Premium Galvanized Steel Coils Manufacturer in China

Discover high-performance galvanized steel coils engineered for superior corrosion resistance and durability. Our comprehensive inventory features hot dipped galvanized steel solutions that meet stringent industry standards, delivering reliable protection for diverse applications across automotive, construction, and manufacturing sectors.

Galvanized Steel Coils

- Corrosion Resistant

- Highly Formable

- Quality Certified

Overview :

Description :

Galvanized steel coils represent the optimal solution for applications demanding long-lasting corrosion protection and structural integrity. Our carbon steel coated products feature a protective layer of zinc applied through advanced hot-dip galvanizing processes, creating a metallurgical bond that shields the underlying steel substrate from oxidation and deterioration. This sacrificial zinc coating provides a formidable barrier against environmental elements, extending material lifespan significantly.

As a trusted galvanized steel supplier and distributor, we maintain an extensive inventory of galvanized coil products in various gauges, widths, and coating weights. Our galvanized steel products undergo rigorous quality testing to ensure compliance with exact specifications, supporting fabrication requirements across construction, automotive, appliance manufacturing, and industrial applications. Each coil delivers consistent performance, excellent formability, and reliable corrosion resistance for demanding environments.

Get a Quote

Explore Our Galvanized Steel Coils Types

Pre-painted Galvanized Steel Coils

Premium color coated galvanized coils featuring polyester, PVDF, or SMP paint systems over zinc substrate. Available in RAL, custom colors with superior UV resistance, scratch protection, and aesthetic versatility for roofing, cladding, and appliance applications requiring decorative finishes.

Hot Dipped Galvanized Steel Coils

Continuous hot-dip galvanized coils with zinc coating weights from Z90-Z600 providing maximum corrosion protection. Ideal for structural applications, manufacturing, and outdoor environments demanding long-term durability without painting. Multiple spangle finishes and substrate grades available for various forming requirements.

Galvalume Steel Coils

Aluminum-zinc alloy coated steel coils combining aluminum's heat reflectivity with zinc's sacrificial protection. Superior performance in high-temperature and coastal environments. Excellent base for painting with enhanced corrosion resistance compared to traditional galvanized products for demanding architectural applications.

Get More Information

Connect with our material specialists to discuss your project specifications, request custom quotes, or explore our complete inventory. We provide technical guidance, samples, and tailored solutions that meet your exact requirements and delivery schedules.

Why Choose Us

- Extensive Inventory Selection: Wide range of galvanized steel coil specifications, coating weights, and widths available for immediate shipment and rapid project fulfillment

- Rigorous Quality Standards: Every coil tested per ASTM protocols ensuring consistent zinc coating thickness, substrate integrity, and compliance with international specifications

- Custom Processing Services: Precision slitting, cutting, and surface treatment capabilities deliver materials to exact dimensions and specifications for your applications

- Technical Engineering Support: Dedicated material experts provide specification guidance, application recommendations, and problem-solving assistance throughout your project lifecycle

Tailored Solutions for Diverse Industries

We deliver comprehensive steel processing and supply chain services designed to meet your unique operational requirements and industry standards.

Custom Processing

Precision slitting and cutting services produce exact widths and lengths tailored to your specifications, eliminating material waste and streamlining manufacturing workflows across construction, automotive, and appliance industries.

Flexible Delivery

Coordinated logistics and just-in-time programs synchronize material arrival with production schedules, reducing inventory costs while ensuring uninterrupted supply for manufacturing operations across diverse industrial applications.

Material Consultation

Expert engineers recommend optimal substrate grades and coating specifications based on your application environment, helping construction, agricultural, and industrial sectors achieve performance targets within budget.

Quality Documentation

Complete mill certificates and compliance reports accompany every shipment, supporting ISO quality systems and regulatory requirements across automotive, electrical, and manufacturing industries with full material traceability.

Sample Programs

Complimentary samples enable testing before production orders, allowing engineering teams across HVAC, appliance, and fabrication sectors to verify formability, coating performance, and application compatibility.

Contract Pricing

Volume agreements provide competitive rates and price stability for recurring needs, benefiting high-volume industries including construction, telecommunications, and manufacturing with dedicated account management and priority allocation.

Superior Corrosion Protection Technology

- Multi-Layer Defense System: Hot dipped galvanized coating creates zinc-iron alloy layers providing sacrificial protection that prevents rust formation

- Extended Service Life: Zinc coating barrier extends material durability by 20-50 years depending on environmental exposure conditions

- Self-Healing Properties: Galvanization process enables zinc to protect scratched or cut edges through cathodic protection mechanisms

- Environmental Resistance: Proven performance against moisture, salt spray, chemical exposure, and temperature fluctuations in harsh conditions

- Maintenance Reduction: Protective zinc layer eliminates painting requirements and reduces long-term maintenance costs significantly

Precision Manufacturing Process

- Continuous Galvanizing Line: State-of-the-art hot-dip process ensures uniform zinc coating distribution across entire coil surface area

- Controlled Coating Weight: Precise molten zinc bath management delivers consistent coating thickness

- Substrate Quality Control: Cold rolled carbon steel base material meets strict chemical composition and mechanical property requirements

- Surface Treatment Options: Post-galvanizing processes including chromating, phosphating, and passivation enhance coating adhesion and longevity

- Quality Testing Protocols: Comprehensive inspection includes coating weight measurement, bend testing, and adhesion verification per industry standards

Specifications for Galvanized Steel Coils

| Specification | Range/Options |

|---|---|

| Substrate Material | Commercial quality, structural quality, deep drawing quality carbon steel |

| Coating Type | Hot-dip galvanized, electro-galvanized, galvannealed |

| Zinc Coating Weight | Z90 (0.90 oz/ft²) to Z600 (2.00 oz/ft²), G30-G90 designation |

| Thickness Range | 0.15mm - 3.0mm (various gauge options available) |

| Width Range | 600mm - 1500mm standard, custom slit widths available |

| Coil Weight | 3-10 metric tons per coil, custom weights available |

| Tensile Strength | 270-550 MPa depending on grade specification |

| Yield Strength | 140-550 MPa based on substrate grade selection |

| Elongation | 10-45% minimum depending on material grade |

| Surface Finish | Regular spangle, minimized spangle, zero spangle, skin-passed |

| Surface Treatment | Chromated, phosphated, oiled, dry, passivated options |

| Edge Condition | Mill edge, slit edge, trimmed edge available |

| Coil ID | 508mm (20) or 610mm (24") standard bore sizes" |

| Spangle Type | Normal, minimized, spangle-free for painting applications |

| Coating Adhesion | Pass bend test per ASTM A653 requirements |

Technical Insights on Galvanized Steel Coils

How do I select the right zinc coating weight?

Choose coating weight based on environmental exposure and service life expectations. Indoor or sheltered applications perform well with Z90-Z180 coatings. Moderate outdoor environments require Z180-Z275. Severe coastal or industrial conditions demand Z350-Z600. Heavier coatings proportionally extend protection duration and corrosion resistance.

What affects galvanized steel formability and welding?

Hot-dip galvanizing adds zinc coating that influences forming and welding operations. Select appropriate substrate grades (commercial, drawing, or deep drawing quality) based on forming severity. Zinc vaporization during welding requires proper ventilation and modified parameters. Resistance welding works well; arc welding may benefit from coating removal at joints.

How do different spangle finishes impact applications?

Regular spangle creates visible crystalline patterns ideal for exposed architectural applications. Minimized spangle provides uniform appearance for general industrial use. Zero spangle delivers smooth surfaces optimal for painting operations where coating adhesion and uniform finish are critical. Skin-passing further improves paint system performance.

What storage practices prevent white rust formation?

Store coils indoors or under breathable waterproof covers in well-ventilated areas below 60% humidity. Provide adequate spacing with dunnage preventing moisture accumulation. Newly galvanized material requires 48-hour air-cure before wrapping. Avoid plastic wrapping that traps condensation. First-in-first-out rotation ensures timely material utilization.

Are galvanized steel coils sustainable and recyclable?

Galvanized steel is infinitely recyclable without quality loss, and zinc coating is fully recoverable during recycling. Extended service life reduces replacement frequency and associated environmental impacts. Life cycle assessments demonstrate favorable carbon footprint compared to alternatives requiring frequent maintenance or replacement, supporting circular economy principles.

✷ Applications of Galvanized Steel Coils✷

Our galvanized steel coils serve critical functions across diverse sectors, delivering corrosion protection and structural performance for demanding applications.

Construction and Building Materials

Automotive Manufacturing

Appliance and HVAC Equipment

Agricultural Equipment

Electrical and Telecommunications

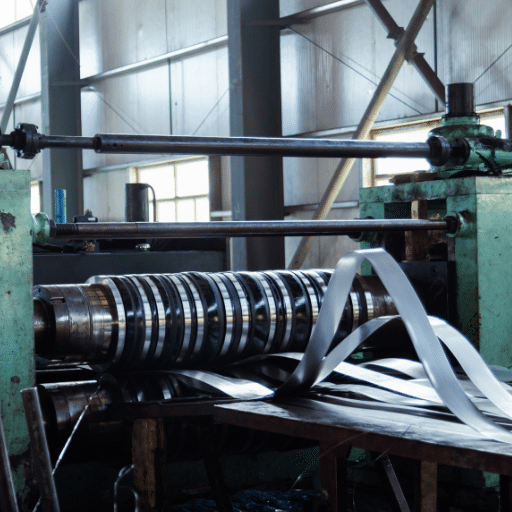

Industrial Manufacturing

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Frequently Ask Questions

What is the difference between galvanized and galvalume steel coils?

Galvanized steel features pure zinc coating providing excellent corrosion protection through sacrificial action. Galvalume uses aluminum-zinc alloy coating (55% aluminum, 43.4% zinc, 1.6% silicon) offering superior heat reflectivity and corrosion resistance in high-temperature environments. Galvalume performs better in coastal and acidic conditions, while galvanized excels in alkaline environments and provides better cut-edge protection.

Can galvanized steel coils be used for food contact applications?

Galvanized steel is generally not recommended for direct food contact due to potential zinc migration into acidic or moist foods. Food-grade stainless steel remains the preferred choice for food processing equipment. However, galvanized coils work well for food storage infrastructure, warehouse shelving, and non-contact support structures where corrosion resistance is needed without direct product exposure.

What causes coating thickness variation across coil width?

Coating thickness variations result from zinc drainage patterns during solidification, steel strip tension, bath chemistry, and air knife pressure settings in continuous galvanizing lines. Modern equipment maintains variations within ASTM A653 tolerances. Center-to-edge thickness differences of 10-15% are normal. Critical applications may specify tighter tolerances requiring additional process controls.

How does substrate steel grade affect final product performance?

Substrate grade determines mechanical properties including tensile strength, yield strength, and elongation independent of zinc coating. Commercial quality suits general fabrication, drawing quality enables moderate forming, and deep drawing quality permits severe deformation. Structural grades provide higher strength for load-bearing applications. Coating and substrate selection work together to meet performance requirements.

What temperature range can galvanized steel coils withstand?

Galvanized steel performs reliably from -40°C to approximately 200°C. Prolonged exposure above 200°C causes zinc-iron alloy layer growth reducing coating ductility. Temperatures exceeding 275°C risk zinc oxidation and coating degradation. Cold temperatures don’t affect coating integrity, though substrate steel may exhibit reduced ductility below -20°C depending on grade and carbon content.

Why do some galvanized surfaces appear dull or matte?

Surface appearance varies based on zinc bath chemistry, cooling rates, and post-galvanizing treatments. Bright shiny finish indicates pure zinc coating with regular spangle. Matte or dull gray appearance suggests galvannealed product where controlled heating diffuses zinc into steel creating zinc-iron alloy surface ideal for paint adhesion. Both finishes provide equivalent corrosion protection with different aesthetic and functional characteristics.