following five ways:

- Thermal Expansion: An increase in temperature leads to thermal expansion of Monel and Phosphor Bronze strings. In this case, Phosphor Bronze will expand more due to its higher thermal expansion coefficient, meaning it will also be less stable in a constantly changing temperature environment.

- Elastic Modulus Variation: Phosphor Bronze strings undergo greater softening with temperature increases, causing a reduction in tension, which may lead to unstable tonal shifting over time, creating an imbalance in elasticity. The elasticity of string materials will always be accompanied by a shift in temperature. Phosphor Bronze strings tend to soften more rapidly under high temperatures.

- Oxidation and Corrosion Resistance: The presence of heat accelerates the mechanical wear and tear of objects, which leads to increased loss of strength and even cuts offshore, particularly in Monel, which can withstand stronger oxidative elements when compared to phosphor bronze. Phosphor bronze does not easily withstand excessive temperatures and humidity. Based on its lower melting point, Bronze is also more prone to premetaller undergoing extreme isothermal conditions.

- Tonal Properties and Vibrational Response: Phosphor Bronze strings tend to lose some brightness and tonal richness at higher working temperatures due to the softening of the material. Monel strings, on the other hand, suffer less from tonal degradation and are more consistent in sound quality over varying temperatures.

- Fatigue Resistance and Durability: The high-temperature exposure significantly aggravates the material’s fatigue. Phosphor Bronze suffers more wear and structural change under these conditions. Monel, with higher fatigue resistance, demonstrates improved durability in high-temperature applications.

These differences highlight the fact that, regardless of changes in temperature and fatigue, the string materials used require specific predefined limitations to ensure proper functionality.

Exploring Thermal Conductivity and Melting Point Differences

While conducting a comparison between the thermal conductivity of Monel and Phosphor Bronze, it’s evident that Monel has greater heat transfer capabilities. Monel’s increased thermal conductivity facilitates faster heat dissipation, making it suitable for areas where rapid heat distribution is necessary. Bronze Phosphor demonstrates effective performance in several situations, but is undeniably placed at a disadvantage in both scenarios in comparison to Monel because of lower thermal conductivity, meaning it retains heat for longer durations, which affects its performance in high-temperature environments over time.

Monel’s advantage becomes clear with the comparison of melting points, as it has a relatively greater one than Phosphor Bronze. This trait allows Monel to withstand high-temperature environments without deformation or failure. Phosphor Bronze, on the other hand, has a marginally lower melting point, which can be a drawback for applications that use high temperatures for prolonged periods.

Monel and Phosphor Bronze depend on which substance is required, thermal properties notwithstanding. In case of heat control structures being the issue, Monel proves advantageous due to its exceptional strength. Bronze Phosphor is, however, reliable for less tough thermal conditions and poses as a cost-friendly alternative.

How Monel Remains Stable Across Different Temperatures

Monel exhibits outstanding thermal stability as it contains primarily a nickel-copper alloy with small portions of iron, manganese, and other elements. This unique metallurgical structure acts like a thermal expansion dam while coping with immense thermal stress, thereby greatly augmenting its usefulness for applications that require extreme temperature variations. Additionally, the alloy has a melting point of approximately 2370 to 2460 °F (1299 to 1350 °C), which magnitude showcases its durability under high temperatures.

Due to Monel’s low thermal conductivity compared to other metals, it possesses remarkable oxidative and corrosive resistance even at elevated temperatures. These properties stretch Monel’s structural capability in harsh environments, including but not limited to aerospace, chemical processing, and marine industry regions. The aforementioned property of thermal stability, coupled with high-demand conditions, makes Monel extremely beneficial.

Monel alloys, more specifically Monel 400 and Monel K-500, showcase remarkable fatigue strength at high temperatures, enabling them to cope with changing loads without significant performance drops. Such characteristics of Monel allow its extensive use in environments that demand great structural dependability while coping with extreme temperatures.

References

- The wearing properties of nitrided nitralloy against various alloys (MIT) – Discusses wear properties of Monel and other alloys.

- A potentiokinetic determination of corrosion rates in artificial seawater-hypochlorite solutions (Naval Postgraduate School) – Compares corrosion resistance of Monel and Phosphor Bronze in seawater.

- Consideration of mechanical and physical on effective EMI shielding (IEEE) – Includes a comparison of electrical conductivity and shielding properties of Monel and Phosphor Bronze.

Frequently Asked Questions (FAQ)

Q: What is the main difference between Monel vs Phosphor Bronze guitar strings?

A: The main difference between Monel and Phosphor Bronze guitar strings lies in their material composition. Monels are made from a nickel-copper alloy, while Phosphor Bronze strings are made from a combination of copper and tin with a small amount of phosphor. This difference results in distinct tonal qualities and durability.

Q: How does the grade of materials affect the quality of guitar strings?

A: The grade of materials used in guitar strings affects their tonal quality, durability, and feel. Higher-grade materials generally result in strings that have better sound quality, longer lifespan, and greater resistance to corrosion and wear.

Q: What is the tonal characteristic of Phosphor Bronze strings compared to Monel strings?

A: Phosphor Bronze strings are known for their bright, clear, and articulate tone, making them ideal for styles that require crisp sound. In contrast, Monel strings provide a warmer, mellower tone that is often described as vintage and rich, which is preferred by many folk and blues players.

Q: Are Monel strings more resistant to acid and corrosion than Phosphor Bronze strings?

A: Yes, Monel strings are generally more resistant to acid, sweat, and corrosion due to their nickel-copper composition. This makes them a durable choice for players who have more acidic sweat or who play in humid environments.

Q: How do Monels compare to PB strings in terms of longevity?

A: Monel strings often have a longer lifespan than Phosphor Bronze strings because they are more resistant to corrosion and wear. However, the actual longevity can vary based on playing style, frequency of use, and maintenance.

Q: Can the choice between Monel vs Phosphor Bronze strings affect my playing style?

A: Yes, the choice between Monel and Phosphor Bronze strings can impact your playing style due to their different tonal qualities. For instance, Monel strings might encourage more expressive, dynamic playing due to their warmer tones, while Phosphor Bronze strings might suit players looking for a brighter, more pronounced sound.

Q: How should I decide between using Monel or Phosphor Bronze strings?

A: The decision between Monel and Phosphor Bronze strings should be based on your preferred tone, playing style, and guitar type. If you prefer a warm, vintage sound, Monel strings could be the right choice. For a bright, clear tone, Phosphor Bronze strings might be more suitable. Consider trying both to see which complements your musical preferences.