Stainless steel comes in many different forms, and selecting the proper one for projects can be challenging, particularly when terms like ‘duplex stainless steel’ or ‘stainless steel’ come into play. Both mystify their users for being highly corrosion-resistant and durable; however, their distinct differences reveal themselves on varying scopes of application. In this article, we use a comparison chart to outline the primary differences between duplex and standard stainless steel, their characteristics, applications, and advantages. This guide is for everyone, from specialists guiding industries to those simply interested in materials science, as it empowers users with the knowledge to choose and fulfill their exact requirements. Let us now explore the differences between duplex stainless steel and standard stainless steel, along with the bearing they have on the functionality of each.

What is the fundamental difference between duplex stainless steel and regular stainless steel?

As with any other type of stainless steel, duplex stainless steel’s defining traits differ from those of regular stainless steel due to duplex’s composition and structural features. To explain further, ductile duplex stainless steel possesses a mixed structure, boasting both austenitic and ferritic phases, which gives it enhanced strength and resistance to corrosion compared to regular stainless steel. Relatively, fully austenitic stainless steel has likeable traits, especially good corrosion resistance, but duplex stainless steel’s greater strength and stress resistance make it superior. That said, the combination of these properties allows duplex stainless steel to be utilized in extreme environments such as those exposed to high pressure and harsh chemicals.

Microstructure: Ferritic and Austenitic phases in duplex stainless steel

The dual-phase structure of duplex stainless steel consists of two parts: ferrite and austenite. Each microstructure’s composition ranges from 50/50 to 60/40. This ratio gives a synergistic blend of the properties provided by both phases. The ferritic stainless steel gives excellent resistance to chloride sress corrosion cracking, and high strength, while the austenitic phase offers good toughness and ductility along with corrosion.

The ferritic phase, which is rich in chromium, imparts an alloy configuration since it improves resistance to pitting and crevice corrosion. The addition of nickel and nitrogen in the austenitic phase tends to reduce the overall ductility and impact strength of the material, propitiating the interphase interplay, thus ensuring good weldability and reducing the chances of hot cracks during fabrication.

Commonly found fractions of duplex stainless steel are 22-25% chromium, 4-7% nickel, 1-4% molybdenum, with lesser quantities of nitrogen. All these allow for its superior mechanical and corrosion-resisting properties. Tubulars’ bonds in duplex stainless steel tend to range at least two folds their austenitic distinct like Type 304 or 316, while increasing yield strength. This makes it particularly useful structurally in seawater and chemical process plants, while the oil and gas industries are relying on it.

Chemical composition differences between duplex and conventional stainless steel

The different properties of duplex steel and conventional austenitic stainless steels are derived from their unique chemical compositions. Duplex stainless steel will always have some amount of austenite and ferrite in its micro-structure. This can be achieved by controlling the amount of chromium (19-28%), nickel (4.5-8%), molybdenum (up to 5%), and nitrogen (up to 0.3%) present. Adding molybdenum and nitrogen greatly improves pitting and crevice corrosion resistance, especially in chloride rich areas.

However, conventional stainless steels such as Type 304 and Type 316 have higher amounts of nickel (8-11% in Type 304 and 10-14% in Type 316) and lower amounts of chromium (18-20% in Type 304 and 16-18% in Type 316). Type 316 contains molybdenum (2-3%) for greater corrosion resistance, but unlike duplex grades, it lacks structural and mechanical strength because of no ferrite.

In addition, the lower nickel composition of duplex stainless steel makes it economical, particularly when there is volatility in the prices of nickel. On the other hand, the higher molybdenum and nitrogen content of duplex grades makes it more applicable to severe conditions where additional strength and corrosion resistance are critical. This difference in composition allows duplex stainless steel to achieve a combination of efficiency and performance that most stainless steels cannot attain for challenging applications.

How duplex steel combines properties of different stainless steel types

The properties of austenitic and ferritic stainless steels come together to form duplex stainless steel, which gives it additional qualities. Its dual-phase microstructure consists of “equal” halves of each type, giving it better mechanical and physical properties. Duplex stainless steels are stronger than traditional stainless steels by almost 2x, which increases their durability while allowing for lighter and more economical designs.

Stress-corrosion cracking, pitting, and crevice corrosion are forms of corrosion that duplex stainless steels are able to resist significantly due to their high chromium content (typically 18%-28%) as well as moderate amounts of nickel. For example, offshore oil and gas platforms make use of duplex grades like 2205 (UNS S32205) because of their high resistance to chloride corrosion.

Economic applications towards the changing nickel market are enabled by the lower nickel content duplex stainless steels hold in comparison to austenitic ones. These steels also perform exceptionally well in high-pressure environments owing to their high tensile and yield strength. Desalination plants and bridges are some of the structures that rely on advancements in metallurgy for resistant frameworks. Modern duplex grades, or lean duplex and super duplex, are engineered specifically for these challenging applications, along with chemical processing equipment.

How does corrosion resistance compare between duplex stainless steel and conventional stainless steel?

When comparing duplex stainless steel with conventional stainless steel, duplex offers greater corrosion resistance. Its dual-phase structure specifically gives it better resistance to stress corrosion cracking and pitting in highly chloride rich environments. This makes it more practical for applications in harsh marine and chemical industry environments where greater durability is needed.

Superior pit corrosion resistance in duplex grades

Duplex stainless steel is known for facing pitting corrosion, especially in high salinity and chloride environments. Pi,t damages, and chlorides and salinity can be dangerous to Duplex stainless steels. This increase in protection is due to the presence of both austenitic and ferritic microstructures. For instance, both duplex and super-duplex grades 2205 and 2507, respectively, possess high pitting resistance equivalent numbers (PREN), which is a measure of corrosion resistance.

Duplex stainless steel is known to have a PREN value ranging from 35 to 40, while super duplex grades are known to surpass 40. The high resistance to localized corrosion is due the the above values. There are also other factors at play, like the high content of chromium, molybdenum, and nitrogen. All of them combined increase its resistance to aggressive corrosive agents. Due to the factors mentioned above, corrosion-resistant alloy has become quite popular with offshore platforms as well as with desalination plants and in chemical processing industries.

Compared to 316L which is an austenitic steel, duplex grades of have lower exposure and maintenance cost which is more economiacally and sustainablly useful to tough industrial tasks. Longer durability means that structures do not move or break with force over long periods. As a result, components stay maintenance free and easy to use withstand exposure to prolonged stress.

The role of chromium and molybdenum in corrosion protection

The corrosion resistance of stainless steels, especially in extreme chemically aggressive conditions, is greatly enhanced by chromium and molybdenum. Steel is protected because chromium, as an alloying element, combines with oxygen, yielding a self-repairing chrome oxide layer that is thin, stable, and also heals itself. It decays to further destroy oxygen entry, yielding oxidation and corrosion. Stainless steels need, at the least, 10.5% chromium to ensure the sustainability of the passive layer along with proper functioning.

Molybdenum is significantly useful too. It increases, to a larger extent, the resistance against pitting and crevice corrosion, yielding localized corrosion. These characteristics are crucial in forage containing chlorides like salt water, of industrial processes containing a lot of salts. 316L grades include roughly 2-3% molybdenum, which enhances resistance to pitting, yielding lower alloyed grades. Duplex stainless steels offer greater resistance and mechanical properties because they combine more chromium, around 22 to 25%, and 3-4% molybdenum. They are suitable for use in things like chemical plants and offshore platforms.

Chromium and molybdenum, when combined, enhance the resistance of the material to harsh conditions improving the longevity of the equipment and infrastructure while lessening the expenses incurred in maintenance. Over the years, with progressing metallurgical techniques, modern alloys have tailored solutions for different industries by optimizing these elements to maximize the required durability and reliability.

Galvanic corrosion between stainless steel types

Galvanic corrosion happens when at least two distinct types of metal contact each other electrically in the presence of an electrolyte, like water or moisture. When stainless steel types of different compositions are coupled, the chance of galvanic corrosion increases when towards chlorides or other aggressive environments. This is due to the fact that the difference in their electrochemical potentials is sufficiently great to form a galvanic cell, which causes the potential corrosion of the more noble metal to be accelerated.

For example, while coupling 304 And 316 stainless steels, it is observed that the later is less prone to corrosion due to higher molybdenum content while 304 acts as the anodic material corroding at a faster rate. Research indicates that 304 stainless steel subjected to such galvanic conditions undergoes much higher material loss than would be the case if similar metals were used under the same conditions.

To protect against galvanic corrosion, industries tend to employ protective coatings, barriers of electrical insulation, or pick combinations of metals with closer electrochemical potentials. Evidence shows that the use of insulating materials placed between the joints of stainless steel can decrease the rate of corrosion by as much as 60 percent. Furthermore, regular maintenance and use of corrosion inhibitors can better protect equipment and infrastructure from galvanic corrosion in aggressive operating environments.

What are the different grades of duplex stainless steel compared to standard stainless steel?

As with other alloys, duplex stainless steels are grouped into different families with specific grades based on their composition and performance characteristics. The most distinguishable features relative to other types of stainless steel are their increased strength and enhanced resistance to corrosion, particularly in chloride-containing environments. Some common grades of duplex stainless steel are:

- Lean Duplex (e.g., UNS S32101, S32304): Contains lower alloy content, thus more economical and appropriate for less aggressive environments, less expensive, and appropriate for less aggressive environments.

- Standard Duplex (e.g., UNS S31803, S32205): More balanced composition offering high strength and excellent corrosion resistance, versatile across many applications.

- Super Duplex (e.g., UNS S32750, S32760): with increased alloy content for more advanced applications in harsh environments like offshore and chemical processing, as their corrosion and mechanical resistance are exceptional.

- Hyper Duplex (e.g., UNS S32707, S33207): provided with ultrahigh strength and corrosion resistance to serve in more extreme conditions.

These grades surpass the strength and resistance to stress corrosion cracking for standard austenitic stainless steels like 304 and 316, making them particularly suitable for very critical applications.

Standard duplex grades vs 304 stainless steel and other austenitic grades

In comparison with 304 and other austenitic grades, duplex stainless steels like UNS S32205 Stand out because of their incredibly high strength, toughness, corrosion resistance, and cost effectiveness. Duplex steels exhibit close to 2 times the yield strength of 304. For instance, curl and duplex steels with their average yield strength tend to be around 450 MPa, while 304 is around 200 MPa. This implies, indeed, stronger sectional structures could be formed while saving on materials and weight.

Corrosion resistance is another critical area. Standard duplex grades restore and enhance qualities needed to withstand both external and internal pressure. Their effectiveness towards stress corrosion cracking SCC strengthens significantly in chloride-rich regions such as seawater and chemical plants. Moreover, standard duplex grades PREN, which correlatively speaks about corrosion resistance, fetches over 30, while 304 stainless steel can offer around 19. Thus, duplex can outperform in harsh conditions.

Looking at it from a cost perspective, the alloying elements economically duplex stainless steels seem more expensive because they contain more chromium, molybdenum, and nitrogen. However, the increased operational life of the duplex steels often makes them more economical over the lifecycle of a project because of their durability. This unique combination of strength, durability, and resistance to corrosion makes duplex grades highly suitable for oil and gas industries, desalination, and chemical processing, where austenitic grades are low performing.

Super duplex stainless steel grades and their unique properties

Recognition of Super Duplex Stainless Steel grades stems from having the best balance of mechanical strength and corrosion resistance which makes them appropriate for many tough industries. Its alloys are known to have Chromium and Molybdenum in high amounts and Nitrogen which are 24-26%, 3-5%. These elements also enhance the alloys resistance to pitting and crevice corrosion, particularly in chloride-rich environments.

As aforementioned, SDSS has many useful properties. One of its most outstanding would be the yield strength which greatly surpasses that of austenitic stainless steels such as 316 or 304. For example, SDSS UNS S32750 and S32760 have a yield strength of 550 Mpa and have great tensile strength. Such strength allows designers and engineers to utilize thinner sections of materials and not lose structural integrity. This proves SDSS to be cheaper in large scale projects.

Further, super duplex grades are applicable in offshore settings, subsea tools, pressure vessels, and heat exchangers since they possess weldability, toughness, and low temperature resilience. Moreover, empirical tests and field data demonstrate their ability to withstand stress corrosion cracking as well as seawater corrosion, which prolongs the operational life of components under harsh conditions. For instance, their application in desalination systems underlines their capability to withstand extreme conditions within saline water without erosion.

In situations where strength, resistance to corrosion, and economic cost efficiency are important, super duplex stainless steels become essential in forming materials needed because reliability and durability are critical.

Lean duplex: the economical alternative to conventional austenitic stainless steel alloys

Lean duplex stainless steels are the go-to alloys for accidentally or purposefully misclassifying steels in economic sectors where stainless steels are not typically needed or utilized. These Duplex Alloys are an economical option for industries that seek performance without breaking the bank. They have been developed with a leaner Duplex and Austenitic stoichiometry, which means they have less Nickel, Molybdenum, and added cheaper materials, allowing them to have a corrosion resistance sufficient for a plethora of applications.

These alloys accomplish their goals by adding greater strength that roughly doubles that of austenitic stainless steels. This gives the alloy the benefit of being thinner and lighter while retaining structural integrity. This provides great material savings for large-scale construction and equipment manufacturing. An example of this would be the lean duplex grades like UNS S32101 (LDX 2101), which has an envied yield strength of 450MPa, making it actively used as structural reinforcements and storage tanks.

At the same time, Lean duplex stainless steels have great resistance to localized corrosion, pitting, and crevice corrosion, specifically for moderate Element of Chlorine content. Coupled with their great mechanical properties and weldability makes these alloys a favorite among the chemical processing, water treatment, architectural, and construction industries.

In conclusion Lean duplex stainless steels are an sustainable and economic solution that help provide reliability to aid in an ever, economical demanding application.

How do mechanical properties differ between duplex and austenitic stainless steel?

Duplex stainless steel typically possesses greater strength than austenitic stainless steel, approximately double in yield strength. Consequently, duplex stainless steel can be used for more durable applications that resist deformation under stress. Moreover, duplex stainless steel is superior to austenitic stainless steel in regards to stress corrosion cracking resistance as well, particularly in chloride-rich environments. Nonetheless, austenitic stainless steel is more ductile while being easier to formed, cut, or welded, thus making it more suitable for complex-shaping applications.

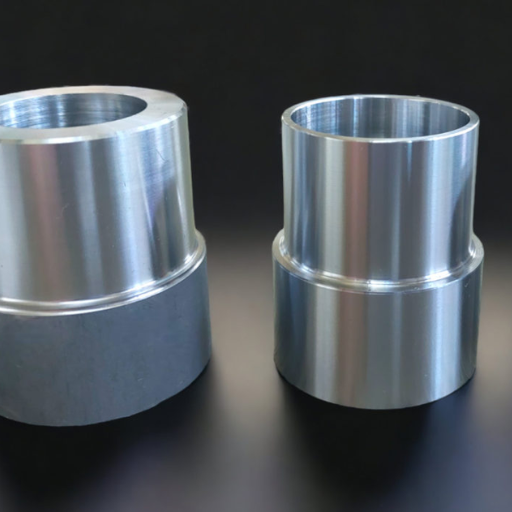

Strength advantages of duplex stainless steel material

The mixed microstructure of austenite and ferrite found in duplex stainless steel gives it greater strength relative to austenitic stainless steel. The increased strength allows the use of thinner materials in structural applications, which reduces weight, cost, and performance.

Impact of nickel content on properties of different stainless steel types

Nickel is essential in determining the characteristics of many types of stainless steel. It is added mainly for improved corrosion resistance and to increase the ductility. For example, nickel is added to austenitic stainless steels in the range of 8% to 12%, which enables their remarkable toughness and resistance to extreme temperatures.

In marine and chemical processing industries, nickel containing stainless steel is useful due to its increased resistance against stress corrosion cracking and pitting in chloride rich environments. On the other hand, ferritic stainless steels have low nickel content, usually less than 2%. This lowers the cost of these steels but offers inflexible corrosion resistance when compared to austenitic grades.

Research suggests that an increase in nickel content improves the metallic stability of the stainless steel. For example, duplex stainless steels are composed of ferritic and austenitic phases and therefore possess moderate amounts of nickel which range from 4% to 7%. Their strength, toughness and corrosion resistance make them ideal for the oil and gas industries that demand durable materials due to the harsh working conditions.

When should you choose duplex or super duplex over standard stainless steel?

Opt for duplex and super duplex stainless steels over standard stainless steel when additional strength, superior corrosion resistance, or better performance in highly aggressive conditions is necessary. These grades of steel are suitable for harsh working environments such as oil and gas extraction, chemical processing, or marine industries because of their resistance to high chloride and extreme pressure. Their enhanced properties enable the use of thinner materials, and the strength provided allows for reduced overall material usage, thus increasing cost-effectiveness.

Applications where duplex and super duplex stainless steel excel

- Oil and Gas Industry

-

-

- Employed in the case of subsea pipelines, manifolds, and risers due to their corrosion resistance, seawater, and high pressure.

- Best suited for steam generators and separators with special consideration for chloride stress cracking.

-

- Chemical Processing

-

-

- Utilized in chambers and reactors for chemicals due to their strength against structural stress corrosion cracking.

- Perfect for water desalination plants and seawater systems such as pumps and valves.

-

- Marine Industry

-

-

-

Employed in shipbuilding together with offshore platforms as structural elements, which are exposed to highly saline water.

-

These materials are widely employed for structural components exposed to a saline environment in shipbuilding and offshore platforms.

-

-

- Pulp and Paper Industry

-

-

- Useful in equipment that comes into contact with acidic and alkaline solutions during paper processing.

- Applicable in storage and digesters, which require efficient mechanical strength alongside strong resistance to corrosion.

-

- Desalination Plants

-

-

- Helpful in evaporators, heat exchangers, and pumps due to handling saltwater at high temperatures and pressures.

-

- Power Generation

-

-

- Used in flue gas desulfurization systems in thermal power plants due to great sustaining support for corrosive processes.

- Helpful in heat recovery systems where construction reliability and the integrity of components are vital.

-

- Architectural and Structural Components

-

-

- Recommended for highly precise and strategically high-load bearing areas due to their reliability and reduced maintenance needs.

-

- Food and Beverage Industry

-

-

-

Exposed in processes of high cleanliness such as in washing process regarding corrosion and sterilizing with ease enduring the highest standards.

-

-

This shows how well duplex and super duplex stainless steels perform under remarkably competitive conditions, which illustrates their versatility and reliability.

Cost considerations: duplex stainless steel vs conventional austenitic stainless steel

When considering the construction of duplex stainless steel versus austenitic stainless steel, it is important to note that both options come with their advantages and disadvantages. Undoubtedly, the material cost of duplex stainless steel is going to be more expensive; however, with its unparalleled corrosion resistant characteristics, duplex stainless steel can save a lot of money during application over the years.

Since duplex stainless steel is much stronger, certain designs can use thinner materials without compromising on strength. For instance, structures that have a high load-bearing or pressure resistant performance can reduce material thickness which decreases the overall weight and expenses. Some studies suggest that compared to austenitic stainless steel, duplex stainless steel has the ability to lower material usage by almost 30%.

Moreover, performing maintenance and upkeep in places like chemical processing or the marine industry is costly. With units such as these, duplex grades are a better option since they have greater corrosion resistance, which reduces monthly upkeep. Other types, such as austenitic stainless steel 304 or 316, do not have as high corrosion resistance, which means they will need to be replaced much more often than desired, thereby increasing overall spending in the long run.

The cost of buying alloying elements impacts pricing quite a bit as well. For example, compared to the expensive austenitic grades, duplex stainless steels contain lower amounts of nickel and molybdenum. Its pricing is more stable in markets where the cost of these elements fluctuates. This is beneficial when budgeting for large-scale projects.

When evaluating initial expenses alongside savings during the lifecycle, duplex stainless steels tend to be overwhelmingly beneficial for industries working under harsh conditions.

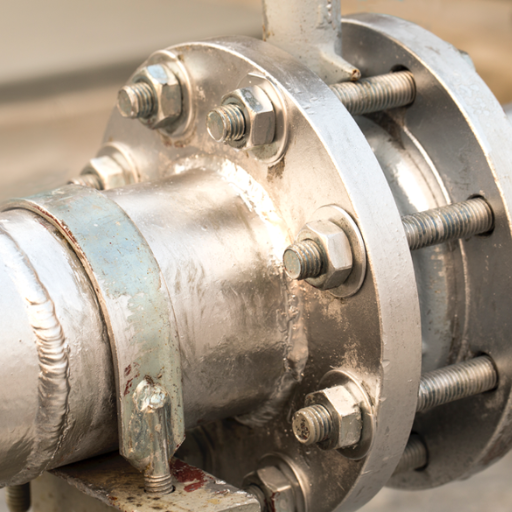

Welding duplex and super duplex compared to standard stainless steel

Advantages and challenges emerge when welding duplex and super duplex stainless steels compared to austenitic stainless steels. Duplex steels comprise a two-phase microstructure consisting of austenite and ferrite, which must be balanced very carefully during welding in order not to lose their mechanical properties and resistance to corrosion.

When welding duplex and super duplex, heat input control is crucial as they contain more than one phase. Excessive heat input could lead to brittle intermetallic phase formation, such as decreased corrosion resistance, toughness, and sigma phase. In order to avoid the formation of such phases, a certain rate of cooling is also required. Preheating is not required in most cases, though post-weld heat treatment is sometimes needed to achieve desired material properties, depending on the application and thickness of the parts being welded.

Compared to other stainless steels, standard weldable stainless steels have more straightforward weldability due to their austenitic microstructure. Weldable austenitic stainless steels are more ductile, easily welded, and experience less cracking. But as compared to duplex and super duplex grades, they tend to lack optimal strength, stress corrosion cracking resistance, and toughness.

As noted in recent technological reports, duplex stainless steel grades typically have a tensile strength around 620 MPa (90 ksi), while super duplex grades may surpass 800 MPa (116 ksi). Standard austenitic stainless steel types like 304/L and 316/L are noted to have lower tensile strengths, approximately 485 MPa (70 ksi). Furthermore, the greater resistance to pitting attack of duplex and super duplex materials, as demonstrated by their Pitting Resistance Equivalent Number (PREN) values, is an added advantage in chloride-rich environments.

For welding duplex and super duplex steels, specialized filler metals of matching or higher alloy content are often used to maintain the correct balance of ferrite and austenite. Equal attention to workmanship, such as ensuring proper joint surface preparation and cleanliness, must also be given for achieving high quality welds.

The challenges not withstanding, the advantages of welding duplex and super duplex stainless steels is making them more and more popular for high performance offshore oil and gas, marine, and chemical processing industries. Ensuring proper instruction and following best practices is crucial to maintain the performance and durability of welded components made from these materials.

What makes super duplex stainless steel different from standard duplex steel?

The super duplex stainless steel differs from standard duplex steel mainly in its mechanical properties and corrosion resistance. This grade contains higher amounts of chromium, molybdenum, and nitrogen, which aid in providing strength along with the ability to withstand highly corrosive environments. Hence, super duplex stainless steel is more suitable for demanding applications that include extreme pressure as well as exposure to aggressive chemicals. Apart from that, it also offers better resistance against pitting and crevice corrosion when compared to standard duplex steel.

Chemical composition differences in super duplex steel

Depending on the content of austenite and ferrite, super duplex stainless steel derives its name from a balanced microstructure. Usually, chromium content increases from 24% to 26%, augmenting the ability to withstand corrosion, more so in exceptionally tough conditions. Pitting and crevice corrosion resistance is greatly enhanced due to molybdenum content, which typically ranges between 3% and 5%. Additionally, super duplex steels generally contain higher amounts of nitrogen, sometimes more than 0.2%, which makes the material stronger by stabilizing the austenitic phase and preventing brittleness.

These excellent properties can also be attributed to nickel (4%-7%), manganese, copper, and tungsten along with carbon in small quantities which increases the mechanical traits and lifespan of the steel. Synergistically, the elements improve the tensile strength of the steel, surpassing the level of 700 MPa, and makes the super duplex stainless steel more efficient for oil and gas, marine application, and chemical processing. Such demanding conditions make the precise and optimized chemical composition of super duplex stand out from duplex variants.

Enhanced corrosion resistance of super duplex grade

Super duplex stainless steel provides excellent corrosion resistance in extreme environments. Its high content of chromium (24 to 26%), molybdenum (3 to 4%), and nitrogen gives the steel superior effectiveness against pitting and crevice corrosion. These components cooperatively increase the efficiency of the passive layer that shields the steel from hostile chemicals, considerably enhancing its overall durability.

Compared to standard stainless steels, super duplex grades have higher resistance in chloride-rich environments, commonly exhibiting critical pitting temperature (CPT) above 50°C. This feature makes them ideal for funds for seawater handling systems, desalination plants, and offshore platforms. In addition, due to the low levels of localized corrosion, stainless super duplex steels steadily increase in value, surpassing 40 pitting resistance equivalent numbers (PREN) levels. Their exceptional defense against stress corrosion cracking alongside uniform corrosion in acidic and saline environments,s results in the growing popularity of super duplex materials within industries characterized by demanding operational requirements.

22%Cr duplex vs super duplex stainless steel grades

While comparing the grade pipes made of 22% Cr duplex stainless steel to super duplex stainless steel, it’s clear that their differences arise from the composition, mechanical properties, and the amount of corrosion they resist. For instance, 22%Cr duplex stainless steel contains 11% nickel, 3% molybdenum, along with approximately 22% chromium, which gives it good structure. Moreover, it provides moderate resistance to pitting and crevice corrosion in chlorinated environments, which makes it useful in marine structural components, water treatment, chemicals processing industry.

In contrast, super duplex stainless steel grades like 2507 have also higher Chromium content (approximately 25% with higher molybdenum ~4% and nitrogen) which significantly improves their resistance to aggressive corrosive environments. Moreover, super duplex grades possess higher mechanical properties, with elevated tensile and yield strength. This ensures good durability in more challenging offshore oil and gas applications, heat exchangers, and seawater handling systems.

Super duplex stainless steels are also shown to have greater resistance to chloride stress corrosion cracking while exhibiting higher PREN values, often above 40, when compared to 22% Cr duplex steels. This still makes them more suitable for highly corrosive and demanding conditions. Their increased alloying content does make them more costly, so careful consideration is necessary for budget-sensitive projects. Choosing the right grade stems from the needs of the application, such as environmental conditions, alongside financial limitations.

Reference Sources

- The Difference of Corrosion Behavior in the Initial Period for Hot-Rolled and Cold-Rolled 2205 Duplex Stainless Steel1:

- Key Findings: This study investigated the microstructure and corrosion resistance of hot-rolled and cold-rolled 2205 duplex stainless steel. It found that cold-rolled materials exhibited faster precipitation of sigma phases, leading to reduced corrosion resistance compared to hot-rolled materials. Pitting corrosion was more prominent in cold-rolled samples due to strain-induced martensite and defects.

- Methodology: The research utilized X-ray diffraction (XRD), scanning electron microscopy (SEM), and potentiodynamic polarization to analyze microstructural changes and corrosion behavior after aging treatments at 850°C.

- Stainless Steel and Corrosion2:

- Key Findings: This paper provided a comprehensive overview of corrosion mechanisms in stainless steel, including pitting, crevice, and stress corrosion cracking. It emphasized the role of chromium and molybdenum in enhancing corrosion resistance and discussed the importance of maintaining the passive oxide layer.

- Methodology: The study reviewed various forms of corrosion and their impact on stainless steel, supported by theoretical and practical insights into material selection and environmental factors.

- Development of a Lean Duplex Stainless Steel3:

- Key Findings: This research introduced LDX 2101®, a lean duplex stainless steel with corrosion resistance comparable to standard austenitic grades. The material demonstrated stable austenite formation and sluggish intermetallic phase precipitation, making it suitable for structural and industrial applications.

- Methodology: The study analyzed the microstructure, impact toughness, and corrosion resistance of LDX 2101® under different thermal treatments, highlighting its performance in demanding environments.

Frequently Asked Questions (FAQs)

Q: What is the main difference between stainless steel and duplex stainless steel?

A: The primary difference between stainless steel and duplex stainless steel lies in their microstructure. Traditional stainless steel typically has either a ferritic or austenitic microstructure, while duplex stainless steel contains approximately equal proportions of both ferritic and austenitic phases. This dual-phase structure gives duplex stainless steel superior strength (about twice that of regular austenitic stainless steel) and excellent corrosion resistance, particularly against stress corrosion cracking. Duplex stainless steels are highly regarded for applications requiring a combination of strength and corrosion resistance in aggressive environments.

Q: What are the differences between duplex and super duplex stainless steel?

A: The difference between duplex and super duplex stainless steel primarily relates to their chemical composition and corrosion resistance. Super duplex contains higher amounts of chromium, molybdenum, and nitrogen compared to regular duplex grades, resulting in enhanced corrosion resistance in aggressive environments. While standard duplex (like 2205) has a Pitting Resistance Equivalent Number (PREN) of 30-40, super duplex grades (like 2507) have a PREN exceeding 40. Super duplex offers superior resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in high-chloride environments such as seawater applications, making it suitable for more demanding conditions than standard duplex.

Q: What are the main classes of stainless steel, and how does duplex stainless steel fit in?

A: The main classes of stainless steel include austenitic, ferritic, martensitic, precipitation-hardening, and duplex grades. Austenitic stainless steels (300 series) contain high nickel content and are non-magnetic. Ferritic stainless steels (400 series) are magnetic and contain little or no nickel. Martensitic grades offer high hardness but lower corrosion resistance. Duplex stainless steel represents a hybrid category that combines properties of both ferritic and austenitic stainless steel, offering excellent strength and corrosion resistance. The family of stainless steels also includes more specialized variants like super duplex and hyper duplex stainless steels, which offer enhanced performance in extreme environments.

Q: What corrosion resistance do duplex stainless steels offer compared to other grades?

A: Duplex stainless steels offer exceptional corrosion resistance, often superior to standard austenitic grades in many environments. They provide excellent resistance to stress corrosion cracking, pitting, and crevice corrosion, particularly in chloride-containing environments. The corrosion resistance of duplex stainless steel stems from its high chromium content (typically 22-25%) and the addition of molybdenum and nitrogen. For instance, 2205 duplex stainless steel (the most common grade) provides significantly better resistance to chloride attack than 316L austenitic stainless steel. Super duplex grades offer even higher corrosion resistance, with improved performance in aggressive media like seawater, acids, and chloride-containing processes.

Q: What are the common duplex stainless steel ASTM grades and their equivalents?

A: Common duplex stainless steel ASTM grades include UNS S31803/S32205 (2205), UNS S32750 (2507), UNS S32760, and UNS S32550. The 2205 duplex stainless steel equivalent in various standards includes EN 1.4462, ASTM A240 S31803/S32205, and AISI 2205. For super duplex, 2507 (UNS S32750) is equivalent to EN 1.4410. Different duplex steel grades are categorized based on their corrosion resistance and alloying elements. Lean duplex grades like S32101 and S32304 contain lower nickel content, standard duplex like 2205 offers balanced properties, and super duplex grades like 2507 provide enhanced corrosion resistance. Each grade has specific applications based on the required strength, corrosion resistance, and cost considerations.

Q: How do duplex stainless steels compare to austenitic and ferritic grades in terms of properties?

A: Duplex stainless steels combine the best properties of both austenitic and ferritic grades. Compared to austenitic stainless steel, duplex grades offer approximately twice the yield strength, better resistance to stress corrosion cracking, and similar or better general corrosion resistance. Compared to ferritic stainless steel, duplex grades provide superior toughness, weldability, and corrosion resistance. Duplex stainless steels are typically more economical than high-nickel austenitic grades due to lower nickel content while still maintaining excellent corrosion performance. They also exhibit better thermal conductivity than austenitic grades and lower thermal expansion, making them suitable for heat exchangers and other thermal applications where dimensional stability is important.

Q: What are the typical applications where 2205 duplex stainless steel is preferred?

A: 2205 duplex stainless steel is preferred for numerous demanding applications, including chemical processing equipment (tanks, vessels, heat exchangers), oil and gas transportation (pipelines, pressure vessels), pulp and paper digesters, desalination plants, and seawater handling systems. It’s also commonly used in architectural applications requiring high strength and corrosion resistance, such as bridges and structural components in coastal environments. The food and beverage industry utilizes 2205 for processing equipment handling corrosive ingredients. Pollution control systems, especially those dealing with flue gas desulfurization, benefit from 2205’s resistance to sulfuric acid environments. This versatile grade represents the best balance of properties and cost-effectiveness among duplex steel products for moderately aggressive environments.

Q: What are the most common questions about duplex stainless steel material grades and selection?

A: Common questions about duplex stainless steel material grades include: how to select between standard duplex and super duplex based on application requirements; what temperature limitations apply to different duplex grades; how to ensure proper welding procedures for maintaining corrosion resistance; whether duplex stainless steels can be used at cryogenic temperatures; what fabrication challenges might be encountered; how to interpret PREN values when selecting grades; what cost differentials exist between duplex and other stainless steels; and how to verify proper microstructure after fabrication. The selection process typically involves analyzing the corrosivity of the environment, mechanical requirements, fabrication methods, and budgetary constraints to determine the optimal kind of stainless steel for specific applications.

Q: How are hyper duplex stainless steels different compared to regular duplex and super duplex?

A: Hyper duplex stainless steels represent the most highly alloyed and corrosion-resistant tier in the duplex family. Compared to regular duplex and super duplex grades, hyper duplex stainless steels feature significantly higher chromium, molybdenum, and nitrogen content, resulting in a PREN value exceeding 48 (versus 30-40 for standard duplex and 40-48 for super duplex). These advanced alloys offer exceptional resistance to localized corrosion in extremely aggressive environments containing high concentrations of chlorides and acids, particularly at elevated temperatures. Hyper duplex grades maintain the balanced austenitic-ferritic microstructure but provide enhanced performance in the most demanding offshore oil and gas applications, chemical processing facilities, and geothermal wells where even super duplex materials might be inadequate.