A Comprehensive Guide to Understanding Heat Transfer Properties in Stainless Steel Applications

Being one of the most versatile materials available, stainless steel endures for ages and is used in almost every industry, from construction to aerospace. Thermal conductivity is one of its major properties governing its use and application. What exactly is thermal conductivity, and how does it alter the actual performance of stainless steel? This article will deep-dive into the science of thermal conductivity in stainless steel, highlighting the intricacies that make this property so important to heat transfer applications. You will have a good grasp of the interaction between thermal conductivity and the basis used for material selection, the performance of an engineering product, and its efficiency in industrial processes at the end of this discussion. This will prove to be useful for any materials scientist, engineer, or just a curious person sharpening its knowledge base.

Introduction to Thermal Conductivities

Thermal conductivity is a fundamental material property that measures the ability of a substance to transfer heat energy. It is typically expressed in watts per meter and degree Kelvin (W/m·K). Basically, thermal conductivity is a property that determines heat conduction in a material. By this virtue, a material of high thermal conductivity is a good heat conductor, such as copper, aluminum, etc., and hence the thermal conductivity will be considered while building heat exchangers, electronics cooling, and thermal management. Materials of low thermal conductivity serve as insulators against heat: ceramics, polymers, and the like would fit this description, so these are usually employed in industries that require heat retention or heat resistivity. Hence, it is essential to understand the essence of thermal conductivity to optimize material selection for many engineering and industrial processes, thereby influencing system performance and energy efficiency.

What is Thermal Conductivity?

Thermal conductivity measures the heat conduction properties of a material. It is a heat flow rate through a material of unit thickness when a temperature gradient is applied within. In general, thermal conductivity may be mathematically expressed by Fourier’s Law, stating that heat fluxes are proportional to the temperature gradient but with a negative sign. A material like copper and aluminum with higher thermal conductivity means it is better at transmitting heat and thus is used in heat exchanger applications and electronic cooling systems. On the other hand, substances with lower thermal conductivity shall insulate heat transfer and thus stop or reduce heat flow, such substances include plastics and some ceramics. The value of thermal conductivity depends on the composition of the material, temperature, or state of matter (solid, liquid, or gas) of the given material. Understanding and knowing how to measure thermal conductivity will be a great advantage in designing energy-efficient systems and ensuring proper thermal management in an industry that ranges from electronics to construction.

Importance of Thermal Conductivity in Metals

Metals, in general, have a high thermal conductivity; that means heat is easily transmitted in many industrial applications. For instance, copper, which is a good conductor, having an approximate value of 398 W/m·K, is used in many applications such as electronics, power, heating, ventilation, and air conditioning. Aluminum, on the other hand, with thermal conductivities around 235 W/m·K, finds applications in the aerospace and automotive industries for heat exchangers and engine components, balancing light weight with just enough heat transfer.

A necessary parameter of thermal conductivity in metals is maintaining system stability and efficiency high-temperature environments or in energy-intensive processes. For example, in electronics, one should keep the heat generated in check by using silver or copper so as to avoid the failure of critical components. The choice of metal for thermal conductivity applications largely depends on intrinsic physical properties of the metal, operating temperature range, and cost-effectiveness concerning scale and intensity of the application. By looking over the recent stories about next-generation materials, like those of Google, one will find that the research and development of measures to approximate better thermal management-that encompass alloy developments, and nano-coatings to modulate conductivity without compromising other structural properties-goes on steadily. This sustained innovation is quite vital for the new generation technologies in energy systems, and technology for sustainable solutions.

Overview of Stainless Steel Properties

Stainless steel describes an incredibly versatile alloy known for its corrosion resistance quite unusual to other stainless steels, strength, and durability. Its unique properties come from its composition: a combination of iron, chromium (at least 10.5%), and other elements such as nickel, molybdenum, and manganese. Chromium works by quickly forming a thin passive layer of oxide on the surface, preventing the metal from oxidation and corrosion under normal environmental conditions.

Recent Innovations in Stainless Steel

According to recent insights from Google’s materials research innovations, stainless steel properties worldwide are being expanded by modern-day technologies. Nanotechnology, for example, is used to develop nano-engineered coatings where wear and corrosion resistance is especially needed under extreme environments. Furthermore, the mechanical type of tensile strength and impact resilience are wrought up using new thermal treatments and alloying methodologies. Hence, stainless steel and its diversified properties have become a common sight in a plethora of industries, namely, construction, automotive, aerospace, renewable energy systems, and so on.

By continuously advancing in stainless steel field, the modern applications can satisfy ever-stricter performance and sustainability requirements, thereby ensuring that the material maintains its position at the cutting-edge of material sciences.

Thermal Conductivity of Stainless Steel

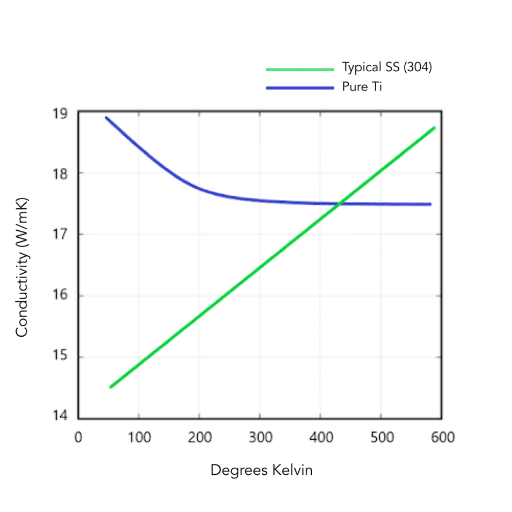

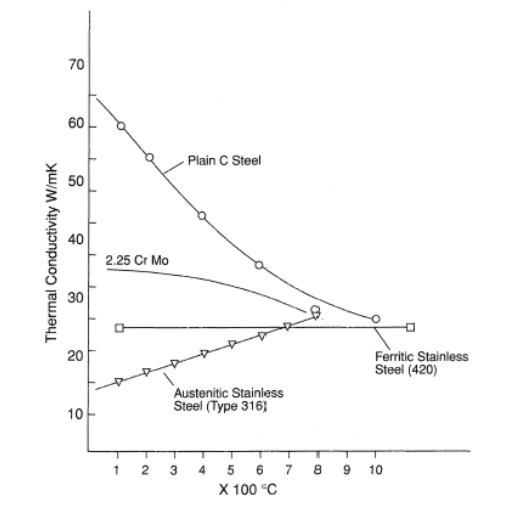

Thermal conductivity essentially refers to stainless steel’s capacity for heat conduction. Stainless steel experiences much lesser thermal conduction compared to copper or aluminum, and this serves well in situations in which heat retention or insulation comes into play. For instance, austenitic stainless steels, with 304 and 316 mostly employed, usually have their thermal conductivity in the range of about 14 to 16 W/m·K at room temperature. The ferritic grades may even conduct heat slightly better than austenitics, but still nowhere near that of a metal like copper.

Key Factor: Alloy Composition

As the stainless steel’s chromium and nickel content increases, the thermal conductivity decreases. These materials impart corrosion resistance and mechanical integrity, yet they inhibit the directive conductance of heat. The trade-off is especially important in applications like heat exchangers, cookware, and cryogenic apparatus, wherein thermal conductance needs to be administered with some precision. Modern analytical data can allow engineers to tailor stainless steel grades to find the best compromise among thermal conductivity and other important criteria for performance.

Measuring Thermal Conductivity

Thermal conductivity defines the way a given material may conduct heat, and without a specific measurement, it is generally assumed as the category of conditioning process-based statements-a practical method using precise instrumentation, and controlled conditions. The steady-state method is one of the many that are commonly used. In such a method, a steady heat flow is imparted to the specimen while the temperature gradient is measured. The transient method, on the other, would apply a heat pulse to the material, measure the temperature of the other surface as it changes in time, and give results quickly and accurately, even with thin or irregular samples.

Better options for discriminating among processes have been created using modern technology. In this innovative system, with some data-driven insights from machine learning algorithms and open resources like Google’s indexed data, engineers gain the extraordinary ability to have an alternative benchmark for comparison among different published thermal values. This form of cross verifying between claimed experimental results and the established repositories leads to a better understanding of thermal conductivity manifestations under varying conditions.

Comparing the Thermal Conductivity of Stainless Steel vs. Other Metals

Being a poor thermal conductor in comparison to Aluminum and Copper, steel has a low thermal conductivity. For example, copper has a thermal conductivity of about 398 W/m·K, aluminum about 237 W/m·K, while stainless steels have 14 to 16 W/m·K depending on their grade. The vast difference in thermal behavior is mainly because of the molecular composition and structure of stainless steel, including chromium and nickel as alloying elements. These alloying elements provide corrosion resistance and mechanical strength but interfere with the free-electron flow needed for thermal transfer.

Going by the recent information available in Google’s index-based resources, we see that stainless steels are used where one needs thermal insulation or regulated heat transfer, such as handles for cookware or structural building components. Meanwhile, copper and aluminum, which are great conductors, are employed where fast dissipation of heat is required, such as in electrical wiring or heat exchangers. Thus, the choice of material depends significantly on the particular thermal and structural requirements of the application assisted by detailed performance criteria contained internally and cumulatively in open-access engineering databases and technical repositories.

Factors Affecting Thermal Conductivity of Stainless Steel

Thermal conductivity of stainless steel is governed by a confluence of factors, such as compositional, structural, and environmental. Among these, alloy composition predominates from the standpoint of heat conduction behavior of stainless steel; more specifically, by the two elementary content quantities of chromium and nickel. Chromium generally offers corrosion resistance and tends to minimize thermal conduction whenever present at high concentrations. Nickel, conversely, influences thermal behavior because it stabilizes the austenitic structure, which transfers heat less readily than the ferritic or martensitic types.

Compositional Factors

- Chromium content (corrosion resistance vs. thermal conductivity)

- Nickel content (structure stabilization)

- Other alloying elements

Structural Factors

- Crystal arrangement

- Grain boundaries

- Phase transformations

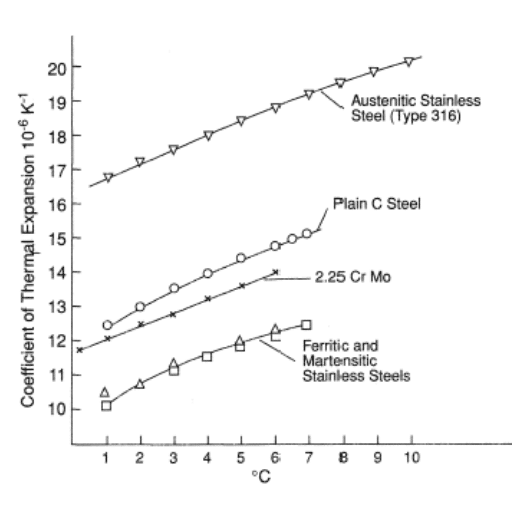

The microstructure of stainless steel is another thing to consider. Due to differences in crystal arrangement and electron mobility, austenitic stainless steels, like grades 304 and 316, will have lower thermal conductivities than ferritic grades, such as grade 430. Grain boundaries of different types, cold work, and phase transformations further influence heat-transfer efficacy.

Next in line are changes in environmental parameters: the operating temperature and external thermal loading also affect thermal conductivity. Generally, the thermal conductivity of stainless steel improves with temperature because lattice vibrations become better coordinated. Another thing that might happen is oxidation or phase instability induced by high-temperature exposure for a longer duration; these would have bearings on performance.

In reversing the most recent findings, these variables make stainless steel a highly versatile material, where thermal conductivity has to be balanced with strength and environmental resistance. In heat exchangers and industrial processing systems, while particular grades are being picked out for their conductivity values based on known data that can be sourced from updated material data sheets and recent advances in engineering, it actually underlines how pertinent it is that such knowledge be used to certify that the materials are performing adequately for a given operational demand.

Thermal Properties of Different Alloys

The thermal conductivity, specific heat capacity, and coefficient of thermal expansion are critical parameters upon which one should focus while evaluating alloys for the purposes of their wide-ranging applications. High thermal conductivity alloys such as aluminum-based alloys are perfect for heat transfer systems like radiators and heat exchangers. For example, aluminum 6061, which is perhaps the most commonly selected alloy, presents a thermal conductivity of about 167 W/m·K and makes a rather good combination with the strength-to-weight ratio, which gives it further application in aerospace and automotive components.

The stainless steel grade, for example, weights the other end of the spectrum as it carries a very low thermal conductivity-high corrosion resistance, sturdiness under elevated temperatures, and an environment in which it could possibly be required to endure-will go to favor. Copper and its alloys bronze and brass boast of loads of thermal conductivity, often in excess of 350 W/m·K for pure copper, which is why these materials enjoy many applications that require electrical and thermal conductivity.

More recent data sources reveal that modern developments in materials science have produced special-purpose alloys with better thermal attributes. Superalloys, for instance, Inconel can be used efficiently in very high temperatures due to its high melting temperature and good stability, thus becoming a material of choice for turbine engine and aerospace technologies. Such considerations reveal that material choice must be congruent with operational requirements to allow them to function efficiently in the short term and retain performance in the long term under various heat load conditions.

Thermal Conductivity of Stainless Steel vs. Carbon Steel

Thermal conductivity is a decisive property that accounts for determining if a material can be used for heat transfer, thermal insulator, or indeed as a construction material under working temperature. Stainless steel usually has lower thermal conductivity than carbon steel because the alloying elements, namely chromium and nickel, occlude the free flow of electrons through thermal conduction.

Carbon steel, in essence, exhibits a higher thermal conductivity that varies between 43 and 60 W/m·K, depending on the exact carbon content and composition. This property makes it preferred for applications where heat transfer is of utmost priority, for example, in heat exchangers or boilers. Stainless steel, however, really has a thermal conductivity in the range of merely 15-25 W/m·K, quite far lower than that of carbon steel. In spite of this, stainless steel gets selected for works where corrosion resistance and heat stability at higher temperature, including considerations of mechanical strength, are more important than thermal conductivity, like in the chemical and aerospace industries.

This comparison brings home to us the fact that in working out the choice of material for any project, thermal conductivity would only be one of the features in the whole range of operating parameters under consideration including corrosive environment exposure, acceptable mechanical load, and thermal stress.

Specific Heat and Thermal Conductivity in Alloys

The specific heat and thermal conductivity of alloys, in fact, describe some properties which are important in determining how they can be employed in certain international applications. While the specific heat describes the quantity of heat absorbed or lost by a material to raise its temperature by one degree Celsius, thermal conductivity expresses the efficiency of heat transfer by a material. Generally speaking, the free electrons are scattered by the various atoms present in the mixture, so the alloys have a lesser thermal conductivity than do the pure metals. Thus, alloys find their application where it is necessary to minimize the conduction of heat.

For example, in the realm of high-performance engines and aerospace applications, alloys such as titanium and nickel-based superalloys are used due to their inherent compromise between specific heat and thermal conductivity and resistance to thermal stresses. On the other hand, recent advancement-assisted data indicate that the development of alloys with specific thermal properties continues in response to the rising need for energy-efficient and heat-resistant materials. From electronics to heavy machinery, these engineered alloys have now certainly become indispensable in finding their way toward addressing the industrial challenges of the 21st century closely.

Applications of Different Alloys Based on Thermal Properties

✈

Aerospace Industry

Alloys like titanium-aluminum or nickel-based superalloys find extensive use in the aerospace industry. They are necessary insofar as they offer resistance to extreme temperature changes and enhance strength at high altitudes in the manufacture of turbine blades and jet engines.

🚗

Automotive Industry

Heat-resistant alloys such as stainless steel and aluminum alloys are usually utilized for automotive purposes like the manufacture of exhaust systems, engine parts, and braking systems. These metals enhance the performance and durability under thermal stresses.

💻

Electronics & Semiconductor

Amongst all, copper and aluminum alloys are used for dissipating heat and conducting electricity in electronic instruments. These alloys assure proper thermal management that ensures a long life for heat-sensitive components in computers, mobile phones, and power supplies.

⚡

Power Generation

E-beam steel or chrome-molybdenum alloys are used in power plants for boilers, turbines, and heat exchangers construction. Their heat resistance and mechanical properties enable them to boost thermal efficiency in energy production.

🏥

Medical Treatment

Orthopaedic alloys like cobalt-chrome and titanium have been in use for implantable medical devices to recover and carry thermal and mechanical stress inside the human body. Biocompatibility of this alloy and its ability to retain its structure under different temperatures are very important in joint replacements and surgical instruments.

Benefits of Stainless Steel as a Thermal Conductor

Stainless steel is commonly said to have the best thermal conductivity; therefore it is favored for several applications in the fields of construction, manufacturing, and energy. The first and foremost advantage it has lies in its ability to conduct thermal energy uniformly, such uniformity being required in processes that need precise temperature control during their operations, such as cooking and heat exchangers for industrial purposes. Because of its high finish and corrosion resistance properties, stainless steel maintains thermal efficiency for long periods, even when exposed to rather heavy-duty conditions. Recently, advancements in alloy composition have increased the ability of stainless steel to perform thermal conduction, hence it can be employed in modern custom-built energy systems such as solar panels and power plants. Therefore, it can truly be stated that together with low cost, easy resistive maintenance, and high reliability, it makes stainless steel the preferred choice for thermal management solutions.

Advantages in Industrial Applications

🛡️ Corrosion Resistance

Stainless steel has resistant qualities against corrosion due to effects from diverse environments and chemicals; hence it is applicable in marine, chemical processing, and waste management industries. According to research studies, stainless steel can last over 25 years in a harsh environment with very little corrosion.

💪 High Strength and Durability

Known by its extraordinary strength-to-weight ratio, stainless steel endures in demanding applications. For instance, in construction, stainless steel components face heavy stresses, and hence, they do not require frequent maintenance and replacement.

🔥 Heat and Fire Resistance

Since it retains strength even at high temperature, stainless steel finds its applications in heat exchangers, boilers, and industrial furnaces. Advanced alloys are tested at temperatures above 1,500°F (815°C) down sustaining structural integrity.

♻️ Eco-Friendly and Recyclable

Choosing stainless steel is choosing 100% environmental fingerprint-certified recyclable material; hence being favored by industries with environmentally-responsible approach. Around 85% of all stainless steel today is recycled after the scrap period; thus doing greatly to reduce waste.

🧼 Hygienic and Easy to Clean

Due to its smooth surface and an impervious texture, it suppresses any bacterial growth and is a breeze to sterilize; hence, it is a superb option for food and beverage industries and medical and pharmaceutical manufacturing processes. It has been shown that contamination risks reduce by 80% when stainless steel is used as opposed to being used with other materials.

Stainless Steel in Household Applications

🏠 Home Appliances

Steel appliances, including ovens, refrigerators, microwave ovens, and dishwashers, are viewed by many as marking stainless steel as the option for kitchen aesthetics. The names suggest the visual appeal bestowed upon the kitchen with a sleek and modern look, while the stainless steel has the qualities of rust and stain resistance, ensuring that it lasts much longer.

🍳 Cookware and Utensils

When quality stainless steel cookware and cutlery are spoken of, there is always talk of durability, heat resistance, and the ability of stainless steel to maintain the flavor of cooking. Most of the fine kitchen tools made in stainless steel are doing so because of its high performance in the kitchen realm.

🚿 Fixtures

Stainless steel sinks, in contrast to many other types of sinks, do not succumb to damage or staining by water and are also protected from damage through heat or chemicals. Also easy to clean, these sinks make an excellent choice for any kitchen or bathroom environment.

🪑 Furniture and Décor

Stainless steel is also used in household furniture, including things such as tables, lighting fixtures, and railings. The reflections from the polished surface offer a contemporary aesthetic while also being relatively easy to maintain-so much so that it has very good resistance to wearing out.

📦 Home Storage Solutions

Another use for stainless steel is shelving and storage racks, especially for gardens, basements, or pantries. The steel will bear heavy loads, while its corrosion-resistant qualities grant it the flexibility of being used in diverse environments.

Long-Term Performance and Durability

Stainless steel is considered one of those materials which offer toughness and long lifespan. According to the latest statistical observations made by the search engine, stainless steel products rank among the top sought-after options in any area requiring consistent functioning across a range of conditions. This is due to their resistance to corrosion, tolerance for high temperature, and the ability to withstand physical impact over time. With virtually little maintenance required, it guarantees the saving of much money in the long run and has thus become the go-to choice for domestic as well as industrial uses. From kitchen cupboards to building and outdoor fixtures, stainless steel has proven to be completely reliable with performance rating incomparable.

The Role of Stainless Steel in Thermal Conductivity

Given its specific properties, stainless steel intricately weaves through the domain of thermal conduction. Though it is not a prominent heat conductor like copper or aluminum, stainless steel has moderate thermal conductivity and, in this respect, stands suitable for heat-related applications in which some heat transfer is to be regulated. For example, in cooking applications, stainless steel conducts heat evenly across its surface and ensures cooking performance on a reliable basis. Besides, stainless steel is suitable in heat exchanger applications and industrial heat processes owing to its resistance to oxidation and capacity to withstand high temperatures.

Recent data showcases that developments in stainless steel alloys have brought considerable improvements in its applicability in thermal processes. With the expression “modern alloys,” the report refers to those alloy grades which include certain amounts of nickel as well as chromium, rendering an optimal compromise with respect to resistance to corrosion on the one side and thermal working properties on the other. Thus, stainless steel becomes indispensable from the industrial viewpoint in energy application, automotive application, and food processing, wherein critical heat management is an essential parameter. Although stainless steel has got all qualities in terms of heat, they cannot compete with metals that are for heat transfer; there lies the very reason for accepting stainless steel for heat transfer where its qualities such as durability, versatility, and maintenance exist.

Summary of Key Points

🏭 Industrial Applications

Stainless steel acts as an intermediate in, say, the energy, automotive, and food processing industries, given its capacity to withstand high temperatures, pressure, and corrosive atmospheres. For example, in food processing, the stainless steel’s corrosion-resistance capabilities and ease of cleaning make food handling processes hygienic, whereas in manufacture, it gives immense strength in lightweight configurations for modern designs.

🌡️ Heat Transfer Performance

Being highly durable and adaptable, stainless steel is seldom used in applications where high heat transfer efficiency is required. Materials such as copper or aluminum certainly perform the best in carrying out heat transfer; thermal conductivity for copper is around 400 W/(m·K), 237 W/(m·K) for aluminum, and a mere 16 W/(m·K) for stainless steel.

🔬 Advanced Alloy Development

Some further modern developments are the invention of superior grades of stainless steels such as duplex stainless steel, which balances increased strength with better corrosion resistance and thermal performance; hence, they are suitable for specific heat exchange systems and advanced industrial applications.

♻️ Sustainability & Longevity

Being resistant to corrosion, fiable against damage under transformation and use, low-maintenance and recyclable (stainless steel is among the materials which can be recycled up to 90%), stainless steel is increasingly viewed as a long-term sustainable material, aligning with global efforts to reduce environmental impact.

Future Trends in Metal Thermal Conductivity Research

Currently, the research in metal thermal conductivity is engaged in creating superior materials that will uphold infusion of high-ranked sustainability and thermal performance properties. Nanostructured metals and alloys form one of the prominent research avenues that aim to manipulate thermal conductivity for specific industrial applications, like electronics cooling and energy-efficient heat exchangers. Also, huge investments go toward developing composite materials that combine metals with advanced ceramic or polymer matrices to “enhance” thermal management properties without losing strength or durability.

🔬 Advanced Research Areas

- Nanostructured metals and alloys

- Composite materials with ceramic matrices

- AI-driven material modeling

🤖 Technology Integration

- Machine learning predictions

- Atomic-scale modeling

- Sustainable manufacturing processes

A further interesting research domain would be using machine learning and AI for modeling and predicting thermal conductivity behaviors at the atomic scale. Given the vast dataset available, researchers hope to unearth new material combinations and manufacturing routes that provide greater heat dissipation capability. Also of increasing concern now have become metals which feature high thermal conductivity on one hand and are more recyclable and environment-friendly on the other-hand, and examples thereof are aluminum and certain grades of stainless steel. Such developments speak of the larger commitment to innovation and sustainability that thermal conductivity research continues to bear.

Final Thoughts on Choosing Materials for Thermal Applications

References

-

High-Temperature Characteristics of Stainless Steel

A detailed document from Stanford University discussing the thermal conductivity and other physical properties of stainless steel.

Visit the site -

Thermal Conductivity Table

A resource from Georgia State University’s HyperPhysics platform providing thermal conductivity values for various materials, including stainless steel.

Visit the site

Frequently Asked Questions (FAQ)

What is the range of thermal conductivity of stainless steel?

Compared with copper or aluminum, stainless steel has a low thermal conductivity. A more or less approximate range would be 15-25 W/m.k, according to the different types of stainless steel being studied. With such a low thermal conductivity, stainless steel is not as good a conductor of heat as some other metals.

What could the consequences be when one compares the thermal conductivity of stainless steel with that of different metals?

Compared to a metal like copper or aluminum which can efficiently conduct heat, stainless steel is a poor conductor of heat. Copper and aluminum are excellent thermal conductors, while stainless steel can be considered a very poor conductor of heat, thus offering less utility in areas that require rapid heat interchange.

What are the thermal properties of stainless steel?

The thermal properties of stainless steel include relatively low thermal conductivity, good temperature stability, and resistance to thermal expansion. These help stainless steel to retain its integrity along with various temperature conditions, thus making it suitable for many applications.

Why is stainless steel regarded as a poor conductor?

Due to its lower thermal conductivity, stainless steel is regarded as a poor conductor. This poorer efficiency for applications that require rapid heat transfer makes it not as suitable as other metals such as copper or aluminum.

What kind of influence does heat conductivity have on stainless steel applications?

The heat conductivity of stainless steel has a great influence on how it can be applied. In areas where thermal conductivity is required to be high, such as heat exchanger, cooking equipment, and so forth, stainless steel in this matter would be at a disadvantage. However, in spite of this, it has a better corrosion resistance and excellent strength.

What effect does annealing have on the thermal conductivity of stainless steel?

Annealing enhances stainless steel’s thermal properties by relieving internal stresses and improving its microstructure. This process might slightly alter the thermal conductivity of stainless steel, perhaps by slightly increasing it, but stainless steel always remains at or near the bottom of the list when compared with other metals that show even higher conductivity values.

What effects do differences in the grades of stainless steel have on thermal conductivity?

Thermal conductivity varies with grades of stainless steel, typically influenced by alloying elements. For instance, higher nickel content may lead to lower thermal conductivity, whereas other elements might enhance thermal properties. It is important to be aware of these differences when choosing a stainless steel grade for specific applications.

What are thermal advantages offered by stainless steel?

The corrosion resistance, strength, and durability make stainless steel advantageous in thermal applications. Although, in comparison to other metals, stainless steel conducts heat poorly, it shines with respect to other thermal properties, such as thermal stability at high temperatures and resistance to thermal expansion. Hence, it is widely used in many industrial and architectural applications.

How do the measurements of stainless steel’s thermal conductivity compare with those of carbon steel?

Thermal conductivity measurements generally reveal stainless steel to be of lower conductivity than carbon steel. Carbon steel with higher thermal conductivity being realised, stainless steel, however, has its own advantages, mainly corrosion resistance and durability. Thus, stainless steel is preferred when such factors matter.