Premium Super Duplex Stainless Steel Pipe Manufacturer in China

Engineered with precision technology for exceptional corrosion resistance, structural integrity, and long-term reliability in demanding industrial environments.

Super Duplex Stainless Steel Pipe

- Premium Quality

- Customizable Sizes

- Industrial Grade

Overview :

Description :

A super duplex stainless steel pipe is a type of duplex pipe specifically made from super duplex stainless steel for more advanced applications such as in oil and gas, marine engineering, and chemical processing. They are made through advanced seamless or welded techniques which allow these pipes to withstand brutal conditions, resist aggressive fluids, high pressures, and strenuous environments. Furthermore, these pipes maintain strength amid aggressive corrosion. Super duplex pipes are also available in a range of diameters and wall thicknesses and lengths up to 12 meters. Most of all, these pipes meet international standards such as ASTM A790, A928 and ASME B36.19.

Super Duplex Stainless with a PREN value higher than 40 and almost twice the yield strength of 42.8 stainless steel makes super duplex stainless steel highly resistant to corrosion and ideal for high intensity applications. The pipes’ after anti- corrosion performance from pitting and crevice corrosion is due to the sandblasted and pickled plus polished surface treatments. With super duplex stainless steel pipes, more advanced manufacturing processes alongside stringent quality control guarantees endurance under harsh conditions without losing integrity over long periods of time.

Get a Quote

Explore Our Super Duplex Stainless Steel Pipe types

UNS S31803 Super Duplex Stainless Steel Pipe

The UNS S31803 Super Duplex Stainless Steel Pipe, or Super Duplex 2205, is an alloy of dual-phase that offers exceptional strength, superior corrosion resistance, and great survivability in extreme conditions. UNS S31803 combines the benefits of austenitic and ferric stainless steels in a single body which enable it to resist incredible seawater, pitting, crevice corrosion as well as stress corrosion cracking which makes it suitable for demanding services in oil and gas, chemical processors, and marine engineering industries. Owing to its great mechanical properties and appertainess, Super Duplex 2205 is used for pipelines, pressure vessels, and structural elements to fabrics them. Furthermore, Super Duplex 2205 is manufactured in accordance with international standards to ensure strategic quality reliability for critical long term services.

UNS S32750 Super Duplex Stainless Steel Pipe

UNS S32750 Super Duplex Stainless Steel Pipe (Super Duplex 2507) stainless steel is a premium, high-strength alloy celebrated for its outstanding corrosion resistance, exceptional durability, and superior mechanical properties. This dual-phase material, blending austenitic and ferritic structures, excels in resisting pitting, crevice corrosion, and chloride-induced stress corrosion cracking, making it a top choice for harsh environments like offshore oil and gas, petrochemical plants, and seawater processing systems. Its robust composition ensures excellent performance in high-pressure pipelines, heat exchangers, and structural frameworks. Produced to rigorous international standards, UNS S32750 Super Duplex 2507 delivers unmatched reliability, longevity, and consistent quality for the most demanding industrial applications.

Uns S32760 UNS S32750 Super Duplex Stainless Steel Pipe

Super Duplex Zeron 100 (UNS S32760) is a type of steel which has a high resistance to corrosion and possesses outstanding strength and durability. Its other distinguished characteristics include resisting damage from pitting, crevice corrosion, and stress corrosion cracking. Such properties facilitate its use in demanding applications within the oil and gas industry, chemical processing, and marine engineering. Due to its exceptional resistance to stress corrosion cracking, ferritic and austenitic features, and great tensile strength, weldability, reliability, Zeron 100 is used to make tough components like subsea equipment, pipelines, and pressure vessels. Zeron 100 is manufactured under strict international guidelines which guarantees its enduring quality and performance, even under the harshest environments.

Get More Information

Feel free to reach out to us for Super Duplex Stainless Steel Pipe price, availability, or any additional information. Let us help you find the perfect stainless steel piping solution for your industry needs.

Why Choose Us

- Expert Craftsmanship : Adopting advanced technology, it is strong and corrosion-resistant, suitable for high temperature and high pressure environment.

- Customizable Solutions : Flexible size (such as outer diameter 10-600mm, wall thickness 0.5-25mm), material and length can be adjusted as needed.

- Certified Quality : Complies with international standards (such as ASME SA789), ISO certified

- Dedicated Support :Provide technical consultation, fast delivery and after-sales service to meet the needs of industries such as oil and gas, marine, etc

Tailored Solutions for Diverse Industries

Unlock the potential of Super Duplex Stainless Steel Pipe with customized solutions for your hygienic applications

Role in Carbon Capture and Storage (CCS)

As global efforts intensify to mitigate climate change, Super Duplex Stainless Steel Pipes are expected to be integral in CCS systems, offering exceptional resistance to CO2-induced corrosion and high-pressure durability for underground storage and transport.

Expansion in Offshore Renewable Energy

The shift toward sustainable energy will increase their application in offshore wind turbines and wave energy converters, where their superior corrosion resistance and fatigue strength ensure reliability in harsh marine conditions over extended lifecycles.

Advancement in Ultra-Deepwater Oil Extraction

As oil exploration delves deeper into more corrosive environments, these pipes will be increasingly required to resist pitting, stress cracking, and crevice corrosion, further improving safety and efficiency in new subsea systems.

Support for Hydrogen Infrastructure

While scaling the hydrogen economy, the Super Duplex pipes are expected to safely transport and distribute hydrogen owing to their resistance to hydrogen embrittlement and high mechanical strength suitable for pipelines and storage tanks.

Growth in Advanced Manufacturing

With the advancement of Industry 4.0 technologies and additive manufacturing processes, it may be possible to tailor Super Duplex pipe designs for specific use cases in aerospace, automotive, and precision engineering domains, thus optimizing performance and material usage.

Enhanced Use in Smart Infrastructure

Future urban development will likely incorporate these pipes in resilient, corrosion-resistant piping networks for water management, desalination, and coastal construction, aligning with the need for sustainable, low-maintenance materials in climate-adaptive designs.

Advantages of Super Duplex Stainless Steel Pipe

- Due to the balanced ferrite-austenite microstructure that super duplex stainless steel pipes have, their yield strength exceeds that of austenitic stainless steels by nearly two-fold. This feature adds to the ability of the pipes to tolerate considerable mechanical loads and pressures which is the reason why they are well suited for harsh conditions such as oil and gas offshore pipelines.

- The alloy’s high chromium, molybdenum, and nitrogen content imparts outstanding resistance to localized corrosion phenomena, including pitting, crevice corrosion, and stress corrosion cracking. This property ensures operational integrity in aggressive environments, such as chloride-rich seawater or acidic chemical processing systems.

- Super Duplex Stainless Steel Pipe possesses a strong metallurgy along with sustaining its mechanical attributes and resisting corrosion even at high temperatures. It can be utilized in extreme industrial processes such as refineries and heat exchangers where performance consistency is crucial.

- The operational lifespan of Super Duplex Stainless Steel Pipe is significantly prolonged due to the combination of its extreme durability level, corrosion resistance, and fatigue strength. For long term infrastructure projects, this provides a reliable solution since it considerably lessens the need for maintenance or replacements.

- Its distinctive characteristics allow implementation in various sectors such as oil and gas exploration, petrochemical processing, desalination facilities, and marine engineering. The pipe’s adaptability to different operational conditions highlights its importance as a versatile material.

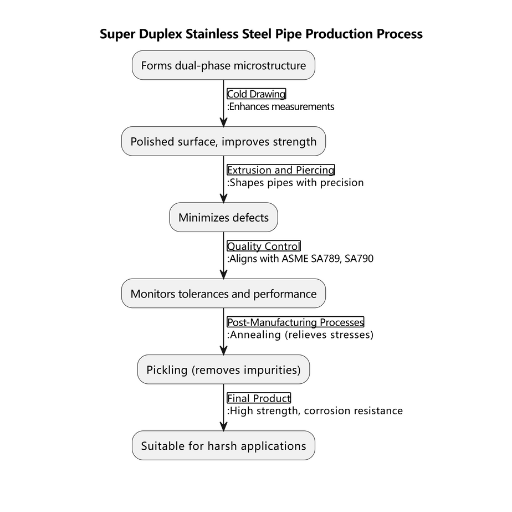

Manufacturing Process

- Super Duplex Stainless Steel Pipes are made by highly advanced cold drawing techniques which further enhance the pipe’s measurements and yield a polished surface. Such a method improves the pipes’ internal strength and consistency to withstand the high standards needed for high efficacy performance demanding applications.

- The manufacturing process incorporates strict quality controls aligned with international standards (e.g., ASME SA789, SA790). Each stage is meticulously monitored to ensure the final product consistently meets specified tolerances and performance criteria, guaranteeing reliability and compliance.

- To create Super Duplex Stainless Steel Pipes, we source the best premium raw materials containing chromium, molybdenum, and nitrogen. These components guarantee the formation of a superior dual-phase microstructure which will provide remarkable mechanical properties including significant tensile strength, and enduring resilience in corrosive setti

- Advanced extrusion and piercing techniques are employed to shape the pipes with exceptional precision and efficiency. These processes minimize production defects, ensuring each pipe adheres to exact specifications for consistent performance across diverse industrial applications.

- Post-manufacturing processes, such as annealing and pickling, are applied to enhance the pipes’ surface quality and corrosion resistance. Annealing relieves internal stresses, while pickling removes surface impurities, improving suitability for hygienic applications (e.g., food processing) and harsh industrial conditions.

Super Duplex Stainless Steel Pipe Specification Chart

| Category | S31803 | S32750 / 1.4410 | S32760 / 1.4501 | S32506 |

|---|---|---|---|---|

| Applications | General use in chemical processing, oil & gas, structural components, heat exchangers | Offshore systems, desalination, oil & gas pipelines, systems with high chloride content | Marine applications, chemical tankers, subsea equipment, acidic environments | Flue-gas desulfurization (FGD), equipment for handling sulfuric and phosphoric acid |

| Properties | - Yield: >450 MPa - PREN: ~35 - Corrosion: Excellent (chloride stress) | - Yield: 550-800 MPa - PREN: >40 - Corrosion: Superior (chloride, pitting) | - Yield: 550-800 MPa - PREN: >40 - Corrosion: Superior (acidic, pitting) | - Yield: >550 MPa - PREN: >40 - Corrosion: Superior (highly acidic environments) |

| Pipe Specification | - ASTM: A789, A790 - OD: 6-1016 mm - Length: Up to 12 m | - ASTM: A790, A928 - OD: 6-1219 mm - Length: Up to 12 m | - ASTM: A790, A928 - OD: 6-1219 mm - Length: Up to 12 m | - ASTM: A790 - OD: 6-610 mm - Length: Up to 12 m |

| Nominal Chemical Composition | 22% Cr, 5.5% Ni, 3% Mo, 0.14% N | 25% Cr, 7% Ni, 4% Mo, 0.25% N | 25% Cr, 7% Ni, 4% Mo, 0.25% N, +W, +Cu | 25% Cr, 6.5% Ni, 3.2% Mo, 0.20% N, +Cu |

| Pipe Fittings | - ASTM: A815 - Size: 1/2 to 48"" | - ASTM: A815 - Size: 1/2 to 48"" | - ASTM: A815 - Size: 1/2 to 48"" | - ASTM: A815 - Size: 1/2 to 24"" |

Super Duplex Stainless Steel Pipe Expert Guide

What Makes Super Duplex 2507 Stainless Steel Unique?

Super Duplex 2507 stainless steel is unique for its exceptional strength, superior corrosion resistance, and high chromium-molybdenum-nitrogen content, making it ideal for extreme environments like offshore oil, chemical processing, and marine applications.

What Are the Applications of Super Duplex Pipe in the Oil and Gas Industry?

Super Duplex pipes are used in oil and gas for offshore platforms, subsea pipelines, and processing equipment, offering high strength, corrosion resistance, and durability in harsh, high-pressure, and chloride-rich environments.

Why Choose Seamless and Welded Super Duplex Pipe Options?

Seamless Super Duplex pipes offer superior strength and corrosion resistance for high-pressure applications, while welded options provide cost-effective, customizable solutions for less demanding conditions. Both ensure durability, precision, and reliability, meeting diverse industry needs with certified quality.

Can super duplex rust?

Super duplex stainless steel resists rust due to its high chromium and molybdenum content, but it can corrode under extreme conditions like prolonged exposure to chlorides or poor maintenance. Proper care ensures its longevity.

Why use duplex stainless steel?

Duplex stainless steel offers high strength, excellent corrosion resistance, and durability, making it ideal for harsh environments like oil, gas, and marine applications. It balances cost and performance, ensuring long-term reliability and reduced maintenance.

Is super duplex stainless steel magnetic?

Yes, super duplex stainless steel is magnetic.

What are the equivalent materials of UNS S31803 equivalent material?

UNS S31803 is equivalent to ASTM A182 F51, EN 1.4462, and X2CrNiMoN22-5-3.

What is the difference between s31803 and s32205?

S31803 and S32205 are both duplex stainless steels with similar compositions. S32205 has slightly higher nitrogen and chromium content, offering improved corrosion resistance and strength. Both are used in similar applications, but S32205 is often preferred for harsher environments.

Resources on Super Duplex Stainless Steel Pipe

✷ Applications of Super Duplex Stainless Steel Pipe✷

Super Duplex Stainless Steel Pipe offer versatile solutions across industries, combining durability, corrosion resistance, and precision for a wide range of applications.

Oil and gas pipeline protective sleeve

Chemical equipment transportation system

Marine engineering structural parts

Food processing pipelines

Automotive parts cooling pipes

Building drainage system

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Frequently Ask Questions

Q: What is the main difference between Duplex and Super Duplex Stainless Steel?

A: Duplex Stainless Steel (such as UNS S31803) has about 22% chromium and lower molybdenum content, with a PREN value of about 35, and is suitable for moderately corrosive environments. Super Duplex (such as UNS S32750) contains 25% chromium, 4% molybdenum and higher nitrogen content, with a PREN value >40, and has stronger resistance to pitting and chloride stress corrosion, suitable for extreme environments such as marine engineering.

Q: In which industries is Duplex Tubing most widely used?

A: Oil and gas (pipelines), chemical (reactors), marine (seawater systems), pulp and paper (bleaching), desalination plants.

Q: What is the Duplex Material Code for Super Duplex?

A: Common codes are UNS S32750 (2507) and UNS S32760, which meet ASTM A790 standards.

Q: What is the chemical composition of 2507?

A: Cr 24-26%, Ni 6-8%, Mo 3-5%, N 0.24-0.32%, C≤0.03%, ensuring high strength and corrosion resistance.

Q: What factors affect the price of Super Duplex Stainless Steel Pipe?

A: Affected by raw material cost, process (seamless/welded), specifications, market supply and demand, the average price in 2025 is about $7,000-$10,000/ton.

Q: How does Super Duplex Pipe perform in extreme environments?

A: Yield strength 550-800 MPa, PREN>40, strong resistance to chloride corrosion, applicable to -50°C to 300°C, suitable for deep-sea oil and gas.