Overview: Stainless steel rectangular tubes are highly versatile structural components recognized for their durability, corrosion resistance, and contemporary aesthetic appeal. Whether you’re an engineer, architect, or DIY enthusiast, understanding the specifications and applications of these tubes will enhance your project scope. This comprehensive guide covers material properties, grade comparisons, selection criteria, and real-world applications across construction, automotive, and industrial sectors.

Overview of Stainless Steel Rectangular Tubes

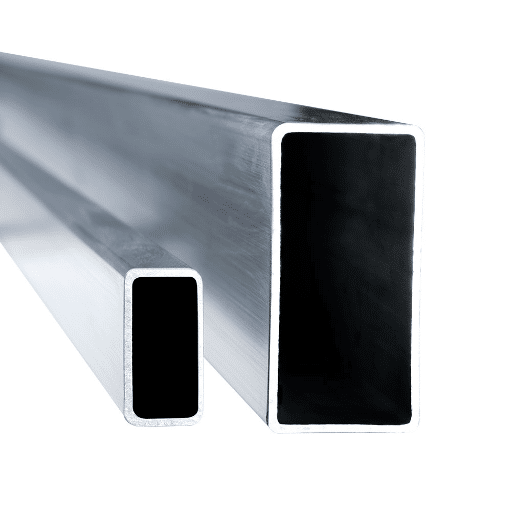

Stainless steel rectangular tubes are versatile structural components widely accepted in industry due to their exceptional strength, durability, and resistance to corrosion. These tubes are produced from alloyed steel containing at least 10% chromium, enabling them to withstand extreme environmental conditions including moisture and chemical exposure.

Their geometrically precise shape combined with flawless surfaces makes them ideal for both practical and aesthetic applications. These tubes are extensively used in construction, automotive, and industrial sectors where reliability and longevity are paramount concerns.

What is a Stainless Steel Rectangular Tube?

Stainless steel rectangular tubes are hollow, elongated structural sections featuring a rectangular cross-section, produced through advanced extrusion or welded processes to guarantee durability and precision. Their key properties include:

- Excellent corrosion resistance

- High tensile strength

- Low maintenance requirements

- Ability to withstand high temperatures

- Superior environmental durability

- Sleek, modern aesthetic appearance

The versatility and durability of stainless steel rectangular tubes make them indispensable for both structural and decorative applications across diverse industries.

Types of Stainless Steel Rectangular Tubes

| Grade Type | Key Characteristics | Primary Applications |

|---|---|---|

| 304 Stainless Steel | Excellent corrosion resistance; low cost | Structural elements, handrails, furniture |

| 316 Stainless Steel | Superior marine/chloride resistance; premium grade | Coastal areas, chemical/pharmaceutical industries |

| 201 Stainless Steel | Low-cost alternative; excellent corrosion resistance; high tensile strength | Decorative applications, low-stress environments |

| 409 Stainless Steel | Ferritic type; oxidation resistance at extreme temperatures | Automotive exhaust systems, high-heat applications |

| 430 Stainless Steel | Good corrosion resistance; attractive appearance | Interior applications, kitchen equipment and appliances |

Key Specifications of Rectangular Tubing

Material Composition

Rectangular tubing is produced from various materials based on application requirements, including stainless steel grades (409, 430), carbon steel, and aluminum.

Dimensional Range

Dimensions vary significantly by manufacturer. Standard options include:

- Cross-Section Sizes: From 1″ × 0.5″ up to 12″ × 8″ or larger

- Wall Thicknesses: 0.035 inches to over 0.5 inches

Tensile Strength

Tensile strength varies by material grade. For example, 430 grade stainless steel achieves approximately 517 MPa, making it suitable for both structural and decorative applications.

Corrosion Resistance

Stainless steel tubing offers excellent rust and corrosion resistance. Grade selection depends on environment:

- 430 Grade: Suitable for low-moisture areas

- 409 Grade: Best choice for high-temperature and oxidizing environments

Customization Options

Most rectangular tubing can be customized to specific dimensions with various finish options including polished, brushed, or raw surfaces, enabling use across industrial, commercial, and aesthetic applications.

Material Grades: 304 vs 316 Stainless Steel

304 Stainless Steel

Composition:

- Iron (base)

- 18-20% Chromium

- 8-10.5% Nickel

Advantages:

- Rust-resistant (most popular)

- Reasonable cost

- Wide variety of uses

- Ideal for general-use applications

Best For: Kitchen sinks, utensils, appliances, general non-corrosive environments

316 Stainless Steel

Composition:

- Iron (base)

- 18-20% Chromium

- 8-10.5% Nickel

- 2-3% Molybdenum

Advantages:

- Superior chloride resistance

- Excellent marine performance

- Harsh chemical resistance

- Extended durability

Best For: Marine environments, chemical processing, medical implants, harsh/corrosive conditions

Which One Should You Choose?

Selection between 304 and 316 grades depends on environmental factors:

| Consideration | Choose 304 If: | Choose 316 If: |

|---|---|---|

| Budget | Cost is a primary concern | Long-term durability justifies higher cost |

| Environment | Non-corrosive indoor/outdoor conditions | Saltwater, harsh chemicals, or extreme conditions |

| Application | General-purpose structural use | Marine, chemical processing, or medical |

| Maintenance | Low maintenance acceptable | Extended service life critical |

Differences in Composition and Properties

The primary differentiator is chemical composition. While both grades contain iron, chromium, and nickel, 316 includes 2-3% molybdenum, which significantly enhances chloride resistance. This additional element makes 316 superior in marine and chemically aggressive environments.

Additionally, 316 stainless steel exhibits better overall lifespan and resistance to pitting or cracking under extreme stress or corrosive conditions, while 304 remains more economical for less demanding applications.

Corrosion Resistance and Durability

Performance data shows that 304 provides excellent resistance for daily use, while 316 demonstrates markedly superior resistance to aggressive environments. The molybdenum content in 316 significantly improves corrosion resistance against seawater and hostile chemicals.

The choice between these materials should align with specific environmental factors and longevity requirements to ensure optimal performance and cost-efficiency.

Common Applications for 304 and 316 Grades

Food and Beverage Industry

- 304 Grade: Widely applied in food and beverage processing where hygiene and basic corrosion resistance are primary concerns

- 316 Grade: Preferred in dairies and breweries to prevent chemical corrosion of products

Marine Environments

- 304 Grade: Suitable for indoor ship areas with minimal saltwater exposure

- 316 Grade: Ideal for boat fittings, coastal structures, and underwater equipment requiring maximum saltwater protection

Medical Industry

- 304 Grade: Used for surgical instruments where sterilization is the primary concern

- 316 Grade: Essential for implants and surgical tools requiring higher durability and resistance to bodily fluids

Chemical Processing

- 304 Grade: Suitable for containers and tanks with weaker acids or neutral chemicals

- 316 Grade: Required in plants processing aggressive chemicals such as pharmaceuticals and petrochemicals

Architectural Applications

- 304 Grade: Most frequently used for non-corrosive indoor environments, decorations, and building facades

- 316 Grade: Selected for exterior use in polluted, moist, or coastal environments

Selection Criteria for Stainless Steel Rectangular Tubes

Grade of Stainless Steel

Grade selection is heavily influenced by application environment. 304 is appropriate for non-corrosive and indoor applications, while 316 suits outdoor applications and areas with moisture, pollution, or coastal conditions.

Load-Bearing Requirements

Assess the total structural load the tubes will bear. For heavy loads or critical infrastructure, higher tensile strength stainless steel grades are advisable.

Corrosion Resistance Needs

Evaluate potential exposure to chemicals, humidity, or other corrosive materials. Industries like petrochemicals or pharmaceuticals should opt for grades like 316 to minimize equipment failure risk and ensure safety.

Aesthetic Finish

Architectural applications may require visually appealing surface finishes. Polished or mirror-finished stainless steel delivers a sleek, modern look, while rough or industrial finishes suit certain functional applications.

Budget Constraints

While high-grade stainless steel (such as 316) is more costly, its extended durability often justifies the investment. Balance project budget with durability and performance requirements.

Compliance with Standards

Choose materials meeting established engineering and building standards such as ASTM or ISO specifications to ensure safety and reliability.

Factors to Consider When Choosing a Tube

Material Compatibility

Determine tube material compatibility with substances it will carry or contact. Verify the tube material meets chemical and temperature resistance standards for your specific application.

Mechanical Properties

Consider tensile strength, yield strength, and ductility. High-pressure applications may require stronger materials or thick-walled tubes.

Size and Dimensions

Match design specifications and service requirements to tube diameter, wall thickness, and length. Correct sizing ensures optimal flow rates, pressure handling, and system fit.

Compliance with Industry Standards

Adherence to industry-standard certifications (ASTM, ISO) is essential for quality, safety, and reliability. Certain industries like aerospace and medical have strict regulatory requirements.

Environmental Conditions

Tube selection must account for operating environment. Extreme temperatures, high humidity, or highly corrosive conditions may require specialized materials or protective coatings.

Longevity and Maintenance Needs

Consider lifecycle costs and maintenance requirements. Higher-performance tubes may have greater upfront costs but typically offer longer service life and lower long-term expenses.

Understanding Wall Thicknesses and Sizes

Wall thickness and tube size are major performance determinants. Wall thickness influences strength, weight, and pressure resistance. Thicker walls increase durability and pressure tolerance but add system weight, while thinner walls reduce weight but may be unsuitable for high-pressure applications.

Tube sizes should ensure inner and outer diameters conform to system specifications. Precise measurements guarantee correct fluid flow rates, minimize leakage risks, and optimize performance.

Standard Sizing: Standardization of sizes using ASME or ISO specifications in procurement is a growing industry trend, facilitating compatibility and securing supply chain efficiency.

Careful consideration of wall thicknesses and sizes relative to operating conditions is essential for system efficiency and tubing longevity.

Environmental Considerations for Selection

Material selection for tubing systems must prioritize environmental factors, supporting both sustainability and regulatory compliance. Current industry trends show increasing adoption of eco-friendly practices, with companies utilizing recyclable and low-impact materials in their designs.

Consider the material’s lifetime performance under various environmental conditions, including heat exposure and corrosive substances. Examine the entire material lifecycle—from production through use to disposal.

By selecting materials with minimal environmental impact that simultaneously meet performance requirements, industries can balance operational efficiency with ecological responsibility.

Applications of Stainless Steel Rectangular Tubes

Construction and Architecture

Stainless steel rectangular tubes are fundamental construction materials for:

- Structural frameworks and support beams

- Railings and balusters

- Modern architectural facades

- Staircases and decorative elements

Their smooth, shiny appearance qualifies them for aesthetic applications in contemporary architectural designs.

Automotive Industry

These tubes are essential for:

- Chassis components

- Exhaust systems

- Roll bars and safety structures

The exceptional strength-to-weight ratio and extreme temperature resistance make them ideal for manufacturers prioritizing vehicle safety and performance.

Furniture Manufacturing

Stainless steel rectangular tubes provide both strength and elegance in furniture applications including tables, chairs, bookshelves, and modern-style components.

Industrial Equipment

Stainless steel tubes are indispensable for machinery and equipment in:

- Food processing

- Pharmaceutical manufacturing

- Chemical handling

Their corrosion-resistant properties ensure hygiene and durability in demanding operating conditions.

Renewable Energy Systems

Applications include:

- Solar panel mounts

- Wind turbine structures

Outstanding resilience and environmental durability make stainless steel tubes ideal for these applications.

Structural Applications in Construction

Building Frames

Stainless steel rectangular tubes provide durable skeletons for structures, particularly in high-rise and commercial buildings, ensuring stability and long-lasting support.

Bridges

Material strength and impermeability make stainless steel the first choice for bridge structures, where corrosion resistance and high tensile strength are critical.

Roof Supports

Lightweight yet strong characteristics make stainless steel tubes ideal for roof frames, enabling innovative designs without compromising safety.

Handrails and Balustrades

These tubes are favored for both indoor and outdoor applications due to their stylish appearance and outstanding damage resistance.

Industrial Facilities

Stainless steel tubes support heavy machinery while creating robust frameworks in harsh industrial conditions.

Architectural Uses and Aesthetic Benefits

Stainless steel tubes are preferred for architectural applications because they combine modernity, strength, and versatility. Bridges, facades, and artistic decorations represent just some applications where stainless steel supports both artistic and functional design objectives.

The material maintains its sleek, polished appearance for extended periods, making it ideal for architects seeking to combine material practicality with visual sophistication. This exceptional combination makes stainless steel a preferred choice for contemporary architectural projects.

Industrial Applications and Fabrication Techniques

Construction and Infrastructure

Stainless steel is extensively employed in construction and architecture through welding and laser cutting techniques that transform the metal into robust, durable structures. Its capability to resist extreme environmental changes has established it as “the material” for constructing bridges, monuments, and skyscrapers. Properly maintained stainless steel structures can achieve lifespans exceeding 100 years.

Food Processing and Catering

Stainless steel is a major component in food processing and service sectors due to its non-reactive and hygienic properties. Cold rolling and electropolishing techniques maintain cleanliness and prevent contamination. Grades 304 and 316 best meet food safety standards.

Automotive and Transportation

Stainless steel is used for exhaust systems, automobile bodies, and train parts. Hydroforming and stamping techniques produce precise shapes while modern alloys reduce vehicle weight and improve fuel economy.

Energy and Power Generation

Stainless steel is chosen for its heat and corrosion resistance in nuclear, solar, and wind plants. Forging and precision machining produce components such as heat exchangers, turbines, and reactor cores. The energy sector consumes over 20% of the world’s stainless steel supply.

Medical and Pharmaceutical Equipment

Stainless steel’s tissue compatibility makes it ideal for surgical instruments, implants, and medical devices. Passivation and micro-machining enhance corrosion resistance and precision. Grade 316L is widely utilized for sterilization and reuse applications.

Stock and Inventory Management for Stainless Steel Tubes

Efficient stock and inventory management is crucial in construction, medical device manufacturing, and automotive production. The key lies in maintaining minimum stock levels while satisfying demand and minimizing holding costs.

Advanced inventory management systems provide real-time updates, demand pattern predictions, and automated reordering. Current best practices indicate that Just-in-Time (JIT) inventory tactics significantly reduce waste and boost efficiency, particularly for expensive stainless steel tubes.

Combining forecasts with search trend data enables companies to identify peak demand periods and adjust purchasing and storage accordingly, ensuring uninterrupted supply at reasonable costs.

Understanding Stock Availability and Requests

Analyzing search trends and consumer behavior enables precise predictions about stock availability and efficient request management. Increased search volume for specific products typically indicates growing demand, allowing companies to adjust inventory levels proactively.

Combining trend data with internal sales records improves forecasting accuracy, reducing overstocking and understocking risks. This strategic approach enhances supply chain efficiency and customer satisfaction.

How to Request Quotes for Stainless Steel Rectangular Tubing

To efficiently handle quote requests:

- Research suppliers online using reliable sources and platforms

- Identify suppliers with positive reputations, competitive pricing, and strong customer feedback

- Contact suppliers via website or phone with clear expression of your requirements

- Communicate key specifications:

- Tubing dimensions (length, width, thickness)

- Grade or type of stainless steel

- Quantity needed

- Specific finishes or certifications

- Utilize online request forms provided by suppliers and marketplaces to expedite the quoting process

- Compare quotations using specified needs and search data insights to make informed decisions

Inventory Management Best Practices

Effective inventory management optimizes operations and reduces costs. Integration of current data and trend analysis provides insights into demand forecasting and customer behavior, enabling data-driven decisions.

Analyzing search patterns predicts demand for specific products during particular periods, allowing inventory level adjustments based on forecasts. Real-time data monitoring of competitor strategies, pricing trends, and emerging product categories improves competitiveness.

Merging these insights with strong inventory management systems ensures optimal stock levels, minimal waste, and maximized profitability and customer satisfaction.

References

- Research Machining Services – Purdue University: This document discusses the availability and types of stainless steel rectangular tubes, including seamed and seamless options.

- Material Properties of Cold-Formed High Strength Stainless Steel – Missouri University of Science and Technology: A research paper investigating the behavior of cold-formed high-strength stainless steel square and rectangular hollow sections.

- KS Metals – Metal Supplier and Manufacturer: A resource detailing various types of tubing, including rectangular stainless steel tubing.

Frequently Asked Questions (FAQ)

What is a stainless steel rectangular tube?

The term “stainless steel rectangular tube” refers to a tube with a hollow cross section that has a rectangular or square shape. It is usually made from stainless steel which belongs to the family of metals known as stainless steel alloys. The application areas of stainless steel tubes are numerous and the most important are the industries where materials must withstand extremely corrosive environments since stainless steels are very resistant to oxidation. The tube can be used in the building and in the design as well as the ornamental field.

What sizes and finishes are available for rectangular stainless tubing?

The sizes and finishes of rectangular stainless tubing vary widely, including a range of standard dimensions and grades that are stocked. In addition, there are different mills finish and polished types of rectangular tubing that cater to the requirements of your project specifically. Furthermore, the stock of different wall thicknesses provides the application needs based customization flexibility.

What are the advantages of using 304 stainless steel for rectangular tubes?

The main advantages of using 304 stainless steel for rectangular tubes are its high resistance to corrosion and its excellent processing capabilities. The material properties of this stainless steel contribute to its wide usage for rectangular stainless tubes in various locations with different climatic conditions. Besides, it is easy to join with other parts of the structure, which makes it suitable for processing in various forms.

Can I buy stainless steel rectangular tubes in custom sizes?

Absolutely, there is a vast array of different types and sizes of stainless steel rectangular tubes available from most of the leading suppliers, and most of them will accommodate your request for a custom size. If your project requires specific measurements that are not included in the standard sizes, do not hesitate to reach out to the suppliers, express your need, and ask them to prepare a quote for you.

What is the difference between 304L and 316 stainless steel rectangular tubes?

The carbon content in 304L stainless steel is lower than that in 304 steel, providing better oxidation resistance and higher weldability. On the other hand, 316 stainless steel has the highest corrosion resistance among all types of stainless steels, especially in seawater-like environments. You can choose either of the two options depending on the intended use to meet your rectangular stainless steel tubing demand.

What applications are suitable for larger rectangular ornamental tubing?

Larger ornamental rectangular tubing finds its application widely in architecture, interior decoration, and supporting structures where beauty is a plus. Thus, it can not only beautify buildings and structures but also supports them by providing the required strength and endurance.

How does the selection of steel affect the performance of rectangular tubes?

The choice of steel type, which includes not only the alloy but also the specification for the finish applied, plays a crucial role in determining the overall performance characteristics of rectangular tubes. The use of different alloys like a554 stainless steel, for example, will permit your fabricating with a range of corrosion resistance and strength features. Thus you have to take care in the selection of material as it plays the most important role in determining the lifetime and reliability of your project outputs.

What should I consider when choosing stainless steel rectangular tubing for my project?

Be sure to consider the specific circumstances of your project, such as the particular use, the environment where it will be, how much strength it needs to have, and the look you want when choosing your stainless steel rectangular tubing. Moreover, take into account the standard sizes and finishes that are available and also whether you will need custom measurements or a certain type of alloy such as 304 or 316 stainless steel.