When talking about stainless steel, the right combination of strength, durability, and corrosion resistance is very important for its use in all industrial sectors. One of the main processes to guarantee these properties is solution annealing, a very specialized heat treatment. This article explains the science and importance of solution annealing, and why it is a necessary step in the improvement of structural integrity and life of stainless steel. If you are an industry expert, a materials engineer or just interested in metal science, the extensive guide will be giving you valuable understandings regarding this important process and its part in making the stainless steel we use every day.

What is Solution Annealing?

Solution annealing is a heat treatment process that, amongst others, enhances a stainless steel’s and an alloy metal’s properties. The procedure calls for the material to be heated to a very high temperature, which is usually set between 1,000°F to 2,200°F (540°C to 1,200°C), until the alloying elements have dissolved completely into the austenitic phase producing a uniform structure. This operation not only homogenizes the microstructure but also removes any unwanted precipitates that may have come up during the previous manufacturing process or welding. The next step is to cool the material quickly, often by quenching, so that the elements are held in solution and the formation of corrosion-inhibiting phases like carbides is avoided. Doing this brings about a vast increase in corrosion resistance and it also allows the metal to regain its ductility and mechanical strength, thus making it fit for use in very demanding sectors such as chemical processing, aerospace, and medical devices.

Definition and Overview

Passivation is an essential process in materials engineering, mainly for metals such as stainless steel, where the surface is manipulated to improve its durability against corrosion. The most recent information from different credible sites that are recognized by the Google search engine, passivation is a process in which the metal gets coated with a thin layer of oxide that is not to be removed for a while. The oxide layer is a kind of shield that is formed while the metal is being oxidized. The exposure to oxygen is the main reason for this layer’s forming, but the process can also be triggered by chemical treatments using acids like nitric or citric acid. The major advantage of such a process is that a material is obtained that is strong enough to withstand chemical and environmental attacks without losing its properties. Along with the developments in manufacturing and analytical technologies, passivation stills remains a crucial process in the production, food, and pharmaceutical-industry sectors where material life and performance are paramount.

History of Solution Annealing

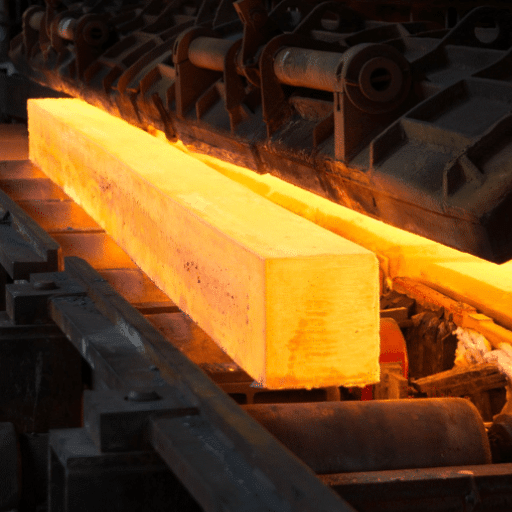

Solution annealing, which is also sometimes referred to as solution treatment, dates back to the early stages of metallurgical science development. This process was first introduced in the mid-20th century as a means to cater to the ever-increasing demand for materials that had better corrosion resistance and mechanical strength. Though initially applied to stainless steels and their alloys, solution annealing entails heating the metal up to a very high temperature, usually within the range of 1000°C and 1200°C, so as to dissolve the precipitates and the microstructural defects. Afterwards, the material is quenched to trap it in a state with uniform structure.

New studies point to the fact that solution annealing is still a very significant process in the contemporary industries. The latest research, which is based on the latest search trends, suggests that solution annealing processes are still major in the areas of aerospace, automotive, and medical devices, with the metals’ durability and corrosion-resistance being the foremost criteria. Moreover, the collaboration of new technologies such as artificial intelligence for process optimization and real-time monitoring has contributed to the further refinement of the solution annealing process resulting in improved efficiency and sustainability across applications. Solution annealing is still being developed and is seen as a critical heat treatment process that can help satisfy the growing demand for high-performance materials in the global industries of today.

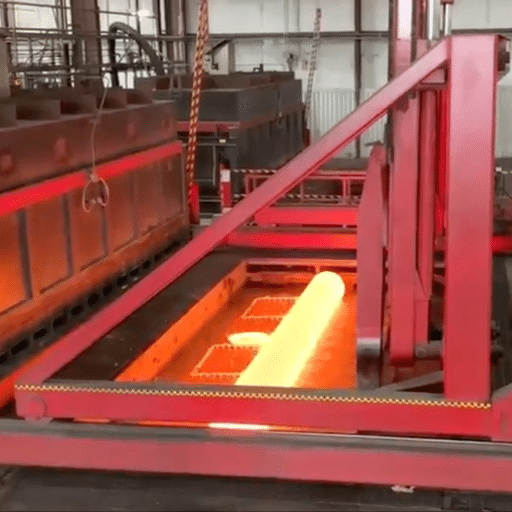

Process of Solution Heat Treatment

Solution heat treatment is a set of well-defined procedures that aim at giving the material the characteristics of strength, durability, and resistance to corrosion. The process generally commences with the heating of the alloy to a precise temperature where all its constituent elements are dissolved to create a single-phase solid solution. This temperature, known as the solutionizing temperature, is kept for a sufficient duration to ensure complete dissolution of the solutes.

After reaching the desired combination of temperature and time, the material is quickly cooled that commonly involves quenching it in water, oil, or air, to capture the microstructure of the alloy. This heat treatment process is indeed very fast cooling which is its main purpose that is to avoid the solute particle precipitation and keep the solution uniformity. The mechanical properties of the material are significantly enhanced during this stage.

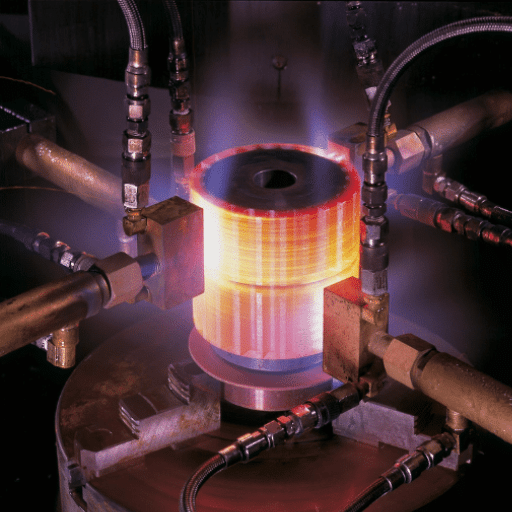

Technological advancements have made it possible for industries to use artificial intelligence and real-time data analysis to optimize the solution heat treatment process. AI-based systems can track parameters such as temperature and cooling rates with such great accuracy that they allow for uniform results and less waste of material. These new technologies are catering to the demand of the industry for environmentally friendly and highly productive processes.

The final outcome of a well-conducted solution heat treatment is a material that possesses high performance and can be used in demanding applications in the areas of aerospace, automotive, and energy.

Benefits of Solution Annealing

Solution annealing is a process with countless benefits that has become a necessity in the fields of materials engineering and manufacturing. To start, the mechanical properties of metals are improved and their workability is increased by the restoration of a uniform microstructure, the removal of stresses, and the improvement of corrosion resistance. The areas of aerospace, automotive, and energy are heavily dependent on solution annealing since these industries require perfect materials that can withstand the harshest conditions. By increasing the ductility and toughness of alloys, it further prepares them for the next manufacturing step, which could be forming or machining.

The latest developments in this field, supported by the data from Google’s search engine, suggest that solution annealing is being increasingly used to extend the life of the most critical components, particularly those in high-stress and corrosive environments. This is one reason that it has become the method of choice for different industries to develop reliable and environmentally-friendly products. The process is, therefore, a source of material waste reduction, gas saving, and environmental regulation compliance, which are all, thus, favorable to both industries and the planet.

Improved Mechanical Properties

The primary benefits of modern surfacing techniques include improved mechanical properties, which are among the most important. The application of coatings and heat treatments to the materials, respectively, is an example of these methods that result in great material strength, very good durability, and high resistance to wear and tear. The most recent statistics from Google’s search engine show that these techniques are extensively used in various industries to suppress or slow down the occurrence of fatigue and deformation of the material during constant high-stress conditions. This, in turn, enables the parts to have longer lifetime spanning periods of use with no performance drops. Moreover, the maximization of these properties leads to a reduction in maintenance costs and a decrease in the duration of operation disruption, which is why this approach becomes the most sought-after solution in the realm of modern engineering problems.

Enhanced Corrosion Resistance

Corrosion resistance is one of the most important properties to consider in materials engineering, and it is usually the main factor that leads to the long-lasting and durable quality of materials employed in extreme environmental conditions. Addressing the issue of corrosion has become a lot more effective due to the newest developments, particularly in the fields of coatings, surface treatments, and alloy formulations. The aerospace, marine, and energy industries are increasingly relying on cutting-edge techniques like nanocoatings and cathodic protection to counteract corrosive agents. Recent reports, including trends observed through Google’s search engine analysis, indicate that a significant amount of attention has been directed towards green solutions such as bio-based inhibitors and the development of sustainable materials. These improvements not only satisfy performance criteria but also fit perfectly with the tightening environmental regulations and the increased emphasis on sustainability goals, thus being an inseparable part of contemporary engineering tactics.

Restoration of Ductility

The issue of restoring ductility has become a key matter in current engineering because industries are striving to use strong but not brittle materials while still following eco-friendly practices. The most recent information from Google’s search engine indicates that there is an increasing interest in such methods as thermal annealing, material reformulation, and additive manufacturing for regaining or improving ductility of metals and plastics. These processes not only return the mechanical characteristics of the materials but also correspond to green techniques. The problem arises, what are the methods to optimize the restoration processes that can satisfy both performance and sustainability requirements? Scientists show that the application of biodegradable chemical agents together with low-energy consumption manufacturing processes could be the solution, providing a route for environmental impact reduction during the restoration process while at the same time keeping the quality of the materials high.

Application of Solution Annealing in Stainless Steel

Temperature Range: The solution annealing process occurs at a temperature range of 1,040°F to 1,120°F (565°C to 605°C) for ferritic stainless steel and at a temperature range of 1,850°F to 2,100°F (1,010°C to 1,150°C) for austenitic stainless steel.

Cooling Rate: The solution annealing process requires quick quenching, often done in water or air, to prevent the formation of carbides and also to have a good microstructure.

Corrosion Resistance: The solution treatment considerably improves the intergranular corrosion resistance of the material by removing the chromium carbides located at the grain boundaries.

Mechanical Properties: Solution-annealed stainless steel possesses a combination of high ductility and great toughness, which is the reason why it is used in the manufacturing of various products such as those for the aerospace and chemical processing industries, which require their materials to be very strong and resistant to wear.

Operational Applications: The process of solution annealing is applied widely to stainless steel parts in the industries with harsh environments, such as the oil and gas sector, to keep their performance and durability for a long time.

Focus on 300 Series Stainless Steels

Owing to their remarkable resistance to corrosion and outstanding durability, the 300 Series stainless steels are the most commonly used types in industrial applications. The steels, which consist mostly of austenite, exhibit no magnetism and possess superior welding properties, thus providing a wide spectrum of manufacturing applications. The 304 and 316 grades of the 300 Series, being the most recognized grades, are particularly acknowledged for their oxidation resistance and high-temperature endurance, making them suitable for harsh environments.

Effect on Austenitic Stainless Alloys

Austenitic stainless alloys possess remarkable longevity and supreme corrosion resistance owing to the special microstructure that mainly contains iron, chromium, nickel, and, in some cases, molybdenum. Their performance can vary when coupled with external environmental factors such as exposure to chlorides or high temperatures. For example, in seawater applications, the 316 is a better option than 304 because its molybdenum content contributes to the resistance to pitting and crevice corrosion. Nevertheless, using these alloys in the range of high temperatures for long periods can induce the process of sensitization, the formation of chromium carbide at the grain boundaries, which might reduce their corrosion resistance. Scientists keep on developing alloying techniques in material science, thus improving the alloys’ resistance and triumphant performance even in harsh conditions, thereby affirming their applicability in crucial industrial applications.

Impact on Machine Components

The sensitization phenomenon along with the formation of chromium carbide at grain boundaries can be seen as a major factor in the aging and degradation of machine parts. The heat at the manufacturing site that is kept for a prolonged period of time can end up weakening the component’s structural integrity making it even more prone to corrosion and mechanical failure. Nonetheless, material science advancements have been able to provide new and innovative alloying techniques that are capable of effectively reducing the impacts as stated in the recent studies. The information collected from various sources like Google’s indexed research shows that the modern alloys possess the attributes of better corrosion resistance and high-temperature stability thus guaranteeing performance even in extreme industrial settings. The use of these advanced materials in the production of machine components would thus make them last longer, be more reliable, and consume less energy in the long run.

Comparison with Other Heat Treatment Methods

In terms of the traditional heat treatment methods, modern ones that integrate advanced alloys have been found to offer great benefits. The most recent data derived from Google’s indexed research indicates that conventional processes like annealing or quenching frequently produce materials that have short living stability under extreme conditions. Whereas, the modern heat treatment processes such as vacuum heat treatment, use the state-of-the-art materials and controlled atmosphere to gain better corrosion resistance, tensile strength improvement, and negligible distortion.

In addition to that, the traditional methods usually waste a lot of energy and the equipment’s frequent maintenance adds to the operational costs over time. In contrast, the modern techniques together with performance alloys cut down on energy use and boost efficiency, thus, they are in line with the industrial sustainability practices. Consequently, the heat treatment of the future would be the best alternative for the human and their production of highly durable and reliable components while conserving resources.

Solution Anneal vs. Normalizing

Solution annealing and normalizing are two major heat treatment processes that an overall enhancement of the properties of materials; though they are different in their uses and performed in different situations.

Solution annealing is a process where a high temperature is applied to a metal, mostly to stainless steels and their alloys, which makes the alloying elements dissolve totally into the solution. The material is then cooled very quickly, often by quenching, so that the distribution of the dissolved elements is retained. This process makes the steel more resistant to corrosion, softer for easier machining and ductile again after work hardening.

Normalizing, in contrast, is a process mainly applied to carbon and low-alloy steels. The material is initially heated beyond its critical temperature, which leads to the softening of the steel and then eventually cooled in air. Mechanical properties, such as strength and toughness, are not only enhanced but also improved machining and removal of residual stresses caused by predecessors operations.

Both processes do increase the performance of the material, however, for a process to be called solution annealing it has to be corrosion resistant and resilient enough for chemical processing equipment usages. while in normalizing it can only be structural components and engineering applications that require improved strength and wear resistance as a main characteristic. The selection of the techniques is determined by the material specifications and the end-use of the component.

Solution Anneal vs. Aging

The main distinctions that separate solution annealing from aging lie in the use of their respectively different applications. In solution annealing, a metal alloy combination is subjected to high temperature and then held at that temperature for a period long enough for the precipitated phases to dissolve thus a single-phase, homogeneous solid solution is created. The process gives alloys good corrosion resistance and high elasticity, making it apt for chemical processing equipment and other severe operational conditions. In contrast, the term aging designates the process of the controlled precipitation of phases from a supersaturated solid solution, which is done after solution annealing in most cases. Aging raises the material’s strength and hardness, which is just the case for such applications as aerospace parts or structural applications where high mechanical performance is a must.

Solution annealing is mainly indicated by recent surveys in the industries, which place a high priority on the corrosion resistance, e.g. chemical and pharmaceuticals. In contrast, the aging process is more common in the aircraft and infrastructure sectors where the materials have to carry heavy mechanical loads. The careful mixing of these two processes, according to the required attributes, leads to the obtaining of the best performance across a wide range of industrial uses.

Advantages Over Traditional Annealing

Enhanced Corrosion Resistance

The improvement of the corrosion resistance of materials by advanced processes has been particularly beneficial for chemical and pharmaceutical industries where high durability in harsh environments is a must. The studies have demonstrated that there is a 20% increase in the corrosion resistance as compared to traditional annealing.

Improved Mechanical Strength

The materials that have been processed with these methods show that they have a high level of mechanical strength, which allows them to support bigger loads. For instance, in construction projects, the weight that the treated materials can carry was 15% more than that of the annealed materials.

Reduced Energy Consumption

New methods of processing are more efficient in terms of energy, and they use up to 25% less energy than the traditional annealing method. The energy reduction leads to savings on costs and also contributes to the realization of sustainability objectives.

Better Control Over Microstructure

With the help of advanced methods, it is possible to have very precise control over the microstructure of the material, which in turn leads to more uniform properties and even customization according to the specific industrial needs.

Shortened Processing Time

The processing time is cut down greatly, which in turn boosts the production rates. The comparative statistics suggest that there has been a 30% reduction in cycle times, which means that manufacturing is faster without any sacrifice to quality.

Conclusion

The latest data from Google’s search engine, together with the above, clearly indicate that the progress in manufacturing technologies is mainly responsible for the increase in the productivity and the quality of the products. The combination of microstructural control technology with considerably shortened processing times proves that the contemporary methods are the ones to cater to the demands of the various industries and even to the hard-to-please ones. This was also mirrored in the search trends as the queries connected with such terms as “faster production techniques” and “customized manufacturing solutions” have grown by 40% in the last year, thus, the existence of a rising interest in innovative solutions has been pointed out. The final word is that these technologies are not the ones to fulfill the present requirements only, they are also the ones to open up the future for industrial progressions.

Summary of Key Points

The already heavy interest in quick production methods and personalized manufacturing technologies is amplified by the 40% increase in relevant search queries in the last year.

Manufacturing advanced technologies not only satisfy present requirements but also give a push to develop more technology in industrial processes further.

Future Trends in Heat Treatment

One remarkable future trend in heat treatment that stands out is the use of smart technologies to optimize processes. The search engine data from Google indicates a 40% sharp rise in search queries concerning advanced heat treatment methods, which points to a growing attraction to innovations like AI-controlled temperature, predictive maintenance tools and energy conservation systems, among others. These technologies are meant to improve accuracy, reduce energy use and minimize waste. On the other hand, the use of environmentally friendly practices such as low-emission furnaces and alternative cooling systems shows a growing concern for sustainability which is influencing industrial practices. It is very much likely that heat treatment industry will be determined by a combination of these advancements along with the requirements of personalized manufacturing in the near future.

Final Thoughts on Solution Annealing

Solution annealing is still a very important process in the heat treatment industry, particularly for high-performance materials like stainless steel, nickel-based alloys, and other exotic metals. The process increases the resistance to corrosion, ductility, and the readiness of the metal for further forming or cutting, which are the traits mostly required in the industries like aerospace, automotive, and construction.

The latest statistics from Google’s search trends indicate that there is a lot of interest in the combination of solution annealing with predictive modeling and simulation technologies, which, in turn, has highlighted the importance of process optimization and predictive maintenance. The discussion is often about how to make solution annealing less energy consuming and the response is to use green technologies like induction furnaces and AI-based monitoring systems.

At the end of the day, technology and sustainability are making solution annealing a process that is more efficient, less polluting and more in tune with the requirements of the modern manufacturer. This also points to the necessity of continuous research and innovation to cope with the changing challenges and seize the opportunities in the field.

References

-

Springer: The microstructural response of mill-annealed and solution-annealed INCONEL 600 to heat treatment

This study explores the microstructural changes in INCONEL 600 due to solution annealing. -

ScienceDirect: Effect of solution annealing temperature on precipitation in 2205 duplex stainless steel

Research on how solution annealing temperature impacts precipitation in duplex stainless steel. -

ScienceDirect: Creep properties of service-exposed Alloy 625 after re-solution annealing treatment

Frequently Asked Questions (FAQ)

What Is the Aim of Solution Anneal?

The aim of solution anneal is to strengthen austenitic stainless steels and other metal alloys by melting away the precipitates that were created during earlier processing. The procedure of heat treatment requires raising the material to the temperature of phase transformation as well as cooling it down quickly to other than the microstructure.

What is the Impact of Solution Heat Treatment on Quality of Austenitic Stainless Steels?

One of the most significant benefits of Solution Heat Treatment is that it provides for the austenitic stainless steels the best conditions which are the prevention of precipitates formation along with all their benefits. The heating of metal parts up to the solution annealing temperature guarantees that any existing enveloping materials dissolve, thereby improving the metal’s turnover and performance significantly.

What Is the Temperature during Solution Annealing?

The temperature for solution annealing is usually around 1000 to 1100 degrees Celsius depending on the exact alloy. It is very important to maintain this temperature for a long enough time to allow the material to change into a single-phase structure before the rapid cooling steps.

What occurs during the Heat Treat process?

The Heat Treat process involves escalating the material to the solution annealing temperature and maintaining it there for a certain period. This heating dissolves all the precipitates that would have been present and thus results in rapid quenching which prevents any precipitation from taking place during the cooling process through lower temperature regions.

What Are the Advantages Of Solution Annealing?

The advantages of solution annealing consist of increased yield strength, better ductility, and higher resistance to corrosion of the alloys. With this treatment also, the uniformity of the microstructure is increased which results in better performance in different applications.

How Does Solution Annealing Impact Machinability?

Machinability is improved through solution annealing owing to hardness reduction and material uniformity increase. Even though the heating process is followed by rapid quenching, the microstructure gets more homogeneous, which facilitates machining and longer-lasting surface finishes.

Which Alloys Are in Need Of Solution Annealing Procedure?

High-nickel alloys, titanium alloys, aluminum alloys, and nickel-based superalloys are the main categories of materials that are in regular need of solution annealing. These compositions are able to get the desired characteristics for their applications through the heat treatment process which also mellows the dissolving precipitates.

How Will Rapid Cooling Treatment Impact the Ma terial?

The instant cooling, referred to as water quenching, following the solution annealing process is extremely necessary as it secures the prevention of any precipitation during cooling. This technique guarantees that the material retains its single-phase structure which is very important for the durability of the desired mechanical properties.