Get in touch with us

Leave a message

+8615057563345

+8615057563345

Engineered with precision technology for exceptional corrosion resistance, structural integrity, and long-term reliability in demanding industrial environments.

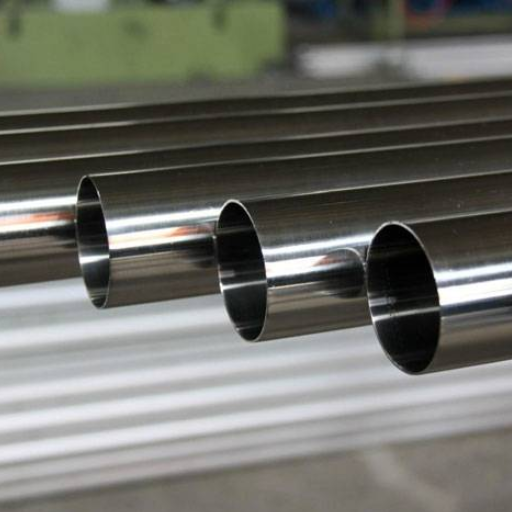

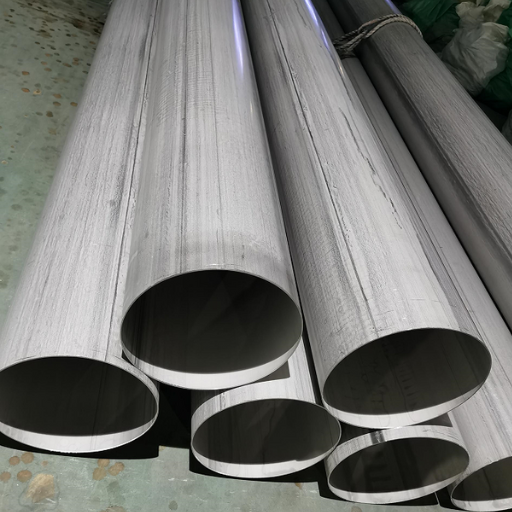

Electropolished Stainless Steel Tubing is a premium piping solution tailored for the stringent demands of high-purity, industrial, and sanitary applications. Crafted using advanced manufacturing techniques and finished with electropolishing—an electrochemical process—these tubes offer exceptional corrosion resistance, strength, and an ultra-smooth surface. Ideal for fluid transport and critical systems, they are available in various diameters, thicknesses, and lengths, providing customization flexibility while meeting standards like ASTM A269, A270, and ASME BPE.

The electropolished finish ensures a mirror-like smoothness and enhanced cleanliness, vital for industries such as pharmaceuticals, food processing, and semiconductor manufacturing. With precise engineering and rigorous quality controls, Electropolished Stainless Steel Tubing delivers reliable performance in demanding environments, making it a trusted choice for high-pressure and hygienic applications requiring long-term durability.

Our 304 electropolished stainless steel tubing offers a versatile, cost-effective solution. The ultra-smooth, high-purity surface provides excellent corrosion resistance, making it ideal for general industrial, food & beverage, and architectural applications where cleanliness and performance are essential.

Engineered for critical applications, our 316L electropolished tubing delivers superior corrosion resistance, especially against chlorides. Its low-carbon, high-purity surface is perfect for pharmaceutical, biotech, semiconductor, and marine environments requiring ultimate cleanliness and durability.

Our 304L electropolished stainless steel tube features a low-carbon content for enhanced weldability. It prevents post-weld corrosion, ensuring long-term integrity for fabricated systems. The ultra-clean, smooth surface is ideal for food processing and chemical equipment applications.

Feel free to reach out to us for electropolished ss tubing price, availability, or any additional information. Let us help you find the perfect stainless steel piping solution for your industry needs.

Unlock the potential of electropolished pipe with customized solutions for your unique applications

Because of their surface finish, electropolished stainless steel pipes will continue to gain adoption in industries such as semiconductors and pharmaceuticals which require a higher degree of cleanliness.

The upcoming advances in electropolishing technology will offer increased precision, enhanced accuracy in addressing pipe quality, and diminished environmental impact during production.

Via the use of smart manufacturing, pipes can now be tailored as per customer requirements to satisfy varying functions.

With improved surface treatments pipes can better withstand corrosion and handle harsher environments.

Reduced expenditures for an increasing number of industries to afford this type of pipe will be possible due to automated production.

In the future, it may be combined with new materials to improve antibacterial or heat transfer capabilities and be used in medical or new energy fields.

| Grade | Type | Corrosion Resistance | Strength | Applications |

|---|---|---|---|---|

| 304/304L | Seamless/Welded | High; enhanced by electropolishing to resist pitting and crevice corrosion | Moderate (Yield: ~210 MPa annealed; up to 1050 MPa cold-worked) | Food processing, architectural, general industrial use |

| 316/316L | Seamless/Welded | Excellent; superior in chloride and acidic environments due to molybdenum | Moderate (Yield: ~210 MPa annealed; up to 1050 MPa cold-worked) | Pharmaceutical, semiconductor, marine, chemical processing |

| 321/321H | Seamless/Welded | High; resists intergranular corrosion post-welding | Moderate to High (Yield: ~205 MPa annealed) | Aerospace, heat exchangers, high-temperature systems |

| 2205 (Duplex) | Seamless/Welded | Very High; excels in harsh, chloride-rich conditions | High (Yield: ~450 MPa annealed) | Oil & gas, desalination, petrochemical industries |

| 2507 (Super Duplex) | Seamless/Welded | Exceptional; ideal for extreme corrosive environments | Very High (Yield: ~550 MPa annealed) | Offshore platforms, subsea pipelines, chemical plants |

| 17-4 PH | Seamless | Good; improved by electropolishing, moderate in harsh conditions | Very High (Yield: up to 1730 MPa heat-treated) | Valves, gears, surgical instruments, aerospace components |

Certainly, employing steel wool for polishing stainless steel is an effective method in getting rid of deep marks or scratches, although, grade #0000 should be used. Be careful to not apply too much pressure, and do a preliminary test on an inconspicuous area first. So as to achieve the desired effect, polish with the direction of the grain of the stainless steel, referred to as the grain.

By smoothing the surface, removing flaws and corrosion, electropolishing increases tubing performance. It has reduced friction, improved cleanliness and increased durability making it useful for sanitary, industrial and high purity applications.

Stainless steel corrosion resistance is improved through Electropolishing by dissolving the oxidized layer. Additionally, minor cases of surface rust may also be eliminated. Deep rust, on the other hand, stands to benefit little from electropolishing and may require some mechanical cleaning first.

Yes, electropolishing removes burrs by smoothing metal surfaces through controlled electrochemical dissolution. It effectively deburrs edges and corners, enhancing tubing finish and performance, especially in precision applications.

Yes, electropolishing removes burrs by smoothing metal surfaces through controlled electrochemical dissolution. It effectively deburrs edges and corners, enhancing tubing finish and performance, especially in precision applications.

Electropolished Pipe tubes offer versatile solutions across industries, combining durability, corrosion resistance, and precision for a wide range of applications.

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

A: Suppliers remark on its resistance to corrosion, smooth surface, and hygiene regarding the pharmaceuticals and food processing industries.

A: They use high-grade steel, follow ASTM standards, and apply advanced electropolishing, verified by testing.

A: Grade, size, raw material costs, and electropolishing fees; typically $100–$500 USD.

A: It removes imperfections, boosts chromium oxide, and enhances corrosion resistance for harsh environments.

A: It removes imperfections, boosts chromium oxide, and enhances corrosion resistance for harsh environments.

A: Its ultra-smooth surface (Ra < 10 µin) prevents contamination, meeting pharma and biotech standards.

Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd., specializes in high-quality stainless steel pipes and fittings, offering reliable solutions for industrial applications worldwide.