The right step for the effective functioning of valves in the Pharmaceuticals, Biotechnology, Food, and beverage industries is the proper selection of Sanitary Valves Construction materials. The construction material selection decision for valve manufacturers is technical but significantly impacts operational efficiency, longevity, maintenance costs, and regulatory adherence. This article walks readers through the construction materials of sanitary valves to help make well-informed decisions. This guide will steer manufacturers towards top-of-the-line valves by equipping them with fundamental material properties alongside industry-specific requirements and pedagogical information. A valve manufacturer that wishes to have a competitive edge in the niche market will learn how to overcome industry challenges.

What materials are commonly used in sanitary valve construction?

- Stainless Steel

Owing to its excellent resistance to corrosion, its 304 and 316 variants are commonly used in the stainless steel industry. This makes it useful in the food, dairy and pharmaceutical industries where maintaining hygiene is extremely important.

- PTFE (Polytetrafluoroethylene)

One of the most common uses of PTFE is for valve seals. It is an extremely strong chemical attendant and can resist high temperatures. It’s non stick surface allows it to be used in sanitary applications.

- Elastomers

Commonly used elastomers include EPDM gaskets, Viton, silicone gaskets, and O-rings. Used in sanitary valves, these elastomers allow for flexiblity as well as strong sealing power which meets FDA approval.

- Hastelloy

This alloy is rarely used in practice due to its high price. Hastelloy is selected in extremely corrosive Settings of harsh chemicals due to its strong resistance to them.

The listed selection is made considering the strict standards of hygiene, durability, and chemical compatibility needed for the materials in the sanitary applications.

Stainless steel options for sanitary valve bodies

Sanitary valve bodies are most commonly made with stainless steel because it is easy to clean, highly durable, and does not corrode easily. The 304, 316, and 316L stainless steels are most often used in sanitary applications. Each of these grades has specific advantages suited for particular needs and conditions.

- 304 Stainless Steel

This is one of the most used grades as it offers reasonable corrosion resistance and cost-effectiveness. It is used in general sanitary applications where the surroundings are not highly corrosive.

- 316 Stainless Steel

Usually chosen for more demanding sanitary applications, 316 stainless steel has molybdenum added, which increases its resistance to chlorides and a range of other chemicals. It is used in pharmaceutical and food processing industries which consider the exposure of chemicals a routine.

- 316L Stainless Steel

This variation of 316 stainless steel contains less carbon, decreasing the susceptibility to corrosion from welding and presenting improved performance in ultra-clean and high use settings. It has a much smoother surface finish which helps reduce bacterial colonization.

As per the industry statistics, 3168L stainless steel has a Pitting Resistance Equivalent Number (PREN) of 24, which is notable for being greater than 20-23 for 304 stainless steel, indicative of superior pitting resistance, even in chloride-containing environments. Moreover, stainless steel valve bodies often comply with tier one specification ASME BPE or ISO 2852, which guarantees their stainless steel construction, fulfilling sanitary requirements that necessitate sterility and hygiene.

The remarkable features and benefits these materials bring, such as outstanding durrability, corrosion resistance, himdegreey compliance alongside excellent sanitary compliance, demonstrates why these types of stainless steels have become the forefront of sanitary valve engineering across industries.

FDA-approved elastomers for sealing requirements in sanitary valves

Sanitary valve applications that require cleanliness and sterility simplify their processes with FDA elastomers. Some of the FDA-approved elastomers are EPDM (Ethylene Propylene Diene Monomer), Mercury silicone, PTFE (Polytetrafluoroethylene), and FKM (Fluorocarbon rubber (FKM)) because these perform well in harsh conditions and are compliant with FDA regulations.

EPDM stands out because it can withstand destruction by heat and water, making it suitable for uses that entail constant sterilization. Silicone’s flexibility allows it to accommodate a wide range of temperatures (-55°F to 300°F), hence finding wide usage in low-pressure pharmaceutical and food and drink systems. PTFE or Teflon is known for it excellent resistance to chemicals and non- stickability’ while FKM is the best for aggressive chemicals and high-temperature operations.

Many biopharmaceutical industries and OEMs find these appropriate as they not only adhere to FDA elastomers but also abide by the United States Pharmacopoeia’s Class VI and European Pharmacopoeia standards. Meticulous attention to selecting FDA-approved elastomers leads to optimum sealing efficiency, waterproofing, the hygiene of the surgeon, and military-grade cleanliness.

High-polish finishes and their importance in sanitary design

High-polish finishes are crucial in the sanitary fabrication of components within the food processing, pharmaceutical, and biotechnology industries. They ensure surfaces on equipment are ultra-smooth, minimizing microbial contamination while making the cleaning processes easier and more effective. As per some recent specifications from the industry, roughness values of polished surfaces (Ra) between 0.4 micrometers or less are optimal for sanitary applications. Such finishes enhance effectiveness against biofilm formation, which may contain harmful bacteria that pose a danger to the product.

Moreover, high-polish finishes increase resistance to corrosion by eliminating tiny crevices, which are places for corrosive agents, such as acids and saline solutions, to gather. This increases the equipment’s lifespan, even in difficult operating conditions. These finishes, in addition to safety and durability, also aid in meeting international hygiene regulations established by the FDA, EHEDG, and 3-A Sanitary Standards Inc. Aligned with safe operational practices, manufacturers achieve product safety and global regulatory compliance, all by prioritizing high-polish finishes.

How do different types of sanitary valves affect material selection?

A direct relationship exists between the selection of materials for construction and the type of sanitary valve used, considering the valve’s function, its working environment, and the substance being processed. This is illustrated with these examples:

- Butterfly Valves are made from stainless steel as it is durable and non-corrosive. Furthermore, elastomer seals are also used, which are food-grade.

- Diaphragm Valves must use polished stainless steel with a PTFE diaphragm because those materials are able to withstand heavy sanitization and cleaning.

-

Ball Valves use stainless steel, which is a good metal, but put the additional requirement that the sealing surfaces must be made of high-temperature and chemically resistant materials.

Valve types and application requirements greatly impact the materials that need to be used, and in doing so, manufacturers fulfill hygienic requirements while ensuring the utmost efficiency and durability.

Material considerations for sanitary ball valves

Sanitary ball valves combine optimal performance with strict hygiene requirements, which makes the level of cleanliness a decisive factor for material selection. One commonly used material is 316L stainless steel because of its superior resistance to corrosion, ideal for applications that involve aggressive cleaning chemicals or high moisture. Recent studies indicate that 316L stainless steel is resistant to pitting and crevice corrosion even in heavily contaminated sanitary conditions with chlorides, which ensures its durability under demanding conditions.

For sealing components, PTFE (Polytetrafluoroethylene) and EPDM (Ethylene Propylene Diene Monomer) are the most commonly used materials. PTFE has outstanding properties such as chemical inertness, low friction, and heat resistance, enduring temperatures from -328ºF to 500ºF (-200ºC to 260ºC). EPDM is, however, known for providing better elasticity and steam, hot water, and cleaning agents resistance making it applicable in dynamic sealing.

To ensure compliance with regulations like the FDA (Food and Drug Administration) and 3-A Sanitary Standards, the surface finishes of sanitary ball valves are critical. Polishing the surface to achieve roughness average (Ra) 32 µin and below gives a surface that retards bacterial growth and cleaning becomes easier.

In addition, other companies are looking into new coating methods like electropolishing because of their smoothing and anti-corrosion properties. This advancement not only enhances the durability of ball valves but also significantly lowers maintenance expenses. Through the selection of materials that fulfill contractual specifications as well as function operationally, sanitary ball valves perform optimally while offering the utmost in hygienic standards with minimal environmental impact.

Sanitary butterfly valve construction materials

In the food, beverage, and pharmaceutical industries, where hygiene and accuracy are critical, sanitary butterfly valves serve as crucial parts. These valves have a body, a disc, and a seat for each valve, which are mostly made out of stainless steel, more specifically, 316L and 304 grade. 316L stainless steel is used in very corrosive environments because it has molybdenum, which helps it withstand severely corrosive environments, like exposure to acids and cleaning solutions.

The sealing parts of these valves, like the disc and seat, are made out of materials such as EPDM, PTFE, or silicone. These materials are selected based on the processing conditions such as temperature, presence of chemicals, and pressure. To illustrate, PTFE is known for its exceptional non-reactivity and resistance to high temperatures, which makes it ideal for aggressive chemicals. Meanwhile, EPDM is best known for applications such as steam and water, where flexibility and resistance are critical.

Advanced fabricating techniques, like surface polishing to the level of Ra ≤ 0.8 µm, are now performed on modern sanitary butterfly valves. This makes sure there is no material accumulation and makes cleaning easier. The polished surface meets the important CIP (Clean-In-Place) and SIP (Sterilize-In-Place) requirements needed to maintain cleanliness and sterile conditions for sensitive processes without contamination.

Sanitary butterfly valves are made of good quality materials that feature innovative designs with the aid of leading industry resources and technologies. This results in long-lasting durability, reliability, and compliance with stringent industry regulations, which proves to operate seamlessly throughout varying applications.

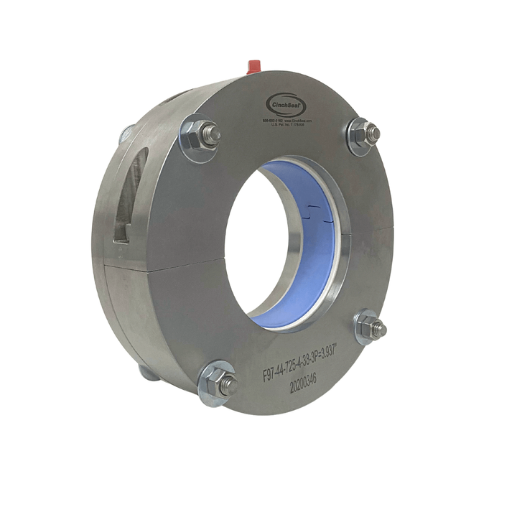

Sanitary check valve and diaphragm valve material requirements

In the food and beverage, pharmaceutical, and biotechnology industries, hygiene is paramount, which is why sanitary diaphragm valves and check valves are crucial. These valves are made of specific materials that guarantee safety, strength, and meet regulatory standards.

Material Standards

- Stainless Steel

The most commonly used subspecies of stainless steel are grades 304 and 316L due to their smooth surface finish, resistance to corrosion, and overall durability. These properties also aid in preventing the growth of harmful bacteria, aiding in sanitation. The 316L grade is often the choice of 316L stainless steel due to its heightened resistance to chemical corrosion as well as its ability to endure the high-pressure cleaning and sterilization common in sanitary settings.

- Elastomers and Polymers

EPDM (ethylene propylene diene monomer), PTFE (polytetrafluoroethylene), and silicone elastomers are regularly utilized for valve diaphragms and seals. These materials are selected because of their flexibility and chemical resistance, as well as their ability to withstand high temperatures. For example:

-

-

- EPDM offers excellent steam process performance and tear resistance.

-

PTFE’s chemical inertness makes it well-suited for aggressive fluid or high-purity applications.

-

- Certifications

Every material used should follow regulatory compliance like FDA (Food and Drug Administration) regulations, USP Class VI certifications, and EN 10204 3.1 material traceability standards. This ensures that the materials are safe for use in food, pharmaceutical, or biotech environments and are traceable within the quality assurance processes.

Specific Requirements and Data

- Surface Finish

Surface finishing alongside the material sanitary valves requires, is a surface finish which is no less than roughness average (Ra) 0.8 µm (micrones) in order to maintain cleanablity. Electropolishing further enhances the smoothness and reduces the chance of contaminants adhering to the surface.

- Pressure and Temperature Tolerance

Sanitary check valves and diaphragm valves face a vast range of temperatures from colder than zero in cryogenic applications to over 300°F (150°C) during steam sterilization. This must be done while resisting thermal degradation with the materials kept under pressure.

As the selected materials satisfy the demanding standards, sanitary valves ensure peak performance, prolonged service life, and adherence to international cleanliness and safety standards.

What are the industry standards for sanitary valve materials?

Sanitary valve materials are regulated for safety, cleanliness, and sturdiness in food, beverages, and pharmaceutical processing. The most widely used standards are:

- FDA Compliance: The material should comply with the FDA’s stipulation regarding food contact substances, signifying that the material is safe and non-poisonous for use in consumable products.

- 3-A Sanitary Standards: Concerns hygiene and specifies corrosion-resistant, cleanable, and sanitary processing suitable materials.

- ASTM Standards: ASTM International sets boundaries on the designated materials for construction, such as grades of stainless steel 316L for mechanical and sanitary functions in diverse conditions.

- European Regulation EC 1935/2004:This regulation applies to materials used in Europe. The materials must be certified not to leach any harmful substances to human health into food.

These standards are recognized to provide dependability and regulations of sanitary valves throughout every industry around the world.

3-A sanitary standards for valve construction materials

To make sure that valve construction materials meet 3-A sanitary standards, I use stainless steel, which fulfills the standards’ hygiene and durability requirements. Their purpose is to maintain food safety as well as simplify the cleaning of contaminants while preventing exterior contamination and ensuring compatibility for a wide range of sanitary applications.

Pharmaceutical grade requirements for sanitary valve materials

Materials used for sanitary valves in the pharmaceutical industry must comply with rigorous safety, purity, and performance standards pertaining to medicine and healthcare to help facilitate the medicine board’s necessities. 316L stainless steel is a commonly used material as it has exceptional corrosion resistance, smooth surfaces that reduce microbial growth, and the ability to endure rigorous sterilization like Steam-in-Place (SIP) and Clean-in-Place (CIP) processes.

Pharmaceutical valves must have specific certifications such as USP Class VI for biocompatibility, FDA 21 CFR for suitability, and STI 21 CFR for pharmaceutical substance compatibility. Respectable finish is additionally critical, roughness values above 0.375 µm (15 µin) Ra for roughened surfaces to reduce cleaning. Moreover, sanitary valves must comply with ASME BPE standards, which govern material, manufacturing, and surface treatment marking for quality in bioprocessing zones. Through the use of these qualified materials, manufacturers shield compliance requirements and maintain strict standards to protect product integrity.

Food and beverage industry material specifications

Food and beverage companies make sure to outline material specifications that lay emphasis on cleanliness and safety to avoid contamination during the production process. Due to the remarkable corrosion resistance and hygienic properties of stainless steel, it is the most commonly used material in these industries. Specifically, 304 and 316L stainless steel are preferred, with 316L having greater resistance to chlorides and acidic compounds found in food-processing environments.

Surface finish requirements are highly important as well for hygiene. For example, surface roughness of ≤0.8 μm (32 µin) Ra is suggested to prevent the retention of food particles or bacteria in cavities where cleaning would otherwise be effective. Furthermore, stainless steel surfaces of food processing equipment are often electropolished, which improves corrosion resistance, lowers surface irregularities, and enhances the aesthetic appeal of the equipment.

Regulatory limits from FDA, EU 1935/2004, and ISO 22000 set rigid requirements for materials that have contact with food and substances used for food preparation. Suppliers and manufacturers need to guarantee material traceability and the compatibility of the materials with cleaning agents, sterilization processes, and the food itself in order to prevent contamination throughout the product’s lifecycle.

How do material choices impact sanitary valve performance?

Choosing certain materials affects the function of a sanitary valve, particularly in terms of its durability, compatibility, and hygiene. That’s why high-quality materials such as stainless steel are often chosen, as they undergo corrosion, rigorous cleaning, and contamination processes without undergoing any harm. To guarantee safety and prevent chemical reactions with the food or fluid within, non-reactive materials are critical. Correct choice of materials also minimizes maintenance and prolongs the valve’s usability, thus ensuring reliable performance in sanitary applications.

Material effects on flow through the valve

The selection of materials affects the flow characteristics and efficiency of the valve. For example, valves made from polished stainless steel, which has a smoother surface, allow for streamlined flow, thus avoiding friction and turbulence which is detrimental in maintaining certain flow rates. Rough materials or those with surface imperfections tend to cause pressure drops which increases energy consumption due to excessive resistance within the system.

As per industrial benchmarks, the corrosion-resistant 316 stainless steel is ideal for sanitary processes as it poses little risk of degrading and obstructing the flow over time. Moreover, a material’s thermal conductivity is of great importance; those that have higher thermal resistance are more capable of stopping temperature changes that are not intended to occur during fluid transfer, therefore maintaining the system’s integrity. Studies indicate that the application of advanced polymer coatings on the internal surfaces of valves is effective in improving flow optimization while reducing damage from abrasive or high-viscosity fluids. Choosing the correct material boosts productivity and operational efficiency while also achieving cost efficiency through a long-term decline in downtimes and maintenance.

Temperature and pressure limitations of different materials

It is crucial to comprehend the temperature and pressure tolerances of various materials owing to the need for industrial and sanitary applications to uphold safety and efficiency. Provided below is a summary of widespread materials and their operational limits:

- Stainless Steel:

-

- Temperature Range: -328°F to 1,500°F (-200°C to 815°C), however this changes on alloy type.

- Pressure Limitations: Reaches up to 10,000 psi for certain grades, though common use is for high pressure environments.

- Applications: Best suited for high heat, corrosion, and steam, for food processing and chemical industry plants.

-

- Polytetrafluoroethylene (PTFE):

-

- Temperature Range: From -328°F to 500°F (-200°C to 260°C).

- Pressure Limitations: Versus thickness and shape, generally 5,000 psi.

- Applications: Seal linings due to better chemical resistance, a rough non-stick surface, and are ideal for smaller hinges.

-

- EPDM (Ethylene Propylene Diene Monomer):

-

- Temperature Range: -40°F to 300°F (-40°C to 149°C)

- Pressure Limitations: Varies between 500-2,000 psi, depending on the compound.

- Applications: Mostly used in low-pressure areas like seals and o-rings in sanitary systems.

-

- PVC (Polyvinyl Chloride):

-

- Temperature Range: 32°F to 140°F (0°C to 60°C)

- Pressure Limitations: Typically up to 300psi but varying with pipe schedules, wall thickness, and tiered cut screws.

- Applications: Best suited for low-pressure water and drainage systems.

-

- Ceramics:

-

- Temperature Range: Up to 3,632°F (2,000 °C) depending on the type of ceramic material.

- Pressure Limitations: Generally suitable for high pressure when used as part of composite systems.

- Applications: Used in extreme heat settings such as combustion chambers and wear-resistant coatings in industrial machinery

-

While observing the operational boundaries of materials, industries improve equipment performance and reduce issues caused by thermal and pressure stress.

What are the mechanical sealing requirements for sanitary valves?

- Hygienic Design: Every seal must meet health standards so they can be cleaned effectively, preventing residue and bacterial contamination.

- Material Compatibility: All seal materials need to be non-toxic and FDA-approved, as well as resistant to chemicals, high temperatures, and pressures of the sanitary applications.

- Leak Prevention: Seals must provide a tight and reliable closure to contain leakage while protecting the system’s integrity, which is crucial for processes with sensitive fluids or gases.

- Durability: Seals must endure cleaning processes like CIP (Clean-In-Place) and SIP (Sterilization-In-Place) without deforming or succumbing to wear.

The criteria described guarantees that the sanitary valves are safe regarding work and sanitation, as well as the effortless operation of the valves.

Gasket and O-ring material selection criteria

Much like any component of a machine, gaskets and O-rings are made from materials with particular properties in mind. For O-rings and gaskets, giving thought to an optimal environmental setting and performance needs is essential. Critical factors to focus on include:

- Chemical Compatibility: The material should not be destroyed when exposed to cleaning materials and solvents or even while in use. For instance, a good candidate is EPDM (Ethylene Propylene Diene Monomer); food, beverage, and pharmaceutical industries utilize it due to its chemical resistance.

- Temperature Tolerance: Make sure ranges of operational temperatures are well within material capabilities, both in performance and tolerances. Silicone is an example due to its ability to perform above and below temperatures of 60°C to 230°C.

- Mechanical Properties: Materials should be a combination of elasticity, tear resistance along with maintain retaining shape while under stress. Fluoroelastomers (FKM) have great mechanical strength along with their ability to resist compression set making them ideal in harsh environments because of their durability.

- Compliance with Regulatory Standards: In verticals like food or pharmaceuticals, materials must fit within FDA, USP Class VI, or even EU stipulations for food-grade documents. PTFE (Polytetrafluoroethylene) is trusted in these critical applications as it is chemically inert and has exceptional compliance issues.

- Abrasion and Wear Resistance: Engineering designs, which include steam or high-friction processes, need the use of materials like NBR (Nitrile Rubber), which are not only resistant but also possess frequent movement reliability.

- Steam and Heat Resistance: For SIP or CIP systems, materials need to combat steam alongside super heating, plus rapid temperature changes oh so called thermal cycling. FFKM (Perfluoroelastomer) is Highly Stabilized thermally and is relevant for super-high temperature sterilization methods.

Proper material selection is crucial to the functionality and longevity of gaskets and O-rings, ensuring safety, efficiency, and compliance with industry standards in critical systems.

Material compatibility with cleaning and sterilization processes

Material compatibility is one of the overriding factors in the selection of gaskets and O-rings used in their cleaning and sterilization processes. Chemicals such as sodium hydroxide, hydrogen peroxide, nitric acid and high-temperature steam are staples in common cleaning procedures like Clean-in-Place (CIP) and Sterilize-in-Place (SIP). These processes require materials with both phenomenal chemical and thermal stability.

For example, PTFE (Polytetrafluoroethylene) is one such material that is widely utilized because it can withstand extreme temperatures between -328°F to 500°F (-200°C to 260°C), in addition to possessing unmatched chemical resistance. EPDM (Ethylene Propylene Diene Monomer) on the other hand also has outstanding complementary with oxidizing chemicals like hydrogen peroxide, making it excellent for food and pharmaceutical industries.

Studies show that FFKM (Perfluoroelastomer) has unparalleled resistance to aggressive chemicals and harsh temperatures exceeding 536°F (280°C). The broad temperature range poses unrivaled challenges, making it a dependable material choice for environments that enforce stringent sterilization cycles or are subject to strong acids and bases.

With these properties, it can be observed that material compatibility incorporates a range of factors such as resistance to steam and chemicals, mechanical characteristics, contraction under heat, and overall wear over time,I n addition to thermal stability. This fundamental selection process permits industries to advance operational safety & efficiency if materials are rightfully tailored to specific protocols and guidelines for cleaning and sterilization.

How do sanitary valve materials differ by application?

Sanitary valves also have differing components depending on the particular environment in which they operate:

- Food and Beverage: These industries tend to use 316L stitches which are very durable towards corrosion, withstands cleaning with strong acids and salts, and handle many scrubbers utilized in production.

- Pharmaceuticals: Pertaining to the industry molds, stamps, electrodes, and other hardware with high purity stainless steel or steel alloys which aids in encapsulation and enhance surface polish level, hence preventing contamination and supporting extreme sterilization.

- Chemical Processing: Uses valves composed of more chemically aggressive PTFE to maintain great tensile strength in extreme environments.

- Biotechnology: Valves in this industry need to use materials which endure multiple cycles of sterilization and also are biocompatible, such as specialty alloys or surface coatings.

The selection of the material is influenced by aspects such as chemical compatibility, temperature resistance, ease of maintenance, and factors that guarantee reliability and hygiene for every application.

Materials for pharmaceutical and sterile processing valves

The materials utilized in pharmaceutical and sterile processing valves are selected to meet the highest industry standards of operational performance, hygiene, and safety regulations. One of the most common materials used is stainless steel, in particular, grade 316L, because of its ability to resist corrosion, ease of cleaning, and enduring repeated sterilization processes like autoclaving. During autoclaving, this grade of stainless steel undergoes low carbon oxidation and is therefore able to minimize carbide structures that form during welding and compromise sterility.

Other more aggressive materials such as Hastelloy® may be used to maintain a greater resistance to aggressive cleaning agents for longer periods of time. Moreover, this alloy is ideal because it will remain structurally intact due to its exceptional corrosion resistance when subjected to harsh chemicals like chlorine and oxidizing acids.

Moreover, additional non-reactive, biocompatible, and moisture resistant compounds are high performance polymers PEEK (Polyetheretherketone) and PVDF (Polyvinylidene Fluoride). Most notably, PEEK will maintain its structural integrity under high temperatures, and can easily be steam sterilized under those conditions.

Biocompatible valve parts are treated with advanced coatings with PTFE (Polytetrafluoroethylene) to protect surfaces from wear resulting from friction and sticking or fouling with biological matter. With these coatings, parts operate more smoothly and outlast previous expectations in their life span within sterile processing.

Analyzed data suggests that no downtime, cost of maintenance, and overall process efficiency improve when the right materials for systems are used to precise measures. Corresponding industry regulations, such as ASME BPE for Bioprocessing Equipment, usually aid the choice of material conforming to rigorous industry policies for compliance to primary valve cleanliness and safety necessary for sterile filtered environments.

Food and beverage industry material considerations

As with many industries, the food and beverage vertical has safety regulations coupled with operational efficiency challenges, which makes material selection very important. Most food-grade stainless steels, especially 304 and 316, are preferred because of their high corrosion resistance, strength, and ease of cleaning. 316 stainless steel, among others, is popular due to its greater resistance to acids and chloride environments, which permeate many food manufacturing routines.

Even primary gaskets and seals for most processing equipment are made from nonmetallic PTFE and EPDM. These materials are hardy to high temperatures, chemicals, and abrasion, which helps maintain the required level of cleanliness in production lines. More recent innovations have shown the potential of utilizing composite materials to increase durability and reduce the rate of wear in high-friction regions of processing equipment.

Manufacturers are ensuring compliance with safety regulations both from the FDA and the EU which puts more emphasis on the selection of materials that are safe for food use. Research indicates that the electro- polished finishes applied to stainless steel reduce microbial adhesion by nearly 60%, which drastically improves sanitation. These facts illustrate the role that advanced material technologies play in the safety and productivity of the food and beverage industry.

Biotechnology and high-purity application materials

The recent progress made in biotechnology, for example, the polymers and alloys, is now being utilized much more in biopharmaceutical manufacturing because of the enhanced chemical resistance and mechanical stability of these materials, which ensures sterility as well as encourages high-purity materials designed for specialized applications.

High-purity elastomers like platinum-cured silicone and high-purity elastomers greatly reduce the risk of leachables and extractables, and therefore mitigate contamination risk for pharmaceutical products.” Modern perform-having materials for critical environments have shown to aid along with extreme toughness, some fluoropolymer coatings have been tested at temperature extremes of 500°F alongside extreme solvents without losing their toughness.

In addition to this, enhanced filtration technologies, which have been innovated because of biotechnology, now utilize high-purity membranes with extremely selective properties that permit the efficient separation and purification of biomolecules. These refined sprays not only streamline production processes; they increase yield, which helps during scalable manufacturing as supplies are then able to meet endless global round-the-clock demands. It’s remarkable how collectively these modern materials transform what biotechnology has yet to achieve in accuracy, efficiency, precision, and unrivaled safety in high-purity usage.

Reference Sources

- Supply Chain Analysis for Water and Sanitation Technology Research Project:

- Focuses on construction materials (e.g., cement) and their role in sanitary pond technology.

- Discusses components like water inlet valves and pre-filters.

- Modeling the Factors Affecting Sanitary System Condition Assessment in Egypt:

- Examines the impact of pipe material, operational pressure, and valve corrosion on sanitary systems.

- Highlights the importance of construction material quality in system durability.

- Sanitary and Hygienic Issues in Heat Supply Systems:

- Discusses sanitary standards and material quality in heat supply systems.

- Explores the role of hygienic design in maintaining system efficiency.

Frequently Asked Questions (FAQs)

Q: What are the main sanitary valve types used in hygienic applications?

A: The main sanitary valve types include ball valves (particularly sanitary 3-way ball valves), butterfly valves, diaphragm valves, check valves (including swing check valves and spring check valves), globe valves, gate valves, and relief valves. Each valve type serves specific functions in sanitary processing. Quarter-turn valves like ball and butterfly valves offer quick operation, while linear motion valves, such as diaphragm and globe valves, provide precise flow control. Every valve manufacturer should understand these variations to design valves that meet specific hygienic requirements.

Q: What makes a sanitary diaphragm valve suitable for pharmaceutical applications?

A: Sanitary diaphragm valves are ideal for pharmaceutical applications because they provide complete separation between the process fluid and the valve’s mechanical components. The flexible diaphragm acts as both the valve seat and sealing element, eliminating dead spaces where product could accumulate. These valves are excellent for handling viscous fluids, slurries, and particulate-laden media. Their drainability, cleanability, and ability to provide reliable sterile barriers make them the valve type of choice for critical pharmaceutical processes. Additionally, they can be operated manually or with pneumatic actuators for automated systems.

Q: What are the key applications of sanitary valves in the food and beverage industry?

A: The applications of sanitary valves in food and beverage processing are extensive. They’re used for flow control, directional control, and pressure regulation in processes like pasteurization, homogenization, CIP (Clean-in-Place) systems, and product transfer. Sanitary valves are also crucial for maintaining product integrity during mixing, blending, and filling operations. Specific applications include tank bottom valves for clean drainage, sanitary 3-way valves for flow diversion, and check valves to prevent backflow. Each application requires a valve that meets strict hygienic standards while delivering reliable performance under various process conditions.

Q: What materials are commonly used by a valve manufacturer for sanitary valve construction?

A: A valve manufacturer typically uses 316L stainless steel as the primary material for sanitary valve bodies due to its excellent corrosion resistance and cleanability. For valve seats, stems, and seals, FDA-approved elastomers like EPDM, FKM (Viton), and PTFE are commonly used. These materials must withstand frequent cleaning cycles and sterilization processes. For specialized applications, higher-grade alloys such as AL-6XN or Hastelloy may be employed. Stainless steel sanitary valves must have smooth surface finishes (typically 32 Ra or better) to prevent product adhesion and bacterial growth, with all materials being certified for food, beverage, or pharmaceutical contact.

Q: How do spring check valves differ from other types of check valves in sanitary applications?

A: Spring check valves differ from other types of check valves (such as swing check valves and lift check valves) by using a spring-loaded valve disc or ball to maintain positive closure force when flow stops. This design provides faster closure than gravity-dependent designs, reducing the risk of water hammer and backflow. In sanitary applications, spring check valves are preferred for vertical installation and pulsating flow conditions. They’re designed with minimal crevices and smooth internal surfaces to prevent product entrapment. The spring mechanism ensures the valve closes before reverse flow occurs, making them ideal for protecting sensitive equipment and maintaining process integrity.

Q: What factors should be considered when selecting a sanitary 3-way ball valve?

A: When selecting a sanitary 3-way ball valve, consider the flow configuration (L-port or T-port), pressure and temperature requirements, and the specific media being processed. The valve body and sealing materials must be compatible with both the process fluid and cleaning chemicals. The valve design should feature full-port openings to minimize pressure drop and product holdup. Additionally, consider the actuation method (manual, pneumatic, or electric), maintenance requirements, and certification needs (3-A, EHEDG, FDA). Sanitary 3-way ball valves are versatile for diverting flow between multiple paths, but proper sizing and configuration are essential for optimal performance in hygienic processing systems.

Q: How do valve designs differ for CIP (Clean-in-Place) versus SIP (Sterilize-in-Place) systems?

A: Valve designs for CIP systems focus primarily on cleanability, featuring smooth surfaces, self-draining configurations, and elimination of dead spaces. These valves typically use elastomeric seals like EPDM that can withstand cleaning chemicals. For SIP systems, valve designs must additionally handle high-temperature steam sterilization (typically 121-134°C). SIP valves often incorporate PTFE or specialized elastomers for the valve seat and seals that maintain integrity during thermal cycling. The valve body and stem designs must prevent thermal expansion issues that could compromise sterility. Both systems require sanitary fittings (typically tri-clamp) for easy disassembly, but SIP applications demand more robust materials and specialized valve variations to maintain sterile barriers.

Q: What maintenance practices are recommended for sanitary valve types to ensure long-term performance?

A: Regular maintenance for sanitary valves includes inspection of valve seats, seals, and diaphragms for wear or damage. Elastomeric components should be replaced according to manufacturer’s guidelines before they fail. Valve stems and actuators require periodic lubrication with food-grade lubricants. Documentation of maintenance activities is essential for regulatory compliance. For pneumatic valves, air supply systems should be regularly inspected for moisture or contamination. Preventive maintenance schedules should align with production schedules to minimize downtime. Advanced maintenance strategies include monitoring valve cycle counts and implementing predictive maintenance based on performance data. Every valve manufacturer should provide detailed maintenance procedures specific to their valve designs to ensure sanitary integrity and operational reliability.