Titanium steel—the perfect interplay between strength, endurance, and elegance—has found much favor across industries. From engineering applications to elite jewelry design, this alloy promises superlative characteristics that are unusual in other metals. Discover the science and applications of one of the most innovative alloys of our time.

Introduction to Titanium Steel

Titanium steel is an alloy formed by combining titanium and steel, creating a material that offers exceptional lightweight properties, durability, and high corrosion resistance. Because of its high tensile strength and excellent resistance to degradation, titanium steel is used across industries, including aerospace, medical instruments, and jewelry manufacturing.

Definition of Titanium Steel

Titanium steel is a hybrid material developed by mixing titanium with steel or other elements to enhance mechanical properties. This versatile composite is lightweight, very strong, and highly resistant to corrosion. Its high tensile strength relative to its density gives it advantages in applications where resilience and weight matter most.

Composition of Titanium Steel

Titanium steel, commonly called a titanium alloy, is a mixture of titanium with other metals, often aluminum, vanadium, or iron. Depending on intended strength, weight, and corrosion resistance requirements, this alloy contains 88-99% titanium.

| Element | Typical Percentage | Primary Purpose | Benefits |

|---|---|---|---|

| Titanium | 88-99% | Base material | Lightweight, corrosion resistance, biocompatibility |

| Aluminum | 2-7% | Strength enhancement | Increased strength and temperature resistance |

| Vanadium | 2-5% | Hardenability improvement | Enhanced strength and toughness |

| Molybdenum | 0.5-3% | Corrosion resistance | Improved resistance to harsh environments |

| Chromium | 0.5-2% | Oxidation resistance | Enhanced durability in extreme conditions |

Elements in Titanium Steel

The composition of these elements is carefully balanced depending on the applications of titanium steel:

- Aerospace applications: Prioritize strength-to-weight ratio and temperature resistance

- Medical devices: Focus on biocompatibility and durability

- Industrial use: Emphasize corrosion resistance and wear resistance

Comparison with Other Materials

Comparison with Pure Titanium

While pure titanium has excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium steel adds enhanced durability and hardness. Pure titanium is softer and less wear-resistant compared to titanium steel, making it less suitable for applications requiring extreme strength and long-term durability under mechanical stress.

Difference Between Titanium and Stainless Steel

| Property | Titanium Steel | Stainless Steel |

|---|---|---|

| Weight | 45% lighter | Heavier but strong |

| Corrosion Resistance | Superior (seawater, chemicals) | Good (general corrosion) |

| Cost | Higher initial investment | More economical |

| Applications | Aerospace, medical, marine | Construction, automotive, kitchenware |

| Biocompatibility | Excellent | Limited |

Properties of Titanium Steel

Physical Properties

- Exceptional tensile strength-to-weight ratio

- Lightweight yet durable

- Maintains structural integrity under stress

- Excellent fatigue resistance

Chemical Properties

- High resistance to oxidation

- Excellent corrosion resistance

- Stable in acidic environments

- Forms protective oxide layer

Thermal Properties

- Maintains strength at high temperatures

- Low thermal expansion

- Good heat resistance

- Thermal stability in extreme conditions

Mechanical Properties

- High tensile strength

- Excellent ductility

- Superior toughness

- Resistance to mechanical stress

Environmental Resistance

Industrial Applications

Aerospace Industry

Primary uses include jet engine components, airframe parts, and spacecraft structures. The Boeing 787 Dreamliner contains 15% titanium by weight, highlighting its importance in modern aircraft design.

- Jet engine components

- Airframe structures

- Landing gear

- Missile parts

Medical Industry

Titanium steel serves many applications in the medical field due to its biocompatibility and non-toxicity. Over one million titanium-based joint replacement surgeries are performed annually worldwide.

- Hip and knee replacements

- Dental implants

- Surgical instruments

- Cardiovascular devices

- Cranial implants

Automotive Industry

Used in high-performance components where weight reduction is crucial. Titanium can reduce part weight by up to 40% compared to traditional materials.

- Exhaust systems

- Suspension springs

- Connecting rods

- Performance vehicle components

Chemical Processing

Ideal for handling corrosive chemicals and extreme environments in industrial processing applications.

- Heat exchangers

- Chemical reactors

- Storage tanks

- Processing equipment

Marine Applications

Excellent seawater corrosion resistance makes it perfect for marine construction and equipment.

- Propeller shafts

- Heat exchangers

- Submarine structures

- Offshore equipment

Consumer Products

Growing popularity in jewelry and luxury goods due to hypoallergenic properties and aesthetic appeal.

- Wedding rings and jewelry

- Luxury watches

- Sports equipment

- Premium consumer goods

Medical Applications and Biocompatibility

Medical Applications Overview

Titanium steel’s biocompatibility makes it ideal for medical applications where the material must integrate safely with human tissue.

| Application | Benefits | Typical Use Cases |

|---|---|---|

| Dental Implants | Excellent osseointegration (bone bonding) | Tooth root replacements, dental prosthetics |

| Orthopedic Implants | Strength, lightweight, durability | Hip, knee, spine replacements |

| Surgical Instruments | Corrosion resistance, precision | Scalpels, forceps, surgical tools |

| Cardiovascular Devices | No adverse reaction with bodily fluids | Pacemakers, heart valves |

| Cranial Implants | Malleability, non-irritating | Skull reconstruction, maxillofacial surgery |

Benefits of Titanium Steel

Key Advantages

Lightweight yet Strong

Exceptional strength-to-weight ratio makes it ideal for applications requiring both durability and weight minimization.

Corrosion Resistance

Superior resistance to environmental degradation from water, air, and various chemicals.

Biocompatibility

Safe for use in medical applications with excellent tissue compatibility.

Temperature Resistance

Maintains properties in extreme temperature conditions.

Environmental and Economic Benefits

- Longevity: Reduced maintenance and replacement costs

- Sustainability: Long service life reduces environmental impact

- Performance: Enhanced efficiency in demanding applications

- Versatility: Suitable for diverse industrial and consumer applications

Overview of Titanium Alloys

Titanium alloys are categorized into three main groups, each with specific properties and applications:

| Alloy Type | Characteristics | Primary Applications | Key Benefits |

|---|---|---|---|

| Alpha Alloys | High weldability, oxidation resistance | High-temperature applications | Excellent heat resistance, easy welding |

| Beta Alloys | High strength and ductility | Structural components | Superior mechanical properties |

| Alpha-Beta Alloys | Balanced strength and fabricability | Aerospace, automotive | Versatile properties, easy processing |

References

-

Titanium Alloys and Their Classification – Mississippi State University – Provides an overview of titanium alloys, their properties, and applications.

-

Titanium Alloy Guide – Lawrence Berkeley National Laboratory – Offers insights into the engineering applications of titanium alloys and their competition with specialty steels.

-

Attributes, Characteristics, and Applications of Titanium – The Minerals, Metals & Materials Society (TMS) – Examines the tensile strength and applications of titanium alloys in comparison to high-strength steels.

Frequently Asked Questions (FAQ)

What differentiates titanium from steel?

Titanium and steel are distinct materials with differing properties. Titanium is lesser in weight and corrosion resistant, while steel is all about strength and durability. Hence, choice between titanium and steel usually depends on the particular use, such as aerospace or medical instrumentation.

What are titanium’s properties?

Titanium is a chemical element with a high strength-to-weight ratio, which is corrosion-resistant and biocompatible. This metal finds massive use in aerospace, medical, and marine fields due to its favorable mechanical properties and low density.

What is titanium steel, and where is it used?

Titanium steel means steel alloys that contain titanium to improve their strength and corrosion resistance. Such alloys find use in construction and automotive industries where high-performance applications are required.

How is titanium produced?

Titanium metal is produced from titanium ore by reduction. One of the processes used in titanium extraction is the Kroll process, whereby titanium tetrachloride is converted into sponge titanium, which can then be processed further.

What types of titanium exist?

There are many types of titanium: from pure titanium to titanium alloys. Terminology referring to grades of titanium metal varies according to their composition and properties, yet some more than others are considered best for particular applications, for example in medicine as titanium implants.

What would be the comparison between titanium steel and stainless steel?

Compositions and properties make titanium steel and stainless steel different from one another. Stainless steel is known for its excellent corrosion resistance; titanium steel boasts of a higher strength-to-weight ratio and is often lighter than stainless steel. The choice to be made between titanium steel and stainless steel would depend on the application’s requirements.

How much is titanium compared to steel?

Because of the elaborate extraction process and the rare occurrence of titanium ore, the price of titanium is generally much higher than that of steel. However, the long-term benefits like durability and lesser maintenance costs might very well justify the initial investment of buying titanium products.

What are titanium implants and their applications?

Titanium implants are made from titanium metal and used in different surgical procedures. Titanium is biocompatible in that it can integrate well with human tissue and hence is suitable for applications like dental implants and orthopedic devices.

What kinds of titanium are used in industry?

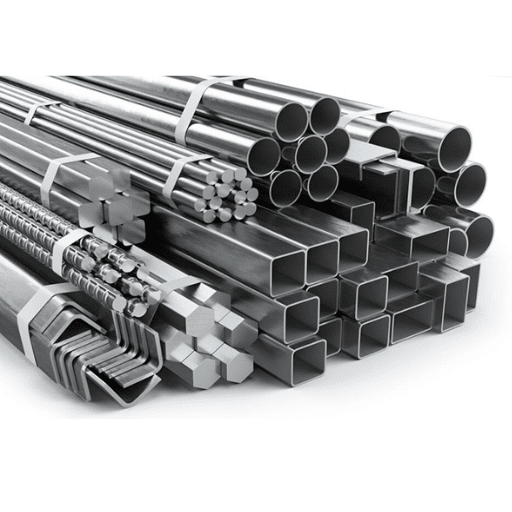

Titanium in different forms includes titanium plates, rods, and pipes. These various types of titanium are used to make titanium products having different industrial applications, including aerospace and medical.