Premium Stainless Steel Sanitary Tube Manufacturer

Engineered with advanced technology for superior hygiene, corrosion resistance, and long-lasting performance in critical food, beverage, and pharmaceutical applications.

Stainless Steel Sanitary Tube

- Premium Quality

- Customizable Sizes

- Industrial Grade

Overview :

Description :

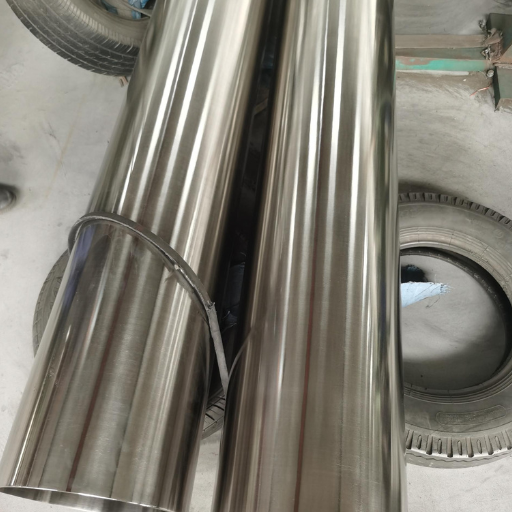

Specifically engineered for the rigorous standards of the food, beverage, and pharmaceutical industries, our Stainless Steel Sanitary Tube is a top-tier piping solution. As a reputable stainless tubing supplier, we use seamless technology to craft sanitary pipes and fittings with high hygiene, durability, and corrosion resistance. Available in various diameters, wall thicknesses, and lengths, they’re ideal for sterile fluid transfer and processing systems, meeting ASTM, ASME, and 3A standards.

With a mirror-polished or satin finish, our Stainless Steel Sanitary Tube ensures a smooth, contamination-free flow, vital for strict sanitary regulations. These sanitary pipes and fittings, made by a trusted stainless tubing supplier with precise engineering, enhance quality and reliability in harsh conditions. They optimize system life and reduce maintenance for high-purity or hygienic processing, making them a robust, compliant choice.

Get a Quote

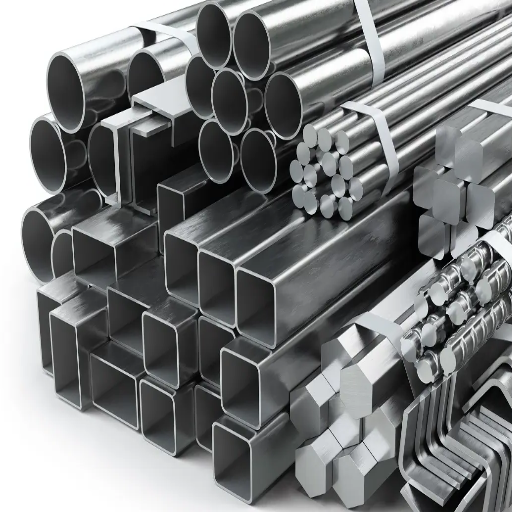

Stainless Steel Sanitary Tube Material Types

304 Stainless Steel Welded Pipe

304 stainless steel welded pipes are a versatile and widely used solution for industrial applications. Renowned for their excellent corrosion resistance, durability, and affordability, these pipes excel in transporting liquids and gases in non-aggressive environments. With a smooth surface finish and reliable weld integrity, they are perfect for structural frameworks, chemical processing, and sanitary pipe and fittings systems. Manufactured to international standards, they ensure consistent performance and long-term reliability. Ideal for food, beverage, and pharmaceutical industries, these pipes meet stringent hygiene requirements.

304L Stainless Steel Welded Pipe

304L stainless steel welded pipes are a reliable and versatile choice for industrial applications. Renowned for their superior corrosion resistance and durability, these pipes excel in transporting liquids and gases in low-corrosion environments. Featuring stainless steel pipe polishing for a smooth, hygienic surface finish and robust weld integrity, they are perfect for structural frameworks, chemical processing, and sanitary systems. Manufactured to global standards, 304L stainless steel welded pipes ensure consistent performance and long-term reliability.

316L Stainless Steel Welded Pipe

316L stainless steel welded pipes are a premium choice for demanding industrial applications. Renowned for their superior corrosion resistance, especially in harsh environments, these pipes excel in transporting liquids and gases. The polished pipe finish ensures a smooth, hygienic surface, ideal for chemical processing, marine applications, and sanitary systems. With excellent weld integrity and durability, they meet global standards, delivering consistent performance and long-term reliability.

Get More Information

Feel free to reach out to us for pricing, availability, or any additional information. Let us help you find the perfect stainless steel sanitary tube solution for your industry needs.

Why Choose Us

- Expert Craftsmanship: Precision manufacturing ensures hygienic and durable stainless steel sanitary tubes for critical applications.

- Customizable Solutions: Tailored diameters, finishes, and lengths to meet your specific sanitary piping needs.

- Certified Quality: Compliant with ASTM, ASME, 3A, and ISO standards for global reliability and safety.

- Dedicated Support: Expert guidance from inquiry to post-purchase, ensuring seamless integration in your projects.

Tailored Solutions for Diverse Industries

Unlock the potential of Stainless Steel Sanitary Tubes with customized solutions for your hygienic applications

Custom Fabrication Services

Our advanced manufacturing capabilities allow us to produce stainless steel sanitary tubes in custom diameters, wall thicknesses, and finishes. Whether you need specific lengths or polished surfaces, we ensure precision engineering that meets your exact sanitary requirements.

Global Supply Chain Support

With an efficient global logistics network, we ensure timely delivery of stainless steel sanitary tubes to your location. From small-scale orders to bulk shipments, our supply chain solutions are designed to keep your projects on schedule.

Sustainability Initiatives

Our sanitary tubes are manufactured using eco-friendly processes and recyclable materials, supporting sustainability goals. We prioritize reducing waste and energy consumption while delivering high-quality, environmentally responsible products.

Hygienic System Compatibility

Designed for sterile environments, our sanitary tubes are ideal for critical applications in the food, beverage, and pharmaceutical industries. Their seamless construction and smooth finishes ensure contamination-free fluid transfer, meeting stringent hygiene standards.

On-Site Technical Consultation

Our team of experts provides on-site or remote technical guidance to help you select the right stainless steel sanitary tubes for your application. From material selection to installation support, we’re here to assist you every step of the way.

Multi-Industry Applications

Whether for food processing, pharmaceutical manufacturing, or beverage production, our stainless steel sanitary tubes are versatile enough to meet the unique challenges of your industry. We deliver solutions aligned with your specific hygienic needs.

Advantages of Stainless Steel Sanitary Tube

- Stainless steel welded pipes resist corrosion and high temperatures, ensuring durability. Used as ornamental stainless tubing or stainless steel pipes for the food industry, they excel in harsh environments.

- Ornamental stainless tubing offers a polished look for railings and furniture, blending style and strength in decorative applications.

- Stainless steel pipes for the food industry prevent bacterial growth, meeting hygiene standards for safe food and beverage transport.

- Welded pipes provide affordable strength for industrial uses, including ornamental stainless tubing and food industry applications.

- Easily fabricated, stainless steel welded pipes suit varied needs, from ornamental stainless tubing to specialized food industry systems.

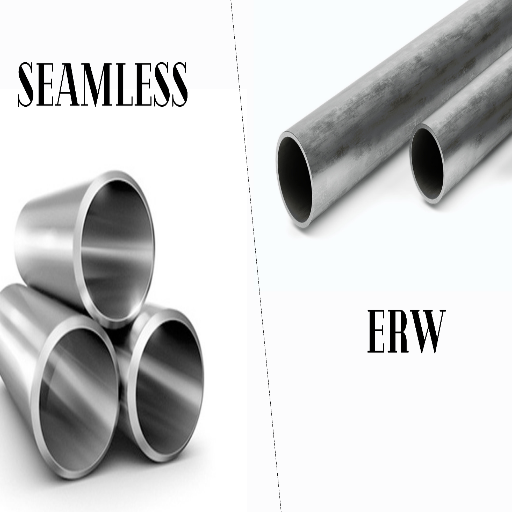

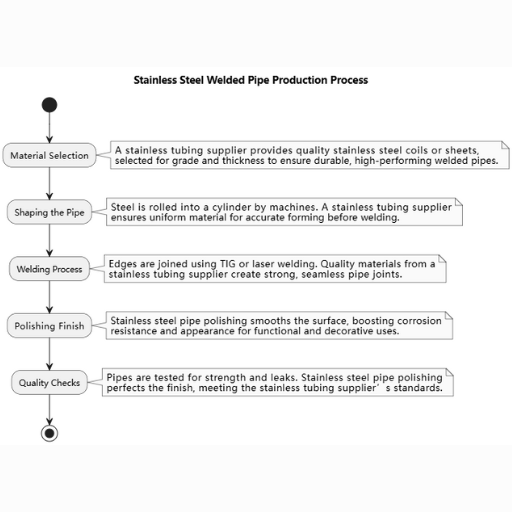

Manufacturing Process

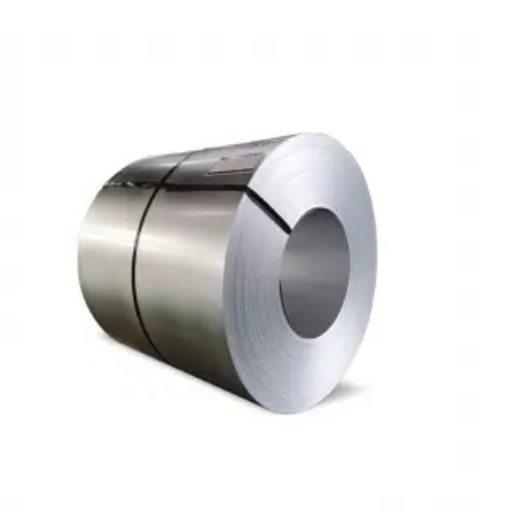

- A stainless tubing supplier provides quality stainless steel coils or sheets, selected for grade and thickness to ensure durable, high-performing welded pipes.

- Steel is rolled into a cylinder by machines. A stainless tubing supplier ensures uniform material for accurate forming before welding.

- Edges are joined using TIG or laser welding. Quality materials from a stainless tubing supplier create strong, seamless pipe joints.

- Stainless steel pipe polishing smooths the surface, boosting corrosion resistance and appearance for functional and decorative uses.

- Pipes are tested for strength and leaks. Stainless steel pipe polishing perfects the finish, meeting the stainless tubing supplier’s standards.

Stainless Steel Sanitary Tube Grade Comparison

| Grade | Type | Corrosion Resistance | Temperature Resistance | Strength | Applications | Size Range (OD x WT) |

|---|---|---|---|---|---|---|

| 304/304L/304H | Austenitic Stainless | Good (general environments) | Up to 870°C | Moderate | Food processing, beverage systems, dairy equipment | 1/2" - 24" x 0.5mm - 10mm |

| 316/316L/316H | Austenitic Stainless | Excellent (chloride resistance) | Up to 870°C | Moderate | Pharmaceutical systems, medical equipment, sterile fluid transfer | 1/2" - 24" x 0.5mm - 10mm |

| 321/321H | Austenitic Stainless | Good (oxidation resistance) | Up to 870°C | Moderate | High-temperature sanitary piping, food-grade exhaust systems | 1/2" - 20" x 0.5mm - 8mm |

| 317/317L | Austenitic Stainless | Superior (acidic environments) | Up to 870°C | Moderate | Chemical processing, pharmaceutical manufacturing, pulp and paper | 1/2" - 20" x 0.5mm - 8mm |

| 347/347H | Austenitic Stainless | Good (intergranular corrosion) | Up to 870°C | Moderate | Heat exchangers, high-temperature sterile processing | 1/2" - 20" x 0.5mm - 8mm |

| 310S/310H | Austenitic Stainless | Good (oxidation resistance) | Up to 1150°C | Moderate | High-temperature food processing, heat treatment equipment | 1/2" - 16" x 0.5mm - 6mm |

| 309S | Austenitic Stainless | Good (oxidation resistance) | Up to 1000°C | Moderate | Industrial furnaces, heat exchangers, food-grade systems | 1/2" - 16" x 0.5mm - 6mm |

| 904L | Austenitic Stainless | Excellent (acidic and chloride) | Up to 400°C | High | Desalination plants, sulfuric acid handling, pharmaceutical systems | 1/2" - 12" x 0.5mm - 5mm |

| S31803 | Duplex Stainless | Excellent (pitting and crevice) | Up to 300°C | High | Oil and gas sanitary systems, chemical processing, hygienic pipelines | 1/2" - 12" x 0.5mm - 5mm |

| S32205 | Duplex Stainless | Excellent (pitting and crevice) | Up to 300°C | High | Petrochemical sanitary systems, seawater applications, sterile piping | 1/2" - 12" x 0.5mm - 5mm |

| S32750 | Super Duplex Stainless | Superior (chloride stress corrosion) | Up to 300°C | Very High | Offshore sanitary systems, desalination, high-pressure hygienic systems | 1/2" - 10" x 0.5mm - 4mm |

| S32760 | Super Duplex Stainless | Superior (chloride stress corrosion) | Up to 300°C | Very High | Marine sanitary applications, chemical tankers, sterile high-pressure systems | 1/2" - 10" x 0.5mm - 4mm |

| N06600 | Nickel Alloy (Inconel 600) | Excellent (oxidation and carburization) | Up to 1100°C | High | High-temperature sanitary systems, chemical processing, sterile equipment | 1/2" - 8" x 0.5mm - 3mm |

| N06625 | Nickel Alloy (Inconel 625) | Superior (acidic and seawater) | Up to 1000°C | High | Aerospace sanitary systems, marine hygienic applications, chemical processing | 1/2" - 8" x 0.5mm - 3mm |

| N08800 | Nickel-Iron Alloy (Incoloy 800) | Good (oxidation and carburization) | Up to 1100°C | High | Heat exchangers, power generation sanitary systems, food-grade furnaces | 1/2" - 8" x 0.5mm - 3mm |

| N08825 | Nickel-Iron Alloy (Incoloy 825) | Excellent (acidic environments) | Up to 550°C | High | Chemical processing, oil and gas sanitary systems, acid production | 1/2" - 8" x 0.5mm - 3mm |

| N10276 | Nickel-Molybdenum Alloy (Hastelloy C-276) | Superior (acidic and chloride) | Up to 1000°C | High | Chemical reactors, pollution control, pharmaceutical sanitary systems | 1/2" - 6" x 0.5mm - 2mm |

Expert Guide to Stainless Steel Sanitary Tube

What Makes Stainless Steel Sanitary Tubing Ideal for the Beverage Industry?

Sanitary pipe and fittings enable stainless steel sanitary tubing to serve the beverage industry perfectly because of their corrosion resistance, durability, and smooth surfaces. They also guarantee the unobstructed flow of beverages, cleanliness during processing and transportation, and effortless cleaning of beverage tanks.

How Does ASTM A270 Standard Enhance Sanitary Tube Quality?

The ASTM A270 standard improves sanitary tube quality by establishing clear requirements for sanitary tube manufacturing. It ensures stainless tubing suppliers uphold industry standards when it comes to cleanliness, surface finish, and material composition. These factors are essential for any hygienic application.

How to Select the Right Sanitary Tube Fittings for Your System?

When choosing sanitary tube fittings, you should address their compatibility with your tubing, pressure thresholds, and maintenance level required. Achieving a sound polished finish on stainless steel pipes adds to the ease of cleaning as well as bacterial growth due to non-porous surfaces.

What type of stainless steel is medical grade?

316L is the usually medical grade stainless steel because of its low carbon and high corrosion resistance. It is also sought after for ornamental stainless tubing due to its eye-catching nature and robust sterile durability.

Can bacteria grow on stainless steel?

Without proper sanitation, bacteria can grow on stainless steel surfaces near sanitation appliances. However, smooth, non-porous surfaces like stainless steel pipes in the food industry resist bacterial adhesion, but not oyster, if regular cleaning is executed.

Is stainless steel tubing food safe?

Yes, stainless steel tubing is food safe. It is inert and resistant to corrosion, which is valuabe in polished pipes used in food processing. Hygiene and safety are always prioritized in such operations.

What type of stainless steel is medical grade?

316L is a medical grade stainless steel type owing to its bio compatibility and corrosive resistance. Its suitability for sanitary pipe and fittings in medical, as well as food places, is also because of these features.

Does stainless steel leach into food?

Under normal conditions, stainless steel does not leach into food and even less so when high grade stainless tubing supplier materials are used. Since its composition does not change much, interactions with food items will be minimal.

How do you connect stainless steel pipes without welding?

Stainless steel pipes can be connected without welding using compression fittings, flanges, or even threaded joints. These techniques are often applied to stainless steel pipes for food industry to ensure sterility, safety, and structure without the use of heat.

What should you not put in stainless steel?

Steer clear of storing items with a lot of vinegar and brine, or stainless steel polish. Because over time, retrieve management can cause deep pits or corrosion.

Resources on Stainless Steel Sanitary Tube

✷ Applications of Stainless Steel Sanitary Tube✷

Stainless steel sanitary tubes provide hygienic, durable, and corrosion-resistant solutions across industries, ensuring safe and efficient fluid transfer for critical applications.

Food Processing Systems

Beverage Production Lines

Water Purification Systems

Dairy Industry Applications

Biotechnology and Cleanroom Systems

Cosmetic Production Facilities

Examples of Stainless Steel Sanitary Tube fittings

Discover the versatility and quality of stainless steel sanitary tubes, perfect for hygienic applications. Contact us today to explore detailed dimensions or request custom solutions!

- Material: Stainless steel grades 304/316L.

- Industry Standards: Meets 3A sanitary standards, ASME BPE.

- Sizes: 1/2 inch to 12 inches nominal diameter.

- Radius: 1.5x diameter for elbows

- Wall Thickness: 0.065" to 0.109"

- Temperature Resistance: -325°F to 300°F

- Material: Stainless steel grades 304/316.

- Industry Standards: ASTM A269, A554 compliant.

- Sizes: 5-inch outside diameter, lengths up to 20 feet.

- Radius: Not applicable (straight tube).

- Wall Thickness: 0.083" to 0.250"

- Temperature Resistance: -425°F to 1500°F

- Material: Stainless steel 316L.

- Industry Standards: 3A, FDA, ASME BPE compliant.

- Sizes: 6-inch nominal diameter, 10 or 20-foot lengths.

- Radius: Not applicable (straight pipe; elbows have 9" centerline radius).

- Wall Thickness: 0.109"

- Temperature Resistance: -325°F to 1200°F

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.