Get in touch with us

Leave a message

+8615057563345

+8615057563345

Precision-engineered for superior hygiene, durability, and efficiency in food, beverage, and pharma industries—ensuring compliance and performance.

Our Sanitary Filtration Equipment is engineered to meet the highest standards of cleanliness and performance, making it the ideal solution for industries like food and beverage, pharmaceuticals, and biotechnology. Crafted with precision, this equipment ensures exceptional filtration accuracy, effectively removing contaminants while maintaining product integrity. Available in a range of configurations to suit diverse applications—from small-scale labs to large-scale production lines—our systems are designed for easy maintenance and long-lasting reliability in even the most demanding environments.

Priced competitively, our Sanitary Filtration Equipment delivers unmatched value without sacrificing quality. Whether you need a solution for stringent regulatory requirements or high-volume processing, this equipment offers the consistency and precision your operations demand. Explore our range today and discover how our filtration systems can elevate your production standards to new heights.

Sanitary Y-Type Strainers are commonly used in sanitary piping systems to mechanically remove solids from liquids or gases. Their compact, Y-shaped design allows them to be installed directly into pipelines, typically before pumps, meters, or valves, to protect them from damage by debris. Featuring easy-access covers for cleaning or replacing the screen, and built with polished internal surfaces and sanitary connections, these strainers provide cost-effective protection without compromising hygienic standards in many sanitary and utility applications.

Sanitary Inline Strainers (often basket strainers or similar straight-through designs) provide robust filtration for removing larger particulates from process streams in sanitary applications. Designed for installation directly in the pipeline, they feature a removable basket or screen that captures debris. With designs focused on smooth internal surfaces, minimal crevices, and quick-opening covers or clamps, sanitary inline strainers facilitate easy and frequent cleaning or basket changes, making them suitable for processes requiring protection from larger contaminants where space allows for straight-line flow.

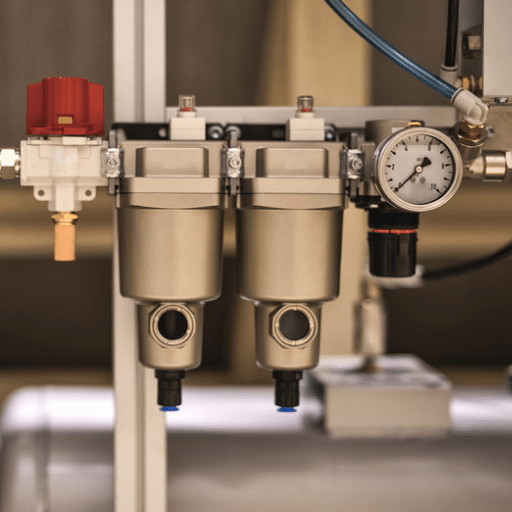

Sanitary Compressed Air Filters are critical for ensuring the quality of compressed air and gases used in direct contact with products or in sterile environments (e.g., for purging, blanketing, or operating valves). These multi-stage filters remove particulate matter, oil aerosols, and moisture to specified purity levels. Constructed with sanitary housings, high-efficiency filter elements suitable for sterile filtration, and designed for hygienic connections and validation, they protect sensitive sanitary processes from contamination originating from the compressed air or gas supply.

Sanitary Bag Filters are versatile filtration systems used for removing larger volumes of solid contaminants from liquid process streams. They utilize disposable or reusable filter bags housed within a sanitary vessel. The design allows for high flow rates and simple bag replacement. Sanitary bag filters are constructed with polished interiors, minimal dead legs, and sanitary connections to ensure cleanability and prevent product buildup, making them suitable for bulk filtration duties, pre-filtration stages, or polishing applications where frequent filter changes may be required.

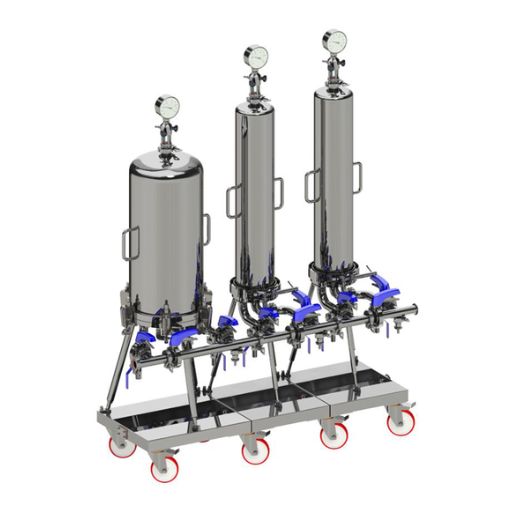

Sanitary Duplex Filters consist of two filter vessels (typically inline or basket strainers) integrated into a single system with diverting valves. This configuration allows the flow to be switched from one filter vessel to the other without interrupting the process flow. While one vessel is in operation, the other can be cleaned or have its filter element replaced. This makes sanitary duplex filters ideal for applications requiring continuous operation where downtime for filter maintenance is unacceptable, ensuring uninterrupted protection of the process stream while maintaining hygienic integrity.

Do not hesitate to contact us for more information on our Sanitary Filtration Equipment concerning its specifications, availability, or even custom tailored configurations to suit your requirements. Allow us to assist you in finding the optimal solution to fulfill your filtration hygiene needs while ensuring the utmost productivity in your industry!

Choose our sanitary filtration equipment to unleash the charm of your project

Polished 316L stainless steel prevents bacterial growth, meeting FDA and USDA/3A standards for food, and pharma applications.

Filters down to 0.5 µm with customizable mesh options, ensuring clean output while maintaining high flow rates.

Sanitary clamp connections allow in-line cleaning and quick filter replacement, minimizing downtime in production.

The tough conditions including humidity and chemicals are no match for durable stainless steel, guaranteeing long-term reliability.

Compact design supports vertical or horizontal setups, fitting seamlessly into diverse sanitary systems.

Certified for high-purity processes, supporting strict industry standards with consistent performance.

| Category | Y-Type Strainer | Inline Strainer | Compressed Air Filter | Bag Filter | Duplex Filter |

|---|---|---|---|---|---|

| Standard Tube Diameters | DN15 to DN100 (1/2" to 4") for sanitary applications; varies by model. | DN25 to DN200 (1" to 8"); depends on flow requirements. | DN15 to DN50 (1/2" to 2"); typically smaller for air systems. | DN50 to DN300 (2" to 12"); accommodates high-capacity bag sizes. | DN25 to DN150 (1" to 6"); designed for continuous flow systems. |

| Tube Length | Varies by diameter; typically 150 mm to 500 mm for sanitary models. | 200 mm to 800 mm; adjustable based on inline setup. | 100 mm to 300 mm; compact for air filtration systems. | 500 mm to 1200 mm; longer to house filter bags. | 300 mm to 1000 mm; dual chambers require extended length. |

| Characteristics | Y-shaped design, removable stainless steel screen, low pressure drop. | Inline design, high flow capacity, easy to clean, often with magnetic inserts. | High-efficiency coalescing, removes oil/moisture, pleated media for larger surface. | Large surface area, high dirt-holding capacity, supports filter bags or baskets. | Dual chambers, continuous operation, switchover valve for maintenance. |

| Surface Treatment | Electropolished to Ra < 0.8 µm for sanitary compliance; mirror-like finish. | Electropolished or mechanically polished; Ra < 0.8 µm for hygienic applications. | Interior/exterior coated aluminum or stainless steel; electropolished for sanitary. | Electropolished stainless steel; Ra < 0.4 µm for food-grade applications. | Electropolished 316L stainless steel; Ra < 0.8 µm to prevent bacterial growth. |

| Dimensions & Specs | 0.8 mm perforations (standard), 0.5 µm filtration, 16 bar pressure rating. | 25 to 2000 µm filtration, 10 bar rating, flanged or clamped connections. | 3 µm to 0.01 µm filtration, 16 bar, 45 to 1625 CFM capacity. | Supports bag sizes #1 to #5, 150 psi, 100 to 5000 GPM flow rate. | 4.5 µm filtration, 150 psi, 360 GPM per chamber, flanged connections. |

| Corrosion Resistance | 316L stainless steel, resistant to chemicals, moisture, and steam in sanitary use. | 316L stainless steel, withstands corrosive fluids like seawater and chemicals. | Stainless steel or coated aluminum, resists corrosion in humid air environments. | 316L stainless steel, excellent resistance to corrosive liquids in food processing. | 316L stainless steel, durable in harsh sanitary environments with chemical exposure. |

| Mechanical Properties | High strength, withstands 16 bar pressure, durable for high-temperature steam. | Robust, handles 10 bar pressure, suitable for high-flow sanitary processes. | Aluminum or stainless steel, withstands 16 bar, durable for compressed air systems. | High tensile strength, supports 150 psi, reinforced for high-capacity filtration. | 316L stainless steel, 150 psi rating, designed for continuous high-pressure use. |

| Processability | Easy to fabricate, weld, and polish; TIG welding ensures crevice-free joints. | TIG-welded, fully customizable for inline sanitary systems, easy to assemble. | Modular design, easy to integrate into air systems, simple filter element replacement. | Welded construction, supports bag changes without tools, adaptable to various flows. | Dual-chamber design, easy to fabricate, supports quick maintenance without downtime. |

| Applications | Food, beverage, pharma; protects pumps and valves in steam and liquid lines. | Wastewater, cooling water in food and pharma; protects nozzles and membranes. | Pharma, food processing; removes oil, moisture from compressed air for purity. | High-capacity filtration in food, dairy, cosmetics; removes large particles. | Continuous filtration in food, pharma; ensures uptime during maintenance. |

| Standards | FDA, USDA/3A, ASME B16.34, ISO 9001 for sanitary compliance. | FDA, USDA/3A, ISO 9001, meets sanitary standards for food and pharma. | FDA, ISO 8573-1 for air purity, ISO 9001 for manufacturing quality. | FDA, USDA/3A, ASME Section VIII, ISO 9001 for high-purity applications. | FDA, USDA/3A, ASME code, ISO 9001 for sanitary and pressure vessel standards. |

| Other Data | Blow-off valves for easy cleaning, 0.5 PSIG pressure drop, vertical/horizontal use. | Magnetic inserts for ferrous debris, 0.5 to 2 PSIG pressure drop, high flow rates. | 99.999% efficiency, automatic float drain, suitable for 250°F max temperature. | Quick-access cover, 4.4 to 6.6 ft² basket area, supports backwash operations. | 1 to 2 PSIG pressure drop, 360 GPM per chamber, continuous operation capability. |

Sanitary filtration equipment must meet strict hygiene standards, using 316L stainless steel for corrosion resistance and FDA/USDA compliance. It should ensure efficient particle removal (down to 0.5 µm), maintain high flow rates with minimal pressure drop, and allow easy in-line cleaning. Equipment must withstand operational pressures (up to 150 psi), support sterilization (e.g., steam at 250°F), and be durable for continuous use in food, beverage, and pharma processes.

Yes, sanitary filters can remove bacteria when equipped with fine filter media, such as 0.2 µm or 0.45 µm membranes, commonly used in sterile filtration for food and pharma applications. These filters, often made of PES or PVDF, trap bacteria while maintaining flow, ensuring product purity. Regular validation and integrity testing (e.g., bubble point tests) are required to confirm bacterial retention.

In sterile applications, a PES membrane filter with 0.2 μm pores is used for bacteria and microorganism retention. The filter is steamed or autoclaved, and all manipulations occur in an aseptic setting. The filter is mounted in a sanitary stainless steel case with clamp type joints. The filter must also have clean flow paths, proper flow direction, and proper sterility validation by integrity tests (including the diffusion test) before and after use in food or pharmaceutical processes.

Select a sanitary filter housing based on your application: 316L stainless steel for corrosion resistance and hygiene in food/pharma settings, with electropolished finish (Ra < 0.8 µm). Ensure compatibility with filter media (e.g., 0.5 µm to 2000 µm), flow rate (e.g., 360 GPM for duplex), and pressure rating (up to 150 psi). Choose designs with sanitary clamps for easy cleaning and maintenance.

For sanitary filtration systems, 316L stainless steel is the best material due to its superior corrosion resistance, durability, and compliance with FDA/USDA standards for food, beverage, and pharma applications. It withstands harsh cleaning (e.g., CIP/SIP at 250°F) and prevents bacterial growth when electropolished (Ra < 0.4 µm). For filter media, PES or PVDF membranes are ideal for sterile filtration.

Discover our premium Sanitary Filtration Equipment, crafted from 304/316 stainless steel, offering exceptional hygiene and durability while meeting FDA standards—contact us to enhance your processes today!

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

A: In food processing, a sanitary strainer removes waste particles from liquids such as juices or dairy, thus safeguarding equipment and ensuring that the product is pure.

A: A sanitary filter, using 0.2 µm media, ensures sterile filtration of injectables, meeting FDA and GMP standards for pharmaceutical safety.

A: A sanitary filter with 0.5 µm to 5 µm ratings is ideal for beverages, removing sediments while maintaining clarity in beer or wine.

A: Select a sanitary filter housing made of 316L stainless steel with electropolished finish (Ra < 0.8 µm) to ensure hygiene and durability in high-purity setups.

A: Yes, water filtration equipment with 316L stainless steel and 0.2 µm filters purifies water for pharmaceutical use, meeting USP standards for sterility.

A: Sanitary food grade water suitable for food processing after thorough contaminant removal by an industrial water treatment system, adhering to FDA food safety regulations.

Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd., specializes in high-quality stainless steel pipes and fittings, offering reliable solutions for industrial applications worldwide.