Anyone engaged in plumbing, construction, or DIY projects need to comprehend various types of copper pipes. Copper pipes have been a reliable option for years due to their endurance, reliability, and ability to be used in many different ways. But not every copper pipe is the same, and selecting the wrong type for your particular application can easily affect its efficiency and life span. This guide will help you recognize copper tubes’ primary types, their distinct properties, and the usual applications of each, thus allowing you to make well-informed choices for your project. It does not matter if you are an expert contractor or a homeowner who is simply interested in learning; the article has a lot of information that will enable you to understand the copper piping fundamentals.

Introduction to Copper Pipes

The Importance of Knowing Different Types of Copper Pipes

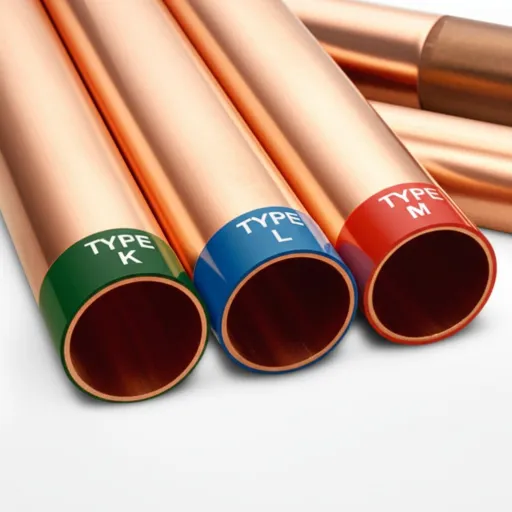

It is very important to know the different types of copper pipes, as it will help you choose the right material for your project needs, thereby directly affecting the project’s efficiency, safety, and cost-effectiveness. The search engine’s latest data lists the types of copper pipes based on commonness as Type K, Type L, and Type M, all made for certain purposes. For example, thick-walled Type K pipes are the best choice for underground installations since they would last there. Type L water supply lines are often used in homes because their strength and price are on the same level. The lightest of all options—Type M—finds its application in low-pressure settings like drainage systems. It is always cost to understand these differences as misunderstandings might end up with extra expenses or even project delays, thus time-saving, and integrity of your project ensured.

💡 Key Insight

Selecting the appropriate copper pipe type directly impacts project efficiency, safety, and long-term cost-effectiveness. Understanding the differences between Types K, L, and M prevents costly mistakes and project delays.

Common Applications of Copper Tubing

Copper tubing is a material that is used by many different industries and applications because of its various useful properties such as being versatile, durable, and corrosion resistant. The most common application is in plumbing systems for residential and commercial properties, where it is the main supply and distribution line for the water. Besides, its high-temperature and pressure-resistance together with the need for air conditioning (HVAC) systems make it a good choice at refrigeration lines and condensers.

Also, among the uses of copper tubing is the medical gas delivery system in hospitals and clinics. The reason for using copper tubing is its high purity and reliability in transportation. Its antimicrobial properties give added value to such applications. Moreover, copper piping is used in the chemical and gas transport industries; its resistance to corrosion is a guarantee of purity for the substances being conveyed.

Copper tubing is a vital component of renewable energy systems—solar thermal systems, for example, where it plays a major role in transferring heat from solar collectors to storage tanks. Moreover, super conductivity makes copper tubing ideal for electrical systems, grounding rods, and wire connections.

Worldwide the demand for copper tubing is still strong due to its critical role in innovative energy-efficient technologies, the healthcare sector, and reliable plumbing solutions.

🔧 Common Applications of Copper Tubing

- Residential & Commercial Plumbing: Primary water supply and distribution systems

- HVAC Systems: Refrigeration lines and condensers due to high-temperature resistance

- Medical Gas Delivery: Hospital and clinic systems requiring high purity and antimicrobial properties

- Chemical & Gas Transport: Industries requiring corrosion-resistant material

- Renewable Energy: Solar thermal systems for heat transfer

- Electrical Systems: Grounding rods and wire connections

Overview of the 4 Types of Copper Pipes

Copper pipes are commonly preferred in plumbing and HVAC installation because of their strength, trustworthiness, and adaptability. The following is a summary of the four major copper pipe types along with their typical usages:

Type K Copper Pipe

The thickest walls of all copper pipes belong to Type K, which holds the title of the most sturdy and long-lived option. It is very often utilized in the underground water supply lines since such a high pressure plus external damage risk are present. The pipe’s anticorrosive nature and strength guarantee a reliable performance that lasts over time.

Type L Copper Pipe

Type L is just a tad thinner than Type K, but still, it is the most widely used among copper pipes in water systems for houses. Its strengths are durability and cost-effectiveness. It finds use in both indoor plumbing and light outdoor applications like HVAC systems, among those are.

Type M Copper Pipe

Compared with Types K and L, Type M has thinner walls making it lighter and less expensive. It is often found in low-pressure residential water systems, but experts warn against high-pressure applications as its durability has been greatly reduced—it is still the lightest option when it comes to being used in heavy-duty applications.

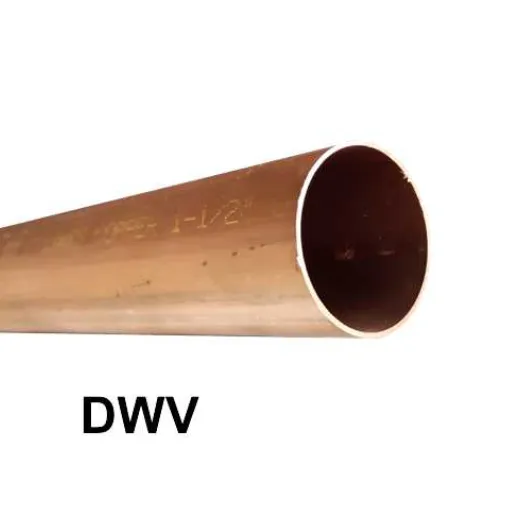

DWV Copper Pipe

DWV (Drain, Waste, Vent) copper pipe is for non-pressurized applications. Its aim is to remove waste and allow venting of toxic gases from household or business premises. Typically, DWV pipes are suited for water drainage but are marked with yellow or orange paint and can be easily recognized.

The continued use of copper pipes is still very much alive; in fact, the latest data and trends show that Type L is the most preferred one in general plumbing applications. So the right type of copper pipe is still to be decided based upon the project demands with regard to pressure, the installation environment, and the budget. Getting to know these options will not only save you time but will also ensure quality services in your plumbing or HVAC projects.

Type K Copper Pipe

Type K Copper Pipe’s Characteristics

Copper pipe of Type K is the thickest and most durable of all the copper pipes available. Thus, it is the best choice for high-pressure applications and underground installations. Its strong walls not only resist corrosion but also withstand structural damage beautifully and hence, it is voted as the best choice for both water and underground services. As per the current data from ‘s search engine, k steel pipe is continuously being suggested for municipal water supply lines and it can bear quite a lot of water pressure, which is usually more than that of the Type L and M pipes. Moreover, its long life span is tied to, a cost that is higher than what is usual, thus it is best for certain critical applications rather than general plumbing work. The type K pipes are marked with green colors that separate them from the rest types and that marks the correct pipe during the project.

✓ Type K Characteristics Summary

- ✓

Thickest wall: Most durable copper pipe option available - ✓

Identification: Marked with green color coding - ✓

Best for: Underground installations and high-pressure applications - ✓

Cost: Higher initial investment, excellent long-term value

Usage and Application of Type K Copper

Type K copper pipe is mainly used in places the pipe can take very high damages like pressure and by nature the material that the pipe will definitely be ruptured in the area around it, thus making it a top choice for municipal water mains and underground service lines. Where there is hope for huge external forces or corrosive conditions, its excellent thickness and hence great strength make it the best choice. On the other hand, the strength of K copper type installations is what makes them not only comfortable for heat transfer but also sound insulation.

According to the latest data from ‘s search engine, Type K copper pipe is also used in fire protection systems industry as excellent quality of performance under extreme conditions is a must. Its ability to be easily bent and shaped makes it useful for both above-ground and underground installations. Although its price is high, its life span is exceptional and maintenance is minimized which often compensates the initial investment, thus providing an attractive long-term value for infrastructure projects.

Advantages of Selection Type K Copper Pipe

Type K copper pipe is a choice that is advantageous in many aspects, making it a “must use” pipe type in various applications, especially in plumbing, gas distribution, and fire protection systems. The latest data confirm that the primary benefit is its unmatched durability. Type K pipe with the thickest wall of all copper types is very hard to corrode, hence it is suitable for underground and harsh environmental conditions also. This durability will keep installations last a long time, thus less frequent replacements and repairs.

Moreover, Type K copper pipe is very versatile as it can be used in houses as well as businesses. Its property to bend makes it possible to install it in difficult areas without adding extra labor costs or time for installation. Also, copper is a naturally antimicrobial material, and thus it gives an extra layer of safety for the water systems as it reduces the growth of bacteria.

Finally, the long-term savings are what make Type K copper pipe a cost-effective choice despite the higher initial investment. Its low maintenance, reliability, and adherence to strict building standards will allow it to perform better for the next decades. It is these characteristics that collectively make Type K copper pipe the best option for infrastructure projects where quality is the prime concern.

Type L Copper Pipe

Type L Copper Tube Features

When the medium wall thickness of type L copper tube is considered it can be said that the features of this tube are adaptability and widespread use in plumbing, heating and other construction works. It is equally durable and easy to install hence being the best copper tube type for the residential and commercial sectors. Type L is a pipe that is usually used for drinking water but not only due to the fact it is quality controlled and safe to use in the first place. It connects easily to different kinds of pipes in the building like soldering and press-fitting.

Moreover, Type L copper tubes have corrosion protection that is resistant to long exposure to certain environmental conditions. They are often the choice for water distribution systems in buildings, and also for heating by water or hot water systems. Although being thinner than Type K copper types, Type L still the strength that comes with it at the same time lower price which makes it a popular choice for projects that are budget-conscious but still need performance and reliability.

Type L Copper Pipe Common Uses

It is quite obvious that Type L copper pipes are used in a variety of places from private houses to big commercial buildings because they have such a good mix of durability, versatility, and price. One of the major applications of Type L pipes is in interior water supply systems for which their corrosion resistance property guarantees clean and safe water distribution over time. They meet plumbing codes for various regions and so are particularly suitable for potable water systems.

Another area of their common applications is in hydronic heating systems where the use of Type L pipes is done to keep hot water or steam moving efficiently through heating units. Moreover, they are also commonly used in fire sprinkler systems due to their capability and dependability that are both great for providing proper and durable operation. Apart from these above-mentioned uses Type L copper is getting more and more preferable in green building projects because of its being recyclable and environmentally friendly.

📋 Primary Applications of Type L Copper

- Interior Water Supply Systems – Residential and commercial potable water distribution

- Hydronic Heating Systems – Hot water and steam circulation in heating units

- Fire Sprinkler Systems – Reliable performance in safety-critical applications

- HVAC Systems – Light outdoor applications requiring temperature resistance

- Green Building Projects – Eco-friendly, recyclable material for sustainable construction

Type L Copper Tubing Advantages

There are many advantages of Type L copper tubing that make it the preferred material for a variety of applications and among these advantages is that its durability coupled with corrosion resistance gives a long-lasting performance. At the same time, the tube thickness provides good strength making it suitable for high-pressure applic plumbing lines and HVAC systems among others. Furthermore, the thing that type L copper is fit for both hot and cold water systems is another of its versatility point. Type L is also a user-friendly material to work with during installation due to its easy handling with soldering or brazing processes and its malleability. Besides, the fact of its being recyclable coincides with the eco-friendly practice of building and thus supporting the sustainability goals of modern construction projects. Being a material with its performance record and flexibility, Type L copper is still a trusted material for both residential and commercial projects.

💪 Durability

Excellent corrosion resistance ensures long-lasting performance in diverse conditions

🔧 Versatility

Suitable for both hot and cold water systems across multiple applications

⚡ Easy Installation

Malleable and user-friendly for soldering and brazing processes

♻️ Eco-Friendly

Fully recyclable material supporting sustainable construction goals

Type M Copper Pipe

Defining Type M Copper Pipe

Type M copper pipe widely chosen among the plumbing pipes for its lightness and cost-effectiveness properties. The no-over the top wall thickness is what makes Type M more affordable but then again it won’t be as strong as Type L when exposed to high pressure or a punishing environment. Type M is generally identified by red labels; its use is recommended during low-pressure applications like up to five floors or domestic water distribution systems. Additionally, it’s not advised using Type M for underground piping or areas that are likely to bear mechanical stress but its price and easy installation are the factors that contribute to its being chosen when budgeting is concerned. Even though the most recent research conducted by experts regarding the demand for water and the factors affecting the cost has not yet addressed these consequences, Type M copper pipes are still widely accepted by homeowners as a good option for a footprint or cost-effective.

⚠️ Important Considerations for Type M

- Identification: Marked with red labels for easy recognition

- Best Use: Low-pressure residential applications (up to 5 floors)

- Not Recommended: Underground piping or high-pressure/mechanical stress areas

- Primary Benefit: Most affordable copper pipe option with easy installation

Applications of Type M Copper Tubing

Type M copper tubing is most frequently applied for residential water supply systems owing to its relatively low cost and good performance in the low-pressure area. It is proper for the situation where the only above-ground mechanics are/ are nearly non-existent, as in the case of water lines in homes and apartment buildings. Because of its low weight, Type M tubing is also an attractive option in retrofitting and home renovation projects since it can significantly lower the cost of materials and labor when compared to heavier materials like Type K or Type L copper tubing.

Type M is also found in air-conditioning systems as a refrigerant line for moderate-duty applications. But it must be remembered that underground piping and areas of high water pressure are not for Type M. The recently collected data shows that its low price is still the main reason for it to be the number one choice among homeowners who think of doing their plumbing or renovation work as part of a DIY project. Always confirm with local building codes and regulations to know if Type M copper tubing is the right choice for your application.

Benefits of Using Type M Copper Pipe

There are quite a few plus points that Type M copper pipe has on its side which is the reason for its selection in plumbing in that it is one of the goods that dominate the market. The first one that comes to mind is the remarkably low price which is a major factor for DIYer and eco-friendly plus cost-conscious homeowner groups alike. In a recent study carried out by the experts this high cost-effectiveness was mentioned as one of the reasons during the residential technology advancement where water supply lines and hydronic heating systems, etc. are not that heavy duty. Then it is dishonest to say that the lightness of Type M copper pipe is its only advantage when it comes to being easy to handle; it cuts, shapes, and installs without any hassle unlike heavy materials. Moreover, its inherent water resistance means it will last as long as the quality of water in which it is submerged is not interrupted by pressure.

In addition, Type M copper pipes are practically synonymous with eco-friendly building practices as they are recyclable and thus less waste is generated. The homeowners and contractors can win the battle of cost and quality performance by making use of Type M’s advantages only if the pipe’s application does not violate the rule of not pushing beyond its recommended usage. Always check with local building codes to ensure compliance and the best results while choosing this type of copper pipe.

| Benefit | Impact |

|---|---|

| Cost-Effectiveness | Most affordable copper pipe option; ideal for budget-conscious projects |

| Lightweight Design | Easy to handle, cut, shape, and install; reduces labor costs |

| DIY-Friendly | Perfect for homeowners tackling renovation projects themselves |

| Recyclable Material | Supports eco-friendly building practices and reduces waste |

| Adequate Performance | Reliable for low-pressure residential applications when used within specifications |

DWV (Drain, Waste, Vent) Copper Pipe

Understanding DWV Copper Piping

DWV (Drain, Waste, Vent) copper piping is a type of piping for non-pressurized systems in plumbing. The main purpose of such pipes is to carry sewage and to vent the system adequately so that no dangerous gases are formed in the buildings. One frequently asked question is if DWV copper pipes can be used for water supply systems. The reply is negative since these pipes are not allowed to handle high-pressure applications because of their thinner walls, which also means they are not fit to carry clean water at pressure. Nonetheless, DWV copper piping is perfectly suitable for drains and vents, thus efficiency in wastewater and ventilation systems remains unaffected in both residential and commercial constructions. Always check the specs and comply with local building regulations when choosing DWV piping.

🚫 Critical Warning

DWV copper pipes CANNOT be used for water supply systems!

These pipes are designed exclusively for non-pressurized applications. Their thinner walls cannot handle the pressure requirements of clean water distribution systems. Use only for drainage, waste removal, and venting applications.

Applications of Copper DWV in Plumbing

Copper DWV (Drain, Waste, and Vent) piping is mainly used in non-pressurized wastewater and ventilation systems. With its rust-resistant property, long life, and simple installation, it has become the preferred material for both residential and commercial plumbing. Drain systems of these pipes are built to easily and quickly carry gray water and sewage away to the respective municipal waste lines. Moreover, copper DWV is the backbone of vents, assisting in air circulation and making sure that the bad smell from the sewer does not come indoors.

Modern construction is oriented towards sustainable building practices, and copper DWV has been one of the leading choices amongst materials with low environmental impact. The reason is that they fully recyclable, thus waste reduction, and also they contribute to the overall durability and reliability of the plumbing system. Although alternatives such as PVC and ABS are used frequently for the same purposes, copper DWV’s resistance to temperature variations and fire risk continues to keep its place, especially under conditions where long-term performance is critical. Check with local plumbing codes and specs when selecting the right materials for your project.

🔍 DWV Copper Pipe Applications

Drain Systems

Carries gray water and sewage to municipal waste lines

Ventilation Systems

Circulates air and prevents sewer gas infiltration

Waste Removal

Efficient wastewater transport in residential and commercial buildings

Benefits of Copper DWV Pipe

Copper DWV (Drain, Waste, and Vent) pipe has various benefits that lead to its being the first choice for certain plumbing applications. The first of these advantages is the natural corrosion resistance which is a guarantee of a performance that lasts even in the most difficult conditions. Contemporary construction practices, moreover, are often extremely stringent concerning the overall environmental impact of the materials being used, among other factors, thus the recyclability of copper pipes and its being environmentally friendly are among the reasons that copper can’t be compared with plastic-based alternatives like PVC or ABS which leave a bigger ecological footprint.

Temperature resistance is one of copper’s many realized advantages. It enters both extremes, hot and cold, without any alteration of physical properties. This would be a great advantage for areas exposed to extreme temperatures. Among other useful qualities, copper’s inability to catch fire comes in handy in unsafe areas. Actually, one of the biggest concerns relating to human health and safety is bacteria growth in plumbing systems. However, copper’s antimicrobial property is a good answer to that.

Last but not least, a meticulously installed and well-taken systems can be of reliable service for several decades. This time span combined with copper DWV’s robustness and recyclability explains why DWV pipe is an ideal investment for both residential and commercial plumbing projects in the long run. Make it a point to keep up with the latest industry practices and local plumbing regulations to maximize the use of copper in your installations.

✨ Key Benefits of Copper DWV Pipe

- Corrosion Resistance: Natural protection ensures lasting performance in harsh conditions

- Environmental Sustainability: Fully recyclable with lower ecological footprint than plastic alternatives

- Temperature Tolerance: Maintains integrity in both extreme hot and cold conditions

- Fire Resistance: Non-combustible material enhances safety in critical applications

- Antimicrobial Properties: Naturally inhibits bacterial growth for improved health safety

- Longevity: Properly installed systems provide reliable service for decades

Comparative Analysis of Copper Pipe Types

Choosing the Right Copper Pipe for Residential Plumbing

It is very important to understand the specific needs of your project when it comes to selecting the right copper pipes for the residential plumbing. The three main types of copper pipes used in residential places are Type K, Type L, and Type M. The advantages of each type are determined by their thickness, purpose, and price.

Copper Type K pipes are the thickest and most long-lasting ones, and thus they are the best for underground installations where durability is the priority. Besides, their pressure resistance and ability to prevent external damage make them the main choice for water mains and large supply lines.

Copper Type L pipes are a little bit thinner than Type K but still good enough for a majority of residential applications. The cold and hot water supply systems inside the house are the main places they are used, and they are the number one choice when it comes to getting the best mix of performance and affordability.

The third type, copper Type M pipes, are thinner and lighter than their counterparts, which brings their price down. The low-pressure applications such as drainage systems are what they are suitable for, as well as places where the financial aspect is more important than long-term durability.

The most recent search engine data shows that homeowners and professionals are more and more inclined to choose Type L pipes due to their valuable and selective nature in indoor plumbing systems. Nevertheless, the water quality and building regulations in the area are among other factors that strongly impact the final choice. A plumbing pro’s advice and sticking to regulations will give the best results for any home project.

| Pipe Type | Wall Thickness | Best Applications | Cost Level | Identification |

|---|---|---|---|---|

| Type K | Thickest | Underground installations, water mains, high-pressure systems | Highest | Green |

| Type L | Medium | Indoor plumbing, hot/cold water supply, HVAC systems | Moderate | Blue |

| Type M | Thinnest | Low-pressure residential systems, above-ground applications | Lowest | Red |

| DWV | Thin (non-pressurized) | Drainage, waste removal, ventilation systems | Moderate | Yellow/Orange |

Best Copper Pipe Types for HVAC Systems

In the case of HVAC systems, choosing the right copper pipe is vital to getting the best efficiency and life span. The most recommended types of copper pipes for HVAC use according to the latest search engine data are Type K and ACR (Air Conditioning and Refrigeration) pipes.

The thick walls of the Type K copper pipes are their greatest asset, which also makes them very durable and suitable for high-pressure systems. This type is sometimes preferred for underground and heavy-duty applications, since its robust design is less prone to leaks and does not suffer from mechanical damage. On the contrary, ACR pipes are specifically designed for HVAC applications and are pre-cleaned, which eliminates any chance of contamination, thus guaranteeing best performance in refrigerant circulation.

In spite of the fact that both options are quite efficient, going through product specifications, local regulations, and seeking expert advice will help to decide which one is the best fit for the particular HVAC project. It is very much the case that the right type of pipe is very important, as it has a direct effect on the life span and the efficiency of the system.

Type K for HVAC

- Thick walls for durability

- High-pressure capability

- Underground applications

- Leak-resistant design

- Long-term reliability

ACR Pipes for HVAC

- Pre-cleaned for HVAC use

- Contamination-free

- Optimal refrigerant circulation

- Purpose-built design

- Industry-specific specifications

Industrial Applications and Copper Pipe Selection

Due to their long lifespan, resistance to corrosion, and great thermal and electrical conductivity properties, copper pipes are an important part of different industrial applications. Such features make the copper pipes suitable for construction, manufacturing, medical equipment, and HVAC systems, and energy sectors. Recent data shows that even solar thermal systems, where the extreme temperature resistance of copper pipes contributes to raising the overall efficiency of the systems, are on the list of sources of increasing demand for copper pipes in the renewable energy sector.

The factors that need to be considered when choosing the right copper pipe for a certain industrial application are pressure ratings, wall thickness, and local standards compliance. In the meantime, new search trends and insights are indicating that industries are keen to adopt the green practices and hence they are more likely to use recycled copper materials to lessen their environmental impacts. Matching up expert opinions with the latest market trends ensures that the copper pipes chosen will not only satisfy the operational requirements but will also be aligned with the sustainability objectives.

Industrial Selection Factors

Pressure Ratings

Critical for system safety and performance

Wall Thickness

Determines durability and application suitability

Standards Compliance

Ensures regulatory and code requirements

Sustainability

Recycled materials reduce environmental impact

Frequently Asked Questions (FAQ)

What exactly is K-type copper pipe and where does it find application?

The K-type copper pipe is the thickest common grade and is extensively used for main water lines and underground service with its thicker wall and high resistance to corrosion. Underground water lines and applications demanding extra durability are some of the reasons for the specification of K-type pipes that come in various sizes including larger nominal. Pipe options such as K-type are heavier, contain more copper than thinner pipes like M-type, making them more expensive but lasting longer as well. Type K copper is covered by plumbing codes in all areas where it is the only choice for main water lines and underground installations when durability is required. When in doubt, think of soil or high pressure; k-type copper pipe is usually suggested for those applications.

How do copper pipe types L and K and M compare?

Copper pipes of type L are a versatile and medium-thickness option that can be used for water distribution in many residential and commercial buildings, and they are sometimes even permitted indoor plumbing drains and vents. L is less heavy than K copper, which has a thicker pipe wall than M, so it is often a common balancing act between durability and cost. K and L copper mainly differ in wall thickness and hence strength, with K at the top, L in the middle, and M being the thinner pipe. There are flexible type L copper options that make pipe installation easier in retrofits, and type L copper pipes and fittings are readily available at supply stores. The plumbing codes vary, so check the local plumbing codes in all areas before selecting L-type copper for an application.

What do I need to know about M-type copper and thinner pipe wall options?

Type M copper is a thinner pipe wall option for residential water systems where thinner pipe is allowed and cost has to be minimized; however, it is not used for main water lines and underground work. The pipe has a wall thickness lower than type L and K, which means it carries less copper and is lighter, making it easy to handle but possibly reducing durability in the long run. The thinner wall makes M unsuitable for high-pressure or exposed outdoor applications where pipe corrosion or damage is a concern. Generally, plumbing codes in many jurisdictions restrict the use of type M copper in certain installations, e.g., main water lines or plumbing drains and vents, so check your local requirements. For smaller sizes such as ½ inch nominal pipe size, type M is typically used for branch lines inside the home where pressures are normal.

What is the impact of pipe sizes and nominal pipe size on copper pipe selection?

Flow capacity and compatibility with fittings and fixtures are determined by pipe sizes and nominal pipe sizes, with copper pipe having an outside diameter that corresponds to named nominal sizes rather than the exact measurement of the interior bore. A ½ inch diameter for copper pipe is a small-diameter option that is commonly used for branch water lines, though the actual pipe diameter and wall thickness vary by type (K, L, M). When plumbing is being planned, pipe diameter, pipe wall, and intended flow must be compared to prevent using a pipe that does not meet system requirements or that compression fittings or soldered joints won’t fit. Water distribution copper pipe must be the same as appropriate copper pipes and fittings to prevent leaks and ensure reliable joining copper pipes techniques. If you are retrofitting and replacing PVC or ABS plastic pipe with copper, be aware that ABS plastic pipe in modern construction and PVC or ABS plastic pipe dimensions may differ slightly from copper nominal sizes and thus require adapters.

Reference Sources

-

ScienceDirect – Copper Tubing Overview

This resource provides an in-depth overview of copper tubing, its applications, and its characteristics, particularly in engineering and construction.

Copper Tubing Overview – ScienceDirect -

MDPI – Brazing of Copper Pipes for Heat Pump and Refrigeration Applications

This study focuses on the brazing process for copper pipes, optimizing their use in heat pump and refrigeration systems, which highlights specific applications of copper pipes.

Brazing of Copper Pipes – MDPI -

The CEU Authority – The Most Common Types of Copper Piping

This article discusses the most common types of copper pipes (Type K, Type L, and Type M) and their applications in residential and commercial construction.

The Most Common Types of Copper Piping – CEU Authority