Premium Stainless Steel Welded Pipe Manufacturer in China

Engineered with precision technology for exceptional corrosion resistance, structural integrity, and long-term reliability in demanding industrial environments.

Stainless Steel Welded Pipe

- Premium Quality

- Customizable Sizes

- Industrial Grade

Overview :

Description :

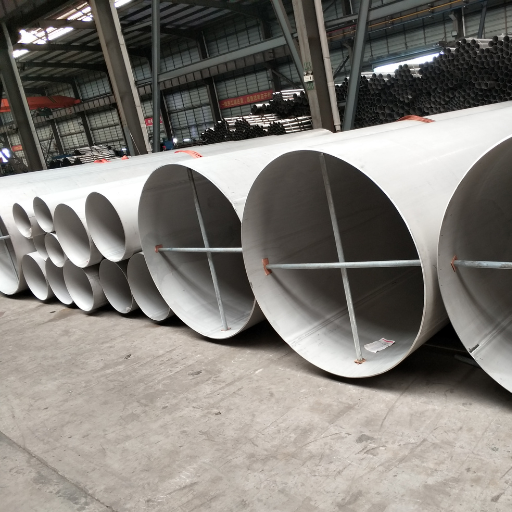

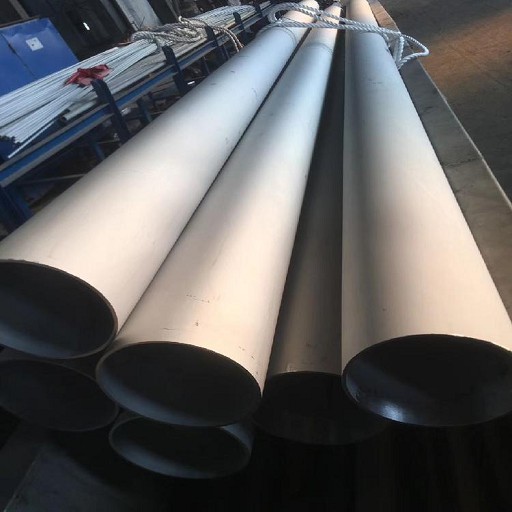

Stainless Steel Welded Pipe is a high-quality piping solution designed to meet the demanding needs of industrial, construction, and manufacturing applications. Manufactured using advanced welding techniques, these pipes provide exceptional strength, durability, and resistance to corrosion, making them ideal for structural and fluid transportation purposes. Available in a wide range of diameters, thicknesses, and lengths, they offer flexibility for custom applications while adhering to international standards such as GB/T, ANSI, stainless steel welded pipe ASTM A312, etc.

The polished or BA surface finish ensures smoothness and aesthetic appeal, which is critical for industries like food processing and medical equipment manufacturing. With precise engineering and strict quality control processes, Stainless Steel Welded Pipes deliver consistent performance, even in challenging environments. Whether for high-pressure systems or decorative purposes, these pipes are a reliable choice for long-term use.

Get a Quote

Explore Our Stainless Steel Welded Pipe Types

304 Stainless Steel Welded Pipe

304 stainless steel welded pipes are a versatile and widely used solution for industrial applications. Known for their excellent corrosion resistance, durability, and affordability, these pipes are ideal for transporting liquids and gases in non-aggressive environments. With a smooth surface finish and reliable weld integrity, they meet the demands of structural frameworks, chemical processing, and general-purpose piping systems. Manufactured to international standards, 304 stainless steel welded pipes provide consistent performance and long-term reliability.

316 Stainless Steel Welded Pipe

The 316 Stainless Steel Welded Pipe is engineered for high performance in corrosive environments. Infused with molybdenum, it resists pitting and crevice corrosion, particularly in chloride-rich settings. This pipe offers excellent tensile strength, making it ideal for marine, chemical, and wastewater applications. Its precise welded design and high temperature resilience ensure durability and efficiency, with availability in various diameters and wall thicknesses to meet diverse industrial requirements.

Stainless Steel Pipe for Water Supply

The stainless steel pipe for water supply guarantees reliability in potable and non-potable systems. Built with superior corrosion resistance, it withstands water chemicals, ensuring long-term performance. Designed for hygienic piping, its smooth inner surface minimizes contamination risks and supports pressure regulation. Perfect for residential, commercial, and industrial plumbing, its robust structure handles variable pressures while ensuring minimal maintenance and extended service life.

Get More Information

Feel free to reach out to us for stainless steel welded pipe price, availability, or any additional information. Let us help you find the perfect stainless steel piping solution for your industry needs.

Why Choose Us

- Expert Craftsmanship : Precision manufacturing ensures durable and reliable welded pipes.

- Customizable Solutions : Tailored sizes, finishes, and lengths to fit your exact needs.

- Certified Quality : Compliant with GB/T, ASTM, and ANSI standards for global reliability.

- Dedicated Support : Expert assistance from inquiry to post-purchase service.

Tailored Solutions for Diverse Industries

Unlock the potential of Stainless Steel Welded Pipes with customized solutions for your unique applications

Custom Fabrication Services

Our advanced manufacturing capabilities allow us to produce pipes in custom sizes, lengths, and finishes. Whether you need specialized dimensions or unique surface treatments, we ensure precise engineering that meets your exact project specifications.

Global Supply Chain Support

With an efficient global logistics network, we ensure timely delivery of stainless steel welded pipes to your location. From small-scale orders to bulk shipments, our supply chain solutions are designed to keep your projects on schedule.

Sustainability Initiatives

Our pipes are manufactured using eco-friendly processes and recyclable materials, supporting your sustainability goals. We prioritize reducing waste and energy consumption while delivering high-quality, environmentally responsible products.

High-Pressure System Compatibility

Designed to withstand extreme pressures, our pipes are ideal for critical systems in industries like oil and gas, power generation, and chemical processing. Their robust construction ensures reliable performance under demanding conditions.

On-Site Technical Consultation

Our team of experts provides on-site or remote technical guidance to help you select the right stainless steel welded pipes for your application. From material selection to installation support, we’re here to assist you every step of the way.

Multi-Industry Applications

Whether for industrial fluid transport, construction frameworks, or precision manufacturing, our pipes are versatile enough to meet the unique challenges of your industry. We deliver solutions that align with your specific operational needs.

Advantages of Stainless Steel Welded Pipe

- Stainless steel welded pipes offer exceptional versatility, as they can be manufactured in a wide range of sizes and shapes to meet specific project requirements. Their production process ensures precise dimensions and consistent quality.

- Compared to seamless pipes, welded pipes are more cost-effective due to their efficient manufacturing process. They are an ideal choice for large-scale projects where high-quality piping solutions are required at a competitive price.

- The welding process used in these pipes ensures strong and durable joints, making them suitable for high-pressure and heavy-duty applications. This reliability makes them a preferred option across various industries.

- Stainless steel welded pipes are lightweight and easier to fabricate, transport, and install compared to other materials. This reduces labor and handling costs, improving overall project efficiency.

- With excellent weld integrity and corrosion resistance, stainless steel welded pipes deliver long-lasting performance in challenging environments. They are particularly effective in industries requiring hygienic and durable systems.

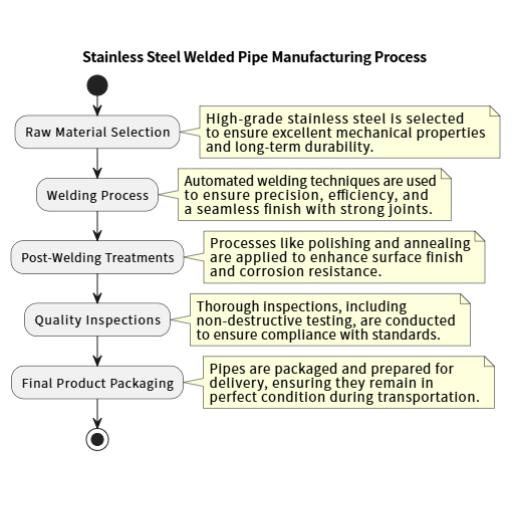

Manufacturing Process

- Stainless steel welded pipes are produced using advanced welding techniques, ensuring a seamless finish and strong joints. The process involves strict quality controls to meet international standards.

- The raw materials used in manufacturing are carefully selected to ensure high-grade stainless steel. This guarantees the pipes have excellent mechanical properties and long-term durability.

- Automated welding processes improve precision and efficiency, reducing production errors. This ensures each pipe meets exact specifications for consistent performance across all applications.

- Post-welding treatments, such as polishing and annealing, enhance the surface finish and corrosion resistance of the pipes. These processes also improve their suitability for hygienic applications.

- Thorough inspections, including non-destructive testing, are conducted during and after production. This guarantees the integrity of the pipes and ensures they meet the highest quality standards.

Stainless Steel Welded Pipe Pressure Rating Specification Chart

| Grade/Standard | Corrosion Resistance | Temperature Resistance | Strength | Pressure Rating Capability | Applications |

|---|---|---|---|---|---|

| 304 | Good (general environments) | Up to 870°C | Moderate | Moderate | Food processing, structural applications, chemical equipment |

| 316 | Excellent (chloride resistance) | Up to 870°C | Moderate | Moderate | Marine environments, medical equipment, chemical storage tanks |

| SA-240/SB-625, A 240 (Alloy 625) | Excellent (pitting, crevice, and high-temperature corrosion) | Up to 980°C | High | High to Very High | Aerospace, chemical processing, marine engineering, nuclear reactors |

| S31254 / 1.4547 (254 SMO) | Excellent (pitting & crevice in chloride environments) | Up to 600°C | High | High | Desalination plants, pulp & paper, flue-gas desulfurization |

| S32205 / 1.4462 | Excellent (chloride stress) | Up to 300°C | High | High to Very High | Heat exchangers, pressure vessels, pipelines |

| SB-424, B 424 (Alloy 825) | Excellent (reducing & oxidizing acids, stress corrosion cracking) | Up to 540°C | Moderate | High | Chemical processing, pollution control, oil & gas recovery, acid production |

| SB-443, B 443, 5599 (Alloy 625) | Excellent (pitting, crevice, and high-temperature corrosion) | Up to 980°C | High | High to Very High | Aerospace, chemical processing, marine engineering, nuclear reactors |

| SB-168, B 168 (Alloy 600) | Good (oxidation and chloride stress corrosion cracking) | Up to 1095°C | Moderate | Moderate to High | Furnace components, chemical processing, nuclear engineering |

| SA-240/SA-249, A240/A 249 | Good (general environments) | Up to 870°C | Moderate | Moderate | Boilers, superheaters, heat exchangers, condensers |

Expert Guide to Stainless Steel Welded Pipe

What ASTM is stainless steel welded pipe?

Stainless steel welded pipes are commonly manufactured to ASTM standards such as ASTM A312, ASTM A358, and ASTM A790. These standards specify the requirements for dimensions, materials, and testing to ensure high-quality pipes for industrial applications.

Can 316 stainless steel be welded?

Yes, 316 stainless steel can be welded using standard welding techniques such as TIG, MIG, or arc welding. It is important to use appropriate filler materials, such as 316 or 316L, to maintain the corrosion resistance and mechanical properties of the weld.

Can 304 stainless steel be welded?

Yes, 304 stainless steel can be welded using various welding methods, including TIG, MIG, and arc welding. Proper heat control and filler materials like 308L are recommended to prevent issues like carbide precipitation that can reduce corrosion resistance.

Is seamless pipe stronger than welded?

Seamless pipes generally have higher pressure ratings and are preferred for critical applications due to their uniform structure and lack of a weld seam. However, modern welded pipes are highly reliable, and advancements in welding technology have significantly reduced the strength gap between seamless and welded pipes.

What is the HS code for stainless steel welded pipe?

The stainless steel welded pipe hs code is typically 7306.40. This code covers stainless steel pipes and tubes that are welded and used in various industrial applications.

What is the difference between ASME B16.5 and B16.36?

ASME B16.5 covers specifications for pipe flanges and flanged fittings, providing details on dimensions, pressure ratings, and tolerances. ASME B16.36, on the other hand, focuses specifically on orifice flanges, which are used for flow measurement in piping systems.

How do I keep my welds from cracking?

To prevent weld cracking, ensure proper preheating, use the correct filler material, and maintain controlled cooling rates. Avoid excessive heat input and ensure the welding area is clean and free of contaminants. Proper joint design and stress relief can also minimize cracking risks.

What is the difference between welded and threaded pipes?

Welded pipes are joined by welding the edges together, creating a continuous structure, and are suitable for high-pressure applications. Threaded pipes, however, have threads at their ends for easy assembly and disassembly, making them ideal for low-pressure or temporary systems.

Resources on stainless steel welded pipe

✷ Applications of Stainless Steel Welded Tubes✷

Stainless welded tubes offer versatile solutions across industries, combining durability, corrosion resistance, and precision for a wide range of applications.

Industrial Fluid Transportation

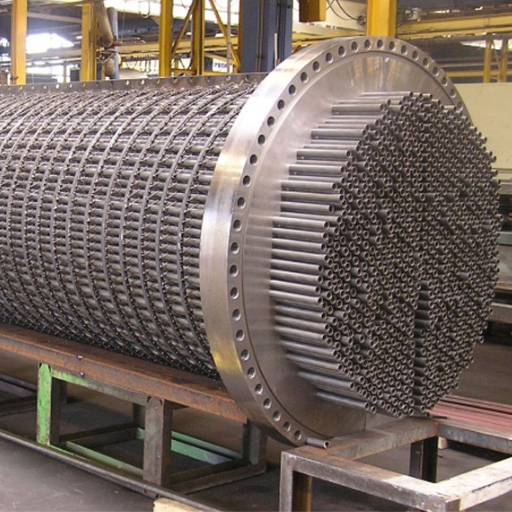

Heat Exchangers

Oil and Gas Pipelines

Chemical Processing Plants

Structural and Architectural Applications

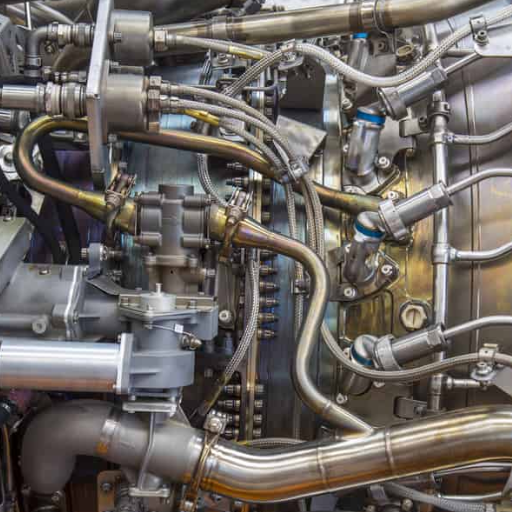

Automotive and Aerospace Components

Examples of stainless steel welded pipe fittings

Explore examples of stainless steel welded pipe fittings, showcasing versatility and quality. For detailed stainless steel welded pipe fitting dimensions or custom options, contact us today!

Material: Stainless steel grades 304/304L, 316/316L, 310/310S.

Industry Standards: ASTM A403, ANSI B16.9 compliant.

Sizes: ½ inch to 24 inches nominal pipe sizes.

Radius: Available in short radius (SR) and long radius (LR).

Wall Thickness: Schedules 5S, 10S, 40S, and 80S.

Temperature Resistance: Suitable for high-temperature applications.

Material: Stainless steel grades 304/304L and 316/316L.

Specifications: Compliant with ASTM A403, ANSI B16.9, and MSS SP-43.

Sizes: Available in nominal pipe sizes from ½ inch to 36 inches.

Types: Straight Tees and Reducing Tees for varied applications.

Wall Thickness: Schedule options include 5S, 10S, 40S, and 80S.

Connection: Designed with beveled edges for optimal weld integrity.

Material: Stainless steel 304/316L.

Specifications: ASTM A403, ANSI B16.9, MSS SP-43 compliant.

Sizes: ½ inch to 36 inches.

Types: Concentric and Eccentric Reducers.

Wall Thickness: Schedules 5S, 10S, 40S, 80S.

Connections: Beveled edges for secure welding.

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Frequently Ask Questions

Q: What are the key advantages of stainless steel welded pipes compared to seamless pipes?

A: Stainless steel welded pipes are more cost-effective, offer precise dimensions, and can be customized in terms of size and length. They are ideal for large-scale projects and provide excellent performance in most environments.

Q: What industries are stainless steel welded pipes commonly used in?

A: Stainless steel welded pipes are widely used in industries such as oil and gas, chemical processing, power generation, construction, and automotive manufacturing, thanks to their durability and versatility.

Q: Can stainless steel welded pipes handle high-pressure applications?

A: Yes, stainless steel welded pipes are designed to handle high-pressure systems. Their strong weld joints and high mechanical strength make them suitable for demanding environments.

Q: What sizes and finishes are available for stainless steel welded pipes?

A: Stainless steel welded pipes are available in a wide range of diameters (Φ6 – Φ762mm), thicknesses (0.5mm – 70mm), and finishes, including polished, brushed, and BA, to meet specific project requirements.

Q: Do you provide custom fabrication for stainless steel welded pipes?

A: Yes, we offer custom fabrication services, including specific dimensions, lengths, and surface finishes, to ensure the pipes meet your exact project needs.

Q: What factors should I consider when sourcing stainless steel welded pipes?

A: When sourcing stainless steel welded pipes, it’s essential to consider factors like material grade, compliance with international standards (e.g., ASTM, ASME), and the manufacturer’s reputation. Many global suppliers, including stainless steel welded pipe manufacturers in India, offer high-quality products that meet diverse industrial requirements. Collaborating with trusted manufacturers ensures reliable performance, durability, and cost-effectiveness for your projects.