Valves are incredibly important in all kinds of plumbing systems, as they manage the flow and control of water throughout residential, commercial, and industrial settings. Understanding the different kinds of valves is crucial for maintaining a plumbing network that is both efficient and effective since there are many types available, each one for a specific purpose.

This guide will introduce you to different types of plumbing valves and their unique applications whether you are a homeowner who wants to take care of small repairs or a professional who needs in-depth knowledge. You will learn about the significant functions that these components perform, such as regulating water pressure and offering shut-off capabilities, and how they help a plumbing system operate smoothly.

Introduction to Plumbing Valves

Plumbing valves play a vital role in every plumbing system because they regulate the water flow and pressure in pipes. Their various functions include closing the water supply, routing the water, and controlling the pressure to avoid system breakdowns. Among the different types of plumbing valves are ball, gate, and pressure-reducing valves, which are made for distinct chores. It is necessary to pick the correct valve based on its application to secure efficient operation and dependability of the whole system.

What is a Plumbing Valve?

A plumbing valve is a mechanical device whose purpose is to control the water or other fluids’ flow in a plumbing system by regulation, direction, or control. The basic functioning of these valves consists of opening, closing, or partially obstructing the pathways of the flow and they hence are very important throughout both residential and commercial plumbing systems.

In today’s plumbing industry, valves come in different materials like brass, PVC, stainless steel, or bronze which are all very strong and resistant to rust. The valves’ roles cannot be overstated – they include cutting off the water supply during an emergency, controlling the water pressure, and making sure the water gets correctly distributed to the sinks and appliances.

Importance of Valves in Plumbing Systems

Valves are an integral part of modern plumbing systems that manage getting water in and out while also having technological upgrades which are somewhat for their performance. The very latest in the growing field of smart valves has a considerable share in this progress because their usual functionality has been modified to allow users to have real-time monitoring and even control of the valves through mobile applications.

The new smart systems not only save water but also prevent leaks and damages by automatic water supply turning off during emergencies. Moreover, controlling flow and pressure are the main reasons that valves are very much in demand when it comes to water conservation, especially in places where water scarcity is a problem.

Overview of Different Types of Valves

| Valve Type | Primary Function | Key Characteristics |

|---|---|---|

| Gate Valves | Allow or block flow completely | Minimal flow resistance, ideal for water supply systems |

| Ball Valves | Open and close fluid flow | Long lifespan, excellent sealing, low leakage |

| Globe Valves | Flow control and throttling | Precise flow rate control, adjustable valve stem |

| Butterfly Valves | Start, stop, and regulate flow | Lightweight, compact, cost-effective |

| Pressure-Reducing Valves | Even pressure distribution | Essential for water conservation |

| Check Valves | Prevent backflow | One-way flow, protects equipment from contamination |

| Solenoid Valves | Automated control | Electrically driven, fast action, industrial applications |

Common Types of Plumbing Valves

Ball Valves

Ball valves are not only reliable but also very easy to use, which is why they are the most popular types of valves in the plumbing system. These valves work using a rotatable ball with a hole in the center, that can either allow or restrict the flow according to the need. Because of their strength and resistance, ball valves are usually found in places like homes and factories where the need for sealing is extremely high.

Ball Valves vs. Gate Valves

According to Google’s search engine, the latest data shows that “Are ball valves better than gate valves” is a very common question asked among the people. Both types of valves serve the same purpose to some extent, but the ball valves are generally considered to be more effective in terms of shutdown applications quickly due to their quarter-turn operation and the negligible chances of corrosion or wear during the lifetime of the valve. On the other hand, gate valves are normally the choice in applications where a gradual and fine control over flow is required.

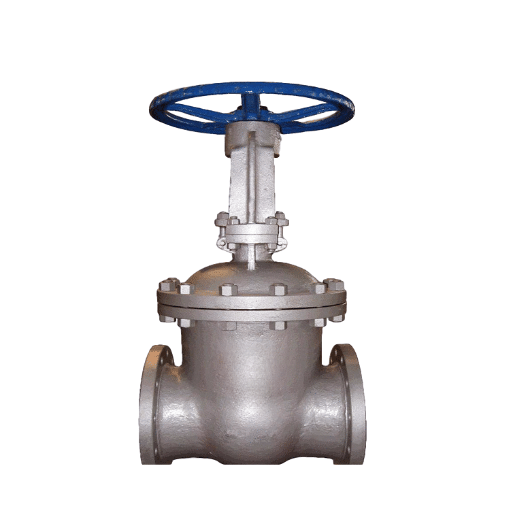

Gate Valves

Gate valves function by simply opening or closing a gate that is either lifted or lowered to allow or stop water flow. These types of valves are perfect for places like main water lines where total unobstructed flow is necessary. On the downside, they should not be used in places requiring regular opening and closing since the constant motion may lead to wear and tear.

Decision-makers point out that the continuing trend of gate valves being majorly used in the water treatment, oil and gas, and power generation industries is primarily due to the complete and unobstructed flow they facilitate when fully opened.

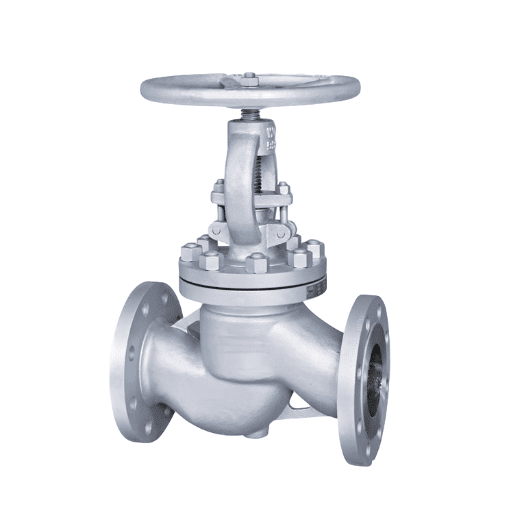

Globe Valves

Globe valves are the most common types of valves used in the plumbing system specifically for flow regulation purposes. The special design of these valves consisting of a disc that either cuts off or back the seat, gives them the precision of flow control that throttling calls for making them one of the best choices. They are mainly found in systems that need constant changes to water flow, hence requiring frequent adjustments.

Globe valves are ranked higher in applications where flow control and pressure drop are crucial while gate valves are better for on/off operations. This very feature has made them indispensable in both industrial and commercial piping systems for a long time.

Butterfly Valves

Butterfly valves operate just like a rotating disc that is flat and positioned in such a way that it can either restrict or allow the flow of water. These valves are light in weight, economical and can easily go along with the bigger pipelines, so they are like the backbone of huge plumbing systems. They are also common in places where quick shut-off capabilities are required.

Check Valves

A check valve is a valve type that allows the passage of a fluid in one direction and at the same time, it blocks the reverse flow. Google’s search engine latest data indicates that check valves are in great demand for use in processes requiring the prevention of reverse flow. The use of these valves in the water treatment, oil and gas, and chemical processing industries is frequently seen. Their automatic operation without requiring human intervention provides reliable system integrity assurance.

Pressure-Reducing Valves

Pressure-reducing valves play a significant role in safeguarding plumbing systems by keeping the water pressure uniform throughout the premises. They work to automatically lower the pressure of the incoming water from a high level to a safe level, thereby, protecting the pipes and fixtures from bursting or leaking, maintaining the efficiency of the system and eventually, countering the repair and replacement costs as well as extending the life of the system.

Relief Valve and Pressure Relief Valve

Relief and pressure relief valves are the backbone of any pressure management system and safety assurance in a variety of industrial uses. A relief valve is mainly aimed at controlling the pressure and stopping the system from going above the set limit, thus protecting the machines from possible harm. In contrast, a pressure relief valve, which is similar in operation, often puts safety first by relieving the pressure automatically when it reaches a certain level to eliminate the risk of failure.

Stop Valves

In a pipeline system, liquid, gas, or steam flow is controlled with the help of stop valves, which are crucial parts. By fully opening or closing, they can regulate the flow or shut it off completely, as the case may be.

Most widely used stop valve types:

- Gate Valves: Used when a straight-line flow with almost no restriction is desired

- Globe Valves: Suitable for throttling purposes with better control

- Ball Valves: High marking for endurance and proficiency in tight seal, favorites for high pressure and temperature fluids

How Each Type of Valve Works

Ball Valves

The operation of ball valves is based on the rotation of a ball with a hole in its middle. The valve gets opened when the hole is in the direction of the flow, and it gets closed when the hole is turned perpendicular to the flow, thus blocking the flow and providing a fast and secure shut-off at the same time. Their strong construction allows them to easily handle working conditions of high-pressure and high-volume, such as gas and liquid flow systems.

Butterfly Valves

The use of a rotating disc located in the center of the pipe is the method of flow control employed by the butterfly valves. The valve is fully open when the disc rotates along with the flow and closed by blocking the flow when it is perpendicular. Characterized by their light weight and fast operation, these valves are commonly found in the HVAC, water supply, and fuel handling systems.

Needle Valves

The precision of needle valves is their main characteristic. Thus, they employ a tiny, tapered point at the end of a screw to carefully handle the flow. The point seats tightly into the valve seat as the screw tightens and adjusts the flow accordingly. This feature makes needle valves ideal for applications that require high precision, such as laboratory experiments or fuel control in engines.

Functions and Applications of Valve Types

| Valve Type | Primary Applications | Best Used For |

|---|---|---|

| Gate Valves | Water distribution, oil and gas pipelines, sanitation systems | On/off use with straight-line flow |

| Ball Valves | Chemical processing, natural gas operations, HVAC systems | High pressure/temperature applications, fast shut-off |

| Globe Valves | Water treatment plants, fuel pipes, steam-based systems | Throttling and precise flow control |

| Check Valves | Wastewater management, oil refining, irrigation systems | Preventing backflow and equipment damage |

| Butterfly Valves | Food and beverage, pharmaceutical production, water supply | Large-scale, cost-effective, low-pressure solutions |

| Needle Valves | Calibration, laboratory settings, engine fuel shut-off | Precise control of tiny flows |

Applications in Plumbing Systems

- Shut-Off Valves: Employed for completely stopping water flow for maintenance work or emergency shut off. Usually placed under sinks and toilets for quick fixture isolation.

- Pressure-Reducing Valves: Control and reduce incoming water pressure, preventing plumbing system damage from high pressure conditions.

- Check Valves: Allow water flow in one direction only while stopping backflow, ensuring proper water flow and uncontaminated supply.

- Ball Valves: Known for robustness, excellent sealing, and simple quarter-turn operation in residential and commercial buildings.

- Mixing Valves: Combine hot and cold water to achieve desired temperature, mostly in shower systems and faucets for comfort and safety.

Choosing the Right Valve for Your Needs

The process of choosing the proper valve for your requirements necessitates taking various aspects into account:

- Application requirements

- Material compatibility

- Operating pressure

- Maintenance ease

- Type of fluid to be controlled

- Expected operational life

As an example, ball valves are incredibly versatile and thus can be used in both kinds of plumbing, residential and commercial, thanks to their sturdiness and ease of use. Conversely, mixing valves are a must in applications that need exact temperature control, like showers and faucets, which come with safety and comfort benefits.

Benefits of Using Different Valve Types

Using different types of valves gives different benefits that depend on application, type of fluid, and operational requirements:

- Ball Valves: Very reliable sealing, perfect for systems with really low leakage requirements, such as gas pipelines

- Gate Valves: Longer life and suitable for situations requiring full flow, like water supply and wastewater treatment

- Mixing Valves: Allow control over fluid temperature, making systems safer and more efficient in HVAC and plumbing applications

Efficiency and Control in Plumbing Systems

Modern valve technologies have drastically improved plumbing’s efficiency and control through innovations such as:

- Smart Valves: Use real-time data and automation to monitor water usage and detect leaks, helping save water and lower bills

- Pressure-Regulating Valves: Maintain proper pressure levels according to system demand, prolonging the life of pipes and fittings

- Automated Flow Controllers: Provide dependability and efficiency in operations for both domestic and industrial settings

Reducing Water Waste

Water waste reduction is a critical step in conservation. Effective methods include:

- Low-flow faucets

- Dual-flush toilets

- Smart irrigation systems

- Timely leak repair

- High water efficiency rated appliances

- Rainwater harvesting systems

Enhancing System Longevity

To increase the lifespan of water systems, a mix of proactive maintenance, technology, and eco-friendly practices is necessary:

- Regular inspections to detect damage

- Advanced leak detection instruments (acoustic sensors, smart meters)

- Use of top-notch materials and proper installation

- Integration of IoT devices for predictive analytics

- Green changes and public involvement

Maintenance Tips for Plumbing Valves

Conduct Inspections Regularly

Schedule inspections throughout the year with major ones every six months. Detect early warnings like damaged seals and surface rust to prevent escalation into major breakdowns and expensive repairs.

Use Valves Regularly

Rotate valve handles completely open and closed a few times every three to six months. This prevents valve stems from freezing and assures emergency operation free of rust or mineral build-up.

Examine and Clear Deposits

Minerals, dust, and dirt accumulate on surfaces and inside valves. Periodic cleaning using proper equipment or cleaning agents prevents deposits from limiting functionality and reducing flow rates by around 20%.

Apply Lubricants to Moving Parts

Use manufacturer-suggested lubrication on valve stems and threads during maintenance to reduce wear and friction, keeping valves in good operating condition and prolonging their life.

Change Out Worn Parts

During inspections, look for signs of wear on washers, O-rings, and gaskets such as cracking and softening. Internal components should be replaced occasionally, as they are frequent sources of leaks in valves over five years old.

Regular Inspection and Testing

Inspections should include thorough checking of external parts for damage or corrosion, and internals if disassembly is possible. Tests should consist of pressure testing to check sealing quality and functionality under expected operating conditions.

Common Issues and Troubleshooting

| Issue | Common Causes | Solutions |

|---|---|---|

| Improper Sealing/Leaks | Deterioration of sealing parts, rust, wrong installation | Regular checks, ultrasonic leak detectors for early detection |

| Actuator Malfunction | Electrical issues, power deficiency, physical destruction | Systematic follow-up, check electrical circuits and power output |

| System Blockage | Debris or sediment accumulation | Install upstream filters, regular system cleaning |

When to Replace a Valve

It is essential to determine the right time to change a valve. The three main signs of valve replacement needed:

- Persistent Leaks: Leaks that never stop even after repairs

- Performance Drop: Declining performance despite repeated fixes

- Physical Wear: Visible corrosion or cracks

Advanced predictive maintenance algorithms backed by data trends can predict valve failures before they happen. Early signs include delays in actuator response time or varying pressure readings.

References

-

University of Oklahoma: Provides a detailed overview of various valve types, including check valves, globe valves, ball valves, and butterfly valves. Read the document.

-

Michigan State University Infrastructure Planning and Facilities: Discusses general-duty valves for plumbing piping, including gear actuators and handwheel-operated valves. Access the resource.

-

University of Maryland: Offers insights into valve operator types, such as ball valves and butterfly valves, for plumbing piping systems. View the document.

Frequently Asked Questions (FAQ)

What are the various kinds of valves that are used in plumbing?

A wide variety of valves can be found in plumbing systems, such as ball valves, gate valves, globe valves, butterfly valves, and check valves. Each valve type has its own specific role and is manufactured to manage the flow of water through the pipes and fittings.

What is the role of ball valves in plumbing?

Ball valves are very often responsible for the stop and start of the flow of water in the plumbing systems. They consist of a round valve body with an opening that lets the water through when it’s opened. On the other hand, when it’s closed, the ball obstructs the passage and the water supply is cut off completely.

What is a gate valve’s role in plumbing?

Gate valves are primarily used in the plumbing industry to provide total control over the water flow. They can be either completely opened or shut off, which comes in handy when there is a need for water to be completely stopped. In contrast to globe valves, they are not fit for flow reduction purposes.

What is the operation of check valves in plumbing?

Check valves are installed in plumbing systems to stop backflow. They are designed to open in the direction of water flow and to close automatically when the flow reverses. This characteristic is very important for keeping a steady water supply and safeguarding plumbing fittings.

What are globe valves and where are they used?

Globe valves are preferred for water flow regulation. Their shape is spherical and they are most commonly employed in situations where very accurate control of the flow rate is necessary. This makes them suitable for all kinds of plumbing applications.

What does a pressure reducing valve do?

A pressure reducing valve is used to bring down the pressure of incoming water to the level that is safe and manageable for plumbing fixtures. It is a great way to keep the plumbing system flowing properly without any risk of damage while also reducing the frequency of plumbing-related problems.

What is the utility of a butterfly valve?

Butterfly valves resemble ball valves in function, but the former adopts a rotating disk method for controlling the flow of water. They are frequently found in the bigger plumbing systems because they have the capacity to manage high flow rates while still being small and light.

What is the function of stop valves in a plumbing system?

Stop valves, also referred to as shut off valves, are meant to cut off the water supply in the lines. They are mainly placed close to plumbing fixtures in order to provide accessibility for doing maintenance and repairs without the need to turn off the whole water supply.

What are pressure relief valves and what is their significance?

Pressure relief valves are among the most important parts of plumbing systems, as they prevent damage to pipes and plumbing fixtures by automatically releasing extra pressure. They are a major contributor to the plumbing system’s strength as they account for the water flow when pressure goes beyond the safe levels.