Overview: Stainless Steel 316 is recognized for its superior performance across diverse industries, with thermal conductivity being one of the main properties enabling its use in critical applications. This comprehensive guide explores the thermal properties, composition, and real-world applications of this high-performance alloy in chemical processing, marine equipment, aerospace, and energy systems.

Understanding Stainless Steel 316

What is Stainless Steel 316?

Stainless Steel 316 is a corrosion-resistant austenitic chromium-nickel alloy that excels in environments where chloride exposure occurs, particularly in marine and industrial settings. The alloy composition of approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum creates a protective oxide barrier that prevents rust and pitting.

The key advantage of 316 over its predecessor, 304 stainless steel, is the addition of molybdenum, which significantly enhances resistance to chloride-induced pitting and crevice corrosion. This makes 316 the preferred choice for harsh, corrosive environments.

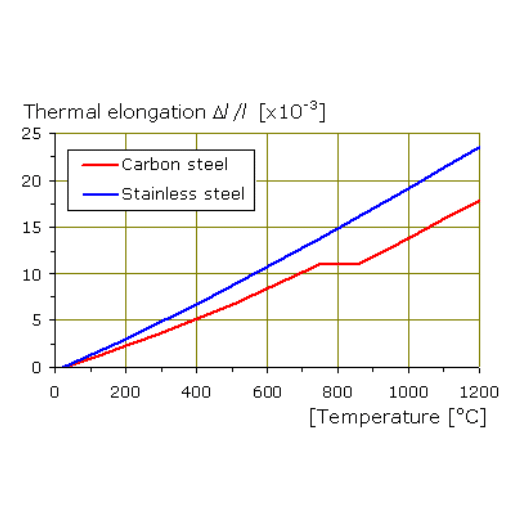

316 Stainless Steel maintains excellent mechanical properties across both high and low temperature ranges, retaining strength and structural integrity even under extremely demanding conditions. The material is available in several forms, with 316L being a low-carbon variant specifically designed for welding applications, minimizing carbide precipitation risk.

Properties of 316 Stainless Steel

Key Physical and Mechanical Properties

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 515 MPa (75,000 psi) | MPa / psi |

| Yield Strength | 205 MPa (30,000 psi) | MPa / psi |

| Thermal Conductivity (20°C) | 16.3 W/m·K | W/m·K |

| Linear Expansion Coefficient | 16.0 µm/m·K | µm/m·K |

| Melting Point | 1,371-1,399°C (2,500-2,550°F) | °C / °F |

| Specific Heat Capacity (25°C) | 500-510 J/(kg·K) | J/(kg·K) |

| Magnetic Properties | Non-magnetic (annealed) | — |

The remarkable ductility of 316 stainless steel allows it to maintain toughness across a wide temperature range, making it particularly suitable for cryogenic applications. Its non-magnetic nature (when annealed) makes it popular in industries requiring magnetic neutrality.

Composition and Microstructure

Alloying Elements:

- Chromium (16-18%): Forms a passive layer of chromium oxide, protecting against oxidation

- Nickel (10-14%): Enhances toughness and tensile strength

- Molybdenum (2-3%): Doubles corrosion resistance, especially in chloride environments

- Iron: Base component

Microstructural Features:

- FCC (Face-Centered Cubic) structure characteristic of austenitic grades

- Exceptional ductility

- Non-magnetic behavior

- Low-carbon variants (316L) minimize carbide formation during welding

Advanced metallurgical techniques have shown that nitrogen alloying can be effective in grain refinement, leading to increased yield strength. This precise composition makes 316 stainless steel ideal for challenging applications including chemical storage tanks, heat exchangers, and seawater equipment.

Thermal Conductivity of 316 Stainless Steel

Defining Thermal Conductivity

Thermal conductivity is a material property that measures how effectively heat energy transfers through a substance. It is expressed in watts per meter-Kelvin (W/m·K). Materials with high thermal conductivity (such as copper and aluminum) are used extensively in electronics cooling, heat exchangers, and energy systems, while lower thermal conductivity materials are preferred for insulation applications.

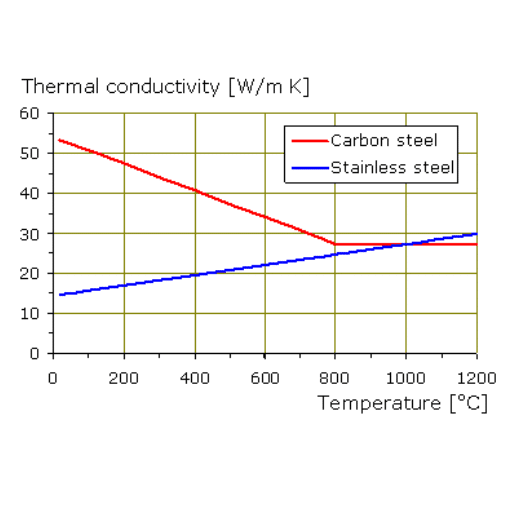

Thermal Conductivity Values

| Temperature (°C) | Thermal Conductivity (W/m·K) |

|---|---|

| 20°C (Room Temperature) | 16.3 |

| 500°C | 21.5 |

Key Point: The relatively low thermal conductivity of 316 stainless steel (compared to aluminum or copper) is characteristic of stainless steels and allows for controlled thermal transfer in corrosive, high-pressure environments. This property ensures effectiveness in chemical processing, marine engineering, and energy production applications.

Factors Affecting Thermal Conductivity

The thermal conductivity of 316 stainless steel is determined by both intrinsic and extrinsic factors:

Intrinsic Factors:

- Atomic structure and electron mobility

- Crystal lattice vibrations (phonons)

- Composition of alloying elements (chromium, nickel, molybdenum percentages)

Extrinsic Factors:

- Temperature changes

- Mechanical stresses

- Material purity and microstructural defects

Impurities or microstructural defects can disturb thermal conduction pathways, reducing the overall thermal efficiency of the material. Thorough thermal assessments are essential in engineering systems where accurate heat transfer predictions are critical.

Temperature Effects on Thermal Conductivity

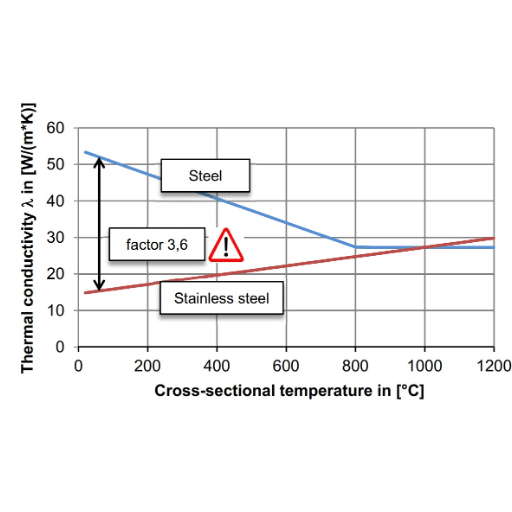

Temperature significantly influences thermal conductivity behavior in 316 stainless steel. Unlike some materials, the thermal conductivity of stainless steel generally decreases with increasing temperature, a phenomenon caused by increased scattering of electrons and phonons at the atomic level.

| Temperature Range | Expected Thermal Conductivity Trend |

|---|---|

| Room Temperature (20°C) | 16.3 W/m·K (baseline) |

| Moderate Heat (200-500°C) | Gradual increase initially to ~21.5 W/m·K at 500°C |

| Extreme Heat (>500°C) | May decrease or plateau due to atomic vibration effects |

In engineering applications involving high temperatures—such as heat exchangers, boilers, and industrial furnaces—even slight variations in thermal conductivity can significantly impact performance. Therefore, accurate, temperature-specific thermal conductivity data must be integrated into design calculations to ensure safety, efficiency, and reliability.

How Temperature Influences Thermal Conductivity

Thermal conductivity fundamentally depends on temperature because the kinetic energy of particles increases with heat. At the atomic level, heat transfers through lattice vibrations (phonons) and free electron movement. Most metals, including 316 stainless steel, experience reduced thermal conductivity at higher temperatures due to increased electron and phonon scattering.

In contrast, non-metallic materials like insulators and ceramics may exhibit different behavior, with thermal conductivity sometimes increasing at lower temperatures as phonon movement becomes more ordered, before plateauing or decreasing at higher temperatures due to lattice anharmonicity and scattering effects.

Specific Heat Capacity of 316 Stainless Steel

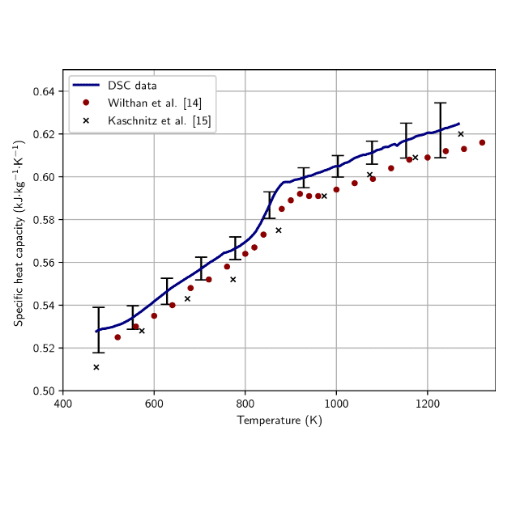

The specific heat capacity of 316 stainless steel typically ranges between 500-510 J/(kg·K) at ambient temperature (~25°C). This value indicates the heat energy required to raise the temperature of 1 kg of the material by 1 Kelvin, reflecting its capacity for heat absorption and retention.

Specific heat capacity may fluctuate with temperature as metals undergo minor alterations in thermal characteristics over extended temperature ranges. For accurate engineering applications, consult manufacturer-specific material data sheets or experimentally obtained data for precise operating conditions.

Applications at Different Temperature Ranges

Low-Temperature Applications (Below 50°C)

In cryogenic systems and refrigeration equipment, high specific heat capacity materials are commonly used. For example, liquid nitrogen at 77 K has a specific heat capacity of 1.04 J/g·K and is employed in biological sample preservation and cooling of sensitive equipment.

Moderate-Temperature Applications (50°C to 200°C)

Heat transfer fluids such as silicone oil and water-glycol mixtures perform well in this range. Silicone oil, with a specific heat capacity around 1.5 J/g·K, is involved in pharmaceutical production, heating system operations, and similar industrial processes.

High-Temperature Applications (200°C to 600°C)

Industrial operations requiring high temperatures utilize specialized oils and molten salts with stable thermal properties. Molten nitrate salts, with a specific heat of 1.6 J/g·K, are widely used for storage and transfer of thermal energy in solar power plants.

Ultra-High-Temperature Applications (600°C to 1,000°C)

Ceramic and metallic materials capable of tolerating extreme thermal conditions are essential in this range. Alumina (Al₂O₃), with a specific heat of 0.88 J/g·K, is frequently used as an insulating material in gas turbines and power generators.

Extreme-Temperature Applications (Above 1,000°C)

Refractory materials like zirconium dioxide (ZrO₂) offer high thermal stability with a specific heat capacity of 0.58 J/g·K. Zirconia is the primary material choice for furnace linings, high-temperature kilns, and aerospace components subjected to intense thermal stress.

Applications of 316 Stainless Steel

Marine Environments

316 stainless steel is exceptionally durable in marine applications due to its high resistance to seawater corrosion, attributed to its elevated molybdenum content (2-3%). Common marine applications include:

- Ship hulls, decks, and superstructures

- Propeller shafts and bearings

- Boat fittings and hardware

- Offshore drilling rigs and platform structural components

- Subsea cabling and protective casings

- Desalination plant equipment (evaporators, reverse osmosis systems)

The material’s resistance to chloride-induced stress corrosion cracking prolongs the life of costly marine installations and reduces maintenance downtime significantly.

Chemical Processing Equipment

The excellent chemical corrosion resistance of 316 stainless steel makes it the preferred material for:

- Storage tanks and reactors

- Process piping systems

- Heat exchangers

- Valves and fittings

Its outstanding ability to withstand oxidation and corrosion under extreme temperatures and pressures makes it suitable for industrial boilers, evaporators, and complex chemical processing environments.

Food and Beverage Industry

316 stainless steel is the preferred material for food-related applications due to its superior hygienic characteristics and ability to withstand repeated cleaning and sterilization cycles:

- Brewing and fermentation tanks

- Dairy machinery and equipment

- Mixers and stirring equipment

- Storage tanks and conveyor systems

- Food processing equipment

Its non-reactive nature prevents chemical interactions with food, ensuring quality and safety standards are maintained.

Medical Implants and Surgical Instruments

The biocompatibility and non-reactive properties of 316 stainless steel make it the choice for:

- Orthopedic implants

- Surgical instruments

- Medical devices and equipment

- Implantable components

The material’s ability to withstand rigorous sterilization processes without degradation, combined with its biocompatibility, reduces the risk of rejection and infection in medical applications.

Oil and Gas Industry Applications

In harsh environments containing sulfides and chlorides, 316 stainless steel is found in:

- Pipelines and flow lines

- Offshore drilling equipment

- Downhole tools and components

- Heat exchangers and process equipment

Its exceptional resistance to pitting and crevice corrosion makes it indispensable in this demanding industry.

Industrial Manufacturing and Heavy Machinery

316 stainless steel serves as a go-to material for numerous industrial processes:

- Structural components for heavy machinery

- Robust frameworks in manufacturing plants

- Fasteners for extreme environments

- Equipment requiring durability and corrosion resistance

The material’s ease of fabrication and welding (especially the 316L variant) contributes significantly to its widespread adoption in manufacturing applications.

References

-

Stainless Steel 316 – Georgia Institute of Technology: This source provides detailed thermal properties, including thermal conductivity, specific heat capacity, and thermal diffusivity.

-

Thermal Conductivity of a Sample of Type 316 Stainless Steel – Northeastern University Library: A book reference discussing the thermal conductivity of type 316 stainless steel.

-

Thermal Conductivity and Electrical Resistivity of Type 316 Stainless Steel – NASA Technical Reports: A NASA technical report providing experimental data on the thermal conductivity and electrical resistivity of type 316 stainless steel.

Frequently Asked Questions (FAQ)

What is the thermal conductivity of stainless steel 316?

The thermal conductivity of stainless steel 316 is around 16.2 W/m·K. This trait makes it a good choice in different industries, especially in places where high corrosion resistance is needed.

How much lower is the thermal conductivity of 316 stainless steel compared to 304?

316 stainless steel has usually slightly lower thermal conductivity than 304 about 16.3 W/m·K; 304 being the more conductive one. This slight difference might make one the more preferred material than the other for specific industrial equipment applications.

What is the significance of stainless steel 316 thermal conductivity for its applications?

Stainless steel 316 is high in thermal conductivity and also has excellent corrosion resistance thus, it is usually very quick to be found in marine environments, chemical processing, and food processing equipment, which indeed all are a very good source for diverse industrial applications.

Can its composition alter 316 stainless steel thermal conductivity?

Definitely, the thermal conductivity of stainless steel 316 can be determined to some extent by its alloying elements. It is true that molybdenum and nickel play a significant role in making its properties different from others, and these properties are thermal performance and corrosion resistance.

What guarantees the 316 stainless steel to be the best in fasteners?

Stainless steel 316 boasts high corrosion resistance coupled with good thermal conductivity therefore, it is an appropriate option for fasteners used in extreme environments like marine or chemical applications where durability is a must.

How do I locate a supplier for stainless steel 316 products?

In searching for a supplier of stainless steel 316 materials, it is best to use the internet to look up directories, industry-related websites, or straightaway contact metal distributors in your area that specialize in stainless steel and can also offer you technical specifications.

What considerations should be taken into account while selecting stainless steel 316 for industrial equipment?

In the process of choosing stainless steel 316 for industrial equipment, one should consider thermal conductivity, corrosion resistance, mechanical properties, as well as the particular environment of usage in order to guarantee the best performance and life span.