Diaphragm valves and ball valves are the most popular choices when it comes to choosing valves for sanitary applications, and both offer unique advantages, which makes them suited for distinct contexts. These valves see widespread usage in the food and beverage industry, pharmaceuticals, and biotechnology, all of which have stringent requirements for cleanliness, optimal performance, and reliability. Understanding the advantages of each device is essential due to the differences in design, functionality, intended use, and operational principles. This article discusses the most prominent differences between sanitary diaphragm valves and ball valves so you can make the best decision for your application. Comprehending these differences, whether for optimizing a production line or ensuring compliance, will help achieve efficiency without undermining quality.

What Are The Key Differences Between Sanitary Ball Valves And Diaphragm Valves?

The main differences between sanitary ball valves and diaphragm valves are found in their design, operation, and applications.

- Design: The design feature that distinguishes Ball valves from others is the utilization of a ball with a hole that can be rotated. This makes an efficient flow-on/off control mechanism. Diaphragm valves use a flexible diaphragm that presses against a seal, offering minimal leakage.

- Applications: In systems needing swift opening and closing of passages and robust durability, ball valves are ideal. Diaphragm valves find their application in industries dealing with food and beverage, and pharmaceuticals, where sanitation is of utmost importance.

- Maintenance: Since Ball valves make use of simple mechanical parts, they are easier to maintain. Because of the flexible membrane inside the pelvic Diaphragm valves, they are more challenging to maintain. They need frequent checks and replacements, especially in high-pressure or abrasive situations.

These distinctions create requirements for different types of valves with regard to operational needs, with a preference for either efficiency or slipstream process.

Operating Mechanism: How Ball And Diaphragm Valves Control Flow

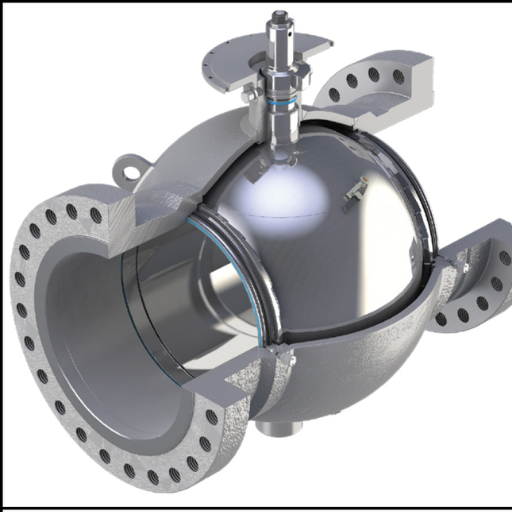

To manage the fluid’s flow in and through the pipeline, ball valves leverage a sphere-shaped ball with a hollow center. As the handle or actuator turns the ball to position its hollow core parallel to the pipeline, fluid can flow unchecked. Turning the ball 90 degrees to cover the opening stops any flow of fluid. This straightforward system assures swift operation, which in most cases requires a quarter turn, and offers an unequivocal indication of whether the valve is open or shut. Furthermore, ball valves are excellent for shut-off applications as they provide a tighter seal even in high-pressure systems.

Diaphragm valves, on the other hand, utilize a flexible diaphragm that pushes against a weir or saddle to control flow. A stem or actuator moves the diaphragm, which is often a rubber or rubber-like material, and needs to be lifted or lowered for the valve to be in the open or closed position. This mechanism helps a lot in processes where accurate control of fluid flow or cleanliness is needed because the diaphragm completely seals the flow path from external contamination. In addition, there are no internal edges creating voids, which reduces the potential for particulate matter accumulating making these valves popular in the pharmaceutical and food processing industry.

Each mechanism serves varying operational requirements, as ball valves possess straightforward functionality and durability, whereas diaphragm valves function best in situations that require aseptic conditions and intricate flow control. These valves demonstrate consideration for diverse, flexible operational requirements across many industries.

Design Features: Comparing The Valve Body And Seal Structures

The distinguishing features of a valve body and its seal components tend to differ based on the body’s specific industrial functions. Ball valves typically have a rugged design that is built from stainless steel, brass, or PVC, which makes them resistant to both high pressure and temperature. Their closure mechanism is positioned in such a way that it is spherical, which further ensures that it is air-tight, hence the lower chances of leakage. This guarantees their efficacy in high-pressure operations. The ease with which they can be serviced, combined with their longevity, is ensured by their simplistic design.

In contrast, diaphragm valves tend to be more intricate since they have a flexible diaphragm that serves as both the enclosing layer and the flow control. This shifting design encapsulates the moving parts and, by doing so, reduces the risk of contamination. Diaphragms are made from substances like PTFE and EPDM, which are known for their chemical resistance and compatibility with sterile environments. In the food and beverage as well as the pharmaceutical industries, the use of water treatment has made diaphragm valves the preferred choice because they work best with low-pressure and low-temperature applications.

These valves are selected based on their operational requirements. For instance, current industry studies state that in specific scenarios, ball valves are able to manage more than 1000 psi, while diaphragm valves are superior in maintaining cleanliness and control in lower pressures. Such insights into design and functionality help guide the selection of the correct valve for given operating conditions and industries.

Applications: Where Each Type Of Valve Performs Best

- Ball Valves

-

-

- Oil and Gas Industry

- Most commonly located within pipelines due to their high resistance to pressure and temperature.

- Data: Can withstand pressures of up to 10,000 psi, and temperatures ranging from -50°F to 400°F.

- Chemical and Petrochemical Processing

- Best suited for dangerous and corrosive materials because of their strong structure and firm shutoff features.

- Data: Stainless steel and hastelloy are used due to their high amounts of effective corrosion resistance.

- Water Supply Systems

- Commonly incorporated within sewage and water distribution systems for controlling the flow of water.

- Data: Useful in systems where the pressure does not exceed 1,500 psi.

- Oil and Gas Industry

-

- Diaphragm Valves

-

-

- Pharmaceutical and Food Processing

- Best suited for clean areas requiring high levels of hygiene.

- Data: Prevents contamination, designed with smooth-flow CIP internal surfaces.

- Water Treatment Plants

- Perfect for the accurate control of water and chemical flow.

- Data: Achieves optimal performance at sub 300 psi with precision flow control.

- Mining Operations

- Suitable for slurry and abrasive minerals associated with mining.

- Data: High abrasion resistance with extended operational life in aggressive environments.

- Pharmaceutical and Food Processing

-

Recognizing the distinct features and uses of ball and diaphragm valves empowers industries to make decisions that boost efficacy and dependability in their processes.

How Do Sanitary Ball Valves Work And What Are Their Advantages?

Sanitary ball valves operate by means of a ball that has a hole at its center. The ball controls the flow of liquid by rotating. The valve opens when the hole aligns with the pipeline, which allows flow, and closes as the valve is rotated to stop flow. These valves have been engineered to have smooth external surfaces and internal cavities with no hidden spaces to avoid contamination filtering through several levels of sanitation hands.

Sanitary ball valves are designed to withstand harsh environments such as oxidation and extreme temperature changes while maintaining the cleanliness requirements within the food industry, pharmaceutical and beverage industries, where operational hygiene is essential. In addition, they provide swift and dependable service requiring minimal personnel attention. The benefits of these valves are remarkable cleanliness, ease of sanitation and maintenance, agility, along with great life cycle resistance.

Ball Valve Design And Flow Path Characteristics

Revolving spheres are utilized to close ball valves. The sphere rotates and either permits or obstructs the flow in a pipe. The pressure drop is greatly minimized when the valve is in a fully open position, as the flow path is wide and free. The circular smooth surface that the valve creates when it is open results in a reduction of turbulence and energy loss. This property makes it efficient in many applications.

Modern-day ball valves come in many configurations, such as full bore, reduced bore, and V-port design. Full-bore ball valves have a flow path that is equal to the diameter of the pipeline, which provides greater flow capacity and decreases the chances of blockage. This feature is helpful in the oil, gas, and food processing industries, where there is a need for uninterrupted flow. Though reduced bore valves are compact, they slightly restrict the flow. Thus, these valves are more economical in applications where a reduction in flow efficiency is acceptable. V-port ball valves are better suited for throttling operations as they provide the ability for precise control of flow.

Improvements in stainless steel and modern polymers technology have increased the efficiency of ball valves as the incorporation of these materials improves the resistance to corrosion and wear. It is reported that stainless steel ball valves have a service life exceeding 30 years under standard operating conditions, extending operational reliability. Furthermore, additional refinements such as anti-static devices, cavity fillers, and fire-safe designs have enhanced efficiency and safety,y catering to severe requirements in petrochemicals, pharmaceuticals, energy, and other industries.

Advantages And Disadvantages Of Ball Valves In Sanitary Applications

Due to their design and the high hygiene standards associated with them, ball valves are very common within sanitary applications. Here is a complete list of their pros and cons:

Advantages:

- Easy to Clean: Ball valves do not allow any residues or contaminants to build up. This is because they are easy to clean with smooth surfaces and low internal cavities. Hygiene is crucial, thus, this is important for the food processing and pharmaceutical industries.

- High Durability: Modern ball valves are frequently made from robust materials, such as stainless steel, which enhances durability. There is reduced corrosion whilst maintaining the chemicals. Heady duty structures ensure longevity while prolonging maintenance needs and expenses.

- Precision Control: Ball valves provide effortless turning shutoff, which is critical for applications that need exact control of fluids. The tight seal. Quick operation is further made possible by the quarter-turn mechanics, which tighten the valve seat.

- Versatility: These valves can be used in complex sanitary systems because they have an expansive range of applications. They can handle thick fluids and gas flow.

- Reduced Contamination Risk: Retain product quality required for sensitive industries through high standards sof ealing and no deadzone designs that eliminate the risk of contamination.

Disadvantages:

- Cost Considerations: Sanitary ball valves made of high-grade stainless steel and with advanced features tend to be more expensive than other valve types.

- Size Limitations: Some valves may not be ideal for larger pipelines due to the design, which may create flow restrictions if not properly sized.

- Potential Maintenance Needs: Ball valves can become less effective over time, especially in systems with abrasive materials, needing seals and lubrication replacement to function properly.

- Temperature Sensitivity: Depending on the material specifications, some ball valves may have difficulty with extreme temperature fluctuations.

- Not Suitable for Throttling Applications: Ball valves are not suitable for applications that involve continuous throttling, as this will cause excessive wear on the ball, seals, and affect reliability long-term.

Taking into account these factors enables industries to choose relevant valve specifications that fit the particular requirements of their sanitary systems.

What Makes Sanitary Diaphragm Valves Unique For Hygienic Applications?

The design and material composition of sanitary diaphragm valves make them suitable for hygienic applications. Their smooth interior surface is free from crevices, which greatly minimizes bacterial growth and allows for easier cleaning. They are made from food-grade or pharmaceutical-grade materials that meet strict hygiene standards. These valves also have a compact and utterly leak-proof design, which is perfect for food and beverage processes or any other processes that require high sterility.

Flexible Diaphragm Design And Contamination Prevention

The flexible diaphragm design serves as one of the critical innovations aimed at preventing contamination from different sources across different industries. These diaphragms are designed to form a seal in systems that have flow or pressure variations, hence the cross-contamination risks are minimized. New materials like polytetrafluoroethylene (PTFE) and elastomers increase a diaphragm’s chemical resistance and durability, which allows them to resist harsh cleaning chemicals and high temperatures typical of the Clean-in-Place (CIP) and Sterilization-in-Place (SIP) processes.

Latest information shows that systems using modern diaphragm valve incorporation have up to 25% less downtime related to contamination, thanks to the increased sealing technology and reduced bacterial retention. Additionally, the range of these valves offers functional ingenuity as they can be used in extremely viscous liquids or particulate-heavy fluid solutions while still observing high hygenic standards. This combination of versatility and ability to perform under strict hygienic conditions highlights their role in the food, biopharm, and beverage industries, where sterility in critical tasks is essential.

Diaphragm Valves In Food And Beverage Processing

In food and beverage processing, diaphragm valves are essential for protecting product safety and helping maintain hygiene standards. Diaphragm valve pressure seals have recently benefited from upgraded cleaning and sterilization technologies alongside advancements in valve material and design, strengthening resistance to heat, aggressive cleaning agents, and regulated standards like the FDA and EHEDG Certifications. Steam sterilization compatibility showcases modern diaphragm valves’ suitability for industries that need clean-in-place (CIP) or sterilize-in-place (SIP) maintenance protocols.

Some statistical analysis shows an increase in the food and beverage sector shift towards aseptic processing for microbial contamination reduction, where diaphragm valves have become increasingly important. These valves are capable of withstanding high-pressure environments, and their smooth, crevice-less interiors eliminate residue accumulation and the associated contamination problems. Research showed that hygienic diaphragm valves offer an ease of maintenance so significant that overall maintenance downtime could be reduced by upwards of 30%.

Moreover, the adaptability of diaphragm valves goes as far as beverage carbonation, products with complex viscid compositions, and even slurry mixtures, which expand their versatility even more. Their precise flow rate control, combined with the aforementioned characteristics, diaphragm valves significantly further the operational efficiency and product quality in the food and beverage industry.

Weir And Elastomeric Diaphragm Options

Weir-style diaphragm valves are particularly suited for applications involving low flow and frequent cycling of fluid. Their design features a curved surface that offers better sealing capabilities with reduced force. This makes them quite effective with clean and aggressive media such as sulfates, nitric acid, and caustic solutions,often encountered in industrial food processes.

Together with elastomeric diaphragms like EPDM (ethylene propylene diene monomer) or PTFE (polytetrafluoroethylene), these valves offer remarkable resilience as well as chemical resistance. EPDM diaphragms are known for their toughness and excellent resistance to extreme temperatures, often ranging from -40°F to 300°F. This makes them suitable for both hot and cold processing. Conversely, PTFE diaphragms are better suited for highly corrosive materials, experiencing far less erosion over many cycles. Recent studies indicate that modern diaphragm valves are often elastomeric materials capable of extending operational life by up to 40%, increasing valve lifespan significantly while lowering maintenance and operational costs.

The flexibility in materials enables manufacturers to customize diaphragm valves to specific requirements for production lines while meeting the rigorous safety and hygiene criteria in food and beverage manufacturing.

Which Factors Should Guide Your Choice Between Ball And Diaphragm Valves?

In deciding whether to use ball valves or diaphragm valves, you should consider the following:

- Application Requirements: In comparison to ball valves, diaphragm valves are suitable for applications requiring high levels of hygiene and precise flow control, while ball valves perform well in high-pressure systems and applications needing swift shut-off.

- Material Compatibility: As with any valve, the material making up the diaphragm valve must be compatible with the fluid or substance being handled to ensure that no corrosion or contamination occurs.

- Maintenance Needs: While the diaphragm in a diaphragm valve usually requires more maintenance than other parts, the opposite applies to ball valves most of the time; they are more durable and require less maintenance.

- Operational Environment: In systems where safety or hygienic protocols must be observed, diaphragm valves are best suited. More rugged and reliable systems will utilize ball valves.

- Budget Considerations: For most applications, ball valves’ low cost makes them widely available, whereas specialized applications such as those requiring diaphragm valves, will be significantly more expensive.

Knowing these factors will assist you in picking the right valve in accordance with your system and operational requirements.

Selecting The Right Valve For Corrosive Applications

Selecting the appropriate valve is important while dealing with corrosive materials to maintain the efficiency and life cycle of the system. Corrosive applications are sometimes defined by the presence of chemicals or other materials that will erode or harm certain valve parts over a period of time. Here are some important points to remember while choosing valves for these types of systems:

- Material Selection: It is necessary that the valve’s material is capable of enduring the corrosion characteristics of the fluids or gases it handles. Some of the commonly employed materials for corrosive surroundings are stainless steel, Hastelloy, titanium, and PTFE or PVDF polymers. An example is PTFE-lined diaphragm valves that are often preferred for exceptionally acidic or caustic applications due to their unmatched chemical resistance.

- Coatings and Linings: Protective linings or coatings can offer remarkable improvement in the resistance of a valve to corrosion. Commercially available rubber or fluoropolymer linings offer valves surrounded by aggressive chemicals added protection, thereby improving the service life of the valve. Research indicates that lined diaphragm valves deployed in industrial applications can achieve nearly 50% greater service life than unlined counterparts.

- Valve Type: Some types of valves are particularly suited for corrosive applications. Diaphragm valves rank high amongst the best due to their construction, which prevents the fluid from touching any metallic part of the valve. Also, some ball valves that are appropriately lined or coated can withstand corrosive fluids.

- Operating Conditions: Check the operating temperature and pressure limits for your system. Some corrosive materials might intensify under specific temperature and pressure conditions. Make sure that the valve you choose is designed for these conditions without causing performance or safety issues.

- Maintenance and Inspection: Corrosive areas or environments require regular inspection and maintenance of valves. This is done to avoid any possible leaks or failures. Elevating maintenance procedures can prevent unplanned downtimes, which directly result in reduced operating expenses.

Taking these factors into account and aligning the valve type and material selection with the application’s needs, system safety, performance and life span can be enhanced while reducing the risks associated with managing corrosive fluids.

Hygiene Requirements And Clean-In-Place Considerations

Maintaining hygiene protocols and standards such as EHEDG and ASME BPE is crucial for ensuring product safety and quality in the food and beverage and pharmaceutical industries. These standards require that valves and other equipment be cleanable, have low retention volumes, and resist biofilm formation.

Cleaning-in-place (CIP) systems are vital in the food industry and other industrial processes where pipelines and systems need to be kept hygienically clean without dismantling them. Modern CIP processes use automated circulatory systems that propel cleaning agents, whether detergent, sanitizer, or water, at preset pressures and temperatures. Research suggests that implementing effective CIP protocols can reduce cleaning times by 20-30%, thereby optimizing water and chemical usage as well. For example, valves that feature self-draining areas with automated cleaning cycles using pressurized water will improve hygiene, boost efficiency, and reduce the need for manual maintenance.

In terms of choosing valves for hygiene-critical operations, additional care has to be taken with materials such as stainless steel (grade 316L or higher) due to its corrosion resistance and ease of cleaning. To aid in microbial contamination, highly polished internal surfaces having Ra (Roughness Average) of 0.4 micrometers or less are often required. These factors help achieve compliance standards as well as safeguard the product’s integrity and reduce costs in operations.

Throttling Capabilities And Precise Control Needs

For controlling throttling along with accuracy, it is important to maintain optimal conditions during process operations in industries like chemical manufacturing, food production, and pharmaceuticals. It’s much easier today due to modern advancements in control technologies, such as smart valves and actuators, which allow for real-time modification of the flow rate, pressure, and temperature. PID (Proportional-Integral-Derivative) Controllers are a good example, augmenting the system response accuracy, routinely achieving control accuracy within ±1% tuning.

Data from industry case studies estimate that automated throttle control systems can optimize energy expenditures by 20% and significantly reduce internal stress in pipeline systems. They are aided by real-time analytics performed by advanced flow meters and sensors, enabling operators to mitigate inefficiencies beforehand and allowing these systems to perform proactively. These capabilities enforce compliance with industrial benchmarks and standards while boosting efficiency and reducing critical process downtime.

What Materials Are Used In Sanitary Valves And Why Does It Matter?

Typically, sanitary valves are constructed from stainless steel grade 304 and 316. These components are selected because of their great resistance to corrosion, mechanical wear, and cleanliness in sanitary sensitive areas like the food, beverage, and pharmaceutical industries. In addition, stainless steel also maintains its high temperature reliability and can withstand high-frequency cleaning cycles necessary to avert contamination. Selection of the right material is very important because it protects product integrity, ensures observance of stringent sanitary requirements, and ensures valve durability in harsh environments.

Stainless Steel Options For Sanitary Valve Bodies

As for steel grades with exceptional corrosion resistance and mechanical strength, 304 and 316 are the most frequently used for sanitary valve bodies.

- 304 Stainless Steel: Widely used in sanitary applications 304 grade is resistant to oxidation and corrosion in varying environments. It has 18% chromium and 8% nickel, which achieves a balanced ratio of strength, cost, and hygiene. While this alloy is useful for many applications, a considerable drawback is its low resistance to chlorides, making it unsuitable for regions with high salt or chloride levels.

- 316 Stainless Steel: This steel grade is well known for its superior corrosion resistance to 304 due to 2-3% molybdenum added alongside chromium and nickel. Molybdenum improves the grade’s ability to endure harsh chemicals, saline environments, or elevated temperatures, which makes it ideal for pharmaceutical or marine settings. It also outlasts 304 stainless in acidic and chloride-laden environments, preventing core degradation over time.

- Duplex Stainless Steel: In cases where the application is extremely demanding, duplex stainless steel may be an option. With the strength of ferritic stainless steel and the corrosion resistance of austenitic grades, duplex steel is capable of withstanding high pressures and temperatures, providing safety and reliability for critical operations.

Different materials have unique characteristics that are appropriate for specific operations with sanitary valves. For instance, in pharmaceutical applications that require sterilization, 316 stainless steel is often suggested because it can withstand strong cleaning chemicals. Moreover, research suggests that purchasing 316 or duplex stainless steel is more beneficial, as it increases the longevity of the valves and decreases maintenance needs, thus minimizing operational costs in the long run.

Selecting an appropriate grade of stainless steel maintains compliance with sanitary norms and improves operational efficiency in sectors where hygiene and dependability are crucial.

Diaphragm Materials And Their Impact On Performance

The selection of diaphragm material is crucial in defining the limits of the capabilities, life span, and the chemicals that can be used with the valve and the pump. Some of the commonly used diaphragm materials are EPDM, PTFE, FKM, and NB, R, which possess specific characteristics helpful in different scenarios.

EPDM (Ethylene Propylene Diene Monomer) is very flexible and can withstand heat, ozone, and light. Thus, it is helpful in industries dealing with water and steam. However, it is not suitable for applications with oils and hydrocarbons. PTFE (Polytetrafluoroethylene, which is normally called Teflon) has superb resistance to the chemical composition of harsh acids, bases, and solvents, but is often inflexible and deforms at high pressure.

FKM (Fluoroelastomer), on the other hand, has the best performance in high temperature regions and is strongly resistant to a wide range of oils, fuels, and any chemical, but is incompatible with amines and ketones. NBR (Nitrile Rubber), on the other hand, is relatively cheaper and is widely applied for petroleum oil and fuel. NBR is also good in resisting abrasion, tear, and cut, but suffers from bad temperatures.

According to performance data, PTFE diaphragms generally survive longer in aggressive chemical environments, while FKM diaphragms perform better with high-temperature processes. Research indicates that choosing the right diaphragm material can minimize downtime significantly and increase the reliability of the equipment, with industries reporting operational efficiency improvements of up to 25% when proper materials are used. This information underscores the need for material compatibility evaluations during the design and selection phase of equipment to achieve the best performance with reduced maintenance costs.

How Do Maintenance Requirements Compare Between These Valve Types?

Maintenance Requirements Comparison

Different valve types have different maintenance expectancies based on their design and operational purposes:

- Diaphragm Valves:

-

-

- Have a low maintenance requirement and have a simple design with fewer moving parts, which means fewer components that could malfunction.

-

The diaphragm, a major component, can require replacement on occasion based on exposure to wear and chemicals.

-

- Other Valve Types (e.g., Ball, Gate, or Globe Valves):

-

-

- Usually need to be maintained more often because of their intricate design and numerous sealing surfaces.

-

Parts such as seals, seats, and stems may fail sooner in high-pressure and abrasive environments.

-

In general, maintenance and downtime are critical for the operation of a facility, which is why, in those scenarios, diaphragm valves are favored over other types which are more complex and require frequent maintenance within harsh environments.

Easy-to-Clean Features In Modern Sanitary Valves

Sanitary valves used in the food industry, as well as the pharmaceuticals and biotechnology fields, are designed keeping the highest quality and hygiene standards in mind. The polished finishes from the inside of the valve include an interior that is entirely seamless, which greatly aids in residue elimination. Ra levels of 0.5 microns on polished surfaces make sure that no contaminants are able to attach to the container walls.

A majority of valves incorporate tri-clamp fittings that get rid of the need to disassemble the valve in order to clean and sterilize it, since the cleaning-in-place and sterilize-in-place systems are already included. These systems also do the job of removing any bacteria, biofilm, or debris that is within the container or valve under high-pressure steam, which minimizes the amount of time it takes to clean the valves and ensures hygiene practices are met. Various studies indicated that the CIP method had the potential to increase operational efficiency up to 40% due to the time savings associated with putting in place processes.

Hygiene and sanitary valves now come with self-draining features, which solves the problem of water stagnation in the valve. Some models use FDA-compliant plus gaskets that are designed to endure aggressive cleaning chemicals without losing strength. Not only do these advanced features enable easier cleaning, but they also ensure that modern valves meet the standards for product hygiene and safety.

Longevity And Replacement Considerations

Valves used in sanitary work have a particular lifespan based on specific elements like composition, usage frequency, and operating conditions. Stainless resistive valves that contain 316L grade are an exception since they tend to be extremely durable and can last for years with continuous operation in high temperatures and pressures. Qualifying of these valves requires meeting conditions of at least 5-10 years of use without a replacement. Industry standards mark these benchmarks.

Sanitary valves certainly require proper valve maintenance. Focusing on wear checks is crucial for seals and gaskets. Lack of proper inspection and mismanagement can lead to expensive issues while fulfilling everyday tasks, proving essential to all manufacturers. Difficulty sometimes involves recurring gaskets that help the whole system run efficiently and give the desired movement. Moreover, annual gasket replacement helps retain the valve system’s entire life.

Furthermore, new technologies in valve machinery provide options like maintenance foresight tools. These tools have the ability to track real-time metrics, including pressure and temperature, with the use of sensors. Sensors in these systems allow operators to collect data and detect issues well in advance, enabling them to schedule replacement activities well ahead of time and preventing unplanned downtimes. Such technologies may exhibit higher costs during initial investments, but the savings that can be accrued over time, especially in safety and efficiency-driven fields, are immense.

Evaluation of these factors guarantees that sanitary valves will operate uniformly while adhering to regulatory requirements for health and safety.

Where Can You Find Quality Sanitary Ball And Diaphragm Valves?

Reputable manufacturers and suppliers of industrial and sanitary equipment can provide you with quality sanitary ball and diaphragm valves. Check their experience in the industry along with certifications to make sure that the business meets the required health and safety regulations. Such trusted suppliers, for example, will stock an assortment of valve materials and sizes to particular application requirements, offer warranties, and provide customer support. These valves can be found on some online sites, like industrial supply stores or official manufacturer sites.

Evaluating Valve Manufacturers For Sanitary Applications

When choosing valve manufacturers for sanitary applications, several important aspects should be evaluated in relation to the valve quality and reliability. Important factors include material certifications, mark compliance, and design innovativeness. Many top manufacturers use high-grade materials such as stainless steel or special alloys, which are corrosion resistant and approved by FDA, 3-A, or EHEDG tests, making them suitable for hygienic environments like food and pharmaceutical manufacturing.

Also, manufacturers with advanced product offerings usually have valves with smooth, crevice-free void interiors aimed at minimizing contamination for easier cleaning. For instance, bi-directional sealing features and Ra < 0.8 surface roughness are common benchmarks of high-performance sanitary valves.

Reports from the market suggest that automated sanitary valves are increasingly more popular, with the overall global valve market projected to grow at nearly 6% CAGR from 2023 to 2030. Other features include remote operation, which improves valve responsiveness, and maintenance workflows, along with precision-grade controls, all of which increase productivity and reduce maintenance windows. For a productive purchase process, choose the right manufacturers who offer customizable solutions that cover all functional requirements while providing quality customer service, part accessibility, and strong warranty and support policies.

Cost Considerations When Purchasing Sanitary Valves

When buying sanitary valves, analyzing costs goes beyond simply looking at the purchase price. One of the most important factors to assess is the total cost of ownership (TCO), which encompasses maintenance, energy usage, and even potential operational downtimes. For instance, while stainless steel valves may initially seem like a bigger investment, their long-term cost benefits outweigh this due to being more durable, corrosion resistant, and having lower maintenance needs. Recent data shows that premium-grade materials can extend the lifespan of valves by 20-30% when compared to standard valve materials, making them much more cost-effective over time.

Also, the presence of automation, as well as self-cleaning and IoT smart technology, self-cleaning and smart IoT integration raises the price. These options alone might increase the initial investment by 15 to 20 percent, but the amount of cleaning and operational delays is greatly reduced, which raises productivity. The adoption of these innovations in industries that must maintain high sanitation standards yields excellent ROI.

Finally, procurement managers need to take value-added services as well as discounts offered from bulk ordering or contracts with long-term suppliers. Those help in managing costs while maintaining their goals of quality. With these considerations, businesses can ensure their spending aligns with operational efficiency.

Reference Sources

- Study on Non-Diaphragm Pressure Reducing Valves1:

- Key Findings: This research focused on designing a pressure-reducing valve without a diaphragm to address issues like diaphragm damage and leakage. The modified design used O-rings and backup rings for sealing, resulting in a 15% increase in flow rate compared to traditional designs. Computational Fluid Dynamics (CFD) was employed to analyze internal flow and pressure characteristics.

- Methodology: The study involved prototype fabrication, pressure testing, and CFD simulations using Solidworks Flow Simulation 2018. Various spring stiffness levels were tested to optimize performance.

- Improving Hygienic Design of Valves2:

- Key Findings: This chapter from the “Handbook of Hygiene Control in the Food Industry” highlights the importance of valve design in maintaining hygiene in food processing. It discusses the sanitary aspects of different valve types, emphasizing features that prevent contamination and ensure easy cleaning.

- Methodology: The work is a comprehensive review of valve designs, focusing on their application in food processing systems.

- Diaphragm Valve Development – Challenging Traditional Thinking4:

- Key Findings: This article explores advancements in diaphragm valve design, such as new materials, innovative tightening mechanisms, and improved interior designs. These changes reduce maintenance costs, minimize contamination risks, and enhance flow regulation. The next-generation valves also feature a more linear flow curve and reduced pressure drop.

- Methodology: The study utilized advanced Finite Element Method (FEM) analysis and steam tests to evaluate the performance of new diaphragm designs.

Frequently Asked Questions (FAQs)

Q: What is the main difference between a diaphragm valve and a ball valve?

A: The main difference between a diaphragm valve and a ball valve lies in their control mechanism. A diaphragm valve uses a flexible diaphragm that seals against a valve seat to control fluid flow, creating a barrier between the fluid and the valve body. In contrast, a ball valve employs a spherical disc that rotates to open or close the flow path. This fundamental difference affects their applications, maintenance requirements, and performance characteristics in various processing environments.

Q: For which applications are sanitary diaphragm valves ideal?

A: Sanitary diaphragm valves are ideal for applications requiring strict hygiene standards, such as food processing, pharmaceutical manufacturing, and beverage production. They excel in environments where preventing contamination is critical because their design eliminates cavities where bacteria might grow. Diaphragm valves provide excellent drainability and are easier to clean than other valve types. They’re also well-suited for applications that require frequent cleaning-in-place (CIP) procedures and handling viscous fluids or slurries that might cause issues with other valve types.

Q: What advantages do ball valves offer over diaphragm valves?

A: Ball valves offer several advantages over diaphragm valves, including higher pressure and temperature handling capabilities. They provide excellent tight seal properties and are known for durability in high pressure applications. Ball valves typically offer higher flow capacity due to their straight-through design, making them suitable for applications requiring high flow rates with minimal pressure drop. They also tend to have longer service lives in certain environments and can be more cost-effective for larger pipe sizes. Additionally, ball valves are generally better suited for on/off service rather than throttling applications.

Q: How do the diaphragm valve vs ball valve maintenance requirements compare?

A: Maintenance requirements differ significantly between these valve types. Diaphragm valves typically require more frequent maintenance as the flexible diaphragm is a wear item that needs periodic replacing. However, this maintenance is relatively simple and typically involves just replacing the diaphragm. Ball valves generally require less frequent maintenance but when service is needed, it’s often more complex and may involve dealing with seats, seals, and the ball itself. In corrosive environments, both valve types may require different maintenance approaches depending on the materials of construction and the specific corrosion challenges they face.

Q: How do sanitary diaphragm valves and sanitary ball valves differ in terms of flow control?

A: In terms of flow control, sanitary diaphragm valves provide more precise flow regulation capabilities, making them excellent for throttling applications. They can achieve fine adjustments in flow rates through gradual compression of the diaphragm against the valve seat. Ball valves, with their quarter-turn operation, are better suited for quick on/off functions rather than precise flow control. While specialized control ball valves exist, standard ball valves typically offer less precise regulation. The fluid dynamics within each valve type also differ, with diaphragm valves often creating more flow resistance but potentially better handling of slurries or fluids with particulates.

Q: How do ball valve vs diaphragm valve cleaning procedures compare in sanitary applications?

A: Cleaning procedures differ significantly between these valve types in sanitary applications. Diaphragm valves are generally easier to clean because they have fewer internal cavities and crevices where product can accumulate. Their design typically allows for effective clean-in-place (CIP) processes without disassembly. Ball valves, while offering good flow characteristics, have more internal spaces around the ball and seats that can trap material. This may require more vigorous cleaning protocols or even disassembly for thorough cleaning in highly sanitary applications. For this reason, diaphragm valves are often preferred in applications where frequent, thorough cleaning is essential.

Q: What factors should be considered when choosing a valve between a ball valve and vs diaphragm valve?

A: When selecting a valve, several critical factors should be considered: the nature of the fluid (viscosity, corrosiveness, presence of particulates), operating pressure and temperature ranges, required flow characteristics (on/off vs. throttling), frequency of cleaning, maintenance capabilities, and budget constraints. Additionally, evaluate whether the application requires a tight seal, handles abrasive materials, needs precise flow control, or must meet specific sanitary standards. For sanitary applications, also consider how the valve integrates with your cleaning protocols and whether the valve materials are compatible with your cleaning chemicals and processes. Ultimately, the choice depends on weighing these factors against the specific strengths of each valve type.

Q: How do actuation methods compare between diaphragm and ball valves?

A: Actuation methods differ between these valve types based on their mechanical designs. Ball valves typically require a rotary motion, where the actuator must rotate the ball 90 degrees from fully closed to fully open. They can be operated manually with handles or with pneumatic, electric, or hydraulic actuators. Diaphragm valves, however, require linear motion to compress the diaphragm against the valve seat. This is typically achieved using handwheels for manual operation or various automated actuators. The force requirements also differ, with diaphragm valves often requiring more force to operate against pressure, while ball valves generally have lower torque requirements once the initial breakaway torque is overcome.

Q: How do diaphragm valves compare to ball valves in terms of chemical compatibility?

A: Chemical compatibility varies significantly between these valve types. Diaphragm valves offer excellent chemical resistance because manufacturers can select specific diaphragm materials (EPDM, PTFE, silicone, etc.) to match particular chemical challenges, while the valve body remains isolated from the fluid. This makes replacing the diaphragm a relatively easy way to adapt to different chemical environments. Ball valves typically rely on their body material and seat materials for chemical resistance. While available in various corrosion-resistant materials like stainless steel, PVC, or lined options, they may face challenges with certain aggressive chemicals that can attack their seals or cause corrosion in tight spaces around the ball. Each valve type requires careful material selection based on specific chemical processing requirements.

Q: How do butterfly valves compare to diaphragm and ball valves?

A: Butterfly valves represent a third valve solution that differs from both diaphragm and ball valves. Like ball valves, butterfly valves use a rotary motion, but instead of a spherical closure element, they employ a disc that rotates perpendicular to the flow. Compared to diaphragm valves, butterfly valves generally offer higher flow capacity and lower cost for larger sizes, but with less precise throttling capabilities and potentially more cleaning challenges in sanitary applications. When compared to ball valves, butterfly valves typically provide a more compact design and lower cost, particularly in larger sizes, but may offer less effective sealing at higher pressures. Butterfly valves generally fall between diaphragm and ball valves in terms of pressure capabilities and maintenance requirements.