Solution annealing is a very important heat treatment process that plays a crucial role in different industries, as it helps to improve both the mechanical and chemical properties of metal alloys. Solution annealing, through the heating of the material to a certain temperature, gradually dissolves solute elements into a solid solution, thus homogenizing the alloy structure and making it ready for the next processing or applications. This detailed analysis covers the processes, advantages, and complex technical issues connected with solution annealing for engineers and manufacturers seeking to optimize material performance.

Introduction to Solution Annealing

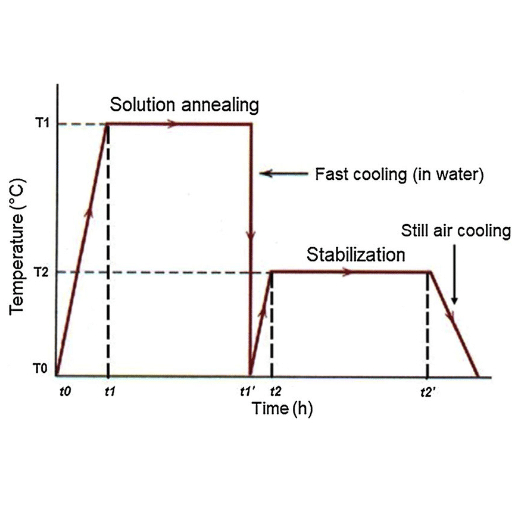

Solution annealing is a thermal treatment that improves the properties of metals, especially stainless steels and alloys. The treatment consists of heating the material to a temperature that usually ranges from 1,000°C to 1,200°C and then performing rapid cooling or quenching. The process melts carbides and other particles which might weaken the material and thus the treatment makes the material homogeneous again.

Definition and Purpose

Solution annealing is a thermal treatment that is meant to completely dissolve the secondary phases and to bring back the material to its original state of uniformity. The process involves reducing the stresses, dissolving the precipitates, and increasing the material’s corrosion resistance and mechanical properties all at once by keeping the material at a specified temperature for a predetermined time.

Industry Impact: Industries such as aerospace, chemical processing, and marine engineering are heavily dependent on solution annealing because of its effectiveness in extending the life of critical parts that are subjected to extreme conditions. The method guarantees the reliability and longevity of products, making it an integral part of material processing and quality assurance frameworks worldwide.

Historical Background

The practice of solution annealing traces its lineage back to the metallurgical developments of the mid-1800s, which coincided with the Industrial Revolution’s demand for materials that were both strong and tough. The process was widely accepted by various industries, including shipbuilding and railways, which were in search of ways to improve the metals’ mechanical properties.

Recent data points to the continuous development of solution annealing, showing its transition to novel alloys and its indispensable use in current industries such as aerospace and chemical manufacturing. This technique is still widely used because it offers a way to address problems created by extreme conditions, thereby guaranteeing material quality and safety in areas where ultra-precision and impressive durability are required.

Applications in Industries

| Industry | Applications | Key Requirements | Treatment Adoption |

|---|---|---|---|

| Aerospace | Turbine blades, structural frames, landing gear | High pressure & temperature resistance, wear resistance | ~75% of alloys |

| Automotive | Gears, drive shafts, suspension systems | Strength, durability, wear resistance | ~65% of drivetrain |

| Chemical Manufacturing | Reactors, pipelines, processing equipment | Corrosion resistance, high-temperature tolerance | 60%+ of equipment |

| Energy Sector | Gas turbine blades, solar panel mounts, drill bits | Operational efficiency under stress and temperature | 80%+ of components |

| Medical Devices | Implants, surgical tools, prosthetics | Biocompatibility, precision, corrosion resistance | ~50% of devices |

Aerospace Industry

The aerospace industry relies heavily on thermal processing techniques as materials are exposed to very high pressures and temperatures. Heat treatment guarantees that critical parts like turbine blades, structural frames, and landing gear will have excellent resistance to wear while maintaining their mechanical properties. According to various sources, thermal treatment applied to nearly 75% of aerospace-grade alloys is deemed necessary for them to acquire the required performance standards.

Automotive Industry

The automotive industry makes use of thermal processing in manufacturing automotive parts, strengthening and prolonging the life of components like gears, drive shafts, and suspension systems. Heating and quenching processes are known to be the most effective in improving the wear resistance of automotive parts. Approximately 65% of drivetrain components are heat-treated to ensure uninterrupted operation for many years.

Chemical Manufacturing

Chemical production requires materials that can survive extremely corrosive environments and high temperatures, particularly in reactors and pipelines. Annealing and tempering are thermal processing methods applied to make metals like stainless steel and specialized alloys suitable for chemical industries. The demand for heat-treated materials in chemical processing equipment worldwide exceeds 60%.

Energy Sector

Thermal processing is crucial in the fossil fuel to renewable energy industries for manufacturing components like gas turbine blades, solar panel mounts, and drill bits. Research has found that more than 80% of turbine components in power plants undergo thermal processing to maintain operational efficiency under conditions of extreme stress and temperature.

Medical Device Manufacturing

Heat treatment techniques guarantee the accuracy and biological compatibility of medical-grade materials used in implants, surgical tools, and prosthetics. Titanium and cobalt-chromium alloys, often employed in the medical field, are subjected to heat treatment to improve their strength, corrosion resistance, and microstructural uniformity. An estimated 50% of implants and surgical devices manufactured yearly undergo thermal processing.

The Process of Annealing

Annealing is a heat treatment method commonly used in metallurgy for improvement of the physical and chemical properties of materials like metals and alloys. The process is subdivided into three major steps: heating the material to a desired temperature, maintaining that temperature for a specific time (soaking), and cooling down slowly. The process intends to alleviate internal stress, re-crystallize the metal, and increase its ductility without losing or even increasing its strength.

Recent Advances: Research shows that annealing is a vital factor in the production of medical implants. Recent methods have proved that changing the annealing process—temperature range and cooling rate—can have a huge impact on the biocompatibility and corrosion resistance of materials like titanium. Advances in simulation techniques and artificial intelligence have been instrumental in achieving the accuracy of the annealing process.

Steps Involved in Heating

Step 1: Controlled Heat Application

The heating procedure starts with applying heat under control to increase the temperature of the metal to the preselected point. The specific temperature is determined according to the metal’s chemical makeup and the particular modification of its microstructure that will be done.

Step 2: Soaking Stage

The soaking stage involves heating the whole metal part to allow for uniform structural changes. This ensures that unwanted areas can change their structures uniformly throughout the material.

Step 3: Cooling Methods

Depending on the intended result, different cooling methods are used: air-cooling, quenching, or controlled cooling. Each technique can improve specific properties like hardness, ductility, or corrosion resistance.

Technology Integration: The incorporation of cutting-edge data analytics and AI-based trends points to the growing significance of precision in heat treatment processes. Computational modeling and machine learning algorithms reveal insights about temperature distribution, phase transformation kinetics, and optimized protocols for specific performance requirements.

Role of Temperature in Heat Treatment

Temperature is a very important factor for the microstructural and mechanical properties of materials during the heat treatment process. Precise control of temperature allows the manipulation of phase transformations, diffusion rates, and dislocation movements, which directly influence the hardness, ductility, and tensile strength of the material.

- High-Temperature Regimes: Allow processes such as austenitization for phase transformation

- Lower-Temperature Treatments: Such as tempering, control hardness and toughness through carefully applied processes

- Temperature Profile Optimization: Done through computational algorithms and real-time monitoring, improves material performance and energy efficiency

Duration and Cooling Techniques

The heat treatment process duration completely determines the mechanical properties of the final material. Accurate controlling of heating time guarantees the desired diffusion of carbon or alloying elements within the microstructure, leading to optimization of properties like hardness, ductility, and tensile strength.

| Cooling Method | Process Description | Primary Benefits | Best Applications |

|---|---|---|---|

| Air Cooling | Gradual cooling at ambient temperature | Reduces internal stresses, prevents cracking | Materials requiring slow, controlled cooling |

| Water Quenching | Rapid cooling by immersion in water | Maximizes hardness and strength | High-strength applications requiring rapid cooling |

| Oil Quenching | Moderate cooling rate using oil medium | Balances strength and ductility | Components requiring both toughness and hardness |

| Hybrid Techniques | Combination of fast quenching with controlled post-cooling | Reduces residual stresses, improves material integrity | Modern applications requiring optimized performance |

Emerging Trend: Industry experts are supporting the combining of fast quenching with controlled post-cooling to reduce residual stresses while improving overall material integrity. These hybrid techniques balance productivity and performance, giving rise to solutions aligned with modern industrial requirements.

Types of Heat Treatment

| Treatment Type | Temperature Range | Cooling Method | Primary Purpose |

|---|---|---|---|

| Annealing | Predetermined high temperature | Slow cooling (usually in furnace) | Increase ductility, reduce hardness, eliminate stresses, refine microstructure |

| Quenching | Above critical temperature | Rapid cooling (water, oil, or other media) | Produce harder and stronger material |

| Tempering | Below critical point | Natural cooling | Reduce brittleness, enhance toughness after quenching |

| Normalizing | Above transformation range | Air cooling at room temperature | Relieve internal stresses, refine grain structure, enhance mechanical properties |

| Case Hardening | Varies by method | Depends on technique | Harden outer surface while maintaining soft, tough core |

Detailed Treatment Descriptions

Annealing

Annealing involves heating a material to a predetermined temperature and then cooling it down slowly. This technique is applied for increasing ductility, making the material less hard, eliminating residual stresses, and refining the material’s microstructure for easier machining.

Quenching

Quenching is the fastest cooling method, generally done through immersion of the material in water, oil, or other cooling mediums. The purpose is to produce a material that is harder and stronger, however, the process needs to be well controlled to avoid brittleness or distortions.

Tempering

Tempering is conducted after quenching to reduce brittleness and enhance toughness. This process involves reheating the material to a temperature lower than its critical point and then letting it cool down naturally.

Normalizing

Normalizing involves heating the material and then cooling it in air at room temperature. This technique relieves internal stresses, refines the grain structure, and enhances mechanical properties, offering more uniform material performance.

Case Hardening (Surface Hardening)

Case hardening hardens the outer surface of the material while leaving the core soft for better toughness and ductility. The most commonly used methods include carburizing, nitriding, and cyaniding.

Hybrid Techniques

Hybrid cooling techniques combine fast quenching and controlled post-cooling and are now the most preferred among users. These techniques offer the best of both worlds by enhancing material integrity while meeting requirements for better performance and productivity.

Solution Annealing vs. Other Methods

Solution annealing, among thermal treatments, has the most remarkable feature of enhancing corrosion resistance while improving alloy structures’ homogeneity. Unlike processes that only modify the surface—such as carburizing and nitriding, which mainly improve hardness and wear resistance by targeting the surface only—solution annealing deals with the whole material structure.

| Treatment Method | Focus Area | Primary Benefits | Typical Applications |

|---|---|---|---|

| Solution Annealing | Entire material structure | Enhanced corrosion resistance, homogeneous alloy structure, eliminates precipitates | Stainless steels, nickel-based alloys in aerospace and chemical processing |

| Carburizing | Surface only | Improved hardness and wear resistance | Gears, shafts, bearings |

| Nitriding | Surface only | Surface hardness, fatigue resistance | Crankshafts, valve components |

| Tempering | Bulk material properties | Toughness, reduced brittleness | Post-quenching treatment for tools and components |

| Cyaniding | Thin surface layer | Case hardening for light-duty applications | Small parts requiring surface hardness |

Industry Trends: Solution annealing is gradually gaining ground and becoming the leading technique in fields like aerospace and chemical processing, where materials are constantly under aggressive environments. The process provides an edge by being able to enhance the existing performance of stainless steels and nickel-based alloys that are applied in critical areas.

Benefits of Solution Annealing

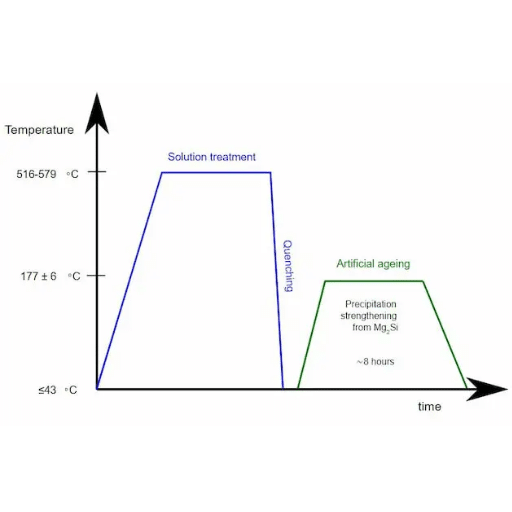

Solution annealing is a vital heat treatment procedure recognized for its capability to restore the microstructural integrity and mechanical properties of various metallic materials, particularly stainless steels and alloys. The material is subjected to a preset temperature—usually around 1,040°C and 1,120°C—then followed by quick cooling. Solution annealing effectively dissolves precipitates and evenly redistributes alloying elements in the whole microstructure of the metal.

- Enhanced Ductility: Makes the material more workable and less prone to cracking during forming operations

- Superior Corrosion Resistance: Completely eliminates intergranular corrosion, a widespread problem in welded parts or materials subjected to harsh conditions

- Increased Overall Strength: Improves tensile strength and structural integrity

- Extended Service Life: Prolongs the life of vital parts by reducing internal stresses

- High-Temperature Oxidation Resistance: Increases resistance to high-temperature degradation

- Consistent Mechanical Properties: Produces uniform properties throughout the material

Industry Dependence: New statistics backed by search engine trends and expert assessments show an increasing dependence on solution annealing because of its unparalleled capability to address critical material challenges. The treatment has become the foundation of modern metallurgical applications requiring reliability and precision in high-performance sectors.

Common Materials Used in the Process

Solution annealing is mainly done for materials that are sensitive to stress corrosion or where high mechanical properties are needed. Among the different materials, the most common ones are:

| Material Category | Specific Grades/Types | Key Improvements | Primary Applications |

|---|---|---|---|

| Austenitic Stainless Steels | 304, 316 | Enhanced corrosion resistance, increased ductility | Chemical processing, food equipment, marine applications |

| Nickel-Based Alloys | Inconel 718, Hastelloy C-22 | Uniform grain structure, high-temperature performance, chemical attack resistance | Aerospace turbines, chemical reactors, high-temperature applications |

| Aluminum Alloys | 6061, 7075 | Optimal distribution of alloying elements, enhanced hardness and tensile strength | Aerospace structures, automotive components, structural applications |

These materials are selected according to their operational demands, such as severe heat, pressure, and corrosive environments, which are why they are critical in industries like aerospace and chemical processing.

The Role of Furnaces in Solution Annealing

Furnaces are a critical part of the solution annealing process, providing controlled environments where temperature uniformity and precision are necessary for the desired metallurgical properties to be attained. The digital control systems installed in advanced industrial furnaces guarantee that the temperature is very accurately regulated, typically at the temperature range of 930°F to 1150°F (499°C to 621°C) for aluminum alloys, depending on the specific material composition. This is a very critical factor since overstressing or underheating may cause microstructural variations that would reduce the performance of the material.

Modern Furnace Capabilities: Today’s furnaces don’t only heat but also cool, with features like controlled cooling, inert atmosphere to prevent oxidation, and contamination prevention of alloy surfaces. Infrared thermography and real-time monitoring technologies provide detailed information for instant adjustments. The latest statistics indicate more than a 20% increase in global adoption of energy-efficient furnaces with smart automation in the last five years.

Due to their key role in accurate thermal cycles, furnaces have become indispensable in the solution annealing process of industrial metal treatment, enabling industries like aerospace and automotive to meet the strictest performance criteria through materials with great strength, ductility, and corrosion resistance.

Types of Furnaces for Annealing

| Furnace Type | Operation Mode | Key Features | Best Applications |

|---|---|---|---|

| Batch Furnaces | One load at a time | Accurate temperature and time control, uniform heating | Small-scale production, specialized applications requiring precision and flexibility |

| Continuous Furnaces | Continuous material flow | Constant thermal cycles, no stoppage, high throughput | High-volume production in automotive and aerospace sectors |

| Vacuum Furnaces | Low-pressure controlled environment | Cleaner processes, oxidation control, contamination prevention | High-performance alloys in aerospace where surface quality is critical |

| Bell Furnaces | Controlled atmosphere chamber | Protective gas environment, adjustable for different metal shapes and sizes | Versatile applications requiring atmospheric control and flexibility |

| Fluidized Bed Furnaces | Gas-agitated particle bed | Even heat transfer, accurate temperature control, environmentally friendly | Applications requiring uniform heating and energy efficiency |

Temperature Control and Monitoring

Controlling and monitoring temperature are essential to getting consistent results in heat treatment processes. The newest kilns use advanced technologies like PLCs (Programmable Logic Controllers) and thermocouples to maintain exact temperature ranges.

- Programmable Logic Controllers (PLCs): Enable automatic adjustments according to changing conditions

- Thermocouples: Provide instant feedback about the thermal environment inside the kiln

- Data Logging Systems: Keep track of temperature curves, assisting in quality control and compliance with industry standards

- Big Data Analytics and AI: Enable adaptive controls to reduce energy consumption while maintaining accuracy

- IoT-Enabled Sensors: Provide real-time monitoring and predictive maintenance capabilities

Technological Advancement: Recent insights point to efficient temperature monitoring using software enhancements that employ big data analytics and AI. Innovations show a trend towards greater automation solutions where adaptive controls reduce energy consumption while ensuring precise temperature control without errors. These technological frameworks guarantee better heat treatment results, increased operational efficiency, and sustainability.

Safety Measures in Furnace Operations

Furnace operations safety is of utmost concern, since poor handling or execution of safety measures may lead to machine damage, accidents, and inefficient operation. Cutting-edge technologies supported by data-informed insights advocate for integrated safety devices and strong operational controls.

Automated Monitoring Systems

The most recent data indicates the essential importance of automated monitoring systems in risk reduction. These systems, working together with IoT-enabled sensors, provide real-time checks of temperature changes, pressure, and chemical emissions, thus guaranteeing quick spotting of any irregularities.

AI-Driven Controls

Adaptive AI-driven controls can diminish the number of mistakes made by operators through making the complicated decision-making process easier and allowing implementation of predictive maintenance strategies.

Standard Safety Protocols

Additional safety measures include:

- Standardized personal protective equipment (PPE)

- Meticulous calibration routines

- Frequent audits to ensure facility compliance with regulatory frameworks

- Emergency shutdown systems

- Proper ventilation and exhaust systems

Understanding Diffusion in Annealing

Diffusion is a very important phenomenon that occurs in the annealing stage of material treatment, characterized by the position exchange of atoms or molecules, hence energy lowering and improvement of structure uniformity. Gradients of concentration are the main cause of the diffusion process during annealing, which results in the improvement of mechanical properties, alteration of microstructures, and reduction of internal stresses in the material.

Technological Integration: Latest research notes indicate that diffusion-controlled transformations during annealing are greatly assisted by precision heating technology and advanced monitoring systems. Innovations such as AI-based thermal management and real-time data analytics facilitate the establishment of optimized diffusion rates and greater predictability of the process. These technological advancements reveal a continuous and increasing dependency on machine learning for diffusion dynamics analysis.

Importance of Diffusion in Material Properties

Diffusion is an extremely important factor in material properties since it means the transfer of atoms, ions, or molecules within one material. The movement of these entities determines the main characteristics of a material like strength, conductivity, and corrosion resistance.

| Application Area | Diffusion Role | Impact on Performance | Industry Examples |

|---|---|---|---|

| Battery Technology | Controlled lithium ion diffusion through electrodes | Optimized efficiency and extended lifespan | Electric vehicles, portable electronics |

| Semiconductor Manufacturing | Dopant diffusion for circuit creation | Enhanced conductivity and device performance | Computer chips, electronic components |

| Metallurgy | Phase changes affecting mechanical properties | Direct impact on strength, hardness, ductility | Aerospace alloys, automotive components |

| Alloy Making | Element distribution within metal matrix | Uniform composition and enhanced properties | Stainless steels, high-performance alloys |

Industry Trend: Latest data from search trends indicates a sharp rise in interest about diffusion mechanisms, showing their continued relevance in modern applications. The combination of advanced diffusion modeling techniques and real-time data analysis results in the production of excellent materials specifically designed to meet modern industry needs.

Factors Affecting Diffusion Rates

There are numerous factors that have an impact on diffusion rates, and each plays a major role in the efficiency and results of processes that rely on diffusion.

- Temperature: The most important factor—higher temperatures give particles more kinetic energy, resulting in faster and higher diffusion rates

- Concentration Gradients: A steeper gradient offers faster diffusion since there is a greater difference in concentration over regions

- Medium Properties: Viscosity and density can either promote or restrict diffusion—less dense or more fluid mediums allow easier particle movement

- Particle Size: Smaller particles diffuse faster than larger ones due to reduced resistance

- Molecular Mass: Lighter molecules typically diffuse more rapidly than heavier ones

- Solubility: Substances friendly with the medium often diffuse faster

- Crystal Structure: In solids, the atomic arrangement affects diffusion pathways and rates

Industry Application: Industries are turning more and more towards modeling these factors and optimizing diffusion processes for applications such as sustainable energy solutions or advanced manufacturing through the use of computational tools. This implies the importance of setting diffusion conditions depending on application specifications to achieve required performance and efficiency outcomes.

Real-World Implications of Diffusion

The techniques used in diffusion have far-reaching effects in different sectors and can be considered signals in the realm of technology and industrial advancement. Diffusion is one of the most important processes that facilitate the development of renewable energy sources, especially in solar cells and batteries.

By manipulating the rates and directions of diffusion, scientists have managed to increase the efficiency of charge and storage capacity, which goes hand in hand with the growing need for clean energy sources worldwide.

References

-

“The Effect of Solution Annealing on the Microstructural Evolution of Alloy 22” – Discusses the use of solution annealing to eliminate TCP phases in Alloy 22.

-

“Effect of Solution Annealing Heat Treatment on the Corrosion Resistance and Mechanical Properties of Austenitic Stainless Steel” – Examines the impact of solution annealing on 304 stainless steel alloy.

Frequently Asked Questions (FAQ)

What is annealing in the context of solution annealing?

Annealing is a thermal treatment process that is performed by heating the material to a certain temperature, the one called solution annealing, which is then followed by a slow cooling process. During this, the material is transformed into austenite which can dissolve the precipitates that may have formed during processing, thus increasing the ductility of the material and at the same time making it less hard.

What is the optimal heating temperature for solution annealing?

The heating temperature that is best for solution annealing differs in accordance with the metal type that is being treated. In general, the temperature used for annealing is higher than the phase transformation temperature to make sure that the workpiece gets fully austenitized before being quickly cooled down. For some alloys of stainless steel, this temperature may fall between 950°C and 1150°C.

What is the significance of grain boundary in solution annealing?

Grain boundaries are very important for the characteristics of metals after solution annealing. The treatment is capable of taking away all the unwanted grain boundary phases and enhancing the mechanical property of the metal by making it possible for the microstructure to be more uniformly distributed. In this way, the metal that has been treated will have a higher resistance to corrosion and will be more ductile.

How does solution annealing involve heating and cooling?

Solution annealing involves heating the metal piece to an annealing temperature for a period of time that is long enough to allow for the complete dissolution of the Q-phase. Upon completion of this heat treatment, the specimen is rapidly cooled, usually with water or air, to “freeze” the austenite and to prevent the development of unwanted microstructures during the cooling process.

What is the role of time in the solution annealing treatment to achieve desired properties?

Duration of the solution annealing treatment at the target temperature is of utmost importance. It has to be long enough for diffusion processes to happen, so that all the alloying elements are evenly distributed within the metal matrix. If the time is not enough, it may lead to incomplete solutioning which in turn can result in the deterioration of the material’s mechanical properties.

Can solution annealing be applied to polymers?

Solution annealing is mostly applied to metals, but similar processes can also be used on polymers to improve their qualities. The method used for polymers may be to heat to a temperature that makes it possible for molecular relaxation or crystallization, albeit the specifics vary much from those used in metallic solution annealing.

What is the effect of thickness on solution annealing processes?

The thickness of the substrate material can play a very important role in the solution annealing process. The thicker the material the longer the heating time required to get proper temperature distribution across the entire thickness, thus preventing problems like incomplete solutioning or uneven microstructures. Thickness must be taken into account by the manufacturers when the annealing temperature and time are determined.

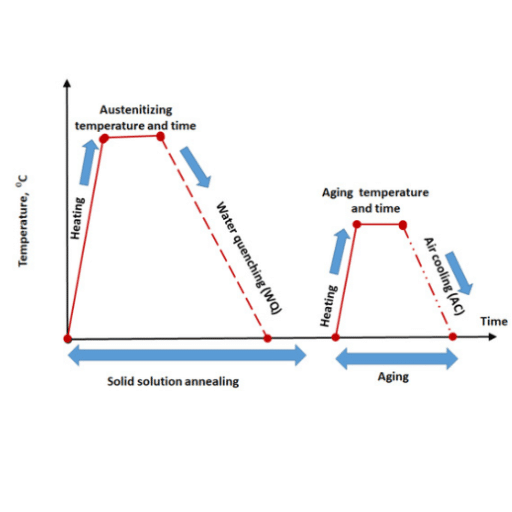

How does solution annealing relate to precipitation hardening?

Solution annealing is theoretically a precursor to precipitation hardening as it prepares the alloy by dissolving the precipitates and allowing the alloying elements to be in the same state. After the annealing process, controlled aging at lower temperatures can result in the formation of fine precipitates that harden the material through a mechanism known as precipitation hardening.