Choosing the right sanitary pipe material will certainly determine the efficiency and durability of your plumbing system for years to come. When planning or updating a plumbing system, the choice of pipe material is essential, considering the magnitude of the task. This guide seeks to ease your burden by outlining the characteristics of different pipe materials so that you can choose the one that best satisfies your needs. It does not matter whether you are a contractor looking for ways to save money or a homeowner looking for reliability; this article aims to guide you through the decision-making process.

What Types of Pipe Are Commonly Used for Sanitary Applications?

- PVC (Polyvinyl Chloride)

Because of their Lightweight, strength, and resistance to corrosion, PVC pipes are an ideal choice for drainage systems.

- CPVC (Chlorinated Polyvinyl Chloride)

Able to withstand higher temperatures than PVC, CPVC is used for hot and cold water supply lines.

- Copper

Copper pipes are widely used for water supply and sanitary drainage because of their strength and resistance to corrosion.

- Cast Iron

Cast Iron pipes are used in large-scale drainage systems in residential and commercial buildings due to their unmatched strength and outstanding sound insulation.

- ABS (Acrylonitrile Butadiene Styrene)

Commonly used in drain, waste, and vent systems, ABS pipes are durable, lightweight, and long-lasting.

These materials are the most utilized for sanitary purposes due to their convenience and usefulness in many different settings. As with any construction project, knowing and following building codes is essential as they, along with other professionals, offer great materials tailored for specific applications.

PVC Pipe and HDPE Pipes for Sanitary Systems

PVC pipes are widely used in sanitary systems because they are reasonably priced, durable, and do not corrode easily. They are simple to use for plumbing in homes and businesses as they are lightweight and easy to install. Furthermore, PVC pipes are able to withstand high water pressure and have a long lifespan of over fifty years in optimal conditions. Additionally, PVC pipes are highly resistant to chemicals, making them useful for carrying wastewater, drainage pipes, and other applications where clean water is not used. Modern improvements in manufacturing ensure that PVC pipes meet environmental and safety regulations, enabling their widespread usage.

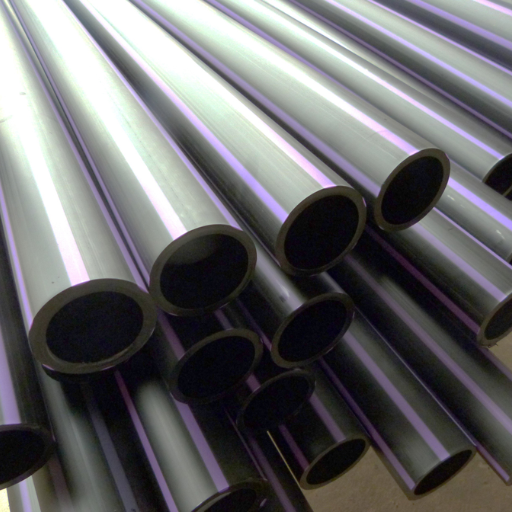

When it comes to high-density polyethylene (HDPE) pipes, they are commended for their remarkable flexibility, toughness, and capability to endure extreme pressures. Unlike PVC, HDPE pipes have a higher resistance to cracking due to their superior ductility. It has the potential to withstand temperatures ranging from below zero to more than 60 degrees Celsius, thus making it suitable for places that experience harsh and fluctuating weather. It also shows great resistance towards chemical and UV radiation, which allows for its use in underground and exposed sanitary systems. As per the latest studies conducted by the industry, HDPE pipes are expected to last over a century, therefore, HDPE pipes can be regarded as an eco-friendly alternative for infrastructure projects. Its smooth internal surfaces aid in efficient fluid flow, which minimizes the chances of maintenance and blockage.

In the end, the selection of materials such as PVC and HDPE pipes tender depends on specific requirements elaborated by a project, the environmental surroundings, and budget limitations. Both materials provide distinct advantages in adaptable sanitary systems that are secure, tough, and efficient.

Cast Iron Pipes in Sanitary Plumbing Systems

The strength and reliability of cast iron make it a prized material in the construction industry, especially for certain plumbing works; cast iron has successfully withstood the test of time for hundreds of years. It is very popular because of its long-lasting qualities (once properly maintained, cast iron lasts with minimal wear for almost a century!). To add, the material is also fire resistant, as it does not combust easily. Because of its strength, cast iron pipes are used for underground drainage, in high-pressure systems, as well as in other heavy-duty applications.

Unlike plastic pipes, cast iron pipes are much quieter, as dense materials reduce vibrations and noise from water flow, making them impeccable in multi-story buildings or quiet residential areas. Quietness is especially beneficial in households with children.

Recycled materials are now widely used to manufacture modern-day cast iron pipes, which significantly helps with sustainability efforts. Cast iron pipes are also deemed to be thicker than their plastic alternatives, making them better with changes in temperature. Studies have proven that cast iron pipes provide lower expansion coefficients, sharper stability over fluctuating temperatures, and enhanced overall performance.

While beneficial, cast iron pipes tend to be pricier than PVC or HDPE materials. They are also heavier, increasing the amount of labor and equipment needed for installation. However, for projects emphasizing long-term durability, noise attenuation, fire resistance, and other considerations, cast iron is still the best option.

Stainless Steel Sanitary Pipes for Specialized Applications

Stainless steel sanitary pipes are designed for applications where cleanliness as well as resistive strength to rust is needed. These pipes can be found in the Food and Beverage industry, pharmacies, and even biotechnology due to the requirements of ultimate sanitation and crucial structural characteristics of the materials utilized. Further description and information on stainless steel sanitary pipes are provided below:

- Material Composition: Material composition includes high-grade stainless steel alloys of 316L and 304, which have exceptional resistance to corrosion and other chemical exposures.

- Surface Finish: Surface Finish includes polishing to a mirror finish or satin finish to ward off bacterial growth and comply with sanitary standards.

- Inner Diameter Range: Inner Diameter Range usually lies in between 0.5 inches and 12 inches, covering different needs for flow.

- Temperature Resistance: Exaggerated temperature resistance permits temperatures from hypothermia-inducing -100F to 800F, allowing for a wide range of thermal processing techniques.

- Pressure Ratings: Pressure Ratings, set to high-range pressure systems, frequently exceed 300 psi, depending on the wall thickness and material grade, citing much strength provided.

- Standards Compliance: Standards as ASTM A270 or ISO 2037 and more guarantee that compliance with precision performance for critical applications is routinely met.

- Applications:

-

- Food Production and Hospitality (dairy transport pipelines as well as brewery systems)

- Healthcare, Pharma, and Biotech (sterile environments such as cleanrooms)

- Chemical Production (withstand acids and aggressive cleaning agents)

- Lifespan: Operational life is long due to the material’s durability and resistance to wear and corrosion.

The blend of advanced technology with high-quality machining gives superior reliability while meeting strict sanitary standards, making stainless steel sanitary pipes stand out in specialized use cases.

Why Is PVC Pipe the Most Common Type of Sanitary Pipe?

The most frequently used type of sanitary pipe is PVC pipe due to its low cost, low weight, and easy installation features. It can be used safely in the transportation of water and other fluids due to its resistance to corrosion and chemicals. Furthermore, the minimal maintenance required and the long lifespan of PVC pipes add to their broad application in plumbing systems in homes, businesses, and industries.

Durability and Resistance to Corrosion in PVC Sewer Pipe

Sewerage works best with superbly durable pipes, which is why PVC sewer pipes are popularly used. Pipes like these are designed to last long and are corrosion resistant, making them a superb long-term sewer infrastructure option. Unlike metal, PVC does not rust or break down when moisture, soil, or a myriad of chemicals typical to sewer systems. PVC pipes under normal operating conditions will outlast a person’s lifespan, studies show they can last for over 100 years. That makes them a sustainable option for modern plumbing systems.

Apart from getting exposed to a mixture of presumably harmful chemicals, PVC pipes give up on resistance at acidic to alkaline pH levels without losing structural integrity. That is especially important for industrial applications where sewer pipes require exposure to harmful waste materials. Beyond that, these PVC pipes hold value over time since they retain strength and flexibility, sustaining position under tremendous pressure and shifting soil conditions. These attributes make PVC pliable/flexible as a lightweight, making it easier to install efficiently, ultimately saving costs for large-scale infrastructure projects.

Cost-Effectiveness of PVC for Residential and Commercial Plumbing

PVC pipes have become popular for their unbeatable value in both residential and commercial plumbing works. This is paramount due to their low materials and production costs, which makes them more affordable than copper or galvanized steel. Research reveals that the lightweight nature of PVC pipes can lower installation costs by 30% because of ease of transportation and handling. Moreover, reduced necessity for repairs due to the resilient nature of the material further minimizes long-term costs.

Being able to endure high water pressures and temperatures makes PVC pipes best suited for residential plumbing needs. In addition, they last over 50 years, making them an economical choice. Industrial plumbing also takes advantage of the scalability and strength of this material, as PVC can withstand high flow rates and the chemical corrosion prevalent in industrial water systems.

Moreover, new developments in PVC technology incorporate features like chlorinated PVC (CPVC), which further increases heat resistance and application scope while still saving on costs. Because of these benefits, CPVC has also become an economical and functional option for plumbing systems in diverse situations.

Easy Installation and Maintenance of PVC Piping Systems

The ease of installation and low maintenance make PVC piping systems very popular across a lot of industries. Due to their lightweight construction, PVC pipes are easy to handle, transport, and fit into place, which decreases both labor costs and installation time. In addition, their work with simple joining techniques such as solvent cementing and push-fit connections means that no specialized tools or extensive training are required.

Statistical insights reveal that the use of PVC in plumbing systems has been shown to reduce installation time by up to 30 percent when compared to other materials such as copper or steel. Not only this, but PVC pipes are also highly durable and resist clogging, scaling, and microbial growth, which cuts down the maintenance costs over an extended period of time. Along with these capabilities, PVC piping systems can withstand changes in the environment, meaning they can be depended on for long-term sustainability, and less intervention, which efficiently saves costs for residential, commercial, and industrial users.

When Should You Use Stainless Steel for Sanitary Pipe Fittings?

Sanitary pipe fittings in industries like food, beverage, pharmaceuticals, and dairy, which require a high level of hygiene, we should consider using stainless steel. It is highly hygienic as its surface doesn’t corrode and is contamination-free. Stainless steel is also resistant to high pressure and temperatures, making it suitable for frequent hot water bathing and chemical cleaning. It is suggested to use stainless steel in case high durability, along with high cleanliness and robust sanitary compliance, is needed.

Food and Beverage Industry Applications for Stainless Steel Pipes

- Dairy Processing

Hygienic stainless steel pipes are used in the transportation of milk and other dairy products in the dairy industry because they do not pose hygiene issues and provide safe movement of the products along the process line. Also, they prevent contamination, and there are high standards of hygiene cleaning required in this field.

- Beverage Production

Carbonated beverages and soft drinks rely on stainless steel pipes to convey and transport the liquids in corrosion corrosion-resistant, clean environment. The purity of the beverages is maintained even in cases of carbonation and acid-supplied conditions.

- Food Processing and Packaging

Food-grade stainless steel pipes are extensively employed at this stage of food production as permanent installations for the movement of sauces, oils, pastes, semi-liquid food, and other materials, making emulsion systems. The internal surface of pipes and their chemical composition are smooth and non-reactive, and thus, food grade holds guarantees the product quality, protecting it from filtration, adhesion, and contamination.

- Breweries and Distilleries

The pipes are extensively used in high-temperature processes as well as in conditions of aggressive environments in the biofuel and food industries. Standard serves in also Brew and steam distilled vessels serve the purpose for the Boiler design of hot water. The steam that comes out of the time to heat the user big to.

- Sugar Industry

Efficiency in production drives the use of stainless steel pipes in the sugar industry due to the fact that the juice of sugar cane and other byproducts are corrosive to pipe materials.

- Meat and Poultry Processing

Meat and poultry is hygienically processed using stainless steel pipes as they can be easily cleaned and sanitized, which is a requirement for certain стерільні industries.

- Fruit and Vegetable Processing

Fruits and vegetables are washed, transported, and processed using stainless steel pipes, which do not decontaminate. They are also corrosion resistant to some acidic products.

- Canning Operations

Canning processes, such as adding soups, sauces, and vegetables into the containers, are mainly done using stainless steel. It provides sanitary tubing with non-stick properties under high pressure and temperature.

- Water Filtration Systems

To maintain high-quality water for food and beverage production, filtration is needed. Stainless steel pipes provide filtration systems with durability and cleanliness.

- Chocolate and Confectionery

Chocolate and confectionery have to be done with utmost precision when it comes to cleanliness, therefore, non-stick and non-reactive stainless steel is preferred.

Due to their exceptional durability, cleanliness, and ability to protect and preserve the essence of the product, stainless steel pipes are used as an integral part of the food and beverage industry.

Benefits of Stainless Steel in Wastewater Treatment Systems

Because of its strength, lack of corrosive degradation, and long-term cost savings, stainless steel is foundational in treating wastewater. The processes of cleaning wastewater typically include subjecting materials to harsh chemicals, severe temperature fluctuations, and high moisture conditions, which can deteriorate less durable materials. For stainless steel, its remarkable opposition to rust and chemical corrosion greatly fortifies its performance at hand, therefore minimizing the amount of repairs and replacements needed.

Furthermore, the smooth and non-porous surface of stainless steel reduces biofilm and contaminant accumulation, which increases sanitation throughout the system. Its mechanical strength enables the fabrication of durable yet lightweight tanks, pipes, and valves that endure the harsh physical conditions. Stainless steel alloys like grade 316 are more suited for use in wastewater systems because of their high chloride and acidic tolerability.

Stainless steel proves to be useful in the industry, especially for its lifecycle and cost efficiency. Even though the upfront cost is high, the extensive service period, low maintenance drains, and additional savings ensure long-term benefits. Furthermore, stainless steel aligns with modern-day treatment facilities as it is 100% recyclable and reusable. Its contribution aids in the effort to protect the environment and reduce waste, but it still operates efficiently in key infrastructures.

What Are the Differences Between Sanitary Pipe Materials?

The categories of sanitary pipes vary largely based on their maintenance, durability, cost effectiveness, corrosion resistance, and other factors significant to an application, such as:

- Stainless Steel: It’s Ideal for long-term demanding environments and for later servicing due to its strength, corrosion resistance, and easy cleaning, although it comes with a higher initial cost.

- PVC (Polyvinyl Chloride): It’s an ideal option for less demanding applications as it is cheap, light, a nd resistant to many chemicals, but not heat resistant nor durable.

- Copper: Heavily utilized for plumbing; copper offers good corrosion resistance, however is more expensive and not suitable for aggressive chemicals.

- Polypropylene (PP) and Polyethylene (PE): Available at a low cost and usable in many applications, these materials are lightweight but may not tolerate high temperatures.

Choosing a material is dictated by the type of application, environmental conditions, budget, and other such considerations.

Comparing PVC and HDPE to Metal Pipes for Drainage

On the aspects of draining applications compared to metal pipes, PVC and HDPE stand out concerning durability, cost, ease of installation, and environmental impacts.

- Durability: Corrosive resistance is one of the most notable qualities of both PVC and HDPE pipes, making them suitable in environments with moisture and chemicals. Additionally, metal pipes manufactured from steel and iron tend to rust and corrode over time, reducing their durability.

- Cost: The maintenance and production cost of PVC and HDPE pipes is significantly lower than metal pipes. Their lightweight means lower shipping and production costs, leading to substantial savings over time.

- Ease of Installation: Transport and installation of PVC and HDPE pipes are simpler due to flexibility and light weight. In comparison, metal pipes are heavier and more difficult to install because of specialized equipment, which increases the expenditure of a project.

- Temperature Resistance:

-

-

- Typically, PVC can endure temperatures of up to 140°F (60°C), which is acceptable for most drainage activities, but it is not suitable for extended exposure to high heat.

- HDPE is more thermally resistant and can endure higher temperature ranges, often up to 180°F (82°C), under certain conditions.

- Because of the extreme variations in temperatures, individual stainless steel pipes can be a better option, although this makes the purchase more costly.

-

- Environmental Considerations: In certain fashions, both PVC and HDPE pipes are less harmful to the environment. Highlighting HDPE again, it is less expensive to create due to lower energy requirements and is 100 percent recyclable. Although some metal ones, like these made out of steel, are also recyclable, giving them a longer lifecycle.

- Lifespan:

-

-

- Depending on the application, PVC pipes tend to last between 50-100 years.

- Because of their flexibility, HDPE pipes are more resistant to cracks under external pressure, meaning they have a similar lifespan.

-

For metal pipes, excessive usage and maintenance will shorten their lifespan. This is especially true for corrosive environments.

-

As previously stated, the selection of PVC, HDPE, or metal pipes should be made after considering the constraints of the project, such as finances, geolocation, and anticipated life. In virtually all cases, thorough research in various fields of industry marks the advantages of PVC and HDPE being the most affordable, durable, and maintenance-free options for drainage.

Cast Iron vs. Plastic Pipe for Sewer Lines

When choosing between sewer cast iron and plastic pipes, factors such as cost, noise insulation, ease of installation, and, most importantly, durability, need to be considered. Cast iron pipes are exceptionally durable and tend to withstand wear and tear for 50 to 100 years if maintained in ideal conditions. Their density allows for the natural mitigation of water flow noise, which is an added bonus for residential and commercial buildings. On a negative note, they are prone to corrosion, especially in acidic water or highly mineralized water regions, leading to a reduced lifespan.

Fortunately, plastic pipes such as PVC and ABS are light, moderately priced, and easy to install. In addition, they are resistant to corrosion and chemicals, which allows them to endure severe soil conditions. Although without proper mitigation measures, they may let out a lot more sound compared to cast iron pipes. Moreover, they are much more sensitive to external impact or extreme temperature shifts.

Data from the industry indicates that with effective installation and maintenance, PVC and ABS pipes can last between 50-70 years. At the same time, studies indicate that the installation cost of plastic piping comprises significantly lesser amounts than cast iron, as it is cheaper in terms of both labor and material costs. For example, plastic pipes are said to reduce labor costs during installations by as much as 30% due to being lightweight and easy to handle.

In the end, the decision about whether to use cast iron or plastic pipes relies heavily on the specific needs of the project. Cast iron pipes may be best suited for cases where control of sound is needed along with long-term durability in relatively stable conditions, while cost-sensitive projects and corrosive environments are better served with plastic pipes. Careful evaluation of both materials is essential, as neither is without its advantages and limitations.

Material Considerations for Potable Water vs. Wastewater

In systems transporting drinking water, safety comes first. Hence, stability and non-corrosive qualities of materials used are a requirement. These are reasons why copper, stainless steel, and some plastics, such as PEX and PVC, are utilized. Copper is the most durable material for drinking water pipes because its antimicrobial properties are exceptional. Also, PEX is now a preferred choice due to its flexible structure and simple installation. Furthermore, materials must have NSF/ANSI 61 certification to ensure there are no harmful substances leached into potable water.

For gas and liquid waste transportation systems, the features called for differ significantly. Their focus is on toughness and resilience against corrosion from chemicals and biological waste. Thus, cast iron, HDPE (high-density polyethylene), and PVC are more commonly used. Although heavy, cast iron provides outstanding long-term reliability and decreased noise levels. Its resistance to chemical corrosion makes PVC an ideal non-pressurized wastewater system, while HDPE, the lightweight and cost-efficient material resistant to impact, is best for pressurized lines.

Recent industry data shows that approximately 55% of plumbing systems in new construction use plastic due to ease of installation and cost effectiveness, with PEX and PVC dominating the market for potable water. On the other hand, wastewater systems still heavily depend on cast iron for vertical drainage and soil pipes, representing almost 40% of commercial installations. These trends in materials used for construction underline the need for proper selection criteria tailored to specific conditions and functional requirements for potable water or wastewater systems.

How Important Are Proper Sanitary Pipe Fittings?

The proper sanitary pipe fittings sustain the efficiency and safety of plumbing systems. They ensure no fitting leaks, prevent the contamination of the water supply, and encourage the wastewater flow. Well-crafted plumbing fittings lower the chances of system breakdowns and reduce the required maintenance, which can damage public health and violate standards. Choosing the right plumbing fittings impacts the structure, and fitting selection is vital to any plumbing system infrastructure.

Types of Sanitary Fittings for Different Pipe Materials

Just as every activity has specific tools, installing sanitary fittings requires knowing the proper hygienic plumbing tools that complement the appropriate pipe structures. Different classes of pipes require different classes of fittings, and below is a sectional breakdown of pipe types of varying materials and their compatible fittings:

- PVC Pipe Fittings

The main characteristics of PVC pipes are ease of handling, structural integrity, and a comparatively cheaper way of spending money. Common fittings for enlisted pipes comprise corroding elbows, corrosive tees, couplings, and many others. Every single one of them is basic in damage resistance and therefore serves plumbing purposes for residential and commercial buildings. Unlike other metals, PVC is much more forgiving in terms of damage and therefore simple construction uses easy solvent cement to fuse parts together and prevent leaks.

- Copper Pipe Fittings

For exceptional service, pipes are automated using tubes. Compared to other methods, they provide longer life, a high damage threshold, and high water flow. Copper pipes are well known for what we call Automated Bi-Directional Holding Loops. BAHLs boast length compared to solenoids with unrestricted, directly attached FIT-IT. Cross-docking docking used at outlets is popularly used. As the IT and cross dock suggest, it doesn’t require limitations and gives endless amounts of brackets, giving it a reasonable left cubicle notch with US Gypsum used below slides.

- Stainless Steel Pipe Fittings

Pipe fitting is when lengths of pipe are connected to each other. Piping systems are made so that they are convenient to use and transport. They are divided into several categories, including but not limited to:

- PEX Pipe Fittings

Steel pipes work incredibly twoard food and industrial operations as they resist chemicals and corrosion while bearing a significant amount of pressure. Wrenches, soldered joints, and cables are the most common tools used alongside plastic piping.

- Cast Iron Pipe Fittings

These pipes are incredibly strong, hence, they are often used for water McKinsy systems. Due to their strength, they can resist a sizeable amount of pressure. Plastic piping can be used alongside these in bell and spigot joints, but so can steel pipes with mechanical joint couplings.

Proper pairing of pipe materials and respective fittings enhances system longevity, reduces the risk of leaks, and improves operability. Each combination is crafted with meticulous parameters such as life cycle, mechanical stresses, temperature, and other external factors.

Ensuring Leak-Free Connections in Plumbing Systems

Eliminating leaks in a plumbing system requires a sharp focus, the correct materials, and high-quality equipment. One of the best approaches is using a thread sealant or pipe joint compound, which also helps to lock threaded connections. Compression fittings are also another helpful method for achieving a strong seal in a particular pipe system, especially in the case of copper or plastic tubes.

Additionally, PTFE tape, commonly categorized as plumber’s tape, is also used widely for sealing and preventing gasket losses by wrapping the threads of fittings.

Reports from different firms suggest that around 30% of plumbing system defects stem from poorly sealed connections during the system’s assembly. In order to contain such problems, almost all professionals test systems under pressure before letting them function. Other instruments like air compressors and pressure measuring systems are capable of checking the strength of garniture and separating water-sensitive areas from air-sensitive ones.

These days, plumbing systems are put in systems enhanced with new sealing materials elastomeric gaskets, that can be constructed to endure different levels of pressure and temperature. Keeping an ear on the most recent arrangements and following the right installation approaches guarantees a greater trustworthy structural framework while preventing further damage during servicing in the future.

What Are the Building Code Requirements for Sanitary Pipes?

The building code requirements for sanitary pipes add such things as proper drainage, leak prevention, and sanitary conditions. Important things to attend to are:

- Pipe Materials: As determined by local codes, pipes must also be constructed from approved and strong materials like PVC, cast iron, or ABS.

- Pipe Sizing: Pipes must be of sufficient diameter to cope with the volumes of wastewater expected for discharge through the sanitary system.

- Slope and Gradient: Pipes must have a water flow slope (normally, 1:4 inch per foot for small pipes) that is adequate for gravity drainage.

- Ventilation: Sufficient ventilation is necessary to restrict sewer gases from freely entering buildings and also to make sure that water available within the system is moved at sufficient pressure.

- Joints and Connections: All joints have to be leakproof, no less than by use of prescribed methods and materials, which might be obvious in the first place.

- Accessibility: Cleanouts must be positioned in a relatively accessible location for effective maintenance and inspection.

As previously mentioned, always double-check with your local building codes and instructions, as there may be differences depending on the region.

Residential Plumbing Codes for Sewer Pipe Materials

As far as the residential plumbing codes for sewer pipe materials are concerned, I adhere to the local building construction codes with regard to the materials and their suitability. Approved materials customarily include PVC, ABS, clay, and cast iron, which provide reliability. I also ensure that all applicable parameters regarding the use of the material and the soil profile of the site are met, including all guidelines controlling installation and joint connections so as to prevent leakage.

Commercial Standards for Sanitary Pipe Systems

As with many engineering domains, commercial sanitary pipe systems have to observe strict codes and standards for optimum efficiency and safety. The materials used, whether stainless steel, PVC, CPVC, or even cast iron alloys, must withstand high-pressure corrosion and waste flow due to their high strength and waste flow resistance. For one, stainless steel is well suited for industrial applications with tempered chemical exposure, violence, and high temperatures due to its robust nature.

The diameter of pipes typically used in commercial systems is no below 1.5 inches, commonly reaching up to 12 inches or larger depending on the building requirements and waste output levels. Slope and grading – or how sharp the angle is – are just as crucial as the standard defined benchmark of 1/4 inch per foot vertical drop in pipe length for optimal flow. Following codes like the International Plumbing Code (IPC), along with local amendments, is essential to maximize performance and safety.

Which modern sanitary systems make use of the previously mentioned sensor technologies for the detection of leaks? Trenchless options for pipe repair further modernize sanitation systems by making sure no undue time is spent out of action for environmental compliance, and downtime is avoided at all costs. To minimize blockages and maintenance costs while further enhancing system sustainability, these improvements aid in reducing system risk.

Reference Sources

- “Establishing the Taxonomy of Building Defects Triggered by Moisture Intrusion and Dampness”:

- Key Findings: This study identifies moisture as a primary cause of structural defects in buildings, including issues with plumbing systems. It highlights the importance of proper material selection and waterproofing to prevent dampness and associated microbial growth.

- Methodology: The research employed literature reviews, visual inspections, and case studies to analyze moisture-related defects.

- “Modeling Every Sanitary Pipe in the City: Unique Aspects and Benefits”:

- Key Findings: This paper discusses the development of a citywide model for sanitary sewer systems, emphasizing the importance of GIS and GPS data in optimizing pipe material selection and system efficiency.

- Methodology: The study used the US EPA SWMM engine for hydraulic modeling and incorporated field data from flow meters and rainfall records.

- “Sanitary Gravity Sewer Design using Sewer GEMS Software Connect Edition for Utsav Vihar, Karala”:

- Key Findings: The research demonstrates the use of SewerGEMS software for designing cost-effective sewer systems, focusing on pipe material selection and hydraulic efficiency.

- Methodology: The study utilized population forecasts, rainfall data, and software simulations to design and analyze sewer networks.

Frequently Asked Questions (FAQs)

Q: What are the different types of materials used in sanitary pipes for plumbing systems?

A: The main materials used in sanitary pipes include PVC (polyvinyl chloride), PEX (cross-linked polyethylene), copper, stainless steel, cast iron, ABS (acrylonitrile butadiene styrene), CPVC (chlorinated polyvinyl chloride), and in some older systems, galvanized steel. Each material has specific applications depending on factors like water pressure, temperature requirements, and installation location. Materials like stainless steel are particularly valued for their durability and corrosion resistance, while PVC and PEX have become increasingly popular for their cost-effectiveness and ease of installation.

Q: What pipe is used for water supply versus waste drainage in a plumbing system?

A: For water supply, copper, PEX, CPVC, and stainless steel are commonly used for their pressure-handling capabilities and safety for potable water. Copper pipes remain a traditional choice, offering antimicrobial properties, while PEX is used for water supply due to its flexibility and freeze resistance. For waste drainage and sewer lines, materials like PVC, ABS, cast iron, and concrete pipes are preferred. PVC is widely used for drainage due to its chemical resistance, while cast iron is valued for its sound-dampening qualities in waste systems. The selection typically depends on local building codes, water conditions, and specific plumbing services requirements.

Q: What are the main types of sewer pipes available and their applications?

A: The main types of sewer pipes include PVC, ABS, cast iron, concrete, and vitrified clay. PVC sewer pipes are lightweight, corrosion-resistant, and easy to install, making them ideal for residential applications. ABS sewer pipes offer similar benefits but with greater impact resistance. Cast iron pipes are durable and excellent for noise reduction in multi-story buildings. Concrete pipes are typically used for municipal sewer lines due to their strength and longevity. Vitrified clay pipes, though less common in new installations, are still valued for their chemical resistance in certain commercial and industrial settings. The choice depends on factors like soil conditions, load requirements, and local regulations for wastewater treatment systems.

Q: What is the importance of sanitary pipe material selection for health and safety?

A: The importance of sanitary pipe material selection cannot be overstated, as it directly impacts water quality and public health. Materials must meet strict health standards, particularly for potable water systems, where lead-free materials are mandatory. Pipes used in food processing facilities require materials that prevent bacterial growth and contamination. For water treatment facilities, pipe materials must withstand various chemicals while preventing leaching. Additionally, proper material selection prevents corrosion and leaks that could lead to structural damage, mold growth, or contamination. In healthcare settings, sanitary pipes play a crucial role in infection control, often requiring specialized antimicrobial materials.

Q: Why is stainless steel a popular choice for sanitary pipes in certain applications?

A: Stainless steel is a popular choice for sanitary pipes, particularly in food processing, pharmaceutical manufacturing, and healthcare facilities due to its exceptional hygienic properties. Its non-porous surface prevents bacterial growth, and it can withstand high-temperature sterilization processes. Stainless steel doesn’t leach chemicals into water, making it ideal for applications where purity is paramount. Its corrosion resistance, especially in grades like 316L, allows it to handle acidic or chlorinated environments. While its cost compared to other materials like PVC or PEX is higher, its longevity and minimal maintenance requirements often provide better long-term value in critical sanitary applications.

Q: What are the main types of copper pipes used in sanitary applications?

A: The main types of copper pipes used in sanitary applications include Type K, Type L, and Type M. Type K has the thickest walls and is an ideal choice for sanitary pipe installations requiring maximum durability, often used in underground water service lines. Type L has medium wall thickness and is commonly used for interior water distribution in residential and commercial buildings. Type M has the thinnest walls and is typically used for low-pressure applications or where cost is a significant factor. All copper pipes are naturally antimicrobial, making them excellent for potable water systems. They can be joined using soldering, brazing, or mechanical fittings, with each method offering different pressure ratings and installation considerations.

Q: How do PVC and CPVC compare as materials used in sanitary plumbing?

A: PVC and CPVC are both popular plastic pipe materials, but differ significantly in their applications. Standard PVC is primarily used for cold water and drainage systems as it cannot withstand temperatures above 140°F. CPVC is chlorinated PVC that can handle temperatures up to 200°F, making it suitable for both hot and cold water supply. While PVC is typically white or gray, CPVC is usually cream or light yellow for identification. Both materials are corrosion-resistant, lightweight, and have smooth interiors that resist buildup. CPVC generally costs 25-30% more than PVC but offers greater versatility. Both are easier to install than steel or copper, requiring simple solvent cement joining methods, and both have excellent chemical resistance for various sanitary applications.

Q: What factors should be considered when choosing pipe materials for a sanitary plumbing system?

A: When selecting pipe materials for a sanitary plumbing system, consider water chemistry (pH, mineral content), as acidic water can corrode certain metals. Temperature requirements are crucial—some plastics deform under high heat, while pipes can withstand varying temperature ranges. Pressure ratings must match system demands, especially for water supply lines. Installation location matters—buried pipes need different properties than exposed ones. Local building codes often dictate acceptable materials. Cost considerations should include not just materials but installation labor and long-term maintenance. Environmental factors like UV exposure for outdoor pipes or freeze potential in cold climates are important. Finally, consider the expected lifespan—copper and cast iron last 50+ years, while some plastics may need replacement sooner.

Q: What are the advantages and disadvantages of using PEX in sanitary plumbing systems?

A: PEX (cross-linked polyethylene) offers significant advantages as it’s highly flexible, allowing for fewer connections and reducing leak potential. It resists freezing better than rigid pipes and installs quickly with specialized tools. PEX is resistant to scale buildup and operates quietly without water hammer. However, it does have limitations—it cannot be used in high-temperature applications exceeding 200°F and must be protected from prolonged UV exposure. While PEX is increasingly used for water supply systems, it’s not typically used in sanitary drain lines. Some localities still restrict its use due to concerns about potential chemical leaching, though modern PEX meets stringent safety standards. Its cost compared to other materials falls midrange—more expensive than PVC but generally less than copper, making it a balanced choice for many residential applications.