Plumbing valves are the unnoticed but indispensable devices in water systems that perform the directing, regulating, and controlling function of water in residential, commercial, and industrial environments. Whether you are a homeowner who is doing the regular maintenance or a professional plumber who is installing a complex system, it is very important to know the different types of water valves. All the different types of valves from ball valves to gate valves have their own unique purposes and are built to work under specific conditions. This article will take you through the common plumbing valve types by explaining functions, benefits, and suitable applications. Finally, you will have a good idea of how these parts help water systems run cleanly and efficiently.

Introduction to Plumbing Valves

Plumbing valves are very important parts of any water system, since they manage water flow and pressure very well. The most frequently used kinds of plumbing valves are ball valves, gate valves, globe valves, and check valves, all of them made for their own special application. Ball valves are the best choice when it comes to opening/closing and they do not leak at all, whereas gate valves limit water flow through them in a straight line. Globe valves are the most suitable ones for controlling the flow rate or pressure, and check valves allow water to flow in one direction only thus eliminating the possibility of backflow. The selection of a specific valve is always based on the required operation, water pressure and system specification, which indeed makes them important instruments for the management of both effective and clean water systems.

What is a Plumbing Valve?

A plumbing valve is a kind of mechanical gadget that is used in piping systems to regulate the flow of liquids, gases, and slurries, direct or control them. It works by opening, closing, or partially blocking the flow paths depending on the system’s needs. The most usual plumbing valves are gate valves, globe valves, ball valves, and check valves which are specialized for different purposes. For instance, gate valves are the best and only suitable ones for the flows that are either fully opened or closed, while globe valves can be used for flow rate or pressure control. Plumbing valves are indispensable in the enhancement of efficiency, prevention of backflow, and ensuring the safe operation of water systems in residential, commercial, and industrial places. Users can improve system functionality and longevity by choosing the right valve according to the pressure, flow requirements, and application.

Importance of Valves in a Plumbing System

Key Benefits: Valves are essential components of plumbing systems, which ensure safety, efficiency, and functionality. The major reason for the necessity of valves in plumbing systems was the recent enactment of laws regulating different types of valves, such as gate valves for on/off control or ball valves for quick, reliable shut-offs. Moreover, the development of smart valve technology is gaining more and more acceptance, as it facilitates modern plumbing systems with automated monitoring and control. The right valves incorporated not only make the operation more efficient but also prolong the life of the infrastructure and keep it safe.

Overview of Different Types of Water Valves

| Valve Type | Primary Function | Best Used For |

|---|---|---|

| Gate Valves | On/off control with tight seal | Transportation of fluids where unrestricted flow is important |

| Ball Valves | Quick operation and reliable shut-off | Residential and industrial applications requiring durability |

| Globe Valves | Precise flow control | Air conditioning, water sprinklers, and throttling applications |

| Check Valves | Prevent backflow | Sump pumps, irrigation systems, and sewage applications |

| Butterfly Valves | Flow control in large pipes | Space-limited installations and water treatment |

| Pressure-Reducing Valves | Lower incoming water pressure | Protecting plumbing systems from high pressure |

| Smart Valves | Automated monitoring and control | Smart homes and industrial water management |

Types of Plumbing Valves (Detailed)

Ball Valves

Ball valves take advantage of a spherical disc to regulate the water flow. They are very much durable, have excellent shut-off capabilities, and are frequently found in both residential and commercial plumbing systems.

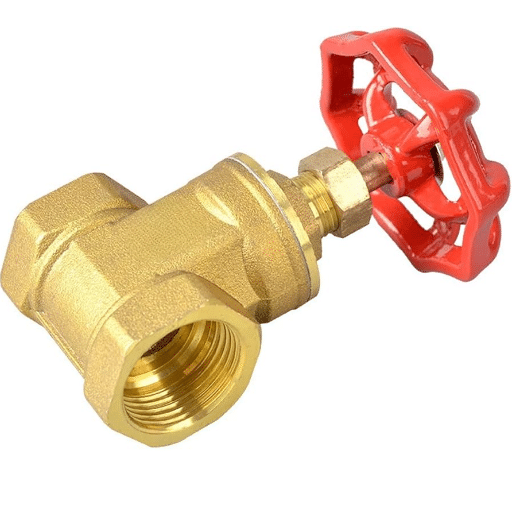

Gate Valves

Gate valves work by moving a gate out of the fluid flow path. They are typically applied in those situations where one wants a straight line flow with very little restriction, like in irrigation or industry needs.

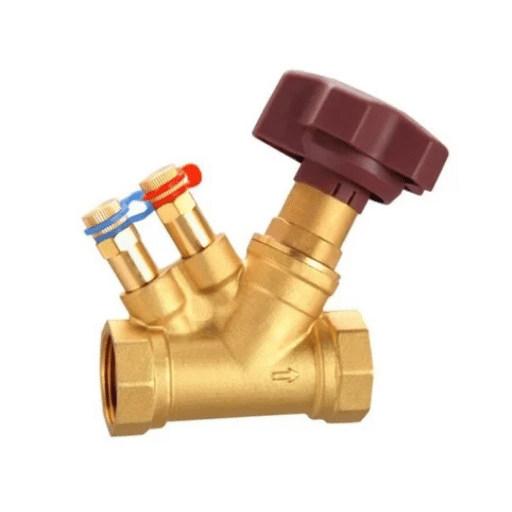

Globe Valves

Globe valves are considered to be the best option for controlling the flow rate and also for throttling during the process. They have a plug or a disc that cuts off the flow which is why they are often installed in faucets, and water treatment systems.

Check Valves

Check valves are utilized to allow only unidirectional fluid flow while ensuring that there is no backflow. They find a common place in sewage and drainage systems.

Butterfly Valves

Butterfly valves employ a turning disc to control the flow rate. They are easy to handle, compact, and can be used in industries where fast shut-off capability is needed, such as in water treatment.

Smart Valves

Smart valves are the cutting-edge technology in plumbing. These valves are connected to the new systems and they provide real-time monitoring and automation through mobile apps or centralized controls. They are very effective in reducing water wastage and thus they are equally important in smart homes and buildings.

Gate Valve: Features and Applications

Features:

- Low Flow Resistance: The straight-through construction results in less pressure loss and excellent flow.

- Full Bore Design: The unrestricted passage allows easy passage for tools or cleaning equipment.

- Tight Sealing Capability: Effective sealing is provided, thus the valve can be used for complete flow isolation.

- Bi-Directional Usage: One valve can be used in both flow directions thus its versatility is increased.

- Durable Construction: They are made up of materials like stainless steel or brass and hence are non-corrosive and resistant to wear.

Applications:

- Water Supply Systems: Used to cut off or permit water flow generally in pipelines.

- Oil and Gas Industry: Capable of effectively handling accidental spills and adverse conditions.

- Chemical Processing Plants: Very resistant to different types of chemicals and good for exact flow control.

- Irrigation Systems: Helps to maintain the needed water supply in crop lands efficiently.

- Fire Protection Systems: Their dependability makes them suitable for use in the pipelines of sprinkler and hydrant systems.

Ball Valve: Benefits and Usage

Ball valves are one of the most dependable and robust designs, thus they are favored in most industries due to their high flexibility. Their tight shutoff capability and exact control are their main features. As per the most recent trends in search engine data, one of the most popular questions is, “What are ball valves’ main advantages over other valves?”

Key Advantages of Ball Valves:

- Outstanding Sealing Property: Prevents leaks even at very high pressures

- Durability and Corrosion Resistance: Ideal for long use in harsh environments

- Ease of Use: Requires little effort to turn completely on or off

- Versatility: Works with gases, liquids, and slurries

- Temperature Range: Handles both high and low temperatures

- Industry Applications: Oil and gas, water supply, and chemical processing

Globe Valve: When to Use It

The globe valves are perfect for those applications where the avenues of flow regulation and the most accurate control are critical. They fall in the group of the strongest control valves and are frequently used in the systems with moderate to high pressure drops and the throttling operations, for their design facilitates the most effective flow control. The electric power, petroleum and gas, and chemicals industries are some examples of the sectors that in most cases, if not always, use globe valves for precise controlling flow.

Common Applications:

- Flow rate of cooling systems

- Isolating systems during maintenance

- Controlling steam or hot water delivery

- Operations requiring linear and non-linear flow profiles

Specialized Plumbing Valves

Check Valve: Preventing Backflow

A check valve functions by permitting fluid to pass in one direction and at the same time, preventing backflow automatically. A mechanism, usually a disc or a ball, is responsible for this function: the pressure of the forward flow opens the mechanism while the reverse flow closes it. These valves, because of their simple design, do not need any manual operation thus they are the most effective and least maintenance demanding solution for backflow protection in systems. Check valves are important parts of almost every piping system, from those that supply water to industrial processes, by providing operational stability and protecting the equipment from possible damage through reverse flow.

Butterfly Valve: Efficient Flow Control

Butterfly valves, in simple terms, are highly efficient devices for controlling or shutting down the flow in a pipe line. The fundamentals of their operation is a circular plate that spins on a pivot, which provides swift and effective control of the media, e.g., water, gas, or chemicals. Thanks to the smallness of their design, light weight, and low cost, butterfly valves are widely used throughout the industries of wastewater treatment, oil, and gas. Their great benefit is that they can switch between on-off and throttling applications, thus serving the different operational demands with their versatility.

Pressure Relief Valves: Safety Measures in Plumbing

Pressure relief valves are essential parts of plumbing systems that guarantee safety by avoiding the gathering of too much pressure in pipes or tanks. The valves are opened by itself to vent the pressure when it goes beyond a certain limit, thus protecting the equipment, pipes, and systems from bursting or being damaged. Recently, there has been an increase in searches for “how pressure relief valves work” and “why pressure relief valves are important”, which indicates the increasing awareness of their importance in all three sectors: residential, commercial, and industrial. Their reliability and simple operation make them a must-have for the preservation of plumbing systems’ integrity and safety.

Choosing the Right Valve Type for Your Plumbing System

Choosing the best pressure relief valve for your plumbing system, you need to think about system pressure, temperature ranges, and the particular application. Google’s search trends data indicates that users mainly want to know about “how to size a pressure relief valve” and “which materials are the best for valves.” Brass and stainless steel are the materials of choice for residential valves because they are very durable and resistant to corrosion. Conversely, industrial and commercial setups may need valves that can withstand higher pressure and temperature while being made of strong materials like carbon steel or specialized alloys.

Critical Selection Factors:

Determining the right valve size is one of the paramount factors, as the wrong choice of undersized or oversized valves will result in inefficiencies or even system failures. To find out the size of the valve, first, calculate the maximum pressure your system will be exposed to and then make sure the valve’s pressure setting is compatible with these requirements. Moreover, knowing the flow rate of your system will be another important factor for making that decision.

Factors to Consider for Different Types of Valves

| Factor | Consideration | Recommended Valve Type |

|---|---|---|

| Shut-off Control | Durability and tight seals | Ball Valves |

| Low Pressure Drop | Smooth fluid flow when fully open | Gate Valves |

| Backflow Prevention | Keeping water supply contamination-free | Check Valves |

| High Water Pressure | Regulating water pressure | Pressure-Reducing Valves (PRVs) |

Residential Plumbing Systems and Valve Selection

Various aspects should be taken into account when choosing valves for residential plumbing systems that will not only work well but also last long. Google’s most recent search data shows that one of the most common questions is about the best type of pressure-reducing valves (PRVs) for houses located in regions with unstable or high water pressure. PRVs are a very good choice as they not only prevent the damage caused to pipes and fixtures but also aid in conserving water by controlling the flow rate of water evenly.

Integration Tips:

- Connect PRVs with backflow preventers for cleaner water supply

- Combine with shut-off valves for emergency control

- Match valve specifications with house water pressure

- Consider flow needs and pipe materials

- Schedule regular maintenance and inspections

Common Mistakes in Valve Selection

Avoid These Errors:

- Ignoring Application-Specific Needs: Not matching valve type to system requirements

- Incorrect Pressure/Flow Matching: Selecting valves that don’t match system specifications

- Material Incompatibility: Overlooking valve material compatibility with fluids

- Improper Sizing: Choosing undersized or oversized valves

- Lack of Research: Not consulting experts or understanding system requirements

Maintenance of Plumbing Valves

To ensure long life, good performance, and safe use, plumbing valves need proper maintenance. The regular inspection of the valves is one of the most important steps in valve maintenance. Look for any signs of wear, corrosion, or leaks, since these problems can develop into major ones if not tackled in time. Cleaning valves on a regular basis will help in getting rid of the dirt and buildup that might block their functioning. It is also recommended to operate the valves occasionally by turning them on and off to avoid seizing or sticking.

Routine Checks for Different Types of Water Valves

To guarantee their proper operation and life span, water valves must be regularly inspected. Maintenance practices differ for various types of valves, including gate valves, ball valves, and check valves, which require different types of maintenance.

Maintenance Checklist:

- Inspect Seals: Check for wear and tear since leaks commonly start there

- Exercise Valves: Rotate or exercise valves regularly to prevent seizing

- Check Valve Handles: Ensure handles are tight and not cracked

- Look for Corrosion: Inspect for corrosion or mineral deposits, especially in hard water areas

- Clean and Lubricate: Remove dirt, clean valves, and apply approved lubricants

- Maintain Records: Keep detailed maintenance records for tracking

Common Issues with Plumbing Valves

| Issue | Causes | Prevention/Solution |

|---|---|---|

| Leakage | Damaged seals, incorrect installation, material wear | Regular cleaning, maintenance, and seal replacement |

| Stuck or Stiff Valves | Mineral buildup, rust | Use rust-proof materials, regular lubrication |

| Sediment Buildup | Hard water, debris accumulation | Periodic flushing, cleaning, water treatment |

| Corrosion | Low-quality materials, harsh environments | Use stainless steel or brass, regular inspections |

Tips for Extending the Life of Your Valves

1. Regular Maintenance and Cleaning

Periodic inspection of your valves for debris, rust, or mineral buildup is a good practice. Cleaning the valve parts will not only ensure the smooth operation but also prevent clogging. For illustration, the process of flushing the system every six months will help in reducing the amount of sediment that accumulates.

2. Use High-Quality Materials

The valves that are made from durable and corrosion-resistant materials like stainless steel or brass should be the ones you invest in. The valves that are made of higher-quality materials generally have longer life expectancies and less susceptibility to wear. For instance, with the proper care, stainless-steel valves can last for as long as 20 years.

3. Apply Proper Lubrication

Lubrication applied regularly to the moving parts will always be a way to reduce friction and wear. Make sure you use a lubricant that is compatible with your valve material. This practice can help in performance and even make it last five times longer than before.

4. Monitor and Maintain Optimal Pressure

To push your valves to their ultimate limits through excessive pressure is a sure way to cause early failure. So, it’s a good practice to use pressure monitoring devices that will enable you to keep the system within the safe operating limits. Simply changing the pressure can make a huge difference in how long the valve lasts.

5. Replace Worn Components Promptly

Troubleshooting small issues like worn gaskets or seals early enough can save you the larger problems and system shutdown. Proactively replacing these parts when needed can prevent costly repairs and loss of productivity due to downtime in the future. To illustrate, the cost incurred in replacing a damaged seal is much less compared to that of repairing a completely leaking valve system.

References

-

VALVES (University of Oklahoma)

This document provides detailed information on various types of valves, including check valves, gate valves, and more.

Read more here -

Valves & Prevention Devices (Hawaii Open Educational Resources)

This resource discusses different valve types like ball valves, gate valves, stop valves, and pressure-reducing valves.

Read more here -

General-Duty Valves for Plumbing Piping (Michigan State University)

This document outlines valve sizes, actuator types, and general-duty valve specifications.

Read more here

Frequently Asked Questions (FAQ)

What are the various kinds of water valves used in plumbing?

Water valves of different types are generally found in the plumbing systems such as gate valves, ball valves, globe valves, and check valves. Each one performs a certain function like controlling the flow of water, regulating the pressure, or preventing the backflow.

In what way do gate valves make a plumbing system function?

The flow of water is controlled by gate valves through the lifting or lowering of a gate inside the valve body. They are suitable for places that require full flow without any pressure drop and are also used in on/off service a lot.

Can you explain what a ball valve is and what its application is?

The ball valves are available in different types and are much preferred for water flow management due to their ability to give a tight seal and instant shut-off. It consists of a spherical disc, which controls the flow through the valve making it efficient for both high and low-pressure applications.

Are there check valves and what are their characteristics?

Check valves are of different types and they are meant to allow the fluid to flow only in one direction thus preventing backflow in plumbing systems. Their usage is prevalent in the cases where the occurrence of water hammer and surge scenarios potentials are present.

By what methods do globe valves control the flow of water?

Globe valves rely on a moveable disk to regulate the flow of water making them suitable for throttling and controlling the water flow. Their structure is such that there is a gradual change in flow which allows them to be used in many plumbing situations.

What are pressure relief valves and why are they important?

Pressure relief valves are safety devices that are of utmost importance since they protect plumbing systems from being subjected to excessive pressure. They work automatically, releasing pressure every time it crosses a certain limit, thus averting damage to pipes and fixtures.

What is a butterfly valve and what is its application area?

Butterfly valves are a disc type valve that revolves to control water flow. They are the first choice for installations that have a space crunch and getting them in water treatment plants and huge plumbing systems is common.

What are the safety valves maintenance requirements?

Safety relief valves maintenance involves routinely testing and inspecting the valves to make sure they work well. It consists of checking leaks, cleaning the valve seat, and confirming the valve opens at the required pressure.

What are the impacts of plumbing valves on the water hammer phenomenon?

Certain valves, particularly check valves, may help reduce water hammer occurrence as they allow fluid to flow in one direction only. In addition, the proper installation of valves significantly lowers the severity of water hammer in the plumbing systems.