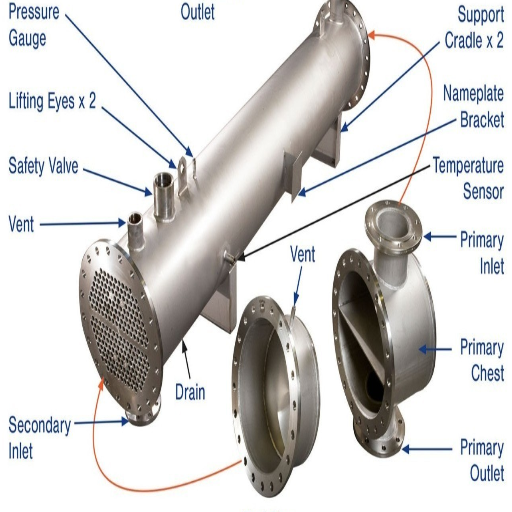

Making the right choice when selecting stainless steel for shell-and-tube heat exchangers is crucial, as it can impact the system’s overall efficiency, durability, and success. The abundance of alloy grades makes it challenging to make a decision, especially if there are certain peculiarities in the operating conditions. But the alloy selection process doesn’t need to be that complicated. From dealing with extreme environments and corrosive or high-pressure substances to making the right decisions, we will cover all the essential properties of stainless steel grades. By the end of the article, you will be able to perform optimally reliable heat exchanger applications. From now on, engineers, designers, and decision-makers don’t have to remember the complexities of Stainless Steel Selection because everything is clearly explained in this document.

Which Stainless Steel Grade Is Best for Heat Exchanger Tubes?

When choosing what grade of stainless steel to use in manufacturing heat exchanger tubes, 316L stainless is the usual candidate. Its long-term usefulness is favorable because it has excellent corrosion resistance, particularly in the presence of chlorides and other aggressive chemicals. Moreover, its low carbon content makes it less susceptible to sensitization, which makes it worthwhile in extreme conditions. For even more excellent resistance, duplex stainless steels like 2205 are also standard due to their higher strength and enhanced corrosion resistance. The operating requirements, such as temperature, pressure, and the fluids the heat exchanger will encounter, determine which grade is best.

Comparing 304 Stainless Steel vs 316 Stainless Steel for Heat Exchanger Applications

Stainless steels 304 and 316 are two of the most popular options in the heat exchangers industry because of their good mechanical properties and corrosion resistance. Both of these materials have their advantages and disadvantages, so one may be more suitable than the other in certain situations.

1. Chemical Composition

- 304 Stainless Steel:

-

- Chromium (18–20%)

- Nickel (8–10.5%)

- Carbon (Maximum 0.08%)

- Manganese (Maximum 2%)

- Silicon (Maximum 1%)

- 316 Stainless Steel:

-

- Chromium (16–18%)

- Nickel (10–14%)

- Molybdenum (2–3%) – adds resistant properties to corrosion, especially with chlorides.

- Carbon (Maximum 0.08%)

- Manganese (Maximum 2%)

- Silicon (Maximum 1%)

2. Corrosion Resistance

- 304 Stainless Steel:

-

- Resistant against many exposures, such as water and weak acids; however, it may corrode in marine or chloride-rich areas.

- 316 Stainless Steel:

-

- Due to the added molybdenum, it exhibits excellent corrosion resistance and is highly effective in seawater, chloride-rich environments, and industrial settings.

3. Temperature Resistance

- 304 Stainless Steel:

-

- Suitable for general heat exchangers, as it works well up to 870°C (1600°F).

- 316 Stainless Steel:

-

- Slightly better than 304 in high temperatures and stronger at elevated temperatures.

4. Cost

- 304 Stainless Steel:

-

- Less expensive than 316 stainless steel; therefore, it is more economical in less aggressive environments.

- 316 Stainless Steel:

-

- Investment is worthwhile in highly corrosive environments, but it is more expensive due to the addition of nickel and molybdenum.

5. Mechanical Properties

|

Property |

304 Stainless Steel |

316 Stainless Steel |

|---|---|---|

|

Tensile Strength |

505 MPa (minimum) |

515 MPa (minimum) |

|

Yield Strength |

215 MPa (minimum) |

205 MPa (minimum) |

|

Elongation (% in 50mm) |

40% |

40% |

|

Hardness (Brinell) |

201 HB (maximum) |

217 HB (maximum) |

6. Applications

- 304 Stainless Steel:

-

- Food processing equipment

- Chemical containers

- Heat exchangers in non-corrosive environments

- 316 Stainless Steel:

-

- Marine applications

- Pharmaceutical and medical equipment

- Heat exchangers in chloride-rich or highly corrosive settings

Summary

In the case of a heat exchanger, the primary concern is determining the operating environment to select between 304 and 316 stainless steel. If the cost is the main factor and the environment is not too corrosive, 304 stainless steel would be ideal. On the other hand, for marine, chemical, or industrial uses where higher corrosion resistance is critical, although 316 comes at a higher cost, its value is substantial in terms of performance.

Austenitic Stainless Steel Properties for Shell and Tube Heat Exchangers

Corrosion Resistance

Austenitic stainless steels, specifically the 304 and 316 grades, are best suited for shell and tube heat exchangers due to their widespread acceptance for use in highly corrosive environments. SS 304 offers good oxidation resistance along with general corrosion control in freshwater and non-aggressive chemical environments. At the same time, type 316 stainless steel becomes preferable for harsh marine environments because the molybdenum addition greatly improves its pitting and crevice corrosion resistance, which is associated with chloride salts. It is also suitable for use in industrial plants that deal with acidic materials.

Thermal Conductivity and Strength

Austenitic stainless steels are often recognized for their ability to preserve both mechanical and thermal attributes across a wide range of temperatures. Although the thermal conductivity of steels is not as high as that of aluminum and copper, these metals outperform other alloys in terms of strength and durability under extreme operating conditions. This balance ensures that applications with temperature cycling and alternating high pressure can operate smoothly. In addition, 316 grade becomes more reliable than 304 because it has higher creep resistance and tensile strength at elevated temperatures.

Longevity and Maintenance

Austenitic stainless steels decrease maintenance needs because their durability diminishes wear processes. This extends the effective operational life of shell-and-tube heat exchangers. The continuous self-repair of corrosion resistance provided by the steel’s chromium oxide layer reduces the need for expensive repairs or replacements. In this aspect, austenitic stainless steel is cost-effective in the long term and sustainable due to its recyclability.

Versatility in Applications

Diverse industries, such as food and beverage, pharmaceuticals, power generation, and petrochemicals, benefit from the unmatched versatility of austenitic stainless steels. These alloys are also invaluable in more sensitive applications because they fully comply with hygienic and sanitary requirements, ensuring safe and efficient operations.

Duplex Stainless Steel Options for Enhanced Corrosion Resistance

Duplex stainless steel is a remarkable material characterized by its unique dual-phase microstructure, which is composed of both ferritic and austenitic components. This structure confers good mechanical strength as well as excellent resistance to localized and uniform corrosion. One of its standout benefits is its ability to withstand aggressive environments, such as stress corrosion cracking with chloride and pitting corrosion.

Sustainable performance is a key factor sought by modern industries, which is why modern duplex grades, such as 2205 and 2507, are strategically designed for oil and gas, chemical processing, and marine applications. Take, for example, duplex stainless steel; its yield strength is up to twice that of austenitic grades, which means construction projects will use less material, optimizing costs and increasing safety and reliability.

Moreover, these steels are readily weldable and fabricable, which broadens their adaptability for the region’s infrastructure. Their high strength, enhanced corrosion resistance, and cost efficiency make them vital for sustaining industries focused on performance.

How Does Stainless Steel Heat Exchanger Tube Material Affect Performance?

The stainless steel used in the construction of a heat exchanger tube has a significant influence on how the heat exchanger performs, thanks to its outstanding corrosion resistance, thermal conductivity, and durability. These properties facilitate proper heat exchanger functioning, minimize contamination, and increase equipment lifespan. Furthermore, stainless steel also performs best in high-temperature and high-pressure environments, making it suitable for use in demanding applications. The low upkeep and long operational life of these materials make them inexpensive, reinforcing value-added benefits.

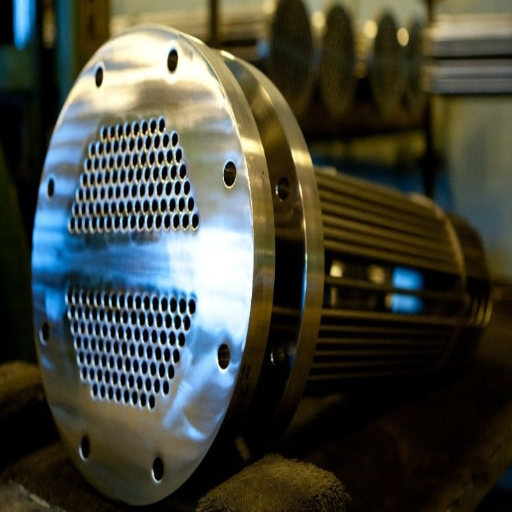

Thermal Conductivity of Different Stainless Steel Grades

Different grades of stainless steel also have a range of thermal conductivities, which is crucial in determining the materials used in heat transfer operations. Ferritic grades, especially 430, usually outperform austenitic stainless steels. Cited as an example, the thermal conductivity of grade 304 stainless steel is around 16 W/m·K at 20°C, while grade 430 considerably surpasses that, with a value of 26 W/m·K.

On the other hand, duplex stainless steels that exhibit features of both austenitic and ferritic grades typically have intermediate thermal conductivity, along with greater strength and corrosion resistance. These differences are crucial in optimizing the performance of systems where heat transfer is a key factor, such as in heat exchangers and specific manufacturing processes. Different grades of stainless steel have their unique properties, and so do alloys. This type of thermal property knowledge is crucial for engineers and designers in stainless steel construction.

Corrosion Resistance Properties of Stainless Steel in Heat Exchangers

Stainless steel is in high demand for use in heat exchangers as it retains its strength over time, even in harsh conditions, due to excellent corrosion resistance. The corrosion resistance of stainless steel is obtained mainly through chromium, which forms a passive oxide layer on the metal’s surface, preventing degradation from opposing forces. This feature is an advantage in cases where heat exchangers are subjected to thermal cycling, high pressure, and exposure to hostile environments, such as aqueous solutions of salts, strong acids, and industrial gases.

Different grades of stainless steel offer varying levels of corrosion resistance, making them suitable for specific applications. For example, 304 stainless steel is widely used due to its general resistance to corrosion and low cost. 316 stainless steel, which contains molybdenum, has enhanced resistance to pitting and crevice corrosion, making it ideal for marine applications. Duplex stainless steels, with their mixed austenite and ferrite microstructure, have excellent resistance to stress corrosion cracking, making them suitable for highly demanding industrial operations.

Furthermore, studies suggest that the addition of alloying elements, such as nitrogen and nickel, enhances localized corrosion resistance, allowing for optimal performance and an extended lifespan of heat exchangers. Adopting the proper grade of stainless steel ensures longevity while keeping maintenance costs low, highlighting the material’s effectiveness in heat exchanger design.

Heat Transfer Efficiency of Stainless Steel Tubes

Known for its efficient industrial uses in power plants, chemical processing, and HVAC systems, stainless steel tubes have exceptional heat transfer properties. Unlike copper, stainless steel offers structural strength while also providing heat transfer, albeit at a slightly lower thermal conductivity. The 304L and 316L grades are well accepted in heat exchange systems due to their high resistance to corrosion and ability to withstand extreme temperatures and pressure.

Research emphasizes the importance of polished surfaces and wall thickness for efficient heat transfer. Finer thickness increases the speed of thermal conduction, while polished surfaces reduce fouling. To improve heat exchange rates, modern stainless steel tubes use advanced geometric designs, such as internally serrated or finned tubes, to increase surface area and promote turbulent flow.

Stainless steel is preferable to carbon steel because it withstands aggressive conditions, extending its lifecycle, reducing maintenance, and these attributes validate it as a top-tier material, ensuring effective energy transfer and dependability in vital systems.

What Are the Key Factors for Stainless Steel Selection in Heat Exchangers?

While choosing stainless steel for heat exchangers, the following considerations are pretty significant:

- Corrosion Resistance – The steel grade must be resistant to corrosion in working conditions, especially in the presence of moisture, chemicals, or elevated temperatures.

- Thermal Conductivity – Although it is not as high as some other materials, stainless steel’s thermal conductivity should meet the efficiency guidelines for the heat exchanger.

- Durability and Strength – The material should withstand mechanical stress, as well as pressure and temperature cycles, for reliable performance over time.

- Maintenance Requirements – Less maintenance and easier cleaning associated with stainless steel can translate to reduced downtime and savings over time.

- Cost-Effectiveness – Compared to alternative materials, the long-term costs and life cycle benefits of increased strength and durability should offset the higher initial expense.

- Compatibility – The material should match the heat exchanger’s design, purpose, and the fluid being processed.

Optimizing these criteria will guarantee that heat exchangers meet performance and lifespan expectations.

Temperature Considerations for Stainless Steel Heat Exchanger Materials

The versatility of stainless steel enables it to be employed in the construction of heat exchangers because it retains its mechanical properties over a wide range of operational temperatures. It is also one of the most thermally conductive materials, which facilitates heat transfer, proving very beneficial during heating or cryogenic cooling. For example, most grades of stainless steel can withstand operating temperatures between -320°F (-196°C) and about 1500°F (816°C).

Moreover, stainless steel’s resistance to heat expansion and contraction also helps with thermal stability, so it does not cause much damage to the structure due to changes in loading. Its mechanical characteristics, including strength, corrosion resistance, and the ability to undergo thermal and mechanical stress, do not deteriorate over long periods of heating. Specific grades of stainless steel, such as 310 and 321, are best used for high-temperature applications because they have the highest resistance to oxidation. For low temperature operations, 304 and 316 austenitic stainless steels are preferred because they offer strength, ductility, and dependability for system reliability.

With the right choice of stainless steel grade, engineers can improve the performance of heat exchangers operating in different temperature domains by integrating these selected mechanical properties into the system layout.

Pressure Ratings for Different Stainless Steel Tube Options

The pressure ratings of stainless steel tubes are determined by grade, wall thickness, and the operating conditions. For example, Type 304 stainless steel tubes, used in various applications, withstand working pressures of up to 2,500 psi for standard wall thicknesses in smaller diameters. In addition, Type 316 stainless steel tubes, which are highly regarded for their corrosion resistance, also hold similar or slightly higher pressure tolerances, making them optimal for harsh marine or chemical environments.

Considering the tube pressure ratings, other factors such as tube diameter and temperature modifications must also be taken into account. For instance, with increasing temperature, the allowable working pressure is usually higher. Following the caliper, a quarter-inch tube diameter with a 0.035-inch wall of 304 stainless steel, at room temperature, should manage pressures up to 3,000 psi, but may drop by over 20 percent above 800°F.

Moreover, heavy-wall stainless steel tubing offers better pressure containment capabilities compared to thinner-walled options. This is especially important in systems where internal pressures can be extreme, such as in hydraulic or pneumatic systems. With some engineering tables or pressure calculators, compliance with ASME or ASTM standards, for example, can be ensured.

Cost vs. Performance Analysis of Stainless Steel Grades

The cost and performance of other grades of stainless steel must also be considered when balancing the cost and performance of various grades, because the material’s properties must align with the application’s needs and its price. For example, widely used grades 304 and 316 stainless steel are relatively inexpensive and offer good corrosion resistance. Grade 304 is less expensive and suitable for standard environments and light industrial work, but more aggressive chemicals and saline solutions will eventually show wear. In contrast, grade 316, which contains molybdenum, offers better resistance to pitting and crevice corrosion, making it ideal for marine or highly corrosive environments.

For higher-temperature applications, 310 or 321 stainless steel grades are preferred due to their excellent resistance to oxidation and thermal stability, although they are more expensive. Duplex stainless steels are more costly than standard austenitic grades. Still, their greater strength and ability to resist stress corrosion cracking reduce long-term maintenance costs in harsh environments, such as the oil and gas sector.

Market reports have noted an increase in demand for super duplex and precipitation-hardened stainless steels due to their use in extreme offshore conditions or with chemical processing plants. Although these specialized grades are more expensive, they offer long-term economic value by decreasing material failure and replacement. Decisions of this kind always need to compare the material cost with the part’s lifecycle performance to ensure the most efficient use.

When Should You Choose Ferritic vs Austenitic Stainless Steel for Your Heat Exchanger?

The choice between ferritic and austenitic stainless steel for a heat exchanger depends on the operating conditions and requirements.

- Ferritic Stainless Steel is best suited to environments with moderate heat and a lower risk of corrosion. Its good thermal conductivity makes it less expensive and suitable for more demanding applications where cost savings are critical.

- Austenitic Stainless Steel is more appropriate for high-temperature applications or those with aggressive corrosion, such as exposure to chlorides or acidic conditions. Though more expensive, austenitic steel excels in corrosion resistance, strength, and extreme durability.

The selection should ensure the required performance and lifespan by evaluating the operating conditions, which include temperature, pressure, and the characteristics of the fluid.

Comparing Ferritic Stainless Steel and Austenitic Steel Properties

Each type of these ferritic stainless steels and austenitic steels displays unique traits that make them more effective for different kinds of applications. The composition of ferritic stainless steel mainly consists of iron and chromium, with a small amount of nickel. Thus, it becomes cheaper than others. It is best suited for use in automotive parts and industrial machinery where moderate corrosion resistance, coupled with excellent resistance to stress corrosion cracking, is necessary. It does, however, not possess welded structures as rigid as austenitic steels.

On the other hand, austenitic stainless steels with higher chromium and nickel content have exceptional corrosion resistance and formability. These steels are also non-magnetic and have good all-round properties at elevated and reduced temperatures, including cryogenic and high-temperature applications. 304 and 316 grades are common as they are readily available. They resist acidic solutions and chloride environments, which makes them useful in the food industry, medical equipment manufacturing, and chemical production.

In comparison, ferritic steels exhibit favorable thermal properties, including better thermal conductivity and lower thermal expansion, which means lower distortion at elevated temperatures. On the other hand, austenitic steels have superior ductility and toughness along with ease of being worked into different shapes. The availability of both steel types provides critical functionality depending on operational requirements, and material selection is a factor in costs, performance, and climatic conditions.

Applications Where Austenitic Stainless Steel Excels in Heat Exchangers

Austenitic stainless steels are considered the best for fabricating heat exchangers because of their anti-corrosive properties, mechanical strength, and thermal endurance, among other reasons. More details below on other areas they excel at:

- Chemical Processing Plants

Due to the presence of corrosive chemicals, strong acids, and alkalis, austenitic stainless steel grade 316L is preferred. Their high molybdenum content offers excellent resistance to pitting and crevice corrosion in heavily perturbed aqueous conditions.

- Food and Beverage Industry

To comply with rigorous hygiene requirements, grade 304 and other austenitic stainless steels are used. They are resistant to corrosion from food and cleaning agents, and are also structurally stable. Because of this, they are well-suited for use as heat exchangers in the dairy, brewing, and juice industries.

- Desalination Plants

Heat exchangers in desalination plants are subjected to highly saline environments. Austenitic grades like 904L or super-austenitic alloys are used due to their outstanding resistance to chloride stress corrosion cracking and their ability to endure long-term operation.

- Power Generation Facilities

Stainless steels of the austenitic type are commonly found in the condensers and heat exchangers of power plants, as well as in nuclear reactors. Their strength at high temperatures makes them dependable even in the most extreme thermal conditions.

- Pharmaceutical Manufacturing

Due to the needs of sterility and resistance to aggressive chemical cleaning, austenitic stainless steels reign supreme in pharmaceutical heat exchangers. For some designs, duplex grades can be added for stronger structures while still maintaining a low corrosion rate.

- HVAC Systems

Thermal endurance and oxidation resistance make stainless steel suitable for use in heat exchangers in HVAC systems. Constant exposure to moisture makes humid environments Grade 316’s forte, and it is frequently used in these situations.

- Marine Applications

The marine setting requires materials that can withstand extreme moisture and high salt concentrations. Austenitic stainless steels, such as 316 or 317, are highly resistant to corrosion and make a long-lasting option for seawater heat exchangers.

- Petrochemical Industry

Austenitic stainless steels have a wide application area in the petrochemical industry, especially in heat exchangers servicing hydrocarbon processing streams due to the multiple hydrocarbon processing streams. Grades such as 321 and 347 serve well because they are stable to oxidation and thermal fatigue.

Each of these applications exemplifies the remarkable traits of austenitic stainless steel in brutal environments, providing a long service life and low maintenance. Their versatility and strength add incredible value to modern heat exchanger designs.

How to Ensure Optimal Tube Side Performance with Stainless Steel Materials?

To guarantee optimal performance of the tube side with stainless steel materials, ensure the following practices are met:

- Material Selection: Choose the grade of stainless steel that best suits the operational environment, including temperature, pressure, and the chemical composition of the fluids.

- Proper Fabrication: Both manufacturing and installation of the tubes must be done in a way that limits stress and defects such as pitting and crevice corrosion.

- Regular Maintenance: Schedule maintenance flushes and inspections to mitigate surface fouling, scaling, and corrosion on the tube surfaces.

- Corrosion Protection: Where the operating conditions are highly corrosive, use suitable corrosion inhibitors or coatings.

- Monitor Operating Conditions: Extreme changes in parameters, such as thermally sensitive materials that are structurally integrated with the heat exchanger, may render the material out of spec for operational windows. Maintain these constants to optimize the material’s thermal properties.

Following these suggested steps helps maximize the service life range ever achieved with stainless steel materials and sustain peak efficiency in heat exchanger operation.

Best Practices for Stainless Steel Tube Installation

Precise installation improves the longevity and optimum performance of stainless steel tubes. Adhering to the practices outlined below will ensure efficient and safe installation:

- Material Handling: Transporting and storing stainless steel tubes requires the use of protective materials to prevent scratching, denting, or contamination.

- Cutting and Preparation: Clean and precise cuts are ensured while cutting stainless steel tubes with tools specifically designed for the material. Every connection requires pristine edges. Therefore, every edge must be cleaned and deburred after cutting to remove any residual particles.

- Fitting and Joining: The alignment of the tubes needs to be precise before joining, and high-quality fittings suitable for stainless steel are crucial. Use copper compression fittings, welding, or press-fit systems, and confirm that the fittings match the grade of stainless steel used.

- Welding Considerations: For welded joints, use filler materials and shielding gas that match the grade of stainless steel to protect against excess oxidation. A thorough inspection must be conducted to ensure all welds are free from cracks and porosity.

- Cleaning and Surface Treatment: All accumulated oils, grease, and dirt from handling the tubes must be removed entirely. If there was mechanical damage or exposure to high temperatures during installation, the protective oxide layer can be restored using pickling and passivation treatments.

- Leak and Pressure Testing: System integrity is ensured with thorough leak and pressure testing after installation, which helps identify weak points in the installation.

- Environmental Considerations: Minimize contact with chlorides or corrosive environments during and after installation.” For very aggressive corrosive environments, consider using protective paints or higher-grade stainless steel alloys.

Following these practices can yield optimal reliability and performance with minimal maintenance and downtime with stainless steel tube systems. Precision preparation, coupled with continuous oversight throughout the installation process, is critical to avoiding typical setbacks and achieving lasting performance.

Maintenance Requirements for Stainless Steel Heat Exchanger Tubes

Maintaining stainless steel exchanger tubes is essential; without it, their lifespan, performance, and efficiency could be adversely affected. Adopting the following recommendations will help ensure these systems are managed properly:

- Regular Cleaning

Increased heat transfer, biological scaling, and other fouling processes can occur when deposits form inside the tubes. Periodic descaling through chemical means, using citric acid or tailored descalers, is essential to restore form. More aggressive methods of mechanical cleaning are also available, such as rotary brushes or high-pressure water jets.

- Corrosion Monitoring

Stainless steel is the best material for resisting corrosion damage. However, localized forms of corrosion, such as pitting and crevice corrosion, can occur in highly acidic environments or locations with high chloride concentrations. Frequent examination and the combination of corrosive damage mitigation strategies significantly reduce domestic harm.

- Leak Detection

Properly scheduled pressure examinations, along with regular leak detection procedures such as ultrasonic and dye penetrant testing, should be implemented to identify potential weak areas within the tubes. Repairing leaks in their early stages halts ongoing deterioration of structural elements and averts prospective system failures.

- Preventing Stress Corrosion Cracking (SCC)

Chloride environments with high tensile loads increase the likelihood of stress corrosion cracking. To mitigate known factors, methods such as stress-relief treatment and using warranted alloys like duplex stainless steel should be implemented for harsh operating conditions.

- Inspection Intervals

Define appropriate intervals for tube inspection based on the operational environment and usage intensity, paying special attention to potential wear, deformation, and thermal fatigue. Such monitoring helps in planning maintenance activities before critical problems emerge.

Implementing these measures greatly enhances system reliability while extending the unit’s life as a whole. Additionally, Operators can keep the stainless steel heat exchanger tubes in the best possible condition, retaining the highest possible operational efficiency. This results in reduced operational downtime and lower costs throughout the system’s service life.

Extending the Service Life of Stainless Steel in Heat Exchangers

Prolonging the service life of stainless steel in heat exchangers requires a combination of preventive maintenance, selecting the appropriate material, and optimizing operational policies. For instance, using stainless steel grade 316 or even duplex stainless steels can provide enhanced resistance to corrosion, particularly in areas where chlorides or other aggressive chemicals are present. These materials are often preferred because they resist pitting and crevice corrosion under extreme conditions.

The need for cleaning commences when the surfaces of the heat exchangers begin to foul and scale. Foulants can reduce the efficiency of heat transfer and accelerate the corrosion of stainless steel. Chemical cleaning of stainless steels used in these applications should employ cleaning materials that will not damage the stainless steel structure. Furthermore, operational controls such as monitoring pressures, temperatures, and flow rates are crucial for detecting changes that may lead to mechanical stresses or thermal shocks, which in turn influence the lifespan of the tubes.

Advanced inspection techniques, such as NDT class methods, including eddy current or ultrasonic testing, enable operators to identify fatigue or damage that is not readily discernible. In addition, industry information indicates that the inclusion of automated monitoring systems allows real-time assessment of system performance with automatic alerts to operators. Integrating these strategies will enable companies to minimize unanticipated equipment downtime, enhance overall system productivity, and improve the return on investment on their heat exchanger units.

Reference Sources

- “A Comprehensive Analysis of Stainless Steel Grades for Heat Exchanger Applications” (2020)

This paper evaluates the performance of various stainless steel grades used in heat exchangers, with a focus on 304, 316, and duplex stainless steels. The study highlights that grade 316 offers superior corrosion resistance in chloride-rich environments, making it ideal for marine and industrial applications. Methodologies include comparative corrosion testing and fatigue resistance analysis under varied temperature conditions.

- “Advanced Materials for Heat Exchangers in Industrial Settings” (2021)

Published in the Journal of Materials Engineering, this study examines how advancements in stainless steel alloys, including super-austenitic and duplex grades, improve thermal efficiency and durability. Key findings demonstrate that duplex stainless steels provide a balance between strength and corrosion resistance, outperforming traditional grades like 304 in high-pressure environments.

- “Corrosion Behavior of Stainless Steels in Heat Exchanger Systems with Extreme Conditions” (2018)

This study explores the corrosion behavior of different stainless steel grades in aggressive chemical and thermal environments. The experimental setup involved accelerated corrosion testing in acidic and saline solutions. Results indicate that lean duplex stainless steels are cost-effective alternatives to high-end alloys for less severe operational conditions.

- “Material Selection Guidelines for Heat Exchanger Design” (2019)

This publication offers a toolset for selecting optimal materials for heat exchangers, with a focus on stainless steel grades such as 316L and 2205. The researchers used a combination of thermal conductivity modeling and mechanical testing to validate the suitability of each material under diverse environmental stresses.

- “The Role of Stainless Steel in Modern Heat Transfer Technologies” (2023)

This recent paper discusses the shift toward sustainable and efficient heat exchanger designs utilizing advanced stainless steel grades. The research used computational fluid dynamics (CFD) simulations paired with real-world performance metrics, concluding that steels with higher alloy content significantly reduce maintenance frequency and extend operational lifespans.

These sources collectively provide an in-depth understanding of the appropriate stainless steel grades for heat exchangers and underscore recent technological advancements in the field.

Frequently Asked Questions (FAQs)

Q: What are the benefits of using stainless steel pipes for heat exchangers?

A: Stainless steel pipes offer numerous advantages for heat exchangers, including excellent heat resistance and corrosion resistance, which extends the life of the heat exchanger. They provide superior durability in aggressive environments, maintain structural integrity at high temperatures, and transfer heat efficiently between fluids. Additionally, stainless steel is easy to clean, environmentally friendly because it is 100% recyclable, and offers versatility for use in various applications, from food processing to the chemical industry.

Q: Which material for your heat exchanger is best when dealing with corrosive fluids?

A: For corrosive fluid applications, austenitic stainless steels like 304/304L and 316/316L are typically the best materials for your heat exchanger. Grade 316/316L stainless steel, with its molybdenum content, offers enhanced resistance to pitting corrosion and is commonly used in heat exchanger applications that involve environments containing chlorides. For highly corrosive conditions, higher alloys such as duplex stainless steels (2205) or super-austenitic grades (904L) may be necessary to ensure optimal performance and longevity of the heat exchanger components.

Q: How do stainless steel shell and tube heat exchangers compare to aluminum heat exchangers?

A: Stainless steel shell and tube heat exchangers offer superior corrosion resistance, higher pressure and temperature capabilities, and longer service life compared to aluminum heat exchangers. While aluminum units have better thermal conductivity and are lighter in weight, stainless steel provides significantly better durability in harsh environments. Aluminum heat exchangers are typically less expensive initially but may require more frequent replacement in demanding applications. Stainless steel exchangers also better withstand pressure fluctuations and are more suitable for food, pharmaceutical, and chemical applications where contamination concerns are paramount.

Q: What is the most commonly used grade of stainless steel for heat exchanger tubing?

A: Austenitic stainless steel grades 304/304L and 316/316L are the most commonly used grades of stainless steel for heat exchanger tubing. Grade 304/304L offers good general corrosion resistance and is economical for many applications. In contrast, 316/316L provides enhanced resistance to chlorides and acids, making it ideal for marine, chemical, and pharmaceutical environments. For more demanding conditions, specialized grades like duplex stainless steels (e.g., 2205) offer improved strength and corrosion resistance. In contrast, 410 stainless steel, a martensitic stainless steel, may be used in applications that require higher strength and moderate corrosion resistance.

Q: How do different types of stainless steel affect the efficiency of transferring heat between fluids?

A: Different types of stainless steel have varying thermal conductivity values that directly impact their ability to transfer heat between fluids. Austenitic stainless steels (304, 316) have moderate thermal conductivity (approximately 16 W/m·K), while ferritic and martensitic stainless steel grades may offer slightly better heat transfer properties. The thickness of the material also plays a crucial role – thinner walls improve heat transfer efficiency, but must be balanced with pressure requirements. Surface finish is another factor, as smoother surfaces reduce fouling and maintain efficient heat transfer over time. In some cases, specialized surface treatments or enhanced tube designs can improve heat transfer rates while keeping the corrosion-resistant properties of stainless steel.

Q: When is 410 stainless steel appropriate for heat exchanger applications?

A: 410 stainless steel, a martensitic stainless steel, is suitable for heat exchanger applications where moderate corrosion resistance is combined with high strength and hardness. It’s particularly ideal for environments with mildly corrosive fluids, high-pressure applications, and where resistance to erosion or abrasion is essential. 410 stainless steel has good heat resistance for temperatures up to approximately 1200°F (650°C), making it suitable for use in heat exchangers in applications such as power generation, oil and gas processing, and specific chemical processes. However, it has lower corrosion resistance than austenitic grades, so it’s not recommended for highly corrosive environments or applications involving seawater.

Q: What factors should be considered when selecting stainless steel for pipe and tube heat exchangers?

A: When selecting stainless steel for pipe and tube heat exchangers, consider the operating environment (temperature, pressure, and fluid corrosivity), thermal conductivity requirements, mechanical properties needed, and budget constraints. Evaluate the chemical composition of process fluids, as certain acids or chlorides may require specific grades, such as 316L stainless steel. Consider temperature extremes, as some grades perform better at elevated temperatures. Assess pressure ratings and mechanical stress requirements, which might necessitate higher-strength duplex grades. Finally, factor in cost considerations, as higher-alloy stainless steels provide better performance but at an increased expense, which affects the overall life-cycle cost of the heat exchanger.

Q: How does stainless steel extend the life of the heat exchanger compared to other materials?

A: Stainless steel extends the life of the heat exchanger through its exceptional corrosion resistance, which prevents degradation even in aggressive environments. Unlike carbon steel or copper alloys, stainless steel’s passive chromium oxide layer self-repairs when damaged, providing continuous protection. Stainless steel also maintains its mechanical integrity at elevated temperatures, resisting creep and thermal fatigue that would compromise other materials. Its resistance to biofouling and scaling helps maintain heat transfer efficiency over time, reducing the need for maintenance. The durability of stainless steel in cycling temperature conditions and its resistance to erosion from high-velocity fluids contribute to longer service intervals and reduced replacement frequency, resulting in lower lifetime ownership costs despite higher initial investment.