Premium Copperubing Manufacturer in China

Seamless Copper Tubing for HVAC, Plumbing & Industrial Applications. Premium Copper Tubes, exceptional corrosion resistance, and unmatched reliability.

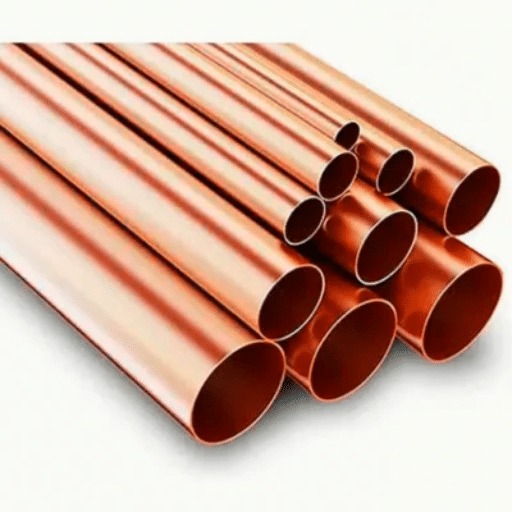

Copper Tubes

- Premium Quality

- Customizable Sizes

- Industrial Grade

Overview :

Description :

Copper tubing is a metal pipe commonly used for water supply lines, heating systems, and air conditioning and refrigeration (HVAC). The seamless manufacture of copper tubing gives it a smooth interior, improving flow and preventing corrosion. Often, the type of copper is specified for its intended application and copper material composition. Different types are used to plumb residential and commercial buildings due to the tube’s durability.

Copper has been the material of choice for plumbing, HVAC, refrigeration, and industrial piping. Its unique combination of properties delivers unmatched performance and longevity. There are primarily four types of copper tubing: Type K, Type L, Type M, and DWV copper. DWV copper is specific to drain applications. Each type is marked for easy identification by a supplier.

Get a Quote

Explore the differences in our Copper Tubes

Copper Tubes by Application

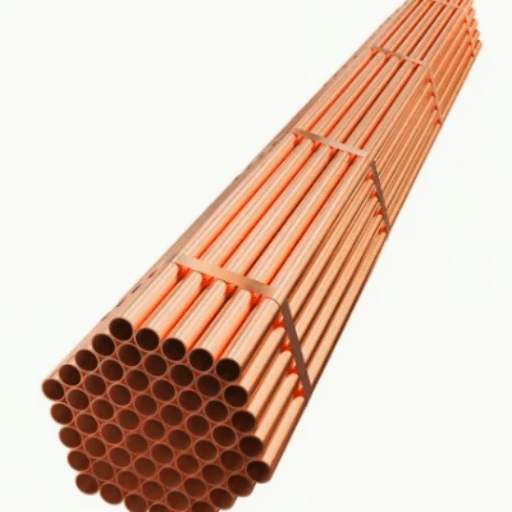

Copper tubes are widely used in plumbing, HVAC systems, refrigeration, and industrial applications due to their excellent thermal conductivity, corrosion resistance, and durability.

Copper Tubes by Material

Available in various grades such as pure copper, alloyed copper (e.g., brass or bronze), and oxygen-free copper, each type is tailored for specific performance needs and environments.

Copper Tubes by Manufacturing

Manufactured through processes like extrusion, drawing, and annealing, copper tubes are crafted to meet precise dimensions and mechanical properties for diverse applications.

Copper Tubes by Wall Thickness

Copper tubes come in varying wall thicknesses, from thin-walled for lightweight applications to thick-walled for high-pressure systems, ensuring suitability for different operational demands.

Get More Information

Feel free to reach out to us for pricing, availability, or any additional information. Let us help you find the perfect Copper Tubes solution for your industry needs.

Why Choose Us

- Industry Expertise: Over decades of experience in manufacturing high-quality copper tubes.

- Certified Quality: Meets international standards for safety and performance.

- Custom Solutions: Available in straight lengths, coils, or custom configurations.

- Sustainability: Environmentally friendly production processes.

Why Copper Delivers Superior Value

Initial cost is only part of the equation. Copper's lifecycle advantages deliver the lowest total cost of ownership.

50+ Year Service Life

Copper plumbing systems routinely exceed 50 years of service life with minimal maintenance. Many copper water lines installed in the 1950s-70s are still performing flawlessly today—outlasting the buildings they serve.

Lower Installation Costs

Lightweight design (30% lighter than steel), field formability, and standard joining methods reduce installation time by 20-30%. No special tools or certified welders required—any HVAC/plumbing contractor can work with copper.

Energy Efficiency

Superior thermal conductivity means smaller coils, less refrigerant charge, and lower operating costs. HVAC systems with copper coils typically use 15-20% less energy than aluminum alternatives for equivalent capacity.

Zero Maintenance

Once installed, copper requires virtually no maintenance. No protective coatings to maintain, no cathodic protection systems, no periodic inspections for corrosion. Set it and forget it for decades.

Universal Code Approval

Accepted by all major plumbing and mechanical codes worldwide (UPC, IPC, IMC, NFPA). Pre-approved material eliminates plan review delays and inspection issues. Required by code for many critical applications.

Health & Safety

EPA-registered antimicrobial surface kills 99.9% of bacteria. No VOC emissions, no leaching of plasticizers or additives. NSF/ANSI 61 certified for drinking water contact with no health advisory levels.

Key Features of Copper Tubes

- The superior corrosion resistance of copper tube is a key feature, ensuring longevity and reliability in various applications. Copper material inherently resists corrosion, making copper tubing ideal for potable water systems.

- Copper tube is available in both soft annealed and hard tempered conditions, each offering distinct advantages. Soft annealed copper tubing, also known as copper coil, is highly malleable and easy to bend.

- Hard tempered copper pipe, or straight lengths, provides greater rigidity and strength.To further enhance the corrosion resistance and durability of copper tubing, various coating options are available.

- These coatings provide an additional layer of protection against environmental factors, extending the lifespan of the copper pipe, especially in harsh conditions. A coat can improve the performance of copper tubing.

- The malleability of copper tubes allows for easy bending and shaping, simplifying installation.

- Copper's antimicrobial properties make it a popular choice for drinking water. This ensures the copper water is always safe.

Manufacturing Process

- High-purity copper (99.9%) is sourced and refined to ensure quality.The raw copper is melted and cast into billets or ingots.

- The copper billets are heated and extruded into hollow tubes.This process shapes the copper into its initial tubular form.

- The extruded tubes are drawn through dies to achieve the desired diameter and wall thickness.This step ensures precision and consistency in dimensions.

- The tubes are heated and slowly cooled to improve flexibility and reduce internal stresses.This process enhances the mechanical properties of the copper.

- The tubes are polished to achieve a smooth, oxidation-free surface.Additional treatments, such as pickling or bright annealing, may be applied for specific finishes.

- The tubes are cut to the required lengths based on customer specifications.Precision cutting ensures uniformity and ease of installation.

- Each tube undergoes rigorous testing for dimensions, wall thickness, and mechanical properties.Non-destructive testing methods, such as eddy current testing, ensure defect-free products.

Copper Tubes Specification Physical Properties

| Property | Value | Unit | Notes |

|---|---|---|---|

| Density | 8.94 | g/cm³ | At 20°C |

| Melting Point | 1,083 | °C | Pure copper |

| Thermal Conductivity | 401 | W/m·K | At 20°C - Highest among common metals |

| Electrical Conductivity | 100% IACS | IACS | International Annealed Copper Standard |

| Coefficient of Thermal Expansion | 16.5 | ×10⁻⁶/K | 20-300°C range |

| Specific Heat Capacity | 385 | J/kg·K | At 20°C |

| Electrical Resistivity | 1.72 | ×10⁻⁸ Ω·m | At 20°C |

Specifications of Copper Pipes and Tubes

Certifications and Standards

All our copper products meet or exceed industry standards, including ASTM and relevant plumbing codes. These certifications validate the quality, performance, and safety of our copper tubing. Meeting those standards ensures safety and quality when working with natural gas, for example. Meeting these standards is important so that you can specify copper.

Medical Gas Tubes

Ultra-clean copper tubes for medical gas systems (oxygen, nitrogen, nitrous oxide). Cleaned per CGA G-4.1 standards with special caps to maintain cleanliness until installation.

DWV - Drainage Waste Vent

Designed for drainage, waste, and vent systems. Thinner walls suitable for non-pressure applications. Corrosion-resistant for long-term reliability in drain systems.

ACR - Air Conditioning & Refrigeration

Seamless, dehydrated, nitrogen-charged tubes specifically for refrigeration and air conditioning. Cleaned, sealed, and ready for immediate use with refrigerants including R-410A, R-32, and CO₂.

Type L - Medium Wall

Most versatile and widely used. Standard for interior plumbing, commercial water distribution, hydronic heating, medical gas, and residential water supply systems. Best balance of strength and economy.

✷ Applications of Copper Tubes✷

Copper tubes are the trusted solution across diverse industries requiring reliable, efficient, and long-lasting piping systems.

Medical & Healthcare

Industrial Processing

Commercial Buildings

Solar & Renewable Energy

Residential Plumbing

HVAC & Refrigeration

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Frequently Ask Questions

Q: How is soldering applied to copper pipes?

A: Soldering is a common method used to join copper pipes. It involves heating the joint with a torch until the solder melts and fills the gap, creating a strong bond. Proper cleaning and preparation of the pipe ends are essential to ensure a strong connection. DIY enthusiasts often find soldering copper tubes to be a straightforward process with the right tools and safety precautions.

Q: What are the quality standards for copper tubing?

A: Quality standards for copper tubing are established by organizations such as ASTM and ANSI. These standards ensure that the tubing meets specific requirements for dimensions, wall thickness, and corrosion resistance. Homeowners should look for copper tubes that comply with these standards to ensure reliability and durability in their plumbing systems.

Q: What is the significance of nominal size in copper tubing?

A: Nominal size refers to the approximate measurement of the outside diameter of the copper tubing. It is important for determining compatibility with fittings and other components in plumbing systems. For instance, a nominal size of 1/2 inch means the outside diameter is about 5/8 inch, which is crucial for ensuring a proper fit in installations.

Q: Can copper tubes be used for fire protection systems?

A: Yes, copper tubes are often used in fire protection systems due to their durability and resistance to corrosion. They can withstand high temperatures and are suitable for both residential and commercial fire sprinkler systems. Type L and Type K copper tubing are particularly recommended for these applications because of their thicker walls.

Q: What is the difference between soft annealed and rigid copper tubing?

A: Soft annealed copper tubing is flexible and can be easily bent or shaped, making it ideal for DIY projects and installations in tight spaces. Rigid copper tubing, on the other hand, is not as pliable and is typically used in applications requiring straight runs and structural integrity, such as gas lines and refrigeration systems.

Q: How do I choose the right diameter of copper tubing for my project?

A: Choosing the right diameter of copper tubing depends on the specific application and the flow requirements. For plumbing and water supply, common diameters range from 1/2 inch to 2 inches. Homeowners should consider the pressure and volume of water needed for their systems when selecting the diameter to ensure optimal performance.