Essential Knowledge: Non-magnetic stainless steel represents a specialized category of alloys that combines exceptional corrosion resistance with the unique property of magnetic neutrality. This comprehensive guide explores the science, applications, and advantages of these remarkable materials.

When it comes to stainless steel, different types exhibit varying levels of magnetic attraction—with some displaying no magnetism at all. Engineers, manufacturers, and consumers alike need to understand the significance of non-magnetic stainless steel, which finds applications in everything from medical equipment to aerospace structures.

What is Non-Magnetic Stainless Steel?

Non-magnetic stainless steel refers to specific stainless steel alloys that display no magnetism even when exposed to magnetic fields. This property results from their unique crystal structure, specifically the face-centered cubic (FCC) lattice arrangement found in austenitic stainless steels.

Key Characteristics:

- Crystal Structure: Face-centered cubic (FCC) arrangement

- Primary Grades: 304, 316, 310, and 316L

- Magnetic Permeability: Very low, making them ideal for sensitive applications

- Composition: High nickel and chromium content

Definition and Composition

Non-magnetic materials are those that do not become magnetized when exposed to external magnetic fields. In stainless steel, this property is achieved through specific compositional elements:

| Element | Typical Range (%) | Primary Function |

|---|---|---|

| Chromium | 16-26% | Corrosion resistance, oxide layer formation |

| Nickel | 8-35% | Austenite stabilization, non-magnetic properties |

| Molybdenum | 2-7% | Enhanced corrosion resistance, especially chlorides |

| Manganese | 2% | Deoxidation, austenite formation |

| Carbon | ≤0.08% | Strength (kept low to maintain corrosion resistance) |

Difference Between Magnetic and Non-Magnetic Stainless Steel

The fundamental differences between magnetic and non-magnetic stainless steel lie in their microstructure and composition:

Non-Magnetic (Austenitic)

- Face-centered cubic crystal structure

- High nickel content (8-35%)

- Excellent corrosion resistance

- Superior formability

- Ideal for food processing and medical applications

Magnetic (Ferritic/Martensitic)

- Body-centered cubic crystal structure

- Low or no nickel content

- Magnetic properties present

- Generally lower cost

- Used in automotive and appliance applications

Important Note: Even austenitic stainless steels can develop slight magnetism through cold working, welding, or mechanical deformation. This can be reversed through annealing processes.

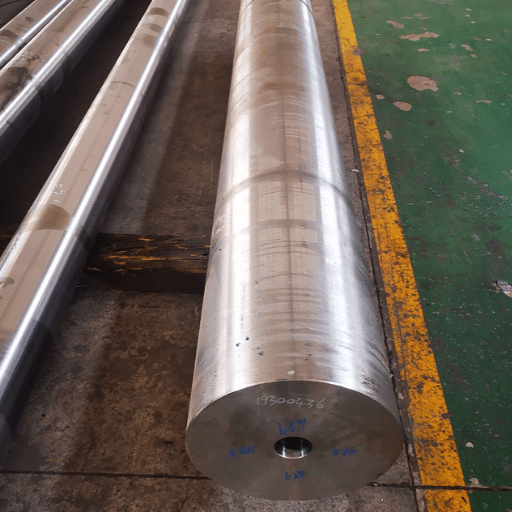

Common Grades of Non-Magnetic Stainless Steel

The 300 series represents the most widely used non-magnetic stainless steels, each offering unique properties for specific applications:

Grade 304 (18-8 Stainless)

Composition: 18% Chromium, 8% Nickel

Properties: General-purpose grade with excellent corrosion resistance and formability. Most widely used austenitic stainless steel.

Applications: Kitchen equipment, food processing, architectural applications, chemical containers

Grade 316 (Marine Grade)

Composition: 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum

Properties: Superior corrosion resistance, especially against chlorides and marine environments.

Applications: Marine equipment, medical implants, pharmaceutical equipment, chemical processing

Grade 316L (Low Carbon)

Composition: Similar to 316 but with ≤0.03% Carbon

Properties: Enhanced weldability and corrosion resistance in sensitized conditions.

Applications: Welded structures, pharmaceutical equipment, high-purity applications

Grade 310

Composition: 24-26% Chromium, 19-22% Nickel

Properties: Exceptional high-temperature and oxidation resistance.

Applications: Furnace components, heat exchangers, high-temperature processing equipment

Key Alloys in Non-Magnetic Stainless Steel

The Role of Chromium

Chromium is the defining element in stainless steel, providing corrosion resistance through the formation of a passive chromium oxide layer. This invisible, self-healing layer prevents further oxidation and corrosion. Key benefits include:

- Minimum Content: 10.5% required for stainless classification

- Optimal Range: 16-26% in non-magnetic grades

- Protection Mechanism: Forms Cr₂O₃ passive layer

- Self-Healing: Layer regenerates when damaged in oxygen-rich environments

The Importance of Nickel

Nickel serves multiple critical functions in non-magnetic stainless steel:

- Austenite Stabilization: Maintains face-centered cubic structure at room temperature

- Non-Magnetic Properties: Essential for achieving magnetic neutrality

- Corrosion Enhancement: Improves resistance in reducing environments

- Toughness: Increases ductility and impact resistance

- Temperature Stability: Maintains properties across wide temperature ranges

Comparison of Austenitic and Ferritic Alloys

| Property | Austenitic (Non-Magnetic) | Ferritic (Magnetic) |

|---|---|---|

| Crystal Structure | Face-Centered Cubic (FCC) | Body-Centered Cubic (BCC) |

| Magnetic Properties | Non-magnetic (low permeability) | Magnetic |

| Nickel Content | 8-35% | 0-1% |

| Corrosion Resistance | Excellent in most environments | Good, better in reducing conditions |

| Formability | Excellent | Limited |

| Weldability | Good | Fair to good |

| Cost | Higher (due to nickel) | Lower |

| Stress Corrosion Cracking | Susceptible in chloride environments | More resistant |

Applications of Non-Magnetic Stainless Steel

Medical Instruments and Equipment

Critical for MRI compatibility and surgical instruments where magnetic interference must be eliminated.

- Surgical instruments and implants

- MRI machine components

- Dental equipment

- Diagnostic instruments

Food Processing and Handling

Essential for maintaining hygiene and preventing contamination in food production.

- Processing tanks and mixers

- Conveyor systems

- Storage containers

- Heat exchangers

Electronics and Electrical

Prevents electromagnetic interference in sensitive electronic applications.

- Electronic enclosures

- Transformer housings

- Switchgear cabinets

- Precision instruments

Cryogenic Applications

Maintains ductility and strength at extremely low temperatures.

- Liquid nitrogen containers

- Cryogenic piping systems

- Space industry components

- Research equipment

Marine and Offshore

Excellent corrosion resistance in saltwater environments.

- Ship components

- Offshore platforms

- Propeller shafts

- Seawater piping

Aerospace Industry

Lightweight, strong, and temperature-resistant for aircraft applications.

- Engine components

- Fuel tanks

- Fasteners

- Heat shields

Industries Utilizing Non-Magnetic Stainless Steel

Healthcare and Medical

The healthcare industry relies heavily on non-magnetic stainless steel for both safety and performance:

- MRI Compatibility: Essential for imaging equipment functionality

- Biocompatibility: Safe for long-term implantation

- Sterilization: Withstands repeated autoclave cycles

- Precision: Maintains sharp edges for surgical instruments

Energy and Nuclear

Critical applications in power generation and nuclear facilities:

- Radiation Resistance: Maintains properties under radiation exposure

- High Temperature: Performs in extreme thermal conditions

- Corrosion Protection: Resists aggressive coolants and chemicals

- Safety Systems: Reliable performance in critical applications

Understanding the Properties of Non-Magnetic Stainless Steels

Corrosion Resistance

Non-magnetic stainless steels offer superior corrosion resistance through multiple mechanisms:

| Corrosion Type | Resistance Level | Mechanism |

|---|---|---|

| General Corrosion | Excellent | Passive chromium oxide layer |

| Pitting Corrosion | Very Good (316 grades) | Molybdenum addition |

| Crevice Corrosion | Good to Excellent | High chromium and molybdenum content |

| Intergranular Corrosion | Excellent (L grades) | Low carbon content prevents sensitization |

| Stress Corrosion Cracking | Moderate | Susceptible in chloride environments above 60°C |

Mechanical Properties

Non-magnetic stainless steels exhibit excellent mechanical characteristics:

- Tensile Strength: 515-620 MPa (75-90 ksi) for annealed condition

- Yield Strength: 205-310 MPa (30-45 ksi)

- Elongation: 40-60% in 2 inches

- Hardness: 150-200 HB (Brinell)

- Impact Toughness: Excellent at both room and cryogenic temperatures

Thermal Conductivity and Its Importance

Thermal properties play a crucial role in application selection:

Key Thermal Properties:

- Thermal Conductivity: 14-16 W/m·K (lower than carbon steel)

- Thermal Expansion: 17-18 × 10⁻⁶/°C

- Specific Heat: 500 J/kg·K

- Operating Range: -196°C to 800°C depending on grade

Case Studies of Non-Magnetic Stainless Steel Use

Case Study 1: Aerospace Cryogenic Applications

In rocket fuel systems, non-magnetic stainless steel 316L is used for cryogenic storage tanks containing liquid oxygen and hydrogen. The material’s ability to maintain toughness at -253°C while remaining non-magnetic prevents interference with navigation systems.

Key Benefits: Cryogenic toughness, dimensional stability, no magnetic interference

Case Study 2: MRI Machine Manufacturing

Medical equipment manufacturers use 304 and 316L stainless steel for MRI machine components. The non-magnetic properties ensure no interference with the powerful magnetic fields (up to 3 Tesla) while providing corrosion resistance and biocompatibility.

Key Benefits: Magnetic neutrality, patient safety, long-term reliability

Trends and Innovations in Non-Magnetic Stainless Steel

Recent Developments in Alloy Composition

Modern metallurgy focuses on enhancing performance while maintaining environmental responsibility:

- Nitrogen Alloying: Replacing nickel partially with nitrogen for strength enhancement

- Lean Duplex Grades: Combining austenitic and ferritic properties

- High-Entropy Alloys: Multi-element compositions for extreme environments

- Nano-Enhanced Surfaces: Surface treatments for improved properties

Future Prospects for Non-Magnetic Stainless Steels

Emerging applications and technologies drive continued development:

- Renewable Energy: Wind turbine components and solar panel structures

- Electric Vehicles: Battery housings and charging infrastructure

- Advanced Manufacturing: 3D printing and additive manufacturing applications

- Sustainable Production: Improved recycling and energy-efficient manufacturing

Environmental Considerations and Sustainability

Non-magnetic stainless steel contributes to environmental sustainability through several mechanisms:

Environmental Benefits

- 100% Recyclable: Can be recycled indefinitely without property loss

- Long Service Life: Reduces replacement frequency and waste

- Energy Efficiency: Manufacturing improvements reduce energy consumption

- Corrosion Resistance: Eliminates need for protective coatings

Environmental Challenges

- Energy-Intensive Production: High melting temperatures required

- Nickel Mining: Environmental impact of nickel extraction

- Transportation: Heavier than alternative materials

- Initial Cost: Higher upfront investment

References

-

Is Stainless Steel Magnetic? – University of Maryland – Explains how the addition of nickel creates non-magnetic austenitic stainless steel.

-

Non-Magnetic Stainless Steels – Fermilab – Discusses the structural properties and applications of austenitic stainless steels.

-

“Non-Magnetic” Materials May Become Magnetized – NASA – Highlights scenarios where non-magnetic stainless steel can become residually magnetized.

Frequently Asked Questions (FAQ)

What is the meaning of stainless steel that is not magnetic?

Sympathetic to the meaning of stainless steel, such elements contain no magnetism. Alternatively, these are austenitic steels with permanent crystal structures and cubes for example grade 2H and3H achieve such characteristics which are realized in better corrosion and shielding of forces from outside with a non-magnetic factor in place as well.

Do all types of stainless steel possess magnetism?

‘Not all types of steel possessing chromium are also magnetic steels’. Some chromium steels have come up in existence but it does not mean that all steels fit that definition. These types include mainly the martensitic and ferritic structures that could be magnetic. Austenitic type steels, more precisely 304 or 316 steels, because of higher content of Nickel in their chemical structure are mainly non-magnetic.

Which are the non magnetic stainless steel with respect to types?

The most practical and commonly used non magnetic stainless steel consists of austenite and thus belongs to the group of austenitic stainless steels. Typical examples would include Grade 316 and 304 where nickel composition stabilizes austenite phase to prevent it from transforming to ferrite phase and hence making them non Magnetic.

Is there a possibility of stainless steel becoming magnetic?

There are circumstances under which stainless steel can be magnetised. Such as during massive strains of cold work on austenitic stainless steel, some magnetism may result. It also happens when ferrite is present or martensitic stainless steel is formed during the processes of metal treatment.

How do ferritic stainless steels differ from austenitic stainless steels?

Ferritic stainless steels contain more of the elements iron and chromium which is why they have a ferritic structure and some form of magnetic characteristics. On the contrary, austeittic non magnetic grade 304 stainless steels have nickel. As for stress corrosion cracking, ferritic steels are better in comparison, but as to the corrosion resistance property austenic steels are better.

Do all stainless steel grades exhibit the same magnetic behavior?

There is a difference in stainless steel grades in terms of their magnetic properties. Ferritic materials, examples of which include 403 and 409, are known to have excellent magnetic properties; however, austenitic materials such as 304 and 316 do not possess such properties or have weak magnetic properties. It is possible for martensitic stainless steels to become magnetic because they are rich in iron.

Does the magnetism of stainless steels depend on their chemical composition, and, if so, how?

The chemical composition is of paramount importance in the development of stainless steels’ magnetic properties. In the case of austenitic stainless steels nickel is added to suppress the formation of any ferrites and hence such steels are non-magnetic. On the contrary, ferritic stainless steels often contain significant portions of chromium and iron that enhances the magnetic properties of the material.

What are usual uses for non-magnetic stainless steel?

Austenitic stainless steels of 304 and 316 grades are used in situations where the magnetic aspect of the material is undesirable. These include implements used in medicine, cooking, and even in the sea, where both corrosion and magnetic possibilities are not desired.

What are the cons of non magnetic stainless steel if any?

Non-magnetic stainless steels perform well in corrosion environments and are perfect for many uses, yet they are sometimes not as robust as magnetic types of stainless steels for example martensitic stainless steels. Apart from that they are likely to cost more due to high nickel content and may as well be less easy to weld. It is important to note the nature of the application before choosing a broad range of spectrum of available material.