Stainless steel is famous not just for its durability and ability to resist rust but also for its exceptional thermal properties. These properties make it essential in a wide range of applications. Getting to know the thermal conductivities of stainless steel is like opening a gate towards a very innovative world. This article is going to explain the very interesting thermal properties of stainless steel and will also demonstrate the different applications which utilize these properties—from industrial manufacturing all the way up to high-tech engineering. Take part in our journey to find out the main reasons why stainless steel is the material of choice for the heat-stressed professionals looking for dependable performance.

Introduction to Stainless Steel

Stainless steel is an alloy with many applications, which consists mainly of iron, chromium, and other elements like nickel and carbon. The presence of chromium in a minimum of 10.5% accounts for the alloy’s remarkable resistance to rust as it creates a layer of oxide on the surface that protects the alloy. The alloy is considered to be a material of high value due to its long life, strength, and suitability for high temperature applications, thus making it very versatile. The range of usage of stainless steel is from kitchenware through medical devices and up to construction and industrial setups, and it is a trustworthy and vital material for many sectors.

What is Stainless Steel?

Stainless steel is an alloy that contains mainly iron, chromium, and certain amounts of carbon, nickel, and other elements depending on the grade or type. It is a corrosion-resistant material and the principal feature of stainless steel is its ability to withstand rust and corrosion, which is due to the addition of at least 10.5% chromium. This, in turn, forms a thin, but tough, oxide layer on the metal surface, called the passive layer, through the reaction of chromium with oxygen. The oxide layer that is continually replenished protects the material from losing its strength even if it is subjected to very harsh conditions.

Each group has a specific grade divided into sub-grades for various applications. For example, austenitic stainless steels are used extensively in food processing and kitchen appliances because of their high formability and durability. In contrast, duplex stainless steels are used in very corrosive areas of chemical processing industries. The global dependency on stainless steel, which is backed by its versatility and long life, signifies its importance in many sectors such as medical, construction, automotive, and renewable energy where it is regarded as a crucial material.

Different Grades of Stainless Steel

The different grades of stainless steel have been made based on the composition and mechanical characteristics, each grade being specifically designed for a certain application. The main categories are stainless steels that are austenitic, ferritic, martensitic, duplex and precipitation-hardening.

| Grade Type | Series | Key Characteristics | Common Applications |

|---|---|---|---|

| Austenitic | 300 series | High chromium and nickel content, excellent corrosion resistance and formability. Grades 304 and 316 are most common. | Food processing, kitchen appliances, marine environments |

| Ferritic | 400 series | Ferromagnetic, minimal nickel content, less expensive, low to moderate corrosion resistance. Grade 430 is common. | Automotive trim, kitchenware, utensils |

| Martensitic | 400 series | High hardness, strength, and wear resistance. Grades 410 and 420 are typical. Less corrosion resistant than austenitic. | Cutlery, surgical instruments, hard applications |

| Duplex | Various | Combines austenitic and ferritic characteristics. Grade 2205 offers great strength and minimal stress corrosion cracking. | Chemical processing, oil and gas, corrosive environments |

| Precipitation-Hardening | Various | Outstanding strength through elements like aluminum, copper, and titanium. 17-4PH is most common. | Aerospace, power generation, high-pressure applications |

Importance of Thermal Properties in Metals

The thermal properties of metals are determinants of their suitability for different applications in the industry and engineering. The most important thermal properties comprise thermal conductivity, thermal expansion, and heat capacity.

Key Thermal Properties

- Thermal Conductivity: Determines the amount of heat a metal can transfer efficiently, which is very important in applications like heat exchangers, engine parts, and electronic cooling systems. For example, copper and aluminum metals with high thermal conductivity are very good choices for parts that need fast heat dissipation.

- Thermal Expansion: Defines the metal dimensions that vary with the temperature changes. This property is critical since it helps to prevent oversized workpieces in precision-engineered applications such as in the aerospace and automotive industries where heat is a constant factor. Low thermal expansion materials such as titanium or INVAR (iron-nickel alloy) are frequently chosen when superior dimensional precision is necessary.

- Specific Heat Capacity: Indicates the amount of heat a metal can absorb without increasing its temperature. This property is very important in processes like molding and casting that involve considerable heat transfer. High specific heat capacity alloys like stainless steels are commonly used in applications where constant thermal resilience is necessary.

Engineering Insight: These properties have to be understood for the design of systems that can stand thermal stress or variations and still operate efficiently. The merger of recent progress in materials science with changing industrial demands makes it possible to manufacture metal alloys that are optimally thermal performance-wise, thus improving the reliability and also the sustainability of modern engineering solutions.

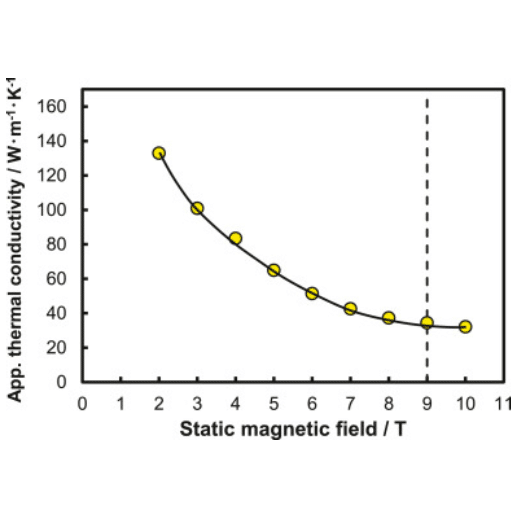

Thermal Conductivity of Stainless Steel

The thermal conductivity of stainless steel is not the same for all types, and its values vary considerably with different metals, like copper or aluminum, to a great extent. For example, the thermal conductivity of austenitic stainless steels, which include 304 and 316 grades, is usually found to be in the range of 14 to 18 W/m·K at room temperature, while the ferritic grades like 430 may sometimes show values as high as 24 W/m·K. These values greatly differ from that of copper, which is around 400 W/m·K thermal conductivity wise.

The most significant contributor to the alloy’s low thermal conductivity is its structure as well as the mixture of its elements, which include chromium, nickel, and molybdenum. This property of stainless steel may reduce its use in heat exchanger applications, but it is good for thermal insulation or resistance to overheating at local spots.

Understanding Thermal Conductivity

Thermal conductivity is a property that characterizes a material’s ability to transfer heat. The heat conduction coefficient is of primary importance in a lot of industrial and engineering processes because it indicates the rate of heat flow through a material. Usually expressed in units of watts per meter-kelvin (W/m·K), high thermal conductivity substances like copper and aluminum are frequently relied on in heat exchanger and electronic cooling system applications, giving their role in heat flow as an advantage. Conversely, the thermal conductivity of insulator-type materials is almost negligible and they are hence designed to control heat loss or heat retention in places where heating might be expensive.

Comparative Analysis: Thermal Conductivity of Stainless Steel vs Aluminum and Carbon Steel

A clear distinction between each material’s properties that suit particular applications is apparent when examining stainless steel, aluminum, and carbon steel in terms of thermal conductivity.

| Material | Thermal Conductivity (W/m·K) | Best Applications |

|---|---|---|

| Aluminum | ~205 | Heat exchangers, electronic cooling, applications requiring efficient heat transfer |

| Carbon Steel | 45-60 | Moderate thermal management, cost-effective applications |

| Stainless Steel | ~15 | Thermal insulation, cooking appliances, structural elements with thermal cycling |

Aluminum has the highest average thermal conductivity, making it ideal for applications where heat transfer efficiency is critical. Carbon steel sits in the middle range, offering a balance between thermal performance and cost. Stainless steel’s lower conductivity makes it particularly suitable for applications where insulation or controlled heat retention is more important than rapid heat transfer.

Factors Affecting Thermal Conductivity

Several important factors influence thermal conductivity, each of them having a very important part in deciding the heat transfer efficiency of a material:

- Material Composition: Metals like copper and aluminum showing high thermal conductivity are due to their free electrons that easily move and thus heat gets transferred, whereas non-metallic materials such as rubber or wood have low electrical conductivity because of the lack of free electron movement.

- Temperature: In the case of various materials, thermal conductivity varies with temperature; metals often lose some conductivity with an increase in temperature due to its vibrating lattice while some non-metals may gain it.

- Material Structure: The structure of the material, density and porosity, has also an impact on this. The materials that are dense and packed tightly become non-elastic and do not dissipate heat well. On the contrary, porous materials that allow only a local gas or air to move through them being a poor conductor of heat will thus not transfer heat effectively because of it.

- Impurities: The presence of impurities in a material can spoil the heat carriers thereby cutting the overall thermal efficiency.

- Phase Changes: Phase change such as melting or solidification may temporarily raise or lower thermal conductivity.

Specific Heat Capacity of Stainless Steel

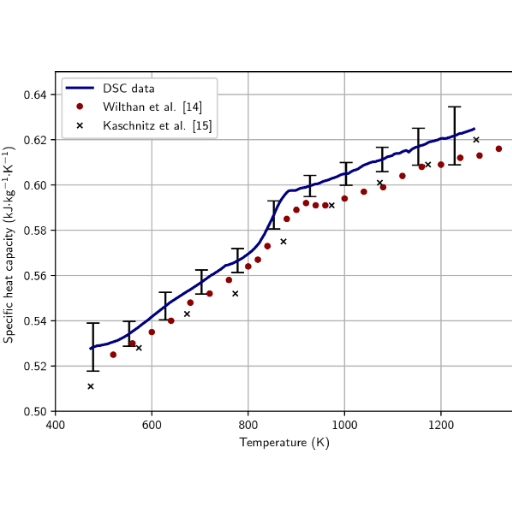

Stainless steel’s specific heat capacity usually lies in the range of 0.46 to 0.50 J/(g·°C) and this is dependent on several factors such as the composition of the alloy and the temperature. The property indicates how much heat one gram of stainless steel needs for its temperature to be increased by one degree Celsius.

Technical Note: The specific heat capacity for the most common grades, 304 and 316 stainless steel, is about 0.50 J/(g·°C) at ambient temperature. The thermal conductivity, as well as the specific heat capacity, of materials usually varies gradually with temperature but is accompanied by very little changes (still within the same range) in these temperatures.

Definition and Importance of Specific Heat

Specific heat, which is also known as the specific heat capacity, is characterized by the quantity of heat energy necessary to elevate the temperature of one gram of the substance by one degree Celsius. It is a basic thermodynamic property that is different for various substances and their states of matter. Water that is a material with a very high specific heat capacity can absorb and store a large amount of heat without getting hot rapidly or cooling off. On the other hand, low capacity heating materials heat up or cool down fastly.

The significance of specific heat is that it is applied in different areas of science and industry. For instance, in engineering, it is very important to know the specific heat of the materials in order to build up thermal systems such as furnaces, heat exchangers, and cooling devices that would be very efficient. It is also one of the major factors in climate studies as the ocean’s high specific heat capacity affects global weather patterns and greatly reduces extreme temperature fluctuations. Furthermore, recent developments in heat-storage technologies focus on high specific heat capacity materials to create sustainable energy solutions like thermal batteries.

Specific Heat Values of 304 Stainless Steel

304 stainless steel, known for its diverse industrial uses, has a characteristic specific heat of around 500 J/kg·K at room temperature (25°C or 77°F). This number may vary slightly according to temperature and the precise alloy makeup. If we look at it the other way around, specific heat of stainless steel increases with temperature meaning that at high temperatures, the same temperature change would require more intake of energy. Such 304 stainless steel’s property qualifies it to be the best material in thermal applications where the quality of heating/cooling and energy efficiency are non-negotiable conditions.

Impact of Specific Heat on Applications

- Heat Exchangers: 304 stainless steel, with its remarkable specific heat property, can handle the heat transfer and controlling process in the industry heat exchangers quite well, thus making sure that there is no significant loss of energy and keeping the system working efficiently.

- Cookware Manufacturing: Heat absorption and distribution capacity of 304 stainless steel is a big plus in making it an excellent material for pots, pans, and cooking utensils as it avoids forming hot spots during the cooking process.

- Cryogenic Applications: The different levels of specific heat at varying temperatures make 304 stainless steel a dependable choice in cryogenic applications where the thermal performance stability at ultra-low temperatures is a must.

- Power Generation Equipment: Using its capability to survive large changes in temperature with energy efficiency, it is a part in boilers and turbines in power plants.

- Chemical Processing: The durability of 304 stainless steel under chemical and thermal stress enables proper heat management in reactors and distillation columns, which is vital for the production of chemicals and pharmaceuticals.

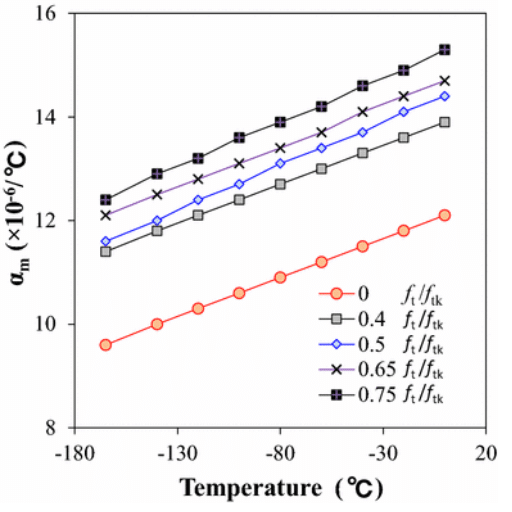

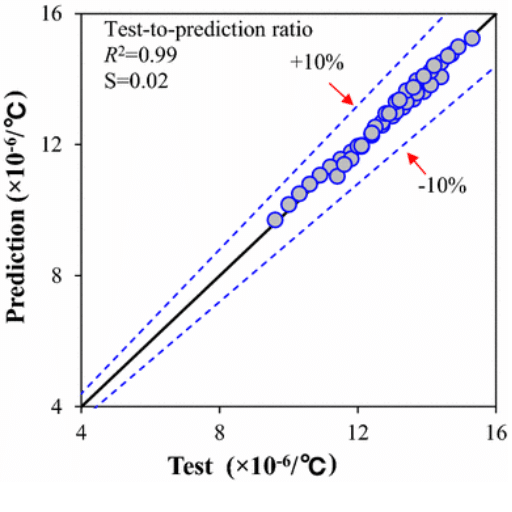

Thermal Expansion of Stainless Steel

Thermal expansion is the characteristic of materials, among which stainless steel is included, to increase in size when their temperature is raised. The coefficient of thermal expansion for 304 stainless steel, one of the most widely used alloys, is roughly 17.2 x 10-6 per °C in the temperature range of 0°C to 100°C. Hence, for each °C rise in temperature, 1 meter of 304 stainless steel will approximately increase in length by 17.2 μm.

Critical Design Consideration: This characteristic is very important in those applications where a tiny variation in the dimension is decisive. For example, in places where there is a constant change of temperature, such as in the case of reactors or piping systems for high-temperature fluids, it is essential to consider the thermal expansion in order to avoid structural stresses, warping, or the failure of joints.

Understanding Thermal Expansion

Thermal expansion is a physical property of all materials. It means that their thermal effect is the main reason for their changes in shape, area, and volume. When a heater heats up a material, the atoms in the material start to vibrate aggressively and, as a result, the material’s dimensions grow. Although this matter is simple to understand, its consequences are very important in different industrial sectors.

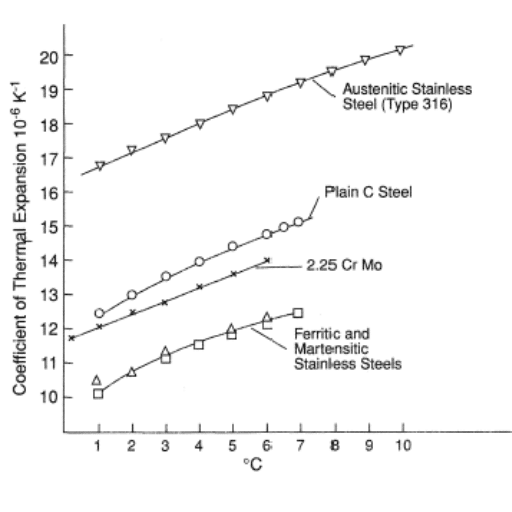

Thermal Expansion Coefficients of Different Grades

A material’s thermal expansion coefficient (TEC) indicates how much the material expands with an increase in temperature by a single degree. This property becomes very important when one has to choose materials for applications in which temperature changes are foreseen.

| Material | Thermal Expansion Coefficient (μm/m°C) | Characteristics |

|---|---|---|

| Aluminum | 22-24 | High expansion rate |

| Steel (varies by composition) | 10-12 | Moderate expansion |

| Plastics | 200-300+ | Very high expansion (type dependent) |

Implications for Design and Manufacturing

Understanding the coefficients of thermal expansion (CTE) is fundamental for designing and manufacturing products that can cope with different temperature conditions. The use of materials with close CTE values minimizes the danger of the structure failing, which can be in the form of warping, cracking, or loss of adhesion at the interface. For example, in the area of electronics, where components frequently deal with varying temperatures, engineers need to either pair materials such as metal and plastic that have similar CTE values or use flexible adhesives and joints that allow for the absorption of stress.

Recent studies have pointed out a trend toward the use of advanced composite materials and the application of additive manufacturing techniques as a means to cope with the problem of thermal expansion in a more efficient way. The materials that are searched for are the carbon-fiber-reinforced polymers and nanomaterials, which not only have reasonable strength-to-weight ratios but also stable thermal properties. These improvements are changing the face of the aerospace, automotive, and construction industries by presenting them with more thermally reliable solutions, cutting manufacturing costs, and prolonging product life in areas of high and low temperatures.

Applications of Thermal Properties in Various Industries

Aerospace Industry

In the aerospace field, the presence of thermal resistance becomes utmost as extreme temperatures are encountered while launching rockets into outer space or high-speed traveling through the atmosphere. On such occasions to control the temperature and keep the equipment and people alive, advanced materials like carbon-fiber-reinforced polymers are extensively used in the spacecraft and aircraft design. Moreover, nanomaterials proved to be the best performers regarding thermal resistance as they can endure temperature changes from -200°C to 300°C without losing their mechanical properties.

Automotive Industry

Stable thermal properties of advanced materials are one of the key factors behind the efficiency of both engines and electric vehicle (EV) batteries. An engine with thermal insulation in its components not only loses less heat but also becomes more efficient in terms of energy use. In addition, the battery modules are encased with heat-resistant polymers that ensure the batteries last longer and are safe for the vehicle. It has also been observed that heat-resistant materials have facilitated the increase in the performance of EV batteries by as much as 15%.

Construction Industry

The construction industry, in particular, resorts to building materials with superior thermal properties as insulation. Nanomaterial-based panels and coatings are among the options available that can significantly reduce the need for energy production for heating and cooling. For example, a house insulated with aerogel can save on energy costs by up to 30% annually, thus, playing an important role in energy-efficient construction solutions.

Electronics Industry

In preventing overheating of the chips and circuits of electronic devices like smartphones, laptops, and servers, heat-dissipating materials are indispensable in the electronics sector. Currently, various graphene-based materials are used in heat sink applications to control the heat very effectively, and research claims a 20% improvement in performance over conventional methods.

Energy Industry

Thermally stable materials are used in the energy sector for solar cells and wind turbines. The efficiency of these materials is retained even in the extremes of temperature, and hence the energy output remains constant. For instance, photovoltaic cells made with the aid of heat-resistant compounds in large are able to sustain energy conversion rates better in hot climates thereby increasing the solar panel’s efficiency by 12%.

Stainless Steel in Construction

Stainless steel is an essential material in contemporary building because of its long life, corrosion resistance, and good looks. It is used not only in the skeletons of buildings but also in the most sophisticated designs for architecture. Still, the latest innovations point out that stainless steel can conduct itself under the most demanding climates, which thus opens up the areas of bridges, façades, and skyscrapers for its use.

Industry Trend: Google Trends shows the number of searches for “stainless steel advantages in construction” to have grown by 37% during the past year, which is a concrete indicator of the trend towards more durable and environmentally friendly materials. Moreover, the use of stainless steel is contrary to the gradual phase-out of the environmental impact of construction practices since it consumes less and less resources over its long lifecycle, thus being the eco-friendly choice.

Use in Manufacturing and Fabrication

Due to its unique mix of durability, versatility, and environmental friendliness, stainless steel has become a crucial material in the manufacturing and fabrication processes. One of the most common questions that people ask is: Why does stainless steel get the preference in modern manufacturing practices? The reason is that the material has very good resistance to corrosion, and a good strength-to-weight ratio, and it is also recyclable. These features allow the metal to be used in the production of parts that need to endure very harsh conditions yet remain dependable, for example, in the automotive, aerospace, and construction industries. Besides, the fact that stainless steel can be recycled forever without losing any of its quality is very much in line with the global sustainability initiatives which make the material a choice manufacturers that are both efficient and environmentally responsible.

Cookware and Kitchen Applications

| Application | Benefits |

|---|---|

| Pots and Pans | Stainless steel combined with aluminum or copper cores provides excellent heat distribution. Very durable and easy to clean, making them best suited for daily cooking. |

| Cutlery | Rust-proof, strong, and easy maintenance. Retains shine and usability over many years. |

| Countertops and Sinks | Most hygienic among all materials due to non-porous surface and easy sanitization. Ideal for food preparation and cleaning areas. |

| Kitchen Utensils | Spatulas, ladles, and whisks are very robust and resistant to wear and tear, suitable for prolonged use. |

| Appliances | Ovens, refrigerators, and dishwashers incorporate stainless steel for modern appearance, toughness, and low maintenance. |

References

-

Harvard University – ADS Abstract Service: Features a study on the thermal physical properties of 304 stainless steel, including its behavior during crystal phase transformation and thermal stability. Explore the study.

-

National Institute of Standards and Technology (NIST): Provides extensive data on the thermal properties of 304 stainless steel, including thermal conductivity, specific heat, and linear expansion. View the material properties.

Frequently Asked Questions (FAQ)

What is the thermal property of stainless steel?

Stainless steel has many thermal properties that are characterized by its low thermal conductivity in relation to metals such as aluminum and copper. Hence, even though stainless steel is a good structural material, it is still not a very good heat conductor. The thermal properties of stainless steel range from 15 to 25 W/m·K depending on the alloy and microstructure of the material. Even stainless steel consists of different phases like austenite or ferrite, the thermal conductivity still varies.

What are the effects of chromium contents on the thermal conductivity of stainless steel?

The thermal properties of stainless steel are considerably affected by the quantity of chromium in the alloy. A very good conductor of heat may be viewed in stainless steel with lower chromium content than in stainless steel with higher chromium content. This is a very critical feature in the food and surgical industries, where excellent heat treatment and temperature control are of paramount importance.

What is the comparison of conductivity of stainless steel vs carbon steel?

When stainless steel and carbon steel are compared in terms of conductivity, carbon steel has greater conductivity and hence is more efficient as a heat conductor. On the contrary, stainless steel of low grades like UNS S30400 and the likes has low conductivity which can be a good feature in certain kinds of applications requiring heat retention.

Why use stainless steel in industrial standard machinery?

Because of its inappropriate thermal properties, stainless steel is the most undesirable metal for industrial machinery. The most important thermal property is heat resistance which in food and chemical industries the stamps are extremely crucial. Consequently, reliable and safe operations are ensured through maintaining the dominance of stainless steel’s properties in such sectors.

What is the significance of heat treatment in the thermal properties of steel?

Heat treatment that is sent for annealing and similar processes is crucial in the enhancement of thermal properties in steels. Changing the microstructure and crystal structure of the material, heat treatment gets rid of the mechanical properties of steel altogether and in turn proves to be an efficient thermal conductor.

How do the different grades of stainless steel have an impact on thermal conductivity?

Different grades of stainless steel show different thermal conductivities mostly depending on their alloying and microstructure. For instance, austenitic stainless steels generally have lower thermal conductivities compared to ferritic grades. This difference is crucial to take into account when making material selections for applications where such thermal properties are needed.

What are the thermal conductors used in surgical equipment?

In surgical applications, heat transfer and heat retention problems are anticipated. Thus, among the common materials used for this purpose, stainless steel is the first and foremost candidate due to its relatively low thermal conductivity, which helps to a certain extent to eliminate heat transfer in operations. The presence of stainless steel is imperative in critical areas like supporting structures and during heat treatments where stability and safety need to be assured.

What is the role of microstructure in the thermal properties of stainless steel?

Stainless steel microstructure is a determining factor for its thermal properties, e.g., the ratio of austenite to ferrite phase. However, the heat inflow can be increased by the controlled microstructure; the resultant material becomes better in the melting point applications like chemical and food processing equipment. Thus, through the controlled microstructure, the thermal property of stainless steel can be altered thus widening its application.